What is a pellet boiler?

One of the main disadvantages of long-burning wood boilers is the fuel itself, it is bulky and requires a lot of storage space.

Classic solid fuel boilers for heating private houses are designed to burn wood, coal, coke and other solid fuels. To do this, they are equipped with a large firebox in which fuel is burned, releasing a large amount of heat. Such boilers require constant addition of new portions of firewood and coal - they burn out quite quickly, which leads to a gradual cooling of the heating system.

Long-burning solid fuel boilers that have appeared on the market and are used for heating private houses have pleased their owners with a reduced number of approaches for loading fuel - some of them can operate for up to 8-10 hours, depending on the fuel used. This approach allows you to count on long-term and uninterrupted operation - you can be sure that the rooms will not get cold by morning.

An alternative to long-burning boilers are pellet boilers that operate on special combustible granules - pellets. This fuel releases a large amount of thermal energy and has many advantages over wood and coal:

- Affordable cost - due to the fact that pellets are a product created from various wastes, their cost is in a very affordable range;

- Convenient storage - just fold the bags of granules in any convenient place. You can also provide a spacious bunker for this;

- Convenient dosage - pellets are a free-flowing and very light combustible material, so they can be dosed with an accuracy of a few grams. It is also very convenient to fill them in - you can use a deep spatula for this.

A pellet boiler for heating a home is a rather impressive unit that runs on pellet pellets. Fuel is stored in a bunker, the dimensions of which can be either small or very large. Pellet fuel gradually enters the combustion chamber, where it burns, releasing a large amount of heat. The heat is then absorbed by the heat exchanger.

The temperature difference between the combustion chamber and the heat exchanger outlet is very large - the combustion products cool here from a temperature of 800-900 degrees to 100-120 degrees.

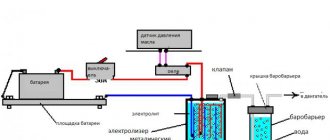

Pellet boilers for home use consist of the following components:

- Bunker – pellet fuel is stored here and taken into the combustion chamber. Some models of pellet boilers have very large hoppers, which allows you to count on the longest warm-up and continuous heating of a private home for several days in a row;

- Auger – ensures a smooth flow of pellets into the working chamber; it is driven by an electric motor;

- Combustion chamber – this is where the combustion process takes place;

The main units and components of the pellet plant.

- Burner – in this module the pellets ignite and burn. We can say that the combustion chamber and the burner are one and the same unit;

- Heat exchanger – this is where heat is transferred to the heating system. Heat exchangers can be very different, ranging from flat steel to multi-pass cast iron;

- Control module – controls the fuel supply to the furnace, checks operating parameters, and monitors safety.

Pellet boilers used for heating private houses also contain many other components - ash collectors, safety valves, ignition systems and much more. But the main ones are the above modules - they are responsible for creating heat and transferring it to the heating system of a private home.

Thanks to the automatic supply of fuel, pellet boilers do not require frequent approaches. One download is enough for several hours, or even several days. Moreover, the most advanced models independently maintain the temperature in the system, regulating the supply of pellets and the combustion of the flame - for this they are equipped with multifunctional automation systems.

How to calculate pellet consumption

Considering the fact that fuel is supplied in bulk or packaged in bags, it is, in principle, not difficult to calculate the consumption of pellets per 1 kW or per 1 m2. There is no need to convert weight units into volume, since delivery always occurs in kilograms, and the heat of combustion of fuel is also measured in kW per 1 kg of weight.

Good quality granules have excellent calorific value; burning 1 kg of such fuel produces almost 5 kW of thermal energy. Accordingly, to get 1 kW of heat for heating a house, you need to burn about 200 grams of pellets. The average consumption of granules per unit area can be easily determined based on the fact that heating each 1 m2 of area requires 100 W of energy

One condition is important: the ceiling height should be within 2.8-3 m. 100 W of heat will be obtained from 20 grams of granules, it would seem simple arithmetic. But it was not there

The figures presented above are correct if the pellet boiler has absolute efficiency - 100% efficiency, but this does not happen in real life. In fact, the efficiency of such heat generators, although higher than that of solid fuel boilers, is still only 85%. This means that after burning 1 kg of pellets in the furnace of the unit, not 5 kW of energy will be obtained, but 5 x 0.85 = 4.25 kW. Conversely, to release 1 kW of heat in pellet boilers, 1 / 4.25 = 0.235 kg or 235 grams of fuel is consumed. This is the first nuance

But it was not there. The figures presented above are correct if the pellet boiler has absolute efficiency - 100% efficiency, but this does not happen in real life. In fact, the efficiency of such heat generators, although higher than that of solid fuel boilers, is still only 85%. This means that after burning 1 kg of pellets in the furnace of the unit, not 5 kW of energy will be obtained, but 5 x 0.85 = 4.25 kW. Conversely, to release 1 kW of heat in pellet boilers, 1 / 4.25 = 0.235 kg or 235 grams of fuel is consumed. This is the first point.

The second nuance is that 100 W of heat per 1 m2 of room is required when the ambient temperature is the lowest, which lasts for 5 days. On average, during the heating season, thermal energy consumption is half as much. This means that the specific heat transfer per unit area is only 50 W. Determining the consumption of pellets in a pellet boiler for 1 hour relative to 1 m2 will be incorrect; the figure will be small and inconvenient. It would be more correct to calculate the weight of pellets burned per day.

Since Watt is a unit of power per 1 hour, then per day for each square of the room you will need 50 W x 24 hours = 1200 W or 1.2 kW. For this purpose, you will need to burn the following mass of pellets per day:

1.2 kW / 4.25 kW/kg = 0.28 kg or 280 grams.

Knowing the specific fuel consumption, we can finally obtain values useful for financial calculations, for example, the average seasonal weight of pellets used per day and per month in a house with an area of 100 m2:

- per day - 0.28 x 100 = 28 kg;

- per month – 28 x 30 = 840 kg.

It turns out that 8.4 kg of fuel is needed per month to heat 1 m2 of a building. At the same time, according to user reviews on various forums, heating a well-insulated house of 100 m2, located in the middle zone, takes about 550 kg of pellets, which in terms of square footage is 5.5 kg/m2. This means that the consumption of pellets in the boiler in the amount of 840 kg per month for a building of 100 m2 is very large and suitable for calculations of poorly insulated houses.

Let us summarize some results in the form of calculation results for dwellings of various sizes. The following are the monthly costs of pellets for heating a private home:

- 100 m2 – 840 kg with poor insulation, 550 kg for good thermal insulation;

- 150 m2 – 1260 kg and 825 kg, respectively;

- 200 m2 - 1680 kg and 1100 kg under the same conditions.

For reference. In many boiler installations, the controller has a function that allows you to see on the display the consumption of pellets in kilograms over a certain period.

conclusions

If you analyze the reviews and collect more statistics, it turns out that the estimated consumption of pellets for heating is not too different from the real one. If initially the calculation was made according to an enlarged scheme, the results are comparable to fuel consumption in a poorly insulated private house. When you have real indicators of the heat load, then you can calculate the financial costs of pellet heating quite accurately.

When calculating costs, do not forget about the electricity consumption of the boiler, for which you also pay money on the meter. It must be taken into account, because the power consumption of the auger motor, electric ignition device and controller can reach 400-500 W/h, which is quite significant. It can be supplemented by the power of an additional screw conveyor, if you have one installed to move pellets from the storage to the bunker.

Construction of pellet boilers

Pellets are solid fuel that is produced from wood waste, peat and agricultural waste. In fact, these are pressed pellets of small diameter, up to 5 cm in length. The main advantage of pellets over other types of solid fuel is their low ash content; therefore, the need to remove soot arises less often than when using firewood

If the impact on the environment is important to the home owner, then pellets cause minimal harm to the environment. Operating principles of a pellet boiler - pellets are loaded into a hopper, then they are fed into the firebox, where they burn, releasing heat. The most important thing is that all processes are controlled by automation

Those. if you need to quickly warm up the house before guests arrive, a pellet boiler will burn fuel at maximum speed, feeding pellets into the firebox using an auger. As soon as the required temperature is reached, the equipment will switch to temperature maintenance mode, reducing the fuel supply rate

The most important thing is that all processes are controlled automatically. Those

if you need to quickly warm up the house before guests arrive, a pellet boiler will burn fuel at maximum speed, feeding pellets into the firebox using an auger. As soon as the required temperature is reached, the equipment will switch to temperature maintenance mode, reducing the fuel supply rate.

Burners in pellet boilers are divided into two types - retort and flare. A retort burner is a bowl with slots into which pellets fall and ignite under the influence of hot air. In torch-type burners, pellets are fed to a platform where hot air creates a torch directed horizontally. There are no clear advantages for any type of burner, so when choosing specific equipment it is not a decisive factor.

Flare-type burners are used in the Metal-Fach Smart BIO line. Smart BIO is the company’s own development; the burner is made in the form of a trench. Designed for burning pellets and grain. The design of the firebox allows the use of coal and firewood.

Most pellet boilers are equipped with an automatic ignition system. The absence of such a function means that the process must be started manually each time, which significantly reduces ease of use. If there is automatic ignition, the boiler can start heating the house on its own using a timer, sensor or command from a mobile phone.

The Metal-Fach SEG BIO model allows you to light a fire from anywhere on the planet by simply sending the appropriate command from your phone or via the Internet. In emergency cases, wood or coal can be used as fuel, but pellets are preferable.

Metal-Fach SD DUO BIO is designed for minimal environmental impact - it is designed for the use of pellets. It can also work on eco-seed coal, wheat grains, and grape seeds. The equipment is automated - there is automatic feeding, automatic ignition, and can be controlled from a cell phone and via the Internet. In addition, boilers of the SD DUO series have a water-filled grate, which increases heat removal. It is worth noting that SD DUO boilers are the flagship in the line of boilers of the Polish company Metal-Fach.

Types of pellets

Pellets are wood waste from wood processing plants compressed into granules. They are considered an environmentally friendly product - after all, no adhesive admixtures are used for their production, and after crushing and drying in a granulator press they are compressed under strong pressure into granules. Bonding occurs with the help of lignin, which is contained in wood and is released under pressure. Therefore, more and more often the choice of homeowners is to use them.

All the above calculations were based on the indicators that high-quality granules produce. But depending on the starting material used for the production of granules, there are different types. Elite solid granules are made from wood waste that does not contain various impurities that reduce thermal output. Granules that contain impurities are much cheaper than elite ones. But their heat transfer is much lower, and the increased ash content makes working with them labor intensive (the need for mandatory constant cleaning of the boiler).

Don't miss: Floor radiators: floor-mounted built-in heating radiators, under-floor appliances built under a window

There are even lower cost granules made from agricultural waste. They contain little resinous impurities. But the resulting thermal output decreases from 5 kW from one kg to 4 kW. Which immediately significantly increases the amount of required mass for a month. And this, accordingly, entails an increase in the cost of heating premises in the winter season.

There are many different types of compressed wood waste with varying levels of various impurities. Due to their quality in boilers with retort burners, they cause malfunctions and sometimes equipment breakdowns. These types of granules can be used in boilers with a torch-type burner. But it is always better to weigh the pros and cons when choosing a particular type of compressed wood waste. After all, some “manufacturers” manage to mix sand into the structure of the raw material to add weight, which can only be determined after burning such a product.

Algorithm for calculating coal consumption

A modern type boiler can operate effectively on both hard coal and brown coal. But if you have a choice, it is better to choose high quality coal - anthracite. It is characterized by the highest thermal capacity and burns almost without a residue. However, the cost of anthracite is higher than other varieties. It is necessary to consider the price of fuel, delivery and its heat capacity, and choose the best option.

There are two ways to calculate coal consumption in a solid fuel boiler. The very first one is elementary, using a bucket. Coal is usually measured in tons, but it is unlikely that your boiler room will have scales to accurately weigh out the required dose for loading.

Approximately, to heat a 200 m² home the following amount of angle will be required:

- In September-October, one bucket per day.

- From November to February - 10 buckets.

- In March-April there are about two buckets.

If you assume that there are 30 days in a month and add up all the values, you can find out the total number of buckets (780 buckets). In kilograms it turns out:

780 x 18 = 14040 kg

Thus, during the heating season, a coal boiler will consume a little more than 14 tons of coal to heat a 200 m² home.

The second method of calculating coal consumption in a solid fuel boiler is more scientific. Combustion of 200 g of coal will require about 1 kW of heat. For comfortable living during the heating season, approximately 50,000 kW of heat is required:

50000 x 0.2 = 10000 kg (10 tons)

How to calculate the consumption of pressed fuel pellets for heating a house

Among solid fuel heating boilers, pellet units stand out due to their automation and low maintenance requirements. However, a boiler operating on granular fuel is very expensive equipment. To understand whether it is possible to save on fuel due to the efficiency of a pellet unit, you need to calculate the cost of the energy carrier during the heating period. Let's look at how to calculate the approximate consumption of pressed fuel pellets for heating a personal home.

Consumption of pressed fuel pellets for heat supply

How to calculate the actual consumption of compressed fuel pellets?

Fuel pellets are pellets made from plant-based raw materials. Fuel is packaged in bags or delivered in bulk, with the unit of measurement being the kilogram. This is convenient for calculating the actual energy consumption - there is no need to convert weight into volume, since the specific heat of combustion is measured in kilowatts per kilogram.

Sources

To calculate the theoretical consumption of granular energy for heating a house, it is important to know:

- the home's need for heat energy (heat load on the heating system) - measured in kW;

- Efficiency of the selected unit for a boiler room operating on pellets;

- the calculated value of the heat of combustion of the fuel;

- the cost of a ton of pellets in the region (this will allow us to determine the material costs of heat supply).

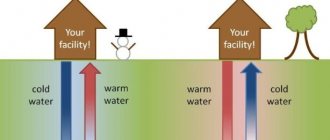

Among the listed data, it is most difficult to determine the real heat load, since this requires professional thermal calculations. The area of the house, the materials from which it is built, the quality of insulation, and climate conditions in the region are taken into account. Perfectly, the calculation of heat losses is carried out for any room that is heated separately, based on the number of external walls and window openings, location relative to the cardinal points and the dominant wind rose.

If it is not possible to contact the services of a heating engineer, the heat load and energy consumption are calculated approximately. There are two ways to calculate:

- Based on the specific use of heat energy per square meter of house area. For the climate conditions of central Russia, the calculation is carried out based on the following figures (under the conditions that the ceiling height does not exceed 2.8 m):

- 100 W/m2 for a living space with one external wall and one window;

- 110 W/m2 for a room with 2 facade walls and one window;

- 120 W/m2 for a living space with 2 facade walls and 2 windows.

- Based on the specific use of heat energy per cubic meter of house volume. This calculation is made if the ceiling height exceeds 2.8 meters. The cubic capacity of heated rooms is summed up and multiplied by 40 W.

How heat is lost from a building

In abstract calculations, which are given for example, in most cases it is believed that for an individual house with an area of 100 m2 the heat load is 10 kW.

To find out the efficiency of a pellet fuel boiler, you just need to look at the technical data sheet of the heat generator. This indicator depends on the properties of the brand and the quality of execution. Famous manufacturers of heating equipment, for example, Buderus and Viessmann, indicate the efficiency of their own boiler room units at 85%. Boilers in the middle price category have lower indicators. For approximate calculations, the figure of 80% is used.

The calculated calorific value of granular fuel varies in the range from 4.9 to 5.2 kW/kg, since the heat transfer of pressed fuel granules depends on the parameters of the raw materials from which they are obtained, technology and manufacturing quality, and moisture level. For calculations, the average standard is taken - 5 kW / kg.

Calculating consumption

As a result of complex calculations, we will find out how much fuel a pellet fuel boiler consumes on average per month during the heating season, and we will calculate how much it will cost to purchase the energy carrier. For clarity, we will calculate the consumption of a pellet fuel boiler for a house with an area of 100 square meters. m.

Poor quality fuel pellets

Act one. We find how much heat energy obtained by burning one kilogram of pressed fuel pellets is spent on heating the coolant, since some of it evaporates into the chimney simultaneously with the flue gases. To calculate, you need to multiply the heat of combustion of pressed fuel pellets (5 kW/kg) by the efficiency of the unit for the boiler room (80%), divided by 100:

5 ? 80 / 100 = 4 kW/kg.

Second action. To make it easier to carry out calculations in the future, we will determine how many pressed fuel pellets need to be burned in a unit for a boiler room with an efficiency of 80% in order to obtain 1 kW of heat:

Third action. When we are talking about specific heat energy consumption, and for a house of 100 m2 the calculated value of 10 kW is indicated, we are talking about the coolest days of the year - the power of the heating unit should be enough to completely heat the house in cold weather. At the same time, during the heating season the weather changes and the temperature fluctuates over a wide range. On average, the actual specific heat energy consumption is two times less than the calculated figure, i.e., in our case, 5 kW. This amount of heat is consumed per hour, so per day you will need:

Based on this, per month: 120? 30 = 3600 kW.

Fourth act. To determine how many kilograms of pressed fuel pellets will be required on average per month of the heating period for a house of 100 m2, it is necessary to multiply the calculated amount of heat by the energy consumption rate to obtain 1 kW of heat energy:

3600? 0.25 = 900 kg.

In central Russia, the duration of the heating period is 7 months, therefore, this time will require 900? 7 = 6300 kg of compressed fuel pellets, i.e. 6.3 tons of pellet fuel.

Using these formulas, it will not be difficult to determine the average monthly energy requirement for houses of the remaining area:

- consumption of pressed fuel pellets for home heating 150 m2 - 1.35 tons;

- consumption of pressed fuel pellets for home heating of 200 m2 is 1.8 tons.

Rapeseed straw fuel pellets

Real consumption

Based on the above calculations, we can determine the theoretical consumption of pellets per day: 120? 0.25 = 30 kg for a detached house with an area of 100 m2.

The average calculated value differs from the actual fuel consumption indicators, since many external factors affecting energy consumption are not taken into account. As practice says, a 100 m2 house requires from 15 to 60 kg of granulated fuel per day.

To calculate the truly required amount of pressed fuel pellets, you need to determine as accurately as possible the need for heat at home and pay your own attention to:

- on the characteristics of the selected (available) granular fuel;

- on atmospheric conditions in the area of residence;

- on the operating efficiency of a pellet heat generator.

If you are planning to purchase a pellet fuel boiler, it is recommended that you read in advance the reviews of home owners who use this type of equipment. This will help you honestly evaluate the performance of the heat generator and draw conclusions about its economic efficiency.

Types of granular fuels

Fuel pellets made by pressing waste from wood processing and crop production are classified as clean, environmentally friendly fuel. No third-party additives are used in their production - particles of plant-based raw materials are glued together thanks to lignin released under pressure.

Very different materials can be used as raw materials for the production of compressed fuel pellets.

The theoretical fuel consumption calculations above are based on the calorific value of high quality compressed fuel pellets made from pure wood material. More inexpensive granules, which contain bark and other inclusions, have lower heat transfer, and they burn with the formation of a huge amount of ash. If you regularly use available fuel, you will have to clean the boiler frequently.

The most inexpensive fuel pellets are pellets made from agricultural waste. Their heat output will be approximately 4 kW per kg. Based on this, to obtain the calculated amount of heat, you will need to purchase and burn more fuel.

Saving on the quality of pressed fuel pellets is not only unprofitable, but also scary - poor manufacturers introduce additives into the composition that, when burned, can damage the burner of the heat generator. To make the fuel heavier, sand can be mixed into the fuel pellets.

Pellet boilers are in increasing demand - automatic units eliminate the need to constantly load fuel manually. When calculating how many compressed fuel pellets you will need for the heating season, do the calculations for pellet fuels with different heating values to find out which low-cost option is best.

Saving on energy quality results in inefficient fuel combustion, in other words, unnecessary financial expenses. Moreover, heating equipment will break down faster.

Do not forget that incorrect storage leads to the accumulation of moisture in wood fuel, which reduces its thermal efficiency. When calculating heating costs, first include the cost of energy delivery.

Factors influencing the level of solid fuel consumption

It is not difficult to calculate how much a solid fuel heating boiler consumes. It is more difficult to correctly select the initial data to perform calculations.

The following presents the calculation method and at the same time provides a calculation of the consumption of the amount of firewood to heat a home of 100 m². However, first let's look at the source data:

- the type of wood that is selected for kindling;

- wood moisture level;

- efficiency factor of a solid fuel stove or boiler;

- thermal power required to heat the room.

If you've ever used a stove, you're probably aware that when wood burns, different types of wood produce different amounts of heat. Let's say birch logs emit more heat than poplar or pine. This is due to the difference in density and thermal output of tree species. In addition, the volume of firewood per 1 kW of heat energy depends on the moisture content in it. Accordingly, the higher the humidity, the more heat is spent on evaporating liquid from the firewood, and less is left for heating the home. As a result, more fuel will be needed to heat the house.

How rationally the energy contained in the fuel will be used depends on the efficiency of a particular heat source. Let’s say a fireplace or stove releases most of its energy into the atmosphere along with combustion products, so their heat transfer reaches only 60%. At the same time, a solid fuel or pyrolysis (long-burning) boiler operates with a heat output of 80%. These nuances should be taken into account when calculating the cost of heating a home.

It is better to take the value of the thermal power required to heat the house according to the calculation made by the craftsmen during the design of the home. However, often such data is not stored by property owners. Therefore, the amount of firewood and its cost can be determined by the average value of power consumption. It is determined in a standard way: heating 10 m² requires 1 kW of heat under the worst conditions, and the average for the season is 0.5 kW. The average figure for a dwelling with an area of 100 m² will be 5 kW/h.

Heating a private house with pellets - pros and cons

A solid fuel pellet boiler for a home with automatic fuel supply, like any other heating option, has both its advantages and disadvantages. Consideration of the pros and cons helps to make the most reasonable decision regarding the advisability of equipping a boiler room with wood pellet equipment.

The disadvantages are the following:

- Dependence on pellets – a few years ago, good quality pellets were difficult to obtain, which significantly affected the cost of fuel. Today, purchasing pellets of plant or wood origin is not difficult. Refilling a pellet boiler lasts for several hours, days or even months, depending on the chosen model. The user is required to calculate the operating time and purchase the necessary fuel in advance.

- High installation cost. Another disadvantage pointed out by opponents of pellet equipment is its high cost and expensive repairs. Today, the price of equipment is gradually declining due to high market saturation.

The reasons for purchasing pellet equipment are:

- Economical - fuel costs are slightly higher than for a gas boiler, but if you take into account the cost of obtaining permits, the need to prepare design documentation, and pay for gas pipeline installation, the difference becomes not so obvious. Economical pellet boilers for home use less raw materials than convection and gas-generating solid fuel units. Heating costs are also lower compared to an electric boiler.

- Simple installation requirements - the boiler is installed fairly quickly. Combined systems with an integrated fuel tank simply need to be connected to the power supply network and a chimney installed.

- Versatility - most modern models manufactured by domestic manufacturers are capable of using, in addition to pellets, firewood, coal, wood waste, and after replacing the burner, can be converted to use liquid fuel.

- Backup heat sources - an automatic pellet boiler, often has a built-in heating element for heating the coolant. If the solid fuel runs out, the boiler automatically switches to using electricity and continues to heat the house until the pellets are refilled.

Having weighed all the pros and cons of purchasing pellet equipment, many buyers come to the conclusion that it is advisable to purchase a heat generator of this type.

Features of pellet boilers

Naturally, the heating is as efficient as possible. eliminating unnecessary fuel consumption, will be carried out by the boiler only if it is operating correctly. You can check the efficiency of boilers of this type in the following way: you need to measure the temperature of the gases leaving the boiler. A temperature in the range of 120-150 degrees indicates normal operation of the equipment, while at the same time its increase indicates that the pellet boiler is faulty.

However, cold in the house does not always indicate ineffective operation of the equipment. Often the cause of uncomfortable temperatures is heat loss caused by low thermal insulation of the house or poor quality of pellets.

Many country property owners who heat using pellet boilers ask the question: is it possible to use this type of equipment for other fuels? If the boiler’s function was originally designed by the manufacturer to operate on other solid fuels, if pellets are not available, the boiler can be fueled with wood or small coal. But at the same time, the main advantage that a pellet boiler has is lost - its autonomy.

Having considered the advantages of equipment operating on pellets, one cannot help but mention its disadvantages. First of all, this is the need for regular cleaning of the boiler from ash, which should be carried out at least 2-3 times a month. This is a rather “dirty” procedure, often requiring the presence of male hands. Today, boilers with a self-cleaning function have appeared on the market, but their price is quite high. This makes their purchase impractical for heating a small country house.

Quality of pellet granules

The characteristics of fuel pellets determine further heating, its feasibility and functionality. Pressed briquettes for this type of boiler require compliance with storage and movement conditions. When compared with the requirements for liquid and gaseous fuel materials, the situation with pellets is much simpler. It is only important to control the permissible level of humidity in the room.

The quality of pellets can be determined by burning a small number of pellets in the firebox, which will be the determining factor in purchasing a whole batch. The key point here should be quality assurance based on the combustion of experimental samples.

If it is not possible to check the granules in this way, then we offer you alternative methods:

- Visual inspection of granules. The surface of the pellets should be smooth and shiny, without obvious cracks or chips. These indicators confirm compliance with the technological process at the time of manufacturing and pressing, and natural wood was used as a binder.

- Perform a fragility test. High-quality fuel material should not crumble upon palpation, so it is best to use solid granules. Pellets with a violation of the manufacturing process will begin to crumble already at the moment of transfer by auger equipment to the furnace.

- Choose pellets packed in bags. Under such conditions of storage and transportation, fuel will not combine with dust, which negatively affects the operation of the entire heating system.

- You should buy fuel material according to the parameters, sizes and types specified in the passport of the boiler installation itself.

- Study the shade of the granules. Light-colored pellets indicate the use in production of wood materials without bark and unnecessary impurities; they are considered the most effective for heating. Dark-colored granules indicate that the manufacturer used bark and wood waste as raw materials, so their effectiveness will be significantly lower.

We recommend: DIY folding table - photos, drawings and projects of the best models of folding tables

Criteria for choosing the power of a pellet boiler

How to calculate the power of a pellet boiler? The criteria are as follows:

- Room area. Power is taken at the rate of 1 kW per 10 m2. Household models start from 15 kW. We recommend taking 20% as reserve.

- Efficiency of a pellet boiler. It ranges from 85% to 95%. With the same power indicators, we choose the one whose efficiency is higher.

- The use of alternative fuels will reduce power by 20-40%.

- Using raw pellets will result in a loss of another 25-35% of power.

Heated area

Room area is the main criterion for choosing a boiler. Temperatures in winter can drop well below average. The costs of additional insulation can significantly exceed the cost of purchasing a more powerful modification of the boiler and cause a lot of household troubles.

Wall material

Different materials have different thermal conductivities. The lower the thermal conductivity of the wall, the less heat loss. For the calculation, you can take the thermal conductivity coefficients from SNiP 23-02-2003 and from SP 50.13330.2012.

The material changes thermal conductivity under different operating conditions, in particular with increasing humidity. The thermal conductivity coefficient under different operating conditions can be found on the manufacturer’s website.

Let us give the average thermal conductivity of some materials under normal conditions:

- brick - 0.7 W/(m*°C);

- reinforced concrete - 1.92 W/(m*°C);

- pine - 0.14 W/(m*°C);

- foam concrete - 0.28 W/(m*°C);

- oak - 0.18 1.92 W/(m*°C).

Wall thickness

The thickness of the wall is determined by thermal engineering calculations. The calculation process is simplified by special complexes where the user needs to enter initial data. The machine will carry out the calculations and produce the finished result.

Window and door openings increase thermal conductivity. The larger the area of the openings, the higher the heat loss. The use of modern metal-plastic double-glazed windows can partially solve this problem.

Room temperature

Walls are only part of the source of increased thermal conductivity. Heat exchange passes through the floors and roof. The presence of a basement will further increase heat loss. To maximize resource savings, you need to carefully insulate all structures.

The temperature in the room is considered comfortable: +22 - +240 C. Optimal humidity is 60-80%. Supply and exhaust ventilation must be provided to create complete air exchange.

Pellet quality

The quality of fuel plays a decisive role in heating a home. If you use raw pellets, the boiler power will drop by 25-35%. Part of the energy obtained during combustion will be used to dry low-quality pellets

It is extremely important to ensure optimal conditions for fuel storage. First of all, it should be a dry and warm place

Raw materials also play an important role. In the West, this type of fuel has been used for more than a century. The production system and criteria have been developed and standardized at the state level. Our country cannot boast of this.

No uniform quality standards have been developed for this type of product. Each manufacturing enterprise is forced to rely only on its own, unfortunately, not rich experience. There is a high risk of buying low-quality products.

Pellet boilers can operate on almost any type of solid waste. There are models that support different types of fuel. But the efficiency of such boilers is usually much lower.

Other factors

Other factors influencing the choice of a pellet boiler include:

- geographical area;

- average annual precipitation;

- average wind strength and direction;

- conditions and frequency of operation of residential premises;

- type of fuel used;

- quality of materials from which the boiler is made;

- ceiling height;

- price.

It is simply impossible to take into account all factors in the calculation. Their performance can change quite significantly over time. For example, winter may be colder than usual. Or the wind speed, instead of the usual 4-6 points, will be 8 - 9.

Pellet fuel consumption

To correctly assess the heat loss of your home, there are many different methods on the Internet that allow you to calculate fuel costs for heating your home. But the fact is that these methods are based on the use of SNiP and other regulations, however, in practice everything turns out differently. If we take, for example, a room with an area of 130 m2 as a basis, then its heat loss in low temperature conditions often does not exceed 100 W per hour. This indicator primarily depends not on the heating system itself, but solely on the design of the room itself. In order to fully understand the question of which fuel is the most profitable during the heating season, it is better to calculate the consumption of several types of material at once. Having complete information, you can create a special table to obtain data on fuel consumption. Anyone can check whether a pellet boiler is doing its job effectively; to do this, you need to measure the gas temperature at the outlet. The optimal temperature is considered to be in the range of 120-150°C.

Recently, many owners of private houses use pressed pellets made from waste of a wide variety of combustible materials to heat the premises of their homes. These granules are called pellets. Those homeowners who are just planning to install hot water boilers in their home that use pellets as fuel are interested in the consumption rates of this fuel material, as well as the amount of heat released during its combustion. We will try to cover these issues in as much detail as possible within the confines of this short article. As a rule, the choice of one or another type of solid fuel boiler is based on the availability and cost of fuel. In addition, many owners of private houses try to choose equipment that requires minimal maintenance. In other words, there is no need to fill the firebox every day, remove combustion products, etc. Therefore, among a wide range of types of boilers operating on solid fuel, pellet equipment is the most in demand.

Pellet consumption for heating a house: 100 m, 150 m, 200 m, 250 m and 300 m

Our individual houses are heated for the most part by autonomous systems. Where mains gas is available, preference is given to gas heating. Sometimes there is heating using diesel fuel and electricity. In all other cases, houses are heated primarily with solid fuel. These are coal, firewood and pellets.

The cost of fuel significantly affects the family budget. Therefore, when purchasing fuel, especially for a new home for the first cold season, when there is no experience, it is important to correctly calculate the required volume. Moreover, when procuring fuel, it is important to evaluate not only the quantity and cost of fuel, but also its calorific value.

Pellet heating is becoming increasingly popular. Their production is increasing, while the cost price is decreasing, and hence selling prices. Heating with pellets is often more convenient and cheaper than heating with liquid fuel (diesel) and conventional firewood.

Pellets - composition and heating features

This fuel is made from various types of combustible organic raw materials. Recently, much attention has been paid to the rational use of resources. What was previously thrown away is now recycled and put to good use.

Given the low cost of waste raw materials, the price is mainly affected by the cost of production, since this is a very energy-intensive process that is carried out on fairly technologically advanced and not cheap equipment.

Fuel pellets are pressed from sunflower husks, corn stalks, straw, wood waste - wood chips, sawdust and shavings. No chemical additives are used.

The consumption of pellets for heating 100 m, 150 m, 200 m, 250 m or 300 m of living space depends on many factors.

- Weather conditions of the current season (what kind of winter it is).

- Thermal insulation properties of the building.

- Efficiency of the boiler and the entire heating system.

When burned, high-quality granules emit quite a lot of heat per 1 kg of weight.

Good granules are determined by their appearance:

- The surface is smooth, with a matte shine.

- There are no cracks or breaks.

- They don't fall apart when pressed hard.

- The color is even.

The last point is especially important for boilers with auger fuel supply. When fed into the firebox, weak granules crumble into dust and cannot burn efficiently, but simply smolder.

Wood pellets of any fraction provide more heat.

When choosing fuel, you should also take into account the recommendations for using the boiler given by its manufacturer.

Fuel in sealed packaging is preferable. It has low humidity, is more convenient to store and transport, and does not lose its properties from precipitation even in open space. When using a boiler with a hopper and auger, it is more convenient to load fuel directly from the bag.

Calculation of granule consumption

You can determine the fuel requirement for a residential building of 100 m, 150 m, 200 m, 250 m or 300 m not only experimentally or approximately, but also using exact formulas. The calculation is based on the following data: 1 kg of pellets, when burned, releases 5 kW of heat. (0.2 kg per 1 kW).

With ceiling heights from 2 m 80 cm to 3 m, an average of 0.1 kW/hour of heat per 1 sq.m. is required. area.

As a result, 0.2 kg per 1 kW x 0.1 kW/hour/sq. meter = 0.02 kg/hour/sq. meter. That is, 20 grams of fuel (0.02 kg) to heat 1 sq.m of area for an hour.

This figure is then multiplied by the area of the house.

100 sq.m x 0.02 kg/hour/sq.m = 2 kg per hour.

Accordingly, for home:

- 150 m – 3 kg,

- 200 m – 4 kg,

- 250 m – 5 kg,

- 300 m – 6 kg.

In order to calculate the consumption per day with continuous heating, these figures are multiplied by 24 hours. For example, for a house 250 m2 - 120 kg of pellets per day. The monthly consumption will be 3 tons 600 kg of fuel.

Let us recall that the calculation was based on the operation of the boiler in continuous mode around the clock without interruptions. As a rule, such modes are used during abnormally severe cold weather, which is not prolonged.

If the system operates in such a maximum mode, when there is a thaw outside, but the house is not too hot, it means that it does not have a power reserve in case of extreme cold. Or the house holds heat extremely poorly. Nevertheless, the above calculations allow us to estimate the reserves of pellets that will be needed for the winter.

It remains to multiply the amount of fuel by the cost of 1 kg of fuel pellets, plus delivery, payment of energy for the operation of the boiler - auger, pump and fan.

Presence of additional reasons influencing the use of pellets

This calculation method is optimal in a theoretical sense. In reality, the volumes of consumption of fuel granules may differ significantly from the existing indicators, either increasing or decreasing.

In fact, the volume of pellets consumed for heating a house is 100 sq.m. is associated with many aspects, among which 2 positions occupy the dominant place:

- Boiler efficiency factor, its characteristics.

- The mode in which this type of heating equipment operates.

Together with the quality indicators of pellets, these parameters have a significant impact on consumption rates per day, and, accordingly, on the cost.

The owner of a private household can significantly reduce costs by choosing equipment of a high technological level and efficiency, with professional monitoring and regulation of its operation.

About the efficiency of solid fuel boilers

Modern heating equipment is created using complex design solutions. A highly functional boiler, the fuel for which is wood pellets, with a small volume of fuel element consumption, and is equipped with a special receiving hopper into which the pellets are loaded.

Fuel is supplied to the firebox using an auger after the previous batch has burned out. The fuel and air supply algorithm is determined using an electronic controller.

Pyrolysis boilers are characterized by maximum energy efficiency. Their efficiency sometimes reaches 85%. This is due to the pressurization and afterburning of furnace gases. Considering this indicator, the estimated volume of burned pellets increases to 20% (0.024 kg/sq.m per hour).

It follows from this that for comfortable heating of a residential building for 24 hours, up to 57.6 fuel components are needed in relation to 100 sq.m. area that is heated.

How does the boiler operating mode affect pellet consumption?

The calculations reflected above were given for boilers operating at the maximum power limit. This operating mode is used only in extreme cases, at critically low temperatures. It can be understood that the normal volume of pellet consumption must be calculated based on smaller parameters: 0.05 kW of thermal energy in relation to heating 1 sq.m of heated area (per hour).

The daily consumption standard for fuel pellets, calculated from the indicators 1 kW/1 sq. m. per hour, must be reduced by 1/2. The estimated fuel consumption in this situation is up to 28.8 kg/sq.m.

Additional cost reduction can be achieved by eliminating heat loss and insulating the house. Installing windows with a 5-chamber profile will also be effective.

Advantages of fuel pellets

Pellets are the ideal choice for those who want the heating of their home to be completely autonomous. Thanks to heating using pallets, the owner of a home can feel independent - after all, the heat in his home is not associated with gas prices and possible shutdowns.

In addition, wood pellets have other undeniable advantages:

- Pellets are an environmentally friendly fuel product. They are small pressed wood shavings. The release of carbon dioxide during combustion is the same as that of ordinary wood.

- Pellets are economical during the heating season. At first glance, it seems that installing the necessary equipment and using the granules themselves is an expensive pleasure. But, with correct operation and correct calculations, you can soon be convinced of the opposite.

- Pellets do not emit toxic smoke with an unpleasant odor when burned; their smoke is colorless.

- Wood pellets have high heat transfer rates, 2.5 times higher compared to firewood (the efficiency of pellet boilers is 94%).

- They do not create pollution and are easy to use. Fuel is added once a week. The equipment is cleaned periodically (technically simple).

- Convenient to store, not prone to spontaneous combustion, and as a result of this, do not require special storage conditions.

- Easy to transport. Several bags of this fuel can easily fit in the trunk of a car.

Despite the undeniable advantages of pellets, they also have certain disadvantages.

These include significant start-up costs when purchasing. Pyrolysis boilers are much more expensive than gas or electric ones. In addition, fuel pellets must be stored only in dry conditions, without access to moisture. Failure to comply with storage rules affects the heat transfer of the material during combustion.

Fuel quality criteria

As you might guess, in order to release a significant amount of thermal energy, pellets must have the appropriate quality. Unfortunately, given the ever-increasing popularity of this heating method, low-quality fuel samples from unscrupulous manufacturers or outright scammers have begun to appear on the market. Of course, the use of handicraft technologies does not allow achieving effective heat transfer. There is a common misconception among many owners of pellet boilers that fuel consumption depends on the color of the pellets. This is not true at all. High-quality dark-colored pellets are made on the basis of wood fractions, which contain tree bark, light yellow ones are made from waste from the furniture industry, and dark brown pellets are made from logging waste. High quality pellets have a fairly high density, the numerical value of which exceeds 1, so they must sink in water. Also, an important parameter that determines the quality of this type of solid fuel is the amount of ash remaining after complete combustion of the pellets (ash content). According to standards adopted in a number of European countries, this figure should not be more than 1.5%. In other words, after burning 10 kg of fuel, no more than 150 g of ash should remain. If this indicator is higher, a significant amount of slag will be formed during combustion. And this significantly reduces the performance of the boiler.

In addition to the characteristics described above, high quality pellets must have the following characteristics:

- The humidity of the pellets should not be more than 10%, otherwise the consumption of pellets will be significantly increased due to the need to compensate for losses in heat capacity.

- The dust content should not exceed 11%. Exceeding this indicator is accompanied by an increase in ash content.

The packaging must be sealed. The most optimal option is when the granules are sold in special bags with a waterproofing film on the inside. Such packaging allows the granules to maintain their original quality characteristics for many years. Currently, 1 kg of fuel costs from 6 to 10 rubles. If a large-volume bunker is used with the boiler, it is best to purchase fuel in large bags (big bags). The mass of one such bag is 900 kg.