How to choose stones?

What stones should be placed in a sauna stove? To make the right choice, you need to take into account several professional tips. It is worth noting that not all stones are suitable for such purposes. The material must have high thermal conductivity and also be environmentally friendly. Stones should not emit substances harmful to human health when heated. Therefore, it is worth purchasing material only from specialized retail outlets that have a good reputation.

You should not use natural stones of unknown origin for these purposes, since not all rocks are safe for humans. Some stones do not give off heat well, which is unacceptable for a stove in a steam room. In the store you need to ask for the necessary information about decorative stones. They must have the following characteristics:

- Heat capacity. This is the ability of a stone to accumulate heat and then gradually release it. This allows you to maintain a high temperature in the room longer.

- Heat resistance. An indicator that characterizes the maximum temperature threshold that a stone can withstand.

- Safety. Stones should not release harmful components into the environment.

- Expansion rate when heated. This figure should be very low. Otherwise, the stone will crumble as the temperature rises.

Before considering how to properly lay stones in a sauna stove, you need to pay attention to choosing suitable rocks.

Which stones are suitable for a bath - a review of popular rocks

The list of popular fillers includes natural breeds that meet all requirements and have a beneficial effect on the human body. They are as follows:

- River and sea pebbles. They are distinguished by a high level of strength and durability, and availability. A good sample for a bath has a flattened shape.

- Jade. Refers to semi-precious minerals. It has excellent performance and healing properties. Chopped rock is chosen for the sauna because it gives off more steam.

- Nephritis. Semi-precious mineral. Its properties and appearance resemble jadeite. But the strength of jade is equal to the strength of steel. The filler also has a beneficial effect on the human body: relieves fatigue, stimulates sweating, improves metabolism, and energizes.

- Wax jasper. A dense mineral with a high heat capacity and a rich red-brown hue. Used as a remedy for insomnia, heart and nervous ailments.

- Soapstone chlorite. Mountain stone from Karelia and Finland. It has increased strength, rapid heat accumulation, long-lasting heat transfer, and the formation of light and pleasant steam. Before use, it is washed and calcined.

- Raspberry quartzite. A material with an attractive appearance and the ability to produce soft steam. For the bath, choose smooth, processed samples.

- Chromite. This stone was at the peak of popularity in Ancient Rus'. They put it in the oven “black” to cure colds. In modern baths, chromite is known as an environmentally friendly filler with excellent heat transfer.

- Porphyrite. Volcanic rock. It is distinguished by an affordable price and high performance indicators. Benefits - the ability to treat headaches, improve the functioning of the respiratory system. Disadvantages - requires careful care before each use.

There is another type of stone for baths - gabbro-diabase. This is a mineral of volcanic origin that accumulates sulfur over time. During the heating process, the room is filled with a suffocating odor. Therefore, experts do not recommend using it in steam rooms.

Types of stones

Placing stones in a sauna stove is a responsible undertaking. It is worth starting its consideration with the main points of choosing rocks suitable for operation at high temperatures. The following types of stones are suitable for a sauna stove:

| Breed name | Description |

| Jade | It is a semi-precious stone. Its properties fully comply with the requirements of steam room stoves. This is a durable mineral that does not absorb water, has durability and high heat transfer. |

| Soapstone chlorite | This is one of the best materials for a steam room stove. It is capable of not only accumulating heat, but also distributing it evenly in the room. In this case, the bath warms up gradually, and the high temperature remains in the steam room for a long time. The heating limit for this stone is 1,600 ºС |

| Basalt | This is a very strong and therefore durable stone. It is often used to equip sauna stoves. Basalt does not crumble and retains its integrity for a long time. It perfectly accumulates heat, which ensures that the steam room maintains a high temperature for a long time. |

| Gabbro-diabase | This stone is a whole set of minerals. Being of volcanic origin, it can withstand high temperatures. Moreover, all components are safe for humans, which makes the mineral especially valuable for use in the steam room. |

| Quartzite | This rock contains 90% quartzite. This mineral heats up quickly, but it must be used in combination with other stones. |

| Peridotite | The composition includes olivine and pyroxene, so the mineral is safe for people. The stone can withstand great heat as it is a volcanic rock. |

| Chromite | The mineral consists mainly of chromium, which is a safe substance for humans. As a result of heating, the structure of the stone does not expand. It is very dense and heavy. |

When laying stones in a sauna stove, you should avoid using rocks such as granite, spar, mica, electroporcelain, quartz, pyrite, marble, flint, and limestone.

How to properly place stones in a kiln? Instructions

General recommendations for the selection and placement of stove stones in heaters of baths and saunas

Properties of stones:

General recommendations for the selection and placement of stove stones in heaters of baths and saunas

Stones placed in heaters of baths and saunas must meet a number of general requirements:

1. For better adhesion (adhesion of water and stone surface), it is recommended to use chipped or bunded stones. Water from polished or ground stones will flow onto the metal, from where it will subsequently evaporate.

2.No cracks. The stones should not have visible cracks and have a uniform structure to prevent their occurrence in the future.

3. Absence of carbonates. Vivid signs of carbonates are white spots or chips along the cleavage, which are easily scratched with a steel needle.

4. Absence of asbestos. Vivid signs of the presence of chrysotile asbestos (a mineral with fibrogenic properties) in the composition are visible fibers on the surface of the stone.

5.No dust. The stones must be clean. To do this, immediately before laying, they must be thoroughly washed (this must be done even if the stones are visually clean).

In addition to the above requirements, there are also a number of highly specialized ones, depending on where the stones are used.

1. For batch furnaces, when the stone backing comes into contact with fire, the selection of stones with the highest possible melting point is important.

2. For places where stones come into contact with metal (for example, the bottom of an open heater), a high thermal conductivity coefficient is important.

3. In places where water is supplied, it is necessary to choose stones that are resistant to sudden temperature changes and have pronounced lithotherapeutic properties.

4. If stones are used as backfill in an economizer or a mesh around a furnace, it is preferable to use a backfill with high decorative qualities, as well as one with lithotherapeutic properties.

5. Attention! When laying stones in electric heaters, it is prohibited to use chromite or jasper.

What else should you pay attention to?

It is important to be confident in each stone that you use as a stove backfill and supply steam without thinking about possible troubles.

The manufacturer remains responsible for such indicators as environmental friendliness, radiation safety, and the absence of minerals in the stone that are harmful to health.

To prevent these invisible human enemies from spoiling your pleasure from the bath, ask the sellers for a certificate of conformity and an expert opinion on the sanitary and epidemiological examination of the stones. Remember, the stones must be certified SPECIFICALLY for use in heaters for baths and saunas.

It is better if the stones you buy have a recognizable brand from a clear, real manufacturer.

Stone size

When choosing stones, be sure to take into account the type of stove. It can be wood-burning, open or electric. Its size is also noticeably different. For example, when considering how to lay stones in a Vesuvius sauna stove (this is one of the most popular models), it is worth noting that the dimensions of the fraction will be different. Laying stones of different sizes is encouraged. Moreover, stone types need to be mixed. This will also have a positive effect on the operation of the furnace.

When laying stones in a Vesuvius sauna stove or other similar structure, you need to select a fraction ranging in size from 6 to 20 cm in diameter. This principle is used for most open and wood burning stoves.

Only large stones are placed in a closed Russian oven. There should be enough free space between them. Too dense masonry will not allow steam to be generated. Therefore, for this type of heater, a large fraction is needed.

If the stove is small, with electric heating elements, you need to choose stones with a diameter of 5-8 cm. They must pass between the heating elements, but not damage them when heated. Therefore, small pebbles will fill the space inside a small electric oven.

What should be the stones in the heater?

Minerals for the heater are not only those you like. Even recommended breeds must meet a number of characteristics:

- Eco-friendly and safe for health.

- In terms of mass, the stones should be heavy, the fraction should be medium, too small are not suitable, as are too large. The density is high. This will prevent the minerals from cracking when interacting with water.

- The coefficient of thermal expansion should be the same; in other words, you need to take stones of the same type and approximately the same size: large ones 7–13 cm, small ones — 4–6 cm. This way the heater will heat up evenly.

- Tolerates high temperatures well.

- The surface is homogeneous.

- Classical and ultrabasic rocks should not contain more than 43-54% silica.

These characteristics are not always characteristic of a particular breed. It is better if most of them are suitable for the selected product.

Why are rock types mixed?

When considering how to lay stones in a mesh sauna stove, open or closed heater, you need to pay attention to one nuance. Often, mineral species are mixed, as this saves money on the family budget. It is quite difficult to fill a spacious oven completely with expensive stones. Therefore, they are diluted with cheaper minerals. You can stack the stones mixed or in layers.

Stones that heat up faster are placed down. Other types of minerals are laid out on top.

Stones are also mixed to create an aesthetic appearance for the stove. The simpler, cheaper varieties of minerals are put down. Beautiful reddish and greenish stones of rich shades are laid out on top.

It is also worth considering that the amount of steam that the oven produces depends on the shape. It is necessary to take into account the order of laying the stone in the sauna stove. Chopped and tumbled forms are best suited for a steam room. The first of these varieties has a large area. However, this is also a disadvantage, since such stones become covered with cracks due to insufficient strength.

Tumbled stones are durable, since during their processing, fragile specimens are eliminated. These stones are not inferior in area to crushed minerals, but their cost is an order of magnitude higher. Therefore, such rocks are laid down, where the temperature is higher. Cheap crushed stones can be laid on top. At the same time, the appearance of such minerals is quite beautiful.

Is it possible to mix stones for a bath?

The answer to this question is definitely positive. You can mix. Moreover, you are free to lay them out in layers or mix different ones within one layer.

Many of those who have an open fire in the stove or are not able to fill the entire volume with expensive rocks use cheaper ones for the lower layers. Or they do the same for other reasons, for example, as mentioned at the beginning, to speed up heating due to the different thermal conductivity and heat capacity of the rocks. The third reason is purely aesthetic. You can choose colors so that they look beautiful when wet. For example, by mixing green and red specimens. Or red and gray.

First installation method

Considering the order of laying stones in a sauna stove, it is worth noting that there are two methods. The first approach is used for open heaters. In this case, harmful gases that are released during combustion will not escape from the stove into the room. Heating will occur due to the sufficient temperature of the furnace walls. Soot and soot will not settle on the stone backfill. Their particles will not appear in the sauna steam.

Open heaters take longer to heat up than closed varieties. Therefore, more firewood will be required for kindling. Therefore, such a system can be considered uneconomical. But with electric heating, it is impossible to heat a room without an open heater design.

In open types of designs, for example, in a Finnish sauna, when stones are correctly placed in a sauna stove, it is possible to create walls of minerals around the heating element. They accumulate thermal energy and then evenly release it into the surrounding space. Since the stones lie tightly, no steam is released. This allows you to increase the temperature inside the steam room, but at the same time the air remains dry.

Stones can also be placed around a boiler with water. They can be quite large. In this case, it will be possible to scoop up heated water and pour it on the stones. This is how you can heat the bathhouse black. In this case there will be a lot of steam. By covering the heating element with stones, you can create high-quality heating inside the room.

How many stones should I put?

You can calculate how many kg of stones you need in a sauna stove yourself; let’s try to do this using a simple example.

So, for example, let’s take the original data:

- The volume of the steam room (excluding the stove) is 15 m3 - quite large.

- We use basalt stone.

- Creating steam every hour 3 times, at the rate of 70 ml/m3, then the stove consumes 0.07x15x3= 3.15 liters of water/hour.

- The operating time of the bath is 5 hours.

- The initial temperature of the stones (measured at a depth of 9-13 cm) is 500 degrees.

- The final heater temperature at which steam can still be produced is 150.

- The temperature of saturated steam from the heater is 110 degrees.

- The temperature of the supplied water is 80 degrees.

Now the calculations:

- The total amount of water poured onto the heater in 5 hours is 4.5 x 5 = 15.75 liters.

- To adjust water from 80 to 100 degrees you need: W1=15.75x1x(100-80)=315 kcal

- In order for this water to become steam: W2=15.75×538=8473.5 kcal

- Next, to heat the steam to 110 degrees: W3 = 15.75 × 0.48 × 10 = 75.6 kcal

- So, all you need is: W1+W2+W3 =8864.1 kcal

- 1 kg of stone, cooling from 500 to 150 degrees, releases heat: W4=C*(Tt)=0.15(500-150)= 52.5 kcal

- Total stones required: P = 8864.1/52.5 = 168.84 kg.

Again, this is conditional data; in reality, everything may differ. But now you know that approximately 1m3 of steam room volume (excluding the stove) accounts for 11 kg of stones.

Second installation method

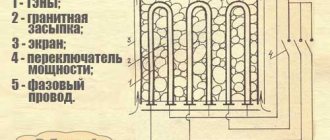

When considering how to properly place stones in a sauna stove, it is worth considering a different method. It is more difficult than the previous one, as it requires a more careful selection of elements. This method is called closed, since the stones are in the path of smoke exiting the furnace. They get very hot.

During bathing procedures, water is poured onto hot stones. It evaporates instantly. Therefore, the steam room is filled with dry steam. If you hear a characteristic pop when pouring water onto the stones, it means the oven is heated very well.

With closed filling, the stones are located above the firebox. They are laid out on a cast iron grid. Instead, the design may include a brick vault with slots. The bottom layer of stones heats up to 1100 ºС. The top layer is slightly cooler. Here the temperature reaches a maximum of 600 ºС.

With this method of laying, stones accumulate heat well and retain it for a long time. But this is not so easy to achieve. You need to know how to properly lay each layer of stone filler. This is a whole science. But with careful selection of all backfill elements, significant results can be achieved.

How to prepare the stone?

Preparation also includes testing. You need to do the following:

- just soak the batch in water without anything for several hours (you don’t have to do this, but this is also a test: watch to see if gas bubbles are released - this is a sign of cracks, specimens with bubbles must be removed );

- then go over each thoroughly with a stiff brush and rinse under running water.

The washed batch can be calcined and thrown into water. If any of them split, they will be rejected.

In the future, the stones will need to be sorted with some regularity. You can do this once a year, every six months, every season. Deterioration in heating quality may be a signal for an unscheduled inspection.

Correct installation in a closed heater

Not every builder knows how to place stones in a sauna stove. This is a whole science that you can master without difficulty. When arranging a closed stove, be sure to leave gaps between the stones. In this case, during operation of the furnace, each element of the filling will be heated evenly. Round stones are more suitable for this type of installation. In this case, free space will appear in any case, making a mistake will be almost impossible.

There should be no grooves or cracks on any backfill element. Otherwise, the stones will crack, crumble and clog the channels. This will negatively affect the operation of the oven.

Before laying, the stones are sorted by size. Large specimens are placed down, and small specimens are placed up. When heated, all stones expand. This is inevitable and will eventually lead to destruction of the furnace walls. Therefore, it needs to be checked and repaired at certain intervals.

If you lay the stones tightly, they will begin to put even more pressure on the walls of the furnace as they expand. Therefore, such filling is strictly prohibited. Otherwise, the oven will quickly become deformed and will no longer perform its intended functions.

A few recommendations from experts

Professionals give some tips on how to place stones in a sauna stove. They recommend rinsing all stones before installation. Often marine or river varieties of materials are used for this. If a round stone has a blue tint, it is not suitable for use in a kiln. Such pebbles will smoke, releasing carbon monoxide into the steam room.

Having sorted through the stones, sorted and cleaned them, you can begin laying them. You need to place the largest elements of the backfill down. They should be directed towards the heated surface with a narrow edge. This way the stone will warm up quickly. In addition, such a position of the pebbles will not allow the thermal energy to be reflected back into the oven; it will easily move upward.

The number of stones is calculated in accordance with the dimensions of the room. Per cubic meter of steam room space you need from 35 to 45 kg of stones. This indicator depends on their thermal conductivity and ability to accumulate thermal energy.

Long stones cannot be laid horizontally. Their location should be exclusively vertical. Otherwise, the heat will not be able to rise up. You can also lay stones on their sides.

The sharp corners of the stones should be directed towards the firebox, and the flat ones should be directed towards the walls of the stove. This allows you to accumulate enough thermal energy to maintain the desired temperature in the steam room for a long time.

Lifetime of stones

Having studied how to place stones in a sauna stove, you need to pay attention to the issues of their operation. Over time, the backfill needs to be changed. It is recommended to completely change the stones every 3-4 years. This is explained by the accumulation of soot and toxins on the surfaces of the backfill elements. Due to expansion and contraction during heating and cooling, even strong stones begin to crack and crumble. By clogging the channels, they reduce the heating efficiency.

To make the stones last longer, do not water them with cold water. They should also not be allowed to come into contact with open fire.

How to properly care for stones in a steam room

Even such a durable material as natural stone , especially used in extreme conditions of a bath or sauna, becomes unusable after some time. This explains the reduction in heat output of furnaces by 15-30% per year (depending on the intensity of operation).

It is recommended, on average, once a year (and sometimes more often, if the steam room is used intensively) to conduct a thorough inspection of the stones, after removing them from the oven: identified defects and damage are a reason for replacement.

The rest should be washed under running water and re-laid. The ideal option is to completely replace the stones every 1-2 years, but this is not necessary, especially if the sauna is not used constantly.

When installing a stove, it is important to correctly calculate how many stones are needed for a bath or sauna . It is always difficult for beginners in the bath business, but if you use the rule of 5-6 kg/m2, then you can be sure that the desired effect from their use will be achieved. You can also use another calculation scheme: 1 part of stones per 50 parts of steam room volume.

The type of stove and the shape of the heater must be taken into account: closed or open. In the first case, a higher temperature is provided, so the selected stones must withstand it. In an open heater, the maximum temperatures are much lower, therefore, deciding which stones to choose for a bath will be easier, since it is possible to use less heat-resistant samples.

Mistakes when choosing a stone for a stove, video:

Furnace Maintenance

During the maintenance procedure, you can leave intact stones. They are cleaned and washed in cold water. This needs to be done if the oven begins to heat up poorly and does not hold heat. Most often you have to change the backfill completely. After a certain period of use, the stones burn out and are called “dead”. The breed loses its ability to accumulate heat. The smaller the stones, the sooner they will need to be replaced.