PROVIDING NATURAL CIRCULATION

Reliable operation of all boiler pipes included in the natural circulation circuit is ensured by maintaining the temperature of their walls close to the saturation temperature, for which a steam generation regime is created in the riser pipes in which a continuous film of water is maintained over their entire surface. Under this condition, continuous heat removal occurs, ensuring that even at a very high thermal load, the temperature of the walls is as close as possible to the temperature of the working fluid. In addition to observing this most important condition, it is also necessary to ensure reliable cooling of the pipe walls to prevent the deposition of sludge or scale on their insides. Such deposits may be associated with improper water conditions in the boiler installation and circulation conditions. With a significant decrease in the circulation rate, not only can the water film on the surface of the pipes collapse, but also the evaporation of soluble salts contained in the boiler water, the formation of abundant local deposits and, as a result, a sharp increase in the wall temperature. The danger of overheating of the metal walls of the pipes also arises when the flow of the steam-water mixture stratifies.Thus, in order to ensure the reliability of the operation of the lifting pipes included in the natural circulation circuit, it is necessary to identify dangerous modes in them. Such dangerous modes for the lifting part of the circuit are: the formation of stagnation of the working fluid in the lifting pipes, overturning of the circulation, stratification of the flow steam-water mixture and the regime of maximum circulation rate. For the lower part of the circuit, a dangerous mode is steam formation in the lower pipes, which can occur as a result of a drop in pressure in the inlet section of the pipe (the so-called cavitation), and as a result of heating of some part of the length of the lower pipes. in the lowering pipes, the normal flow of water into the rising pipes is disrupted. The formation of stagnation of the working fluid in the rising pipes occurs when their heating is significantly uneven. Figure 7.6 shows a diagram of the circulation circuit, in which, along with normally heated pipes B, there are weakly heated pipes A, and also unheated pipe C. The level height in pipe C, characterizing the pressure drop between the drum and the collector (provided that the water in the pipe is at saturation temperature), is determined from the relation

Obviously, in the absence of heating of pipes A, the location of the free level in them (when this pipe is inserted above the level in the upper drum) will be the same as in pipe C. When pipe A is heated only at a height of HMax, the position of the level will not change, since circulation there will be no water in the pipe. However, the wall temperature will quickly reach the temperature of the surrounding gases, which will lead to pipe rupture. If pipe A is heated only in the section below the free level or simultaneously in both sections of the pipe, but its thermal load is insignificant, then the free level in pipe A may form in a cross section slightly larger than the cross section of the free level in the unheated pipe. With increasing heating of pipe A, its thermal load will increase so much that the amount of steam formed in the lower section will raise the level to the outlet section of the pipe and normal circulation will begin.

Comparing the value of the useful pressure of the circulation circuit with the value of the pressure of the weakly heated pipes of this circuit makes it possible to identify the boundary of the transition from the normal circulation mode to stagnation modes of the working fluid. The value of the useful pressure in a separate weakly heated pipe, at which stagnation of the working fluid of the RSVD is formed, is easily determined if the flow rate of DJP steam (or water) passing through this pipe is known. If this pressure is equal to or less than the useful pressure of the circulation circuit, then a stagnation mode of the working fluid will occur. Consequently, to prevent such a regime, it is necessary that the useful pressure of the weakly heated pipe pTr be greater than the useful pressure of the circulation circuit Ppol. i.e., so that the condition is met

Circulation reversal, which is understood as the transition from the upward movement of water and steam-water mixture to the downward movement, can only be observed in pipes led into the water space of the drum. During this transition, the formation of a free level and the associated danger of pipe burnout are inevitable. Therefore, checking for the absence of stagnation of the working fluid is also a check for the absence of circulation overturning.

Circulation in the riser pipes may be disrupted when the steam-water mixture stratifies. Since this mode is only possible in horizontal and slightly inclined pipes at a low mass flow rate, it is best to avoid the use of such pipes in the circulation circuits of boilers with natural circulation. Dangerous modes for lifting pipes also include the regime of maximum circulation ratio, since in this case the circulation ratio is close to unity. Almost complete evaporation of water occurs and, consequently, strong local deposits of salts present in the boiler water are formed. In this regard, in boilers with natural circulation, it is recommended not to reduce the average circulation ratio below 3 for high-pressure drum boilers. Elimination of the dangerous modes described above ensures reliable circulation of the lifting part of the circulation circuit. To ensure reliable circulation of the lower part of the circuit, it is necessary to prevent cavitation and vapor formation in the lower pipes.

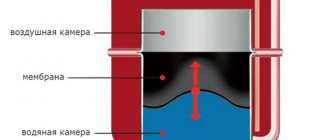

The pressure drop at the entrance to the downcomers due to the creation of water velocity in the pipe and losses to overcome the local resistance of the entrance from the drum to the pipe is determined from the expression

Steam formation in heated downpipes can occur if the amount of heat absorbed by them is equal to or greater than the amount of heat required to heat the water in the downpipes to a state of saturation. When making appropriate calculations based on average values, it is necessary to take into account both the uneven heat absorption of the lower rows and the uneven distribution of feed water between individual pipes. Checking for the absence of steam formation in the downpipes is carried out according to the formula

To ensure reliable operation of the circulation circuits, it is necessary to eliminate the causes that cause the occurrence of dangerous conditions in the riser and fall pipes. Violation of the normal operating conditions of circulation circuits occurs mainly when there is significant uneven heating of the riser pipes. The lower the heat absorption of individual pipes, the less water passes through them and, therefore, the lower the speed of water movement in them. Uneven heating of the riser pipes occurs both due to the design features of the circulation circuits of the furnace, burners, and due to operating conditions. The design features are determined by the different lengths of the heated sections, the need to bypass screen pipes around the embrasures and burners and the nature of the location of the latter. These features cause inevitable uneven distribution of the thermal load.

A significantly greater influence on the heating intensity is exerted by operational factors, of which the most important are slagging of screens and convective beams, drifts of heating surfaces with fly ash, sudden changes in the furnace mode, fuel quality, etc. Consequently, to increase the reliability of the operation of circulation circuits, it is necessary first of all strive to eliminate uneven heating of pipes. This can be achieved through operational and constructive measures.

The most effective operational measures are to prevent slagging of combustion screens and the drift of pipes with fly ash. In addition, it is necessary to exclude the possibility of sudden changes in the combustion regime. Of the constructive measures that help improve the reliability of circulation, the most important are increasing the cross-section of the downpipes and sectioning the screens. Increasing the cross-sections of the downcomers leads to an increase in water flow through all pipes of the circulation circuit, including through weakly heated pipes, in which favorable circulation conditions are thus created. In addition, increasing the cross-section of the downpipes reduces the useful pressure and therefore makes the formation of a free level unlikely. Sectioning the screens made it possible to avoid complex circulation circuits characterized by significant thermal and hydraulic unevenness. Dividing the combustion screens into a number of sections with a relatively small heated surface ensures a much more uniform heat absorption of the riser pipes.

Heat generating installations: Textbook. for universities. G. N. Delyagin, V. I. Lebedev, B. A. Permyakov. M.: Stroyizdat, 1986.