Features of polycrystalline panels

Polycrystals are produced by gradually cooling molten silicon.

This technology is cheaper than artificially growing single crystals; however, there may be graininess on the edges of polycrystals, which leads to a decrease in their efficiency. The fundamental difference from monocrystalline ones is their heterogeneous structure and color. This is due to impurities and the fact that the system contains crystals of different types. Features: efficiency is lower than that of monocrystalline elements - up to 17-18%;

affordable price - production of polycrystalline panels is less expensive;

the rate of power loss (degradation) of polycrystals is less than that of single crystals.

Thus, if the task is to obtain a certain amount of electricity, using polycrystalline panels will require a large area. There is an opinion that it is more profitable to use them in regions with a predominance of cloudy days - when there is insufficient sun, polycrystals provide more energy than single crystals.

Advantages and disadvantages

The most obvious advantages of this system include the following nuances.

- Renewability. Unlike other sources of electricity (such as fuel), solar energy is a renewable resource that will keep the battery running for as long as the solar system lasts. The quality of the power supply will depend only on the type of device and the condition of its elements. The power of modern models ranges from 200 to 500 W.

- Environmentally friendly. Solar panels are a significant step for humanity to protect the climate from global warming. They are installed by many enterprises that advocate environmental protection. This system does not emit any caustic or toxic substances that can harm nature, but at the same time it provides electricity no worse than other sources.

- Economical. The system does not require large additional costs, except for annual cleaning of photocells. By purchasing a solar battery, you can use the electricity it generates for several decades, saving significantly without having to pay a bill for electricity consumption.

- Availability. You can purchase and install this equipment without any problems. In many European cities, solar panels are the main source of electricity.

- Silence. Autonomous operation of solar panels is not accompanied by noise. It is easy and comfortable to use.

- Durability. Most solar panels last up to 20-30 years.

However, such a system also has certain disadvantages.

- High price. Especially in Russia, where the use of solar panels is still not widespread, it can be problematic to find a high-quality product at a low cost. You can turn to international suppliers to save money, but including tax and delivery, the price will not be very different from what domestic sellers offer.

- Impermanence. These batteries convert electricity from sunlight, but obviously this can be a problem at night and on cloudy days. For a powerful system this will not be a significant problem, but it may affect more budget models that will not be able to receive sufficient energy during prolonged cloudy weather.

- Low power density in contrast to electricity produced using fuels such as oil, coal, gas.

- Low availability of spare parts. Not all companies offer spare parts for their models. That is why, in the event of a breakdown, it will not always be possible to repair the equipment efficiently and quickly.

The advantages of solar panels largely outweigh their disadvantages. That is why the demand for this system among Russian buyers is only growing every year.

Polycrystals and the use of solar cells

Monocrystalline wafers are advanced and superior to polycrystalline wafers.

Due to their flexible structure, they can be placed on the roof of a house or gazebo.

Polycrystalline elements are good for outdoor station,

Since they are installed only on a flat surface, it is necessary to find a separate place for them in the garden. When placed in a gazebo, glazing of the panels is not allowed, as this reduces the efficiency. The efficiency of commercially produced panels is approximately 18%, which is lower than monocrystalline panels. Polycrystalline wafers suffer efficiency losses mainly due to surface heterogeneity.

Flexible monocrystalline wafer is convenient

Comparison of monocrystalline and

So, which solar cell is better - monocrystalline or polycrystalline? To answer this question, you must first understand how they differ?

The photo below shows two main types:

The first thing that catches your eye is the appearance.

Monocrystalline elements have rounded corners and a uniform surface. The rounded corners are due to the fact that cylindrical workpieces are obtained during the production of monocrystalline silicon. The uniformity of color and structure of monocrystalline elements is due to the fact that this is one grown silicon crystal, and the crystal structure is uniform.

In turn, polycrystalline elements have a square shape due to the fact that rectangular blanks are obtained during production. The heterogeneity of the color and structure of polycrystalline elements is due to the fact that they consist of a large number of heterogeneous silicon crystals and also include a small amount of impurities.

The second and probably the main difference is the efficiency of solar energy conversion.

Monocrystalline elements and, accordingly, panels based on them have the highest efficiency today - up to 22% among mass-produced ones and up to 38% among those used in the space industry. Monocrystalline silicon is produced from highly purified raw materials (99.999%).

Commercially produced polycrystalline cells have an efficiency of up to 18%. The lower efficiency is due to the fact that in the production of polycrystalline silicon, not only highly purified primary silicon is used, but also secondary raw materials (for example, recycled solar panels or silicon waste from the metallurgical industry). This leads to the appearance of various defects in polycrystalline elements, such as crystal boundaries, microdefects, carbon and oxygen impurities.

Cell efficiency is ultimately responsible for the physical size of solar panels. The higher the efficiency, the smaller the panel area will be for the same power.

The third difference is the price of the solar panel.

Naturally, the price of a battery made from monocrystalline cells is slightly higher per unit of power. This is due to a more expensive production process and the use of highly purified silicon. However, this difference is insignificant and averages about 10%.

So, we list the main differences between monocrystalline and polycrystalline solar cells:

Appearance.

Efficiency. Price.

As can be seen from this list, for a solar power plant it does not matter which solar panel will be used in its composition. The main parameters - the voltage and power of the solar panel do not depend on the type of elements used and panels of both types with the same power can often be found on sale. So the final choice remains with the buyer. And if he is not bothered by the heterogeneous color of the elements and a slightly larger area, then he will probably choose cheaper polycrystalline solar panels. If these parameters matter to him, then the obvious choice would be a slightly more expensive monocrystalline solar panel.

In conclusion, I would like to note that according to the European Association EPIA in 2010, the production of solar cells by the type of silicon used in them was distributed as follows:

1. polycrystalline - 52.9%

2. monocrystalline - 33.2%

3. amorphous, etc. - 13.9%

That is, polycrystalline solar cells occupy a leading position in the world in terms of production volume.

Types of solar panels

What is each module and what is the difference between them? This question is most often asked by buyers before deciding on the type of panels to install a solar station. Mono- or polycrystalline panels are made from silicon. When the sun's rays hit a silicon solar cell, free electrons are created, which create a current when moving. Despite the same operating principle, the price and technical characteristics of these solar panels differ.

Monocrystalline module

Monocrystalline panels are made from just one crystal. This crystal is carefully grown, which takes a lot of time, and the process itself is quite labor-intensive. The battery itself is cylindrical in shape and consists of many squares, presented in a uniform color, which indicates the use of high quality silicon. Subsequently, the module is cut into thinner plates. Due to the presence of a silicon grid, the corners of the battery are slightly cut. Monocrystalline designs are quite compact and powerful, due to which you can save space and not lose on overall performance. A high percentage of efficiency is associated with the use of the entire surface of the crystal wafer, preventing the scattering of sunlight that hits the photocell. Monocrystalline batteries pay for themselves faster than polycrystalline batteries.

As a result of using specially grown high-quality crystals, the efficiency of monocrystalline modules reaches 22-24%.

Polycrystalline module

Based on the name, the essence of a polycrystalline module is the use of several crystals. Moreover, they are not grown, but ready-made silicon is simply melted and rectangular shapes in the form of panels are formed from it. To produce polycrystalline structures for a solar system, unusable monocrystalline modules can be used and cut into pieces. The plates themselves are quite thin, no more than 1 mm, since the photocells are glued to a special sheet and then painted over. The last step is to create the frame and seal it. Polycrystalline batteries are much cheaper than monocrystalline batteries, but they are inferior in performance. The efficiency indicator is in the range of 17-18%.

Now about amorphous batteries

Let's start with the advantages: the method of their manufacture is the simplest and lowest-budget, because cutting and processing of silicon is not required. This is reflected in the low cost of the final product. They are unpretentious - they can be installed anywhere, and they are not picky - they are not afraid of dust and cloudy weather.

However, amorphous modules also have disadvantages that outweigh their advantages: compared to the types described above, they have the lowest efficiency, they degrade faster - efficiency decreases by 40% in less than 10 years, and require a lot of space for installation.

The power of solar panels for off-grid systems is selected based on the required power output, time of year and geographic location.

The required generated power is determined by the power required by the electricity consumers that are planned to be used. When calculating, it is worth taking into account losses for converting direct voltage into alternating voltage, charging and discharging batteries and losses in conductors.

Solar radiation is not a constant value and depends on many factors - the time of year, time of day, weather conditions and geographical location. These factors should also be taken into account when calculating the amount of solar panel power needed. If you plan to use the system year-round, then the calculation should be made taking into account the most unfavorable months in terms of solar radiation.

When calculating for each specific region, it is necessary to analyze statistical data on solar activity for several years. Based on these data, determine the average actual solar flux power per square meter of the earth's surface. These data can be obtained from local or international weather services. Statistical data will allow you to predict with minimal error the amount of solar energy for your system, which will be converted into electricity by solar panels.

Rare earth materials

There are several types of rare metal solar panels, and not all of them are more efficient than monocrystalline silicon modules. However, the ability to operate in extreme conditions allows manufacturers of such solar panels to produce competitive products and conduct further research.

Cadmium telluride panels are actively used for cladding buildings in equatorial and Arabian countries, where their surface heats up to 70-80 degrees during the day. The main alloys used for the manufacture of photovoltaic cells are cadmium telluride (CdTe), indium-copper-gallium selenide (CIGS) and copper indium selenide (CIS).

Cadmium is a toxic metal, and indium, gallium and tellurium are quite rare and expensive, so mass production of solar panels based on them is even theoretically impossible. The efficiency of such panels is at the level of 25-35%, although in exceptional cases it can reach up to 40%.

Previously, they were used mainly in the space industry, but now a new promising direction has emerged. Due to the stable operation of photocells made of rare metals at temperatures of 130-150°C, they are used in solar thermal power plants. In this case, the sun's rays from tens or hundreds of mirrors are concentrated on a small panel, which simultaneously generates electricity and ensures the transfer of thermal energy to a water heat exchanger.

As a result of heating the water, steam is formed, which causes the turbine to rotate and generate electricity. In this way, solar energy is converted into electrical energy simultaneously in two ways with maximum efficiency.

Which modules to choose

The choice of the optimal option must be made based on a combination of cost, quality and technical indicators. It is wrong to be guided only by the design; such an approach can lead to wasted money. It is necessary to determine the electricity needs of the house, add the necessary reserve for unforeseen situations and for a drop in productivity with increasing service life.

Have you already decided to buy a solar power plant, but are not sure whether mono or polycrystal is better? In this article we will look at all the pros and cons of technology.

Polycrystalline solar panels. Myths and misconceptions

Of course, every seller and manufacturer is interested in selling their own product, and therefore persistent misconceptions have formed regarding some technologies on the market. Polycrystalline silicon technology is no exception and has characteristic differences from monocrystalline, pure silicon. Hence, many features of poly batteries are more often interpreted as advantages. But is it? Here are some claims from sellers selling solar panels

:

- “Polycrystalline silicon works better in cloudy weather!”

- “The service life of poly modules is the same as that of a single crystal.”

- “Polycrystalline solar cells are cheaper and therefore more accessible”

It is worth noting that the first statement in itself suggests that you are not communicating with a professional. Silicon solar panels have almost the same performance in cloudy weather, regardless of technology. “Non-silicon” amorphous solar cells can be proud of such quality as “efficient operation at low insolation”, the total efficiency of which ranges around 6-9%.

Poli - elements are actually a little cheaper, since their production process is not labor-intensive and fast. But given the fact that their efficiency is 15-25% lower, to achieve output comparable to MONO technology, the area of the products must be larger. This means higher costs for the product (glass, box, case) and transportation costs. The costs of installing products, the costs of fastening elements and switching also become higher. Determine for yourself what will be cheaper for you, but the initial price of the products is not yet a solar power plant.

Their work resource is also exaggerated. Poly-crystal solar cells reduce efficiency significantly in a shorter period compared to “pure silicon”.

Let us now examine the misconceptions regarding mono-crystalline solar cells.

Solar panels for home - the highest efficiency!

The advantages of monocrystalline solar cells are undeniable. But minor fluctuations in price are not always perceived correctly by the end buyer. Solar panels for home

, the mono type, is indeed a little more expensive and is not available from all manufacturers and sellers.

Monocrystalline silicon panels have a number of advantages:

- More compact overall dimensions per watt of power output;

- Long service life with minimal loss of crystal efficiency (no more than 20%, over 25 years);

- The highest efficiency of energy conversion (from solar to electrical).

Isn’t this enough to make a choice towards more advanced and efficient technology?

Monocrystalline panels

Monocrystalline panels have both pros and cons. The advantages of this type of panels include: 1. Quite high performance indicators. This is achieved due to the high degree of silicon purification. 2. High level of productivity. It reaches 18-23%. It is for this advantage that monocrystalline panels are in demand among users. 3. Solar panels from leading monocrystalline manufacturers can provide higher performance in low light conditions (morning and evening hours) and significant cloudiness. 4. Compactness. The area used is small to accommodate the battery. At the same time, its performance is higher than that of a polycrystalline panel. 5. Long period of operation. Thus, the guaranteed service life of a monocrystalline panel is from 25 to 30 years.

The only drawback of this type of battery is its cost. It is significantly higher than polycrystalline elements. Therefore, to install this type of panels it will be necessary to make capital investments.

Kinds

Before making a purchase, you need to familiarize yourself with the types of solar panels that modern companies offer. The performance, durability, power and price of the device depend on their choice. The difference lies in the material from which the solar cells of the system are made. There are several options.

The most budget-friendly type, designed to power small-sized equipment.

Made from polycrystalline silicon

It is characterized by its low price, in contrast to batteries with photoconverters made of monocrystalline silicon, however, it is less effective in the process of obtaining and processing solar energy. This option is designed for purchase by individuals to supply power to small areas.

Made from monocrystalline silicon

The most expensive model, which is characterized by high performance. Such batteries, as a rule, have a compact size, but at the same time they are characterized by high power generation capacity. The main advantage also lies in high quality - photocells are extremely resistant to moisture and other adverse conditions.

The purchase of a solar battery should be guided not so much by the budget, but by the need to provide an uninterrupted power supply to individual equipment, premises or enterprises. The better the quality of the photocells, the better the result and the more durable the product. If the choice is between purchasing monocrystalline or polycrystalline panels, it is best to choose the first option.

How to choose solar panels?

At first glance, all solar panels are the same: the cells of solar cells are interconnected by busbars, and on the back side there are two wires: plus and minus. But there are a lot of nuances in this matter. Solar panels come from different elements: amorphous, polycrystalline, monocrystalline. I will not advocate for one type of element or another.

Let me just say that I myself prefer monocrystalline solar panels. But that's not all. Each solar battery is a four-layer cake: glass, transparent EVA film, solar cell, sealing film. And here every stage is extremely important. Not just any glass is suitable, but with a special texture, which reduces the reflection of light and refracts light incident at an angle so that the elements are illuminated as much as possible, because the amount of energy generated depends on the amount of light.

Next come the elements themselves, and they are distributed by type, depending on quality: Grade A, B, C, D and so on. Of course, it is better to have quality A elements and good soldering, because with poor contact, the element will heat up and fail faster. Well, the finishing film should also be of high quality and provide good sealing. If the panels become depressurized, moisture will quickly enter the elements, corrosion will begin, and the panel will also fail.

How to choose the right solar panel? The main manufacturer for our country is China, although there are also Russian manufacturers on the market. There are a lot of OEM factories that will paste any ordered nameplate and send the panels to the customer. And there are factories that provide a full production cycle and are able to control product quality at all stages of production.

How can you find out about such factories and brands? There are a couple of reputable laboratories that conduct independent tests of solar panels and openly publish the results of these tests. Before purchasing, you can enter the name and model of the solar panel and find out how well the solar panel matches the stated characteristics.

To make a confident choice, contact a specialist who will help you choose the option for your specific situation.

If your space is not large, but you need maximum energy, in this case, look for monocrystalline panels with the highest power. If your budget is limited and installation is planned on the ground, then think through all the possibilities in advance.

Please note: the choice between polycrystalline and monocrystalline batteries with a power of 250 W is not significant, so take those with a lower cost or decide on other factors. Installing a solar collector has a huge practical advantage

Such an investment will serve you for a long time and reduce your energy costs. Batteries serve as sources of constant energy supply, and their resources are endless

Installing a solar collector has a huge advantage in practical terms. Such an investment will serve you for a long time and reduce your energy costs. Batteries serve as sources of constant energy supply, and their resources are endless.

What is the difference between monocrystalline panels and polycrystalline panels?

When choosing a solar module, the buyer often faces the question of which module to choose, monocrystalline or polycrystalline ?

At the moment, a large number of tests have been carried out regarding this issue, as a result of which the following results were obtained:

1. Temperature indicator.

During operation in real conditions the solar module heats up, as a result of which the rated power of the solar module is reduced. As a result of research, it was recorded that as a result of heating, the solar module loses from 15 to 25% of its rated power.

On average, mono and polycrystalline solar modules a temperature index of -0.45%, in other words, with a temperature increase of 1 degree Celsius from standard STC conditions, each solar module will have a power loss according to the temperature index.

This indicator also depends on the quality of solar cells and the manufacturer. Some manufacturers have temperature indicators in modules below -0.43%.

2. Degradation during operation LID (Lighting Induced Degradation).

Monocrystalline solar modules have a slightly higher degradation rate than polycrystalline solar modules in the first year.

The power of a high-quality polycrystalline module in the first year decreases by an average of 2%, and of a monocrystalline module by 3%.

Subsequently, the monocrystalline module degrades by 0.85%, while the polycrystalline module degrades by 0.8% annually, and this is a very insignificant difference.

3. Price.

The production cost of a polycrystalline solar module is lower than that of a monocrystalline solar . This is due to a more expensive production process and the use of highly purified silicon.

However, this difference is insignificant and averages about 10%. Therefore, lower cost is an important argument in favor of a polycrystalline module

4. Photosensitivity.

In our country, there is still a myth that a polycrystalline module functions more efficiently in cloudy weather, however, no one has ever found any official evidence that this is actually the case.

This question relates more to the quality and photosensitivity of solar cells.

The results of most tests showed that mono and polycrystalline modules behave virtually the same under different light levels and have the same photosensitivity.

You can determine the output of solar modules under different illumination by the coefficient. At 250 W mono at 200 W/m2 and 260 W mono at 400 W/m2 they are the highest. But the difference is still minimal.

5. Total output per year.

The world-famous PHOTON laboratory constantly publishes the results of its research, in which manufacturers from all over the world participate. The results are very paradoxical. Based on the results, it is quite obvious that the total output of polycrystalline modules is no higher than that of monocrystalline ones. Much depends on the quality of solar cells and their photosensitivity, as well as the quality of assembly and soldering.

As of 2013, more than 70% of network stations are assembled based on polycrystalline solar modules . This fact is justified by the fact that investors primarily look at the total cost of the project and the payback period, and not at the maximum efficiency indicators of the stations and their durability.

Today, some Russian sellers convince buyers that there is no difference between mono and polycrystalline modules, except that polycrystalline modules are less efficient and take up a little more area than monocrystalline ones.

Almost all Russian manufacturers, or rather assemblers of solar modules, because... A full production cycle simply does not exist in Russia; they switched to polycrystalline solar cells in order to reduce the cost of their products as much as possible and remain competitive at least in the domestic market.

a difference between mono and poly , but it is very minor.

A high-quality monocrystalline module is always more efficient and produces more power in the same size, but polycrystalline modules are always cheaper.

The choice is always yours.

Production of silicon crystals

The production of solar panels begins with the production of mono- or polycrystalline silicon cells. Monocrystalline silicon requires more complex and labor-intensive technology.

Its creation is carried out in several stages:

- Multi-stage purification of quartz sand containing large amounts of silicon dioxide. As a result of purification, oxygen is removed from it. This process is performed at high temperatures to melt and then synthesize the material with other chemicals.

- Next, crystals are grown from purified silicon. First, individual pieces of pure material are placed in a crucible, inside which they are heated and melted. A seed is placed in the molten mass, used as the basis of the future crystal. Silicon atoms, settling in layers on this seed, gradually take on a clear, ordered structure. The end result of this prolonged action is a large, homogeneous crystal.

- In the next step, the single crystal is measured, calibrated and processed to the required shape. At the output, it turns out to be in the shape of a cylinder, which is not entirely convenient for subsequent processing. Therefore, the cross-section of the workpiece turns into a square with rounded corners. Then, the finished single crystal is cut into separate thin plates using steel threads. After this, they are cleaned, quality checked and performance checked.

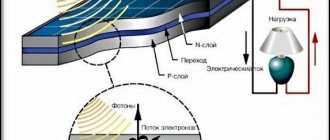

- The ability to generate electricity appears in silicon after adding boron and phosphorus to it. The n-type side is coated with phosphorus, which provides free electrons. On the p-type side there is a hole-conducting boron layer. Thus, a pn junction is created between the two elements. When sunlight hits the cell, an increased release of electrons and holes will begin from the atomic lattice. They spread throughout the electric field and rush towards their charge. The resulting current is collected using conductors soldered on each side of the plate.

- At the final stage, the plates are connected into chains, after which they are assembled into larger blocks. Battery power depends on the number of cells. When they are connected in series, a certain voltage value arises, and when connected in parallel, a current strength arises. To protect from external influences, the cells are covered with film, transferred to glass and installed in a rectangular frame. At the end of assembly, the current-voltage characteristics are checked, after which the panel is ready for use.

Monocrystal panels

It is very easy to understand that you are looking at monocrystalline solar panels. Their surface consists of a large number of squares, which have cut corners. Single crystals with this shape are obtained during the manufacturing process, and this is explained by the structure of the silicon crystal lattice.

From the name it is clear that one silicon crystal is used in production. To make it, a melt growth process is started using pure silicon. As a result, a crystalline element in the shape of a cylinder emerges, which is subsequently cut into thin plates, and they take the form of cut squares.

This form helps prevent wastage of usable space. The monocrystalline panel has a uniform color and structure. This indicates high purity of silicon (up to 99.99%).

The individual square parts are folded into a single panel, surrounded around the perimeter by a plastic shell. After this, the solar module is ready for operation.

Advantages

Monocrystalline solar cells have a number of advantages:

- They have the best efficiency among all modern models.

- Function well in low temperature conditions .

- They have a long service life (up to 25 years).

- Requires less space compared to other analogues with the same heat output.

Are there cheap solar panels?

Experts and scientists are striving to create batteries that will become widely available to the entire population. With small but successful steps they are approaching this goal and at the same time each time improving the materials used in this technology. Of course, there are also manufacturers who are negligent in the goods they offer to customers and knowingly sell low-quality products. This is precisely the main problem if you suddenly want to purchase an inexpensive solar battery.

Not only residents of the Russian Federation, but also European countries are convinced that inexpensive installations are offered by Chinese manufacturers. It can be noted that it was Chinese manufacturers who flooded the solar panel market, forcing many large companies that simply could not stand the competition with the Chinese to declare themselves bankrupt.

So, for example, you should know which products can be budget-friendly and which are not. Cheap monocrystalline panels are unlikely to be found, since these types include the most powerful elements

Therefore, it is very important to know what characteristics the installation includes

On the other hand, there are giant companies that, thanks to government subsidies, reduce the cost of the solar panels they produce. These include large German and, of course, Russian production. If you decide to purchase Chinese products, then it is better to give preference to some well-known company that has already lived up to its name in the market.

What is a solar battery? It is a direct current photovoltaic type generator that converts solar energy into electrical energy. These batteries use silicon semiconductor modules.

In order to choose a solar battery for your home, you will need to pay attention to a few of our tips. Namely:. Namely:

Namely:

When purchasing a solar panel system, keep in mind that it must be suitable for your home. Firstly, the climate of your area plays a big role. The duration of sunlight above the house and, naturally, the time of the accumulation mode will depend on it. In order to determine how suitable your area is, you will need to use a light map. Consider the amount of heat you ultimately want to receive. The best option would be a battery that can cover approximately 40-80 heat needs. Systems that are less efficient will cost an order of magnitude more. You also need to take into account the design and capabilities of the entire system. This can guarantee you the stability of the installation in cases of force majeure.

It is better to entrust all these calculations to specialists

Be sure to pay attention to the battery manufacturer, as well as the material that was used in the production of the photoelectronic element of the module. There can be either mono or polycrystalline silicon

Not only the price, but also the efficiency, as well as the service life of the installation, will depend on these qualities.

By following these tips, you can choose exactly the type of installation that suits your area. But it’s still better to have people involved in this field of activity handle your calculations.

Curiosities of solar energy

In light of the above, the so-called “reviews” that can be found on YouTube look especially funny.

The author compares modules of different generations. Mono – with 2 buses, poly – with 3 buses. When moving from 2 to 3 busbars, as well as moving to the now standard 4 current-collecting busbars, the efficiency of solar cells increases by several percent. Therefore, the difference in power is not due to the type of crystal, but due to the generation and quality of solar cells. Moreover, for the brand that the author “reviews”, the source of solar cells is unknown, and elements from different manufacturers may be used from batch to batch.

Sometimes on the Internet you can read the following “nonsense”:

Silicon polycrystalline batteries are most effective in cloudy weather, absorbing not only direct solar radiation, but also scattered light penetrating through clouds. This is due to the fact that in polycrystalline cells the silicon crystals are oriented not in an orderly manner, but chaotically, which, on the one hand, reduces the efficiency of the battery under direct solar radiation, and, on the other hand, reduces it slightly under diffuse lighting typical of cloudy weather.

Of course, different directions of the crystals have no effect on the transformation of scattered light . The person who wrote these lines has no idea how a solar cell works. There is no data proving that polycrystalline elements convert scattered light better than monocrystalline elements. More difference can be seen between the operation of p-type and n-type than between mono- and polycrystalline. The difference in the performance of solar cells under different illumination is mainly determined by the quality of manufacturing and technology, and not by the type of crystal. There are specific polycrystalline modules that perform better than specific monocrystalline ones. Which in turn can work better than other polycrystalline ones. As usual, the larger and more famous the manufacturer, the more predictable the result and the better the quality. That is why we always recommend well-known and trusted brands of solar panels for purchase. All of them are listed in our online store in the “Solar Panels” section, as well as on our website in the “Solar Batteries” section.