- home

- Services

- Sauna stove heater

For true connoisseurs of the Russian bath, we offer to build a real sauna stove, popularly called a heater stove. We will help you choose the optimal model. It is also possible to combine a sauna stove with a fireplace or fireplace stove, or equip a panel for heating the second floor with the heat of a sauna stove. Contact us.

Call or write to us for details (Sergey), (Alexandra) /

The stove's task is not an easy one - you need to heat the steam room well, and also heat the stones red-hot to make the steam light and pleasant. It’s hard on the stove, it has to be kept at a high temperature for a long time, it has to cope with high humidity, and it’s also pleasing to the eye. Therefore, by design, sauna stoves are the most complex, the slightest misdeed by the stove maker will immediately come to light - the brick will crack, the thick seam will come apart... and then remember the name of the stove along with the sauna. But a good stove maker will not allow this, he is attentive to his work, he loves his creation and is proud of every stove.

Advantages of the stove - heater

| 1. | Optimal temperature The heater warms up the steam room well, providing a temperature of 60 - 80 degrees, which at 60% humidity is considered the most optimal for bath procedures and does not harm your health. |

| 2. | High quality steam Water vapor, it turns out, comes in different forms. At 100 degrees the water begins to evaporate, but this steam is heavy. At higher temperatures, water is atomized into smaller fractions, producing increasingly lighter vapor the higher the temperature. And the stones in the heater heat up to 800 degrees. Can you imagine the light steam that is produced when water hits such stones?! Therefore, it is easy to breathe in the steam room. |

| 3. | The oven is hot, but moderately The heater is designed for high temperatures and is protected from overheating. The walls of the stove are brick, and even double-layered, and heat up no higher than 90 degrees. You will not get burns or heatstroke near such a stove. The warmth radiates soft and gentle. |

| 4. | Time The sauna stove will not cool down with just one ladle of water. She is capable of more. The first day after kindling the temperature stays around 80 degrees, on the second day - 50 degrees. So you don’t have to rush, you’ll have time to steam up and drink kvass. |

| 5. | Fire safety The outer walls of the stove are protected from overheating by fire-resistant bricks, the wooden structures are separated by fire-resistant cuts, the chimney is lined with a stainless steel pipe, all the doors are securely fastened, so there is no need to worry. The fire is only in the stove, and the smoke is only on the street. |

Main varieties

All types of wood stoves currently on the market can be divided into several groups. At the same time, they differ from each other in the features of their production assembly. Various types of wood-burning sauna stoves:

- Classic. In these variations, the heater is located only in the upper part. The firebox is equipped with a door made of glass or metal.

- Grid. The main advantage of such structures is that their casing is presented in the form of a mesh assembled from steel rods.

- With pre-installed steam generator. In such models, a special container is installed as an addition. You can pour water into it to create steam.

- With water tank. This model is complemented by a container where the water is heated to high temperatures.

There are many stoves for saunas, for example, with and without a water

tank. According to the features of their operation, wood-burning sauna heaters can be divided into two key groups. These include:

- Long-term heating stoves. As a rule, they operate using a small number of stones, which are separated from the firebox by a sheet of metal. In general, they do not heat above 350°C. At the same time, it is worth paying attention to the fact that experts strongly discourage watering stones, as there is a possibility of soot particles being released into the surrounding area.

- Ovens with periodic heating. These models are filled with a large number of stones. There is no partition in these designs, so the heater gains temperature from the flame. In such furnaces, stones can be watered, and the ash will not fly into the surrounding space. This type of stove is ideal for setting up a private steam room.

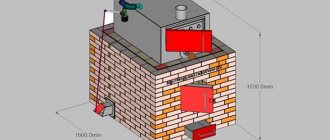

Construction of a sauna stove

A brick stove is heavy. 1500 - 2000 bricks are needed for such a furnace, and this is 6 - 8 tons of weight. Therefore, a reliable foundation is necessary. And since there is a foundation worthy of such a stove, then we get to work.

The heater stove is laid out in 2 stages. First, the fireclay core is made; this is not only the firebox, but the entire furnace. Next, the core is scalded with a metal frame so that the corner bricks do not try to crawl out. Next, the fireclay is covered with basalt cardboard and lined with high-quality ceramic bricks. All oven doors are also attached to the outer wall.

The heater consists of three chambers: a firebox, a stone filling and a heating bell shield. Each chamber has special cast-iron doors: in the firebox - for storing firewood, in the stone filling - for pouring water on the stones and generating steam, in the chambers of the shield - for cleaning it from soot and warming up the steam room.

For laying, the stones used are not simple ones, but those that are highly resistant to high temperatures, such as crimson quartzite and gabbrodiabase.

According to their design, heater stoves are of open and closed type.

Principles of classification of sauna stoves

Properly selected heater stoves have an optimal set of thermal properties, determined mainly by the volume of the room. More precisely, three rooms: a steam room, a washing room and a relaxation room, because... Most often, the entire private bathhouse is processed by one heat generator. Agree, it is unreasonable to install an insufficiently heat-intensive and powerful unit in the spacious steam room of a reputable family bathhouse. You will still have to change to a more productive system. It is somewhat strange to build a huge stove in a small country bathhouse: it will take up too much usable space and will not work “at full capacity.”

The article /pechi_otzyvy/kakaya-pech-dlya-bani-luchshe.html will tell you how to choose the right stove for a bath.

Material as the basis of thermal engineering

The performance of sauna stoves depends on the dimensions of the firebox, and such an important characteristic as heat capacity depends on the technical characteristics of the material. A sauna stove welded from metal sheets or from a ready-made barrel will heat up at the highest rate, but will have little heat retention. It takes much longer to heat a brick structure, but it more diligently conserves the resulting thermal energy.

Nobody really gives an exact answer to the question whether metal or brick is better to use in the manufacture of a sauna stove. Both options have disadvantages and undeniable positive qualities. Therefore, in practice, elements made of metal alloys and brickwork are often combined in a single design, for example:

- the brick heater is enclosed in a reinforcing metal frame welded from a corner;

- install metal fireboxes, stakes, guide panels for cutting the flow of smoke, firebox doors, a blower and holes for watering hot stones in order to generate steam in the brick walls of the stove;

- install metal views in brick chimneys;

- install metal chimney pipes, which should preferably be insulated and combined with asbestos-cement analogues;

- lined - line the firebox of a welded metal stove from the inside with brick and use the same method to increase the heat capacity from the outside.

And detailed information on how to line a stove with bricks with your own hands can be found here: /delaem_pech/kak-oblozhit-metallicheskuyu-pech-kirpichom.html

The internal brick lining of a metal sauna heater is usually mounted on brackets welded to the walls of the firebox. But the outer cladding can be “removable”, i.e. not secured with mortar. If it is necessary to shorten the combustion period, the brick shell of such a stove is removed, and after warming up the room, the stove is again covered with bricks.

In principle, any of the sauna stoves can only be made of brick or welded from metal. Technological openings in a brick structure can be covered with brick inlays. With the metal version, everything is extremely simple. However, a reasonable combination of metal and brick is a priority, because the technical advantages of one “cover” the disadvantages of the other.

In the manufacture of sauna stoves, roofing metal sheets with a thickness of 4-5 mm, high-quality fired, uniformly red refractory bricks are used. Fireclay or Gzhel material of the fire-resistant category is used to construct the fuel core. Brick markings should be M150 and higher. Metal parts and housings thinner than 4 mm will quickly burn out; they are only applicable if immersed in masonry, for example: metal door clamps. There is no need to buy hollow bricks and rejected material with shells, cracks and large chips. Sand-lime brick is not acceptable at all, because it does not bond with the sand-clay mortar traditional for laying stoves and absorbs moisture formed during temperature changes.

Video tips for novice stove designers:

Type of fuel as a division criterion

Bath heating units are heated with all types of flammable substances used in everyday life:

- natural gas, the use of which is possible only after obtaining permission from Fire Supervision and state authorities inspecting heating systems;

- products from the processing of liquid carbon, if the sauna stove is equipped with a burner with a liquid fuel supply regulator;

- solid fuel, mainly firewood, because When burning coal, it is too difficult to control the heating process; explosions and poisoning due to leaked carbon monoxide components cannot be ruled out.

Those who want to build a flawlessly working stove for their favorite bathhouse with their own hands should not get carried away with complex systems with burners for gaseous and liquid fuels. With your own production of electrical equipment, things are even more complicated; it is better to purchase it ready-made. Quite an impressive payment for electricity rarely suits the owners of bathhouse buildings, and conditions for connecting electrical systems are not always available.

In environmental and economic terms, among the types of fuel used, firewood is the leader. To fire a small country bathhouse, one or two small chopped logs are enough. Therefore, we will give a classification based on wood-burning stoves; moreover, it is similar to the division into classes and types of stoves operating on other types of fuel.

And the article /banshikam/toplivnye-brikety-ili-drova-chto-luchshe.html will tell you what is better for the stove: fuel briquettes or firewood

Types of stoves by combustion method

According to the heating method, bath heating systems are divided into two basic types:

- Constantly fired units, the temperature in which must be maintained without noticeable interruptions during procedures. These include metal welded structures operating on any of the acceptable types of fuel, small lined stoves and factory-made electrical equipment;

- Periodic combustion units, which are heated only during the period of preparing the bathhouse for washing. A classic representative of periodic options is a stove for a “black-style” bath, which does not allow the use of the room until the firewood is completely burned out. Improved designs of periodic fireboxes are built from brick, but also metal counterparts with a firebox lined with brick on the inside.

The structural difference between continuous-fired stoves and their periodic counterparts is the presence of a waterproof slab on which bath stones are laid. The stone filling accumulates heat and serves as a kind of evaporator, turning water poured onto its surface into healing bath steam. If the stones are placed on an impenetrable slab, you can generate steam while burning without fear of flooding the wood with water. If a heater stove for a country bath is made not with a stove, but with a grate on which stones with steel and cast iron ingots are stacked, then it will be possible to produce steam only after the firewood has completely burned out.

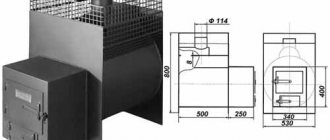

Open type heater

This is a kind of hybrid between a brick and an iron sauna stove. With its advantages and disadvantages.

The stones are not located inside the oven, but outside, in a special stainless steel box. Fire and smoke do not pass through the stones; the stones are heated through the walls of the metal box, figuratively speaking, the stones are fried in a large and deep frying pan. We build stoves of this type based on the developments of I.V. Kuznetsov under the name: Russauna bath stove.

| Advantages | Flaws |

| The stone backfill always remains clean. | The temperature of the stones is lower than in a classic heater - 200 - 300 degrees, the steam is not so light. |

| We lit the stove and after an hour and a half you can already go steaming, adding wood to the stove as needed. | Keeps warm for less than a day. |

| Obtaining higher temperatures in the steam room, up to 90 degrees, due to exposed stones and metal. | The high cost of making a box for stones from high-quality stainless steel. |

| The stone backfill always remains clean. | |

| We lit the stove and after an hour and a half you can already go steaming, adding wood to the stove as needed. | |

| Obtaining higher temperatures in the steam room, up to 90 degrees, due to exposed stones and metal. |

Construction of a brick heater for a bath with your own hands

Our instructions for building a heater will help you cope with this matter. So let's get to work.

Laying the foundation

First of all, it is necessary to build a foundation, which is an integral part of such massive structures. When building a foundation, it is important to consider not only the weight of the stove, but also the maximum volume of water poured into the tank. The strength of the entire structure depends on the correct construction of the foundation.

First, the boundaries of the future foundation are marked on the ground. Then, in place of the rectangle, a pit with a depth of at least 0.5 m is dug. It must be taken into account that the base will be somewhat wider than the stove itself, presumably half a brick, but it should not be placed close to the base of the bathhouse. It is permissible to leave a gap of 5 cm, which will then be filled with sand.

After leveling and compacting the bottom, the pit is filled with concrete mixture. If the soil is dry, bricks are laid in the prepared recess using cement, lime or a combination mortar. After five days, a layer of cement mixture is applied to the poured concrete or brickwork, and a lath and building level are used to level it.

Arrangement of waterproofing

After two weeks, which are allotted for complete drying of the foundation, you can begin the construction of the walls of the stove. However, it is also necessary to take care of waterproofing the base. To do this, perform the following steps:

- We evenly cover the surface of the foundation with roofing material so that one sheet lies on top of the other in parallel with an overlap of 10 cm. The edges of the strips of material should be 5 cm longer than the borders of the stove base.

- The second layer of roofing material is placed in a similar way, only now perpendicular to the laid canvases.

- Due to the fact that the first row of the furnace is a solid brick layer, there is no need to use molten bitumen or special mastic for gluing strips of roofing material.

Carrying out masonry

Using ordinary (not hollow or silicate) bricks, the walls of the furnace are built. It is appropriate to use heat-resistant material for laying such parts of the structure as the firebox and lining. Before starting work, all bricks must be soaked in water for two minutes. This preparation method promotes good adhesion of the base material to the solution, for the preparation of which you will need sand and clay in a 1:1 ratio. If the last component is too fatty, you will need twice as much of the first.

Features of laying seams

Tightness is the main condition that must be adhered to when sealing joints. A dense and carefully laid layer of solution will protect the room from the penetration of carbon monoxide. That is why it is so important to pay attention to the impermeability of masonry joints. It should be noted that the mortar is applied across the entire width of the brick. The thickness of the seams for a regular bar should be 5 mm, for a fire-resistant bar - no more than 3 mm.

With minimal experience in masonry work, it is difficult to achieve the desired results, but it is possible if you follow our further instructions:

- Two guides, made in advance from a metal rod of a suitable diameter, will help in making a seam of the required thickness. We recommend using welding electrodes that have been stripped of insulation.

- First, prepared guides are placed on both sides of the previous row of masonry. After pressing the next brick tightly against the rods, we get a perfect seam. Then these auxiliary elements are removed from the masonry.

- When the rods are placed along the edges of the bars, a void is formed, which is necessarily filled with a solution from the sequentially laid material.

Bonding of brickwork

We recommend that you first adjust the bars of each row to dryness and only then place them on the solution. A construction square will help in checking the correctness of the corners. Bonding of bricks is mandatory when constructing a heater stove.

It is important to remember that ordinary and heat-resistant bars are incompatible in the same row, since these types of building materials have different degrees of expansion when heated. Such dressing is unacceptable to avoid the appearance of cracks in the seams and possible leakage of carbon monoxide.

Furnace fittings

When constructing sauna stove equipment, all additional elements are installed simultaneously. You can secure the doors well using an asbestos cord, which must be wrapped around the frames before installation. The product in the form of a bundle serves as a compensator when the metal of the frame expands when heated. Thus, the winding will prevent cracks from appearing on the fittings.

Furnace equipment with a chimney

It is not difficult to install a pipe on an already finished structure. You need to purchase a product made of metal or asbestos cement. A pipe made of the first material must be wrapped in galvanized sheet or foil. The exit point of the channel through the ceiling of the bathhouse must be insulated using fire-resistant material. To prevent precipitation from entering the chimney, its upper part must be covered with a tin umbrella.

Arranging a heater for a bath

Schematically, the construction of a heater can be represented as follows:

Closed heaters

This is a type of classic heater stove. The stones are located in a special chamber inside the furnace, and are heated by an open fire through a separating grate made of cast iron or fireclay. When wood is burning in the firebox, it’s too early to steam, because if you open the door of the stone lining, the smoke will go into the steam room. You need to heat the heater for 4 - 5 hours, until the stones are red-hot and all the soot in the chamber burns out, and let it sit for another hour or two, and then you’re welcome. But it's worth it.

| Advantages | Flaws |

| Stones heated to 800 degrees produce very light steam. | The stove needs to be heated for 4-5 hours until the stones are red hot. |

| The stove holds heat perfectly for 2 days. | |

| The optimal temperature in the steam room is 60 - 80 degrees. |

Tips for use

Studying the instructions is the primary task of the stove buyer. The documentation for the product describes the rules for use, care, maintenance, and installation of additional elements.

Some operating tips:

- Before operating the heater, all protective films must be removed;

- the first heating of the heater is carried out either in the open air (outside the bathhouse) or in the bathhouse with open windows and doors;

- the heated water from the tank after the first fire must be drained;

- Loading stones should be done after the stove has completely cooled down according to the rules specified in the section above.

When the heater is fired for the first time, an unpleasant odor may appear. This is due to the combustion of industrial oils applied to the metal in the chamber, and after several subsequent fires the smell should disappear. The inner walls of the chamber may also become deformed, but this does not affect further operation.

The Teplodar wood-burning sauna stove is an excellent choice for a smart consumer. If used properly, our products will last for decades.