Pie brick walls

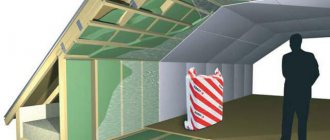

Typically a combined brick wall consists of the following layers:

- plaster or lime mortar

- wall masonry (slit or porous brick)

- insulation (foam plastic, mineral wool)

- cladding (face brick, plaster, special panels)

- galvanized steel mesh (for tying together the pieces of the pie).

This option is just a single solution for creating a brick wall pie. The number of combinations in this case can include several dozen combinations of different materials, including all types of brick, concrete, wood, foam plastic, mineral wool, cladding and plaster, which are selected depending on specific conditions and requirements.

Where to place the insulation in the wall pie

When building a house for permanent residence, it is recommended to place a layer of insulation on the outside, since such walls have better heat and humidity conditions than with internal insulation.

Insufficient wall thickness with irregular heating conditions leads to their complete freezing. Therefore, when the heating is turned on, condensation appears on the inside of the walls. Drying such “crying” walls and creating a normal thermal regime in the house is quite difficult and very expensive. To avoid such situations, they create a multi-layer wall pie with external insulation.

When heated, this pie releases excess moisture and accumulates heat, so during heating interruptions it does not cool down for quite a long time. In addition, the insulation prevents the penetration of cold from the outside.

When the insulation is placed on the inside, it will retain heat in the room, but the wall itself will freeze through. Therefore, it will be warm in a heated house, and if the heating is turned off, the temperature in the rooms in a few hours will be almost equal to that on the inner surface of the wall.

Therefore, the construction of a brick wall pie with an inner layer of insulation is well suited for a summer house or temporary residence, in which the temperature inertia of the walls in winter is extremely undesirable.

Since brick walls take a long time to cool down and also take a long time to warm up, it will not be possible to fully warm up the house if you need to live in winter. The temperature in it will be uncomfortable, a large mass of frozen walls will require increased fuel consumption, and condensation will collect on their internal surfaces. In this case, it is imperative to install waterproofing on the outside of the insulation, and provide for the removal of condensate formed in the wall design.

Wall pie protection

Insulation saturated with water vapor or precipitation will not work. Therefore, to protect the outer layer of brick walls with a thermal insulation layer of polystyrene foam or mineral wool slabs, they are plastered with a vapor-permeable solution over a mesh. It is also possible to cladding with special panels with air vents installed in them.

The wall of a brick house can consist of a variety of layers, including different types of bricks, insulation and finishing materials. The choice of a constructive solution for the wall pie is made depending on the requirements that the owner places on the future home.

Approximately half of the thermal energy that is lost in brick houses penetrates into the street through the walls.

High-quality insulation of wall structures slows down heat transfer and retains thermal energy in the house much longer.

Such insulation is no less useful for residents in the summer; such a house will always be cool.

Methods for insulating the walls of a brick house

But this is much more important is the fact that a wall, isolated from a warm room, will freeze and thaw several times a season, depending on weather conditions.

But the frost resistance of any building material is determined precisely by the number of freezing/thawing cycles that it can withstand and after which cracks appear in the material.

Another consequence is that the vapor permeability of the wall will have to be greatly reduced, or even reduced to zero. This leads to a whole chain of undesirable phenomena:

- Having made the walls vapor-tight, you will have to increase the intensity of ventilation, otherwise there will be increased humidity in the house;

- along with ventilation performance, heat loss will also increase;

- to compensate for increased heat loss, you will have to use a thicker layer of thermal insulation, which will “eat up” even more internal space.

However, in some cases, the home owner still has to make a choice in favor of internal insulation. Most often, residents of high-rise buildings find themselves in this situation who do not have access to the outside of the wall due to a nearby neighboring building or the presence of an unheated extension behind this wall.

Despite the fact that, as a rule, more heating radiators are installed in corner apartments, precious heat is not always preserved. How to insulate a wall in a corner apartment from the inside? Read useful tips on choosing insulation and installation work.

An overview of thermal insulation materials for insulating the outside of a house is presented here.

And in this topic https://microklimat.pro/uteplenie/doma/potolka/v-chastnom-dome.html everything is about how to properly insulate the ceiling in a private house. Materials and methods of installing insulation.

Why do you need to insulate brickwork?

The annual rise in electricity prices forces homeowners to look for efficient heating methods. All over the world, the main way to reduce heat supply costs is to insulate a building.

If the walls in a building do not have thermal protection, condensation will form on them. The air space near the wall has natural moisture, which, when it hits a cooled wall at sub-zero outside air temperatures, cools and turns into water.

It becomes a medium for the formation of various biological contaminants in the form of mold on surfaces, which create problems for walls and harm people’s health, since they are strong allergens and cause asthma attacks.

Consequences of absence

In order for a brick house to be warm, a wall thickness of more than 800 mm is required; it is clear that such houses are not built today. Therefore, any brick wall will be initially cold, quickly remove heat from heated rooms to the street and heat up very slowly during the startup of the heating system.

In addition, the dew point that will be created on a cold wall contributes to the formation of condensation, which damages the vital structures of the house: walls, basement and foundation.

When might it be necessary to insulate a house on both sides at the same time?

External insulation of the facade is the basic method of thermal protection of a building ; it is always performed when technology conditions allow.

But internal thermal insulation is performed extremely rarely, when it is impossible to carry out external work, for example, on the facade of a historical building.

External insulation is carried out by fixing a layer of insulating material to the wall of the house, followed by covering it with plaster or performing facing work with lightweight putties.

External thermal insulation of brick walls is performed using:

- expanded polystyrene,

- mineral wool,

- polyurethane foam,

- penoplex, which are completed with finishing.

When choosing a heat-insulating material, pay attention to the size of the plates and thermal conductivity, not higher than 0.3 W / m2K.

Internal wall insulation is carried out by attaching rigid insulating panels to the wall or by constructing a frame structure, the cells of which will be filled with insulating material.

When choosing a heat-insulating material for internal installation, you need to be careful , since it has special requirements for sanitary and fire safety, since it will be directly placed in a residential area.

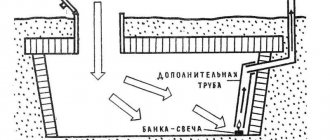

An even rarer option for thermal protection of an object is double-sided, when the insulation is installed simultaneously on both sides. Typically, this scheme is used for temporary structures: cabins, verandas and any outbuildings with thin, cold walls.

The technology of double-sided fastening of a heat insulator assumes that a frame made of edged boards is installed on both sides of the walls. Insulation is laid between its cells, which is fixed and sheathed with building materials: clapboard or blockhouse.

The structure must have ventilation openings for efficient use of heat in the building and air exchange of the air gap near the walls, to prevent the formation of humidity.

Rating of insulation materials for brick walls

User ratings are compiled by large online trading platforms based on customer requests. The highest ratings are given to insulation materials with a low price, easy installation and high thermal characteristics. Rating of insulation for brick walls:

- Foam plastic has a fairly low price, easy installation, a good degree of protection and durability. The imperfections of the material undoubtedly include its flammability and the ability to release poisons when burning. Therefore, it is not recommended to install it indoors. In addition, it is damaged by rodents.

- Extruded polystyrene foam (EPS) is a modern insulation material that does not have many of the disadvantages of foam plastic. It began to be produced with higher density, lower thermal conductivity, low flammability, increased strength and low water absorption, which allows it to be used without auxiliary vapor and waterproof layers.

The disadvantages include the high price and almost zero vapor permeability, so in a house with EPS there must be good ventilation, since walls covered with EPS practically do not “breathe”.

Mineral wool is made with different densities, with higher densities the price is also high. The material has excellent vapor and air permeability, as well as additional noise absorption and a low heat transfer coefficient. The material does not burn, smolders with gradual self-extinguishing, it does not emit toxic substances or smoke.

Not afraid of rodents. The big disadvantage of mineral wool is its hygroscopicity, so it must be installed with layers of steam and water protection in the form of films and membranes.

- Glass wool is similar to mineral wool, except that it has higher elasticity, always returning to its original shape, and is resistant to vibration loads. Its disadvantage is considered to be an increased danger when performing work, in case of contact with the respiratory system, skin and eyes.

- Ecowool is a modern environmentally friendly insulation material; it does not shrink like mineral wool. The material not only does not support combustion, it extinguishes, thereby extinguishing the fire, which allows it to be used inside the house. The disadvantages include the high cost of this insulation.

- Liquid-ceramic thermal insulation is the thinnest insulation for walls. Outwardly similar to ordinary paint, it contains microvacuum spheres that create an insulating effect. Foam-polyvinyl chloride thermal protection consists of artificial resin, under the influence of electromagnetic vibrations and light it acquires a foam structure and is a universal heat insulator.

What types of insulation are available for the external and internal walls of a brick house, and how to choose the best one, can be found in this article.

Do-it-yourself materials and technology for insulating a brick wall from the inside

Insulating brick walls from the inside is not the best solution.

It will be much more reliable to insulate either on both sides or only on the outside. But if, due to circumstances, it is impossible to insulate the facade, then this article will be useful to those who are interested in the rules of insulation from the inside. How to insulate a brick wall from the inside in a private or apartment building, what materials are best to work with and what mistakes to avoid? This will be discussed below.

Insulated structure device

Thermal protection of brick houses is carried out according to a technological map developed after checking the house for heat loss. This will help find cold areas of the building and help correctly calculate the thermal insulation cake.

Outside

Home owners who care about the fire resistance of their home, especially those with stove heating, most often choose mineral wool, which has high heat and fire retardant properties.

When choosing the insulation thickness, climatic indicators are taken into account; on average, a mineral wool layer of 150 mm is taken. For brick houses, the preferred material is with a density of at least 35 kg/m3, otherwise, loose mineral wool will settle and can create cold bridges.

Option for external insulation with mineral wool:

Insulation of a brick house: 4 suitable materials

By insulating a brick building, you change the appearance of your home. Such a brick building, like a house, has the ability to retain heat, but without insulating the roof walls and so on, there is no way to save on heating. And if you are the owner of your own home, then you are faced with the task of making your home a cozy environment and giving it comfort. This applies to houses built of brick. It is very difficult to choose a material for insulation, since there is a huge range of insulation materials on the market. We will figure out how to insulate a house, what material to use, and how to achieve minimal heat losses.

How to prepare an estimate correctly?

The basis for the production of a brick house insulation system is an estimate. This is an extremely significant document that reflects the list of operations performed by the contractor, their volume and the construction materials required for implementation.

In order to easily resolve disagreements between the contractor and the customer in the future, they must enter into an agreement between themselves for the performance of work, in which the estimate is a confirmation of financial obligations .

The estimate determines the budget for the work and helps determine the most optimal options and type of insulation. It draws up a detailed plan of actions that need to be carried out during construction and installation work. Therefore, a competent and responsible approach to the matter of drawing up estimates is considered a guarantee of success and achievement of a positive result when performing thermal protection of a brick house.

An estimate is precisely the document that obliges the contractor to perform certain operations in the required volume and at established prices, and gives the customer the opportunity to control the progress of the insulation installation.

The final cost of the work depends on many factors and may deviate up or down, taking into account the modernization plan and the wishes of the customer, by introducing or excluding some stages. The price for installing thermal protection for a brick building is directly related to the chosen installation option, modification of basic materials and the volume of transport services.

When developing an estimate, the specialist must be guided by the FER-20011/GESN-2001 standards in force at the time of construction.

Main characteristics of materials for thermal insulation

A very important task when insulating a brick house is choosing a reliable and durable material for treating the outer part of the walls.

It must have certain characteristics that must withstand precipitation, high humidity, wind and frost, as well as heat. Therefore, it is important to consider the following characteristics when choosing:

Water absorption. It is better to give preference to materials with a low water absorption coefficient. Thermal conductivity. This is the main criterion when choosing insulation. The amount of heated air in the house that is lost in one hour per square meter of material with a thickness of one meter depends on it. It is this indicator that you should rely on when choosing the thickness of the insulation layer. The most suitable materials for this would be polystyrene foam and mineral wool. Flammability. This characteristic determines the danger of the material in case of fire. Thus, products can be divided into 4 classes according to this characteristic, and it is better to give preference to G1, which can go out without an open flame

For example, polystyrene foam boards have a high ignition rate, and if they are used for cladding a house, you should choose the C marking, which means self-extinguishing. Pay attention to the density, which determines the amount of additional weight on the structure. The lower the indicator, the lighter the material will be. Sound insulation level

Allows you to reduce noise penetrating into the building. Almost all materials for thermal insulation have this characteristic. Environmental friendliness. For exterior wall decoration, this criterion is not particularly important, since it determines the level of health safety of the material. However, it is still better to use natural rather than synthetic materials. Difficult to install. In the case of finishing it yourself, without the help of specialists, it is better to give preference to a simple and understandable technology for laying heat-insulating material.

Thus, the choice of material is a decisive factor, depending on which the final result will depend, as well as the service life.