The cheapness of foam concrete makes it increasingly popular among Russians who have decided to build a bathhouse on their site.

At the same time, some have already built, while others are only thinking about what is better to invest in, what to build a bathhouse from, and are leaning towards a block one.

The latter really should think carefully and weigh everything, because this material for construction is quite controversial . Some express delight, others criticize. We suggest weighing the pros and cons. And you can get food for thought from our article.

The feasibility of using foam blocks

Baths made from this material are actually usually very inexpensive. In addition, foam blocks have almost all the same advantages as wood: they allow air to pass through (“breathe”), are very easy to cut, and are not too heavy. Their advantage, compared to timber and logs, is that they do not burn at all and do not rot. The disadvantages of walls made of this material include the fact that it is capable of absorbing moisture, while gradually collapsing. Therefore, projects for bathhouses made of foam blocks must be developed taking into account the characteristics of this material, in particular its hygroscopicity.

According to SNiP standards, it is prohibited to build baths from foamed cement. However, these rules were invented quite a long time ago. Since then, a huge number of new, modern materials with truly unique properties have appeared on the market. Foam concrete also belongs to them. In addition, SNiP standards were developed mainly in relation to public baths. Of course, in this case the rules must be very strict. A small country bathhouse made of foam blocks can become a very convenient and quite durable structure. But of course, only if all rules and construction technologies are observed.

Advantages of twin blocks

- Thermal insulation. Twin block structures are up to five times warmer than their concrete counterparts.

- Durability and strength. Twin blocks belong to class B3.5.

- Noise insulation. The material copes best with low frequency sounds.

- Verified block sizes.

- Reduced load on building foundations (up to 5 times).

Conventional woodworking tools are suitable for working with twin blocks. They can be drilled, grooved, or sawed using standard power tools.

Advantages of a foam block bath

In addition to being cheap and having a rather pleasant microclimate, the advantages of such structures include environmental safety. When heated, foam blocks do not emit any harmful substances. In addition, they retain heat very well, meaning you will have to heat the bathhouse no more than once on a wash day. Since the foam block is not flammable, you do not have to comply with any special standards when installing the heater.

And of course, the undoubted advantage of this material is its ease of installation. Assembling a bathhouse from a log or timber is a rather labor-intensive task and at the same time technologically complex. Not everyone has experience in constructing such structures in our time. Probably any owner of a suburban area can lay out block walls.

Bathhouse designs made from foam blocks can be anything, that is, the owners of the site have the opportunity to choose the layout of this structure at their discretion. The material is easy to cut even with a regular hacksaw.

Disadvantages of foam block baths

The disadvantages of a bathhouse made of foam blocks are, first of all, dampness and destruction of the walls; in particular, saturating the blocks with water is dangerous in the winter. In a heated bath, vapors easily penetrate into the porous material. After the steam room cools, the water freezes and, expanding, simply breaks the concrete. Therefore, when building a bathhouse from foam blocks, special measures should be taken to waterproof the walls. In addition, the building will also have to be insulated. In this case, the walls will take longer to cool, and therefore, even if water gets into the material, it may have time to dry before freezing. In addition, much less condensation collects on insulated walls.

Experienced owners of suburban areas also recommend installing ventilation in such bathhouses. This will prevent stagnation of damp air, therefore extending the life of the walls.

Of course, all these tricks: waterproofing, insulation, ventilation - will cost the owner of the bathhouse a pretty penny. Therefore, structures for this purpose made of foam blocks are usually built only in steppe regions, that is, where it is difficult to obtain wood or it is very expensive. In forested areas of the country, it may be more advisable to build a wooden bathhouse. Most likely, it will not cost much more than paving stones.

Construction of a house from twin blocks

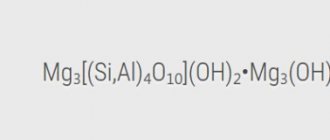

The materials for making the blocks themselves are lime, aluminum powder, water and cement.

Construction goes through the following stages:

- Preparation of the mixture. Laying twin blocks is usually carried out at temperatures from +5 to +25 degrees (if the temperature is higher, additional moistening of the material with water is necessary, and if lower, glue with special anti-frost components is used). It is necessary to ensure waterproofing of the foundation and masonry. It can be used as bitumen or special waterproofing solutions. Mixing the solution is best done mechanically. To ensure the mixture is homogeneous, stir it constantly.

- Surface preparation. It is not a fact that your foundation surface will be perfectly flat. If this is not the case, then you need to apply a leveling layer of cement and sand mortar. After this, you can begin laying the first row.

- Preparation of twin blocks. The blocks are marked along the axis of the wall of the position of the receptions at the junctions of the external and internal walls. To prepare the blocks you will need a square and a hacksaw.

- Laying. The first row of twin blocks needs to be given special attention. The surface must be perfectly flat, otherwise all subsequent rows will also be laid at an angle. After checking the level for evenness, the solution is laid, and the first row of twin blocks is placed on it. If you have a difference in height, it doesn’t matter, it can be easily leveled using the same solution. The block must be installed on the solution no later than 15 minutes after its application. Upon completion of laying the first row, use a plane to remove all unevenness and roughness.

In what cases is additional reinforcement of twin block masonry necessary:

- Increased load on walls or parts thereof.

- Elongated walls that must cope with high lateral pressure.

- The first row of blocks must be reinforced.

- The supporting surfaces of the lintels and the bottom seams of window openings are also reinforced.

The material of grade A-III has proven itself best as reinforcement. To lay the reinforcement in a block, you need to cut grooves in it and fill these grooves with glue before laying the rods. Next, the reinforcement bars are pressed into the grooves.

The video shows the features of building a house and laying walls from twin blocks with your own hands:

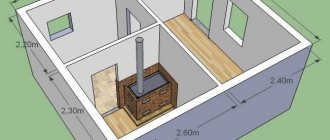

Bathhouse made of foam blocks: price

The cost of such a structure will depend, of course, primarily on the layout and size. A wall foam block 60x30x20 costs about 2,500 rubles per cubic meter. A small bathhouse measuring 3x4 meters with one partition and a ceiling height of 2 m will require a little more than 6 m3. That is, the construction of the actual walls will cost about 16-20 thousand rubles. This will require about 5 m3 of mineral wool. It will cost about another 8 thousand rubles. About 2000 rubles will be spent on the glue solution. Thus, the walls of a small bathhouse made of foam blocks, at a rough estimate, will cost about 30 thousand rubles. Of course, to this amount you will need to add the cost of the foundation, lumber for the floor, ceiling and roof, waterproofing and lining.

A large 6x4 bathhouse made of foam block will, of course, cost more. It has recently become very fashionable to build attics on such structures. This is, of course, very convenient and allows you to save space on the site, but of course, it will additionally increase the cost of the structure. The walls and partitions of a standard 6x4 m bathhouse will require about 11 m3 of blocks.

Construction of foundation and walls

Building a bathhouse from foam blocks is a simple procedure. Such a structure is erected in approximately the same way as a brick one. The difference is that the seams in the masonry of foam blocks are very thin, and special glue is used as a solution to hold the blocks together. When building even a small bathhouse from this material, it is advisable to reinforce the walls. To do this, in every fourth row, metal rods are placed in gutters cut out with a grinder. An armored belt must also be placed on top of the masonry.

It is recommended to make the foundation for a bathhouse made of foam blocks strip and quite powerful. All foam materials are fragile. And therefore, even with small movements of the soil, walls made of them can crack. For the same reason, blocks should be laid as evenly as possible, using piers, plumb lines and a level.

Bathhouse floors made of foam block

To prevent the walls from being saturated with water from below from the ground, it is worth installing special floors in such a structure. They need to be made concrete and slightly inclined towards the center. In this case, a receiving tray and a plastic drain are installed in the middle of the bath. The pipes should be laid underground below the freezing level and extended to the septic tank.

In order to extend the service life of concrete floors, they should be covered with tiled rough tiles. The base itself should be treated with penetrating waterproofing before laying it. In the future, special wooden gratings are usually installed on top of the tiles. After taking water procedures, they can be taken outside and dried.

Foundation waterproofing

This operation must be performed. In this case, you will get a durable bathhouse made of foam blocks. Reviews from owners about such buildings are not bad, but only if they are waterproofed according to all the rules. For the foundation of a bathhouse, both vertical and horizontal waterproofing are usually used. When installing the tape at the bottom of the pit, be sure to pour a sufficiently thick layer of sand. After the foundation concrete has gained sufficient strength, its top is glued with two layers of roofing material.

The walls of the base of the bathhouse must be protected from moisture both outside and inside. In this case, you can also use roofing felt. Penetrating agents are also considered a very good solution for waterproofing the foundation of a bathhouse. Sometimes the base walls are coated with bitumen mastic in two layers.

The use of twin blocks in construction and the features of their masonry

A very big advantage of this building material is its lightness. One block of material weighs about 23 kilograms (which is much lighter than similar-sized blocks made of brick, reinforced concrete or ordinary concrete), but it is very durable and strong, and also has excellent thermal insulation. The twin block structure is filled with air bubbles, making it lightweight. Twin blocks have low shrinkage - this gives them additional durability and layer integrity.

First of all, the waterproofing layer is laid. The laying of twin blocks itself must begin from the corner. A solution approximately one centimeter thick is applied to the waterproofing and corner blocks are installed. After the corners of the load-bearing walls are completely completed, the first row of twin blocks is laid.

Laying the first row is very important, because the evenness of the entire structure will depend on its quality.

After laying the first two rows of twin blocks, it is necessary to wait until they dry completely. It is important that the first rows rest exclusively on cement, while subsequent rows can be mounted on glue, the consumption of which will be minimal if the parameters of its use are correctly observed.

If we take the totality of such characteristics as appearance, practicality, environmental friendliness, labor intensity of operations and the price of material, then we can safely call twin blocks the leaders of the construction market. Low cost combined with excellent characteristics, reliability and durability make twin blocks indispensable in the construction of building structures.

People's reviews of buildings made from twin blocks, such as bathhouses or houses, are also positive, since the material is quite easy to use and is widely available for sale.

How to place twin blocks correctly is shown in the video:

Waterproofing walls

To protect the enclosing structures of the bathhouse from moisture, it is best to use foil vapor barriers. You can take special isospan or penofol. Today on the market there are foil materials designed specifically for baths. The waterproofing is secured to the wall with beams. The joints should be additionally nailed and taped on top with metallized tape. The lining is subsequently attached to the beams.

The ceiling of the bathhouse is usually made of boards. You can protect it from moisture by using impregnating waterproofing designed specifically for wood. A bathhouse with a foam block attic is very comfortable. However, when choosing just such a project, you should keep in mind that in this case, most likely, the roof will also have to be waterproofed from the inside. In the attics of baths, the microclimate is usually quite humid.

Roof construction

If the owner wants to make an attic space on the bathhouse, then they install a gable roof. This design is more popular than the single-slope one. This option provides for a sharper roof angle , which will prevent snowdrifts from forming on it.

Installation of rafter roofs is carried out as follows:

- Attaching the Mauerlat to the bathhouse wall.

- Creation of a roof truss.

- Installation of two roof trusses at different ends of the roof. To ensure that they are well fixed, the structures are strengthened with special struts.

- At the level of the ridge, a rope is pulled between the outer rafters, with the help of which the exact location of installation of the remaining trusses is indicated.

When installing a pitched roof, its angle of inclination becomes more gentle, which is why a snowdrift begins to form on it. The weight of snow can cause the roof to collapse .

The frame is attached to the Mauerlat using metal corners and copper wire. The rafters are carried outside the bathhouse box at a distance of up to half a meter. This is to protect the external walls from bad weather.

It is mandatory to make two holes in the ceiling for ventilation. From the outside, the roof is covered with corrugated sheeting, and the pediment is covered with roofing felt.

Bath insulation

Next, let's look at how to insulate a bathhouse made of foam blocks. A structure made of this material can be insulated from the cold using both expanded polystyrene and mineral wool. The latter material is considered more preferable. The fact is that polystyrene foam does not allow air to pass through very well. When using it, the walls of the bathhouse will not “breathe”. Insulation should be carried out exclusively from the outside. The fact is that when sheathing from the inside, the so-called dew point moves inside the walls, and they begin to become damp.

How is a bathhouse made of foam blocks insulated? Reviews from owners about such structures are only good if this operation is carried out correctly. Foam block wall insulation technology usually includes the following steps:

- The walls are covered with timber lathing.

- Insulation is installed between its elements. Cotton wool can be installed simply by surprise. Expanded polystyrene should be additionally secured with mushroom dowels.

- The frame with insulation is covered with waterproofing material.

- External cladding is being installed. It can be a lining, a block house, etc. Foam block baths covered with façade vinyl siding that imitates stone look very nice.

You can also cover the walls of the bathhouse with very dense mineral wool with additional fastenings - “fungi”, and then finish it using decorative plaster.

Finishing the bath inside and outside

It must be remembered that when laying communication networks inside a bathhouse, such work is much easier to carry out than in wooden buildings. Aerated concrete can be easily chipped. The flooring in the bathhouse can be made of tiles or wood.

The quality of the construction of the finishing of the bathhouse made of aerated concrete inside and outside determines what performance qualities the building as a whole will have. Before choosing the type of finishing, the surface of the ceiling and walls should be coated with special compounds to increase the waterproofing properties of the materials. For the same purpose, foil film is often used.

Often the walls of aerated concrete baths are covered with liquid glass. This allows you to make them significantly warmer. Lining can also be used for finishing. This material is made from alder or larch.

The appearance of a bathhouse made of gas blocks is not very attractive. In addition, it must be properly protected from external influences. The outside walls of the building are covered with brickwork or a layer of special primer, which has hydrophobic properties.

The façade of a ventilated bathhouse or wooden lining can be chosen.

How to arrange ventilation in a bathhouse

Thus, you now know how to build a bathhouse from foam blocks, as well as insulate and waterproof it. Next, let's figure out how to make ventilation in this structure. The foam block bathhouse must be ventilated. Ventilation in the bathhouse is arranged as follows:

- In the immediate vicinity of the stove, at a height of no more than 30 cm from the floor, a supply hole is made in the wall. Sometimes it is also done in the foundation of a bathhouse. In the latter case, a hole (with a valve) should be made in the floor.

- An exhaust hole is hollowed out in the opposite wall at the top. A valve is installed on it. If the opposite wall does not face the street, the exhaust hole should be made in the same wall as the supply hole, but on top and in the opposite corner. In the latter case, an exhaust fan should be used to ensure good air flow.

Twinblock calculator

To calculate the required amount of material, you must first calculate the perimeter of the building, which will be equal to the sum of its double length and double width. To calculate the area of the walls, the calculated perimeter must be multiplied by the height.

The most important operation in calculating twin blocks is determining the wall thickness. To match it with the area of the building, it is necessary to convert all obtained values into meters. The amount of material is calculated as the area of the building walls divided by the thickness of the twin block (in meters). In addition, you can use online calculators that allow you to calculate the required number of twin blocks, for example, for building a house.

Ready-made projects of houses built from twin blocks

house number 1

house number 2

house number 3

house number 4

Bathhouse made of foam blocks: reviews from owners

The owners of suburban areas have a very good opinion about buildings of this type. The owners of bathhouses made of foam blocks note, first of all, that they retain heat very well. In addition, such buildings do not require any special care: treatment with anti-rot compounds, caulking, etc.

Of course, foam block baths have earned good reviews due to their low cost. Almost anyone can build such a structure on their site. If you line the inside of a foam block bathhouse with linden clapboard, it will smell like a real wooden one. The same applies to the benefits of taking water procedures. In addition, in a bathhouse made of foam blocks, judging by the reviews of the owners, the smell of dampness never appears. The outside of such a bathhouse can be covered with a block house, and then it will look quite traditional.

As you can see, if all the required technologies are strictly followed, a very good bathhouse can be built from foam blocks. Reviews from owners about such structures are mostly good. But only if ventilation is provided in the bathhouse, and its walls are well insulated and waterproofed.