When completing the construction of a house, you should think about vapor barrier. It is this that protects the rafters and other wooden structural elements in the attic from the formation of condensation, which causes the wood to deteriorate. In addition, moisture is an ideal environment for the growth of fungus and mold. Based on this, it becomes clear that the use of vapor barrier when insulating the ceiling is an extreme necessity. If you do this kind of work without involving specialists, the costs will be minimal.

The lifespan of a house without major repairs is influenced by factors such as weather conditions, quality of building materials, steam and water. Vapor barrier materials save from premature aging and destruction of wooden structures. They can also serve as insulation. However, such an energy-saving layer still requires additional thermal insulation materials.

High-quality installation of vapor barrier on the floor and ceiling requires very little attention and step-by-step implementation of all operations. Following the instructions, which the Internet is simply full of, an amateur can cope with such work no worse than a qualified roofer. The only difference is that an inexperienced home owner will spend much more time on this, and this is understandable, because he will try to do everything reliably and efficiently.

With proper calculation and the right choice of material, in just half an hour, laying a vapor barrier on the ceiling will become commonplace. It will seem like you've been doing this your whole life. It's no more difficult than laying a carpet on the floor. Only in the first case does the material need to be overlapped and secured to the ceiling. In addition to the fact that such insulation greatly prolongs the performance of wooden structures, it also helps to save a significant portion of funds on heating.

Why do you need a ceiling vapor barrier?

In modern homes there is much more moisture in a vapor state than, for example, half a century ago. Its sources are the bathroom, kitchen, indoor plants, etc.

Part of the moist air escapes through the ventilation ducts (if the natural one cannot cope, you need to install forced ventilation). But even with optimal air exchange conditions in an apartment or house there will be higher humidity than outside (with the exception of a few days when the humidity outside is about 90%). But even in this situation, due to the higher partial pressure indoors (it’s simply warmer inside an apartment or house), steam molecules will break through the structural elements of the building (floor, walls, ceiling) to the outside.

As a result, the uninsulated ceiling under a cold roof will freeze. After thermal insulation, a second problem arises: the dew point shifts into the insulation, creating a new headache (what the “dew point” is and the processes occurring inside the insulation layer are described in the article “Rules for the selection and technology of installing vapor barriers for the roof”).

Attention: for those who do not want to look at the link, let us clarify a little: vapor barrier is not needed when insulating the ceiling between the floors of a residential building and between the living and attic premises - there is no critical temperature difference that causes the formation of condensation.

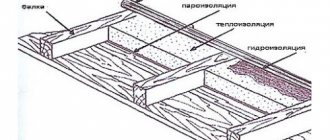

Scheme of vapor barrier from inside the room.

A vapor barrier film helps prevent the accumulation of moisture in the insulation - it puts a barrier in the path of steam molecules. It allows:

- extend the life of the ceiling, especially wood;

- eliminate the problem of accumulation of vaporous moisture in the insulation, preventing the formation of condensation in the winter;

- keep the insulation dry - any material in a dry state holds heat better.

Use for walls on the room side

Most often, this vapor barrier is used to insulate vertical walls and enclosing structures from the inside. Next, we will discuss in detail how “Izospan V” is installed in this case. Instructions for use for walls are as follows:

- First, a beam is attached to the surface, the width of which is equal (or slightly greater) to the thickness of the insulation. When used for finishing drywall sheathing, a metal profile can be used.

- Next, slabs of mineral wool or expanded polystyrene are installed.

- On top of them - on bars, slats or staplers - the vapor barrier "Izospan V" is fixed.

- Next, the finishing is installed.

Types of vapor barrier films

Vapor barrier materials differ in the material from which they are made, the principle of operation and the level of vapor permeability, which must be kept in mind when choosing a vapor barrier for the ceiling.

Type of material

For the ceiling, you can use roll and coating (painting) vapor barrier.

Rolled vapor barrier materials. Various types of vapor barrier films are classified as roll insulators. They can be in the form:

- films - do not allow steam to pass in both directions. This is a silent, although sometimes relative, vapor barrier. The vapor barrier film for the ceiling can be one-, two-, or three-layer, with or without reinforcing mesh;

- diffusion membranes that allow vapor to pass through from the side of higher partial pressure. Construction specialists and manufacturers sometimes say that these are membranes with one-way flow, which is fundamentally wrong. If you look at the material in cross-section (the diagram is shown below), you can see that vapor molecules can move in any direction. They cannot get to the insulation due to the higher vapor pressure in it. Therefore, the membrane can be laid on the ceiling on either side;

- foil films - used as reflective vapor barriers. Produced for baths, steam rooms and saunas. They are not used for residential premises - acquisition costs are disproportionate to the functions performed. Simply put, simple, cheap plastic wrap will work just as well.

Coating vapor barrier. Coating vapor barrier materials are represented by various types of mastics on a bitumen-polymer base. They can only be used outside and on concrete floors.

For a ceiling that is also a flat roof, in addition to mastic, liquid rubber is sometimes used.

Principle of operation

Vapor barrier film for ceilings can be of several types: A, B, C, D, F.

- A (some manufacturers mark it with the letters AM) - creates an insurmountable barrier to water molecules and allows steam to pass in both directions. Used to remove steam from the insulating layer;

- B is a typical representative of vapor barrier materials: does not allow steam to pass in both directions;

- C is a type of film B, only reinforced;

- D - laminated polypropylene;

- F - foil film.

Vapor tightness

Based on the level of vapor permeability, films are divided into classes:

- Class I - foil and foil films;

- Class II - vapor barriers made of propylene;

- Class III - soft material with a high coefficient of vapor permeability.

Sometimes, instead of a class, marking with the letters “SD” with a digital value of vapor permeability is used. For example, SD 50 means that in an hour, steam equal to 1 molecule of water will break through 50 m2 of film. For the ceiling, this indicator should be at the SD level of 30-40.

Advice from professionals

Laying a vapor barrier cannot be called an extremely complicated process, but to get the job done efficiently, read a number of recommendations from experts:

- before installing the vapor barrier, remove dirt and dust from all surfaces, seal all cracks with sealant;

- lay the film without stretching it unnecessarily; it should lie slightly sagging;

- if the canvas is secured with a stapler, then it is better to place cardboard or other dense material under the staples;

- Solid material should be laid in the corners to cover the corner;

- to completely eliminate cracks, as well as increase the level of sealing, lay the canvas, gripping the walls;

- take care of the material, do not pierce it with nails;

- create a ventilation gap between the film and the ceiling finish;

- Do not lay the vapor barrier close to the insulation.

Be careful: after the vapor barrier material has been laid, check whether the joints and installations of junction boxes, electrical cables and pipelines are airtight.

It also happens that the ceiling has already been hemmed, but they forgot to put in a vapor barrier, or did not know about it at all. Of course, there is no need to panic. But you need to find out what kind of material was used for the hemming. If it's drywall, you're in luck - it absorbs moisture quite well.

If chipboard was used, there is also no reason to worry. This is a dense material where glue is used as a connecting element. In principle, regular paint is also good protection.

You can see how to avoid mistakes when laying vapor barriers in the following video.

Tags: pour, fasten, ceiling, correctly

« Previous entry

Criteria for choosing a vapor barrier for a ceiling

Before going to a construction market or hypermarket to buy building materials, the buyer always mentally determines the criteria by which he is going to choose the product he needs. With regard to vapor barrier films, the following requirements are reduced to:

- to the principle of film operation. Sometimes everything comes down to the coefficient of vapor permeability, which in principle one can agree with, although this formulation of the question is not entirely correct;

- type of material;

- strength;

- durability;

- resistance against low temperatures;

- installation features;

- cost 1 m2.

In addition, an important criterion is the film manufacturer.

Operating principle. For the ceiling you need 2 types of films:

- a one-way diffusion membrane that freely allows vapor molecules to pass through and retains water molecules. It is laid on insulation only if a vapor barrier is installed on the ceiling when the attic is cold from the outside. This means that when insulating the ceiling below and in the attic, it should not be there at all (if desired, you can install it in the attic, but this is money thrown away). Indicated on the packaging by the letter “A” or “AM”;

- classic vapor barrier film (type B or C), creating a barrier to the movement of steam in both directions.

Attention: when choosing a vapor barrier for a bath, you should buy foil film (type F) or clean foil.

Type of material. Vapor barrier for the ceiling in a wooden house should only be of the roll type. For concrete floors when insulated from below - film, from above - film or mastic. Their effectiveness is approximately the same. Here you need to look at other factors, for example, price.

Strength. For a ceiling, the strength indicator is not as important as for vapor barrier of walls or roof. It is only needed during transportation and installation. After all, cheap film materials can easily be damaged during the installation process by accidentally touching them with a tool, as a result of which the integrity of the vapor barrier sheet is lost. In addition, you need to take into account this point: durable film tolerates sudden temperature fluctuations.

For suspended ceilings you can buy films marked type B, for plasterboard sheathing and vapor barrier of external insulation - type C is better suited.

Durability. The service life of the vapor barrier should match the service life of the insulation or be longer. Information of this kind is difficult to find - only on the official websites of manufacturers, and even then not always. In this case, you need to focus on the warranty period - the higher it is, the longer the film will last. In addition, you can look at consumer reviews on various forums.

Resistance to critical temperatures. Temperature parameters are important only for the diffusion membrane (type A or AM) - they must be in the range from -70oC to +90oC. When purchasing other types of film, you can ignore this criterion.

Installation features. Recently, manufacturers have begun to indicate in the instructions the types of fastening the film to the ceiling: nails with a large head, staples, glue, lath, double-sided tape. Therefore, when buying a film, you must immediately take the appropriate fasteners.

Price. For the average Russian, price is of no small importance. We need to strive for the best ratio of cost and quality. But there are pitfalls here: the price is indicated per package, and different manufacturers have different film areas. Therefore, the cost of 1 m2 will be more objective. It is not difficult to perform such calculations on your own. The area is indicated on the packaging, the cost is in the price tag.

"Izospan V": instructions for use when insulating roofs

When assembling the “pie” of roofs, the material is attached in approximately the same way as in the first case. However, in this case, the vapor barrier itself is first fixed. It is fixed from the attic side with staplers or by installing internal horizontal sheathing under the final finishing from a narrow board in increments of 50-80 cm.

Next, slabs of mineral wool or expanded polystyrene are laid between the rafters on the vapor barrier. Thanks to the sheathing, they will not fall inside, into the attic. Sometimes instead of the latter, ordinary wire is used. It is pulled from the attic side in such a way that the insulation slabs are subsequently firmly held between the rafters.

After installing the mineral wool, a waterproofing material (with a slight sag) is attached to the rafters. It is fixed with bars, onto which a transverse sheathing is subsequently placed. The selected roofing material, in turn, is attached to it.

Manufacturers

There is a huge selection of films from different manufacturers on sale. At the same time, high-quality vapor barriers can be found not only in time-tested brands. This means that when choosing a little-known supplier, there is a risk of receiving material that is not of the same quality as planned.

No, not a marriage, but a combination of characteristics. The conclusion is simple: either you need to have a recommendation from acquaintances, friends or professional builders regarding an unpromoted brand, or you still need to buy a product from a well-known company.

Promoted brands include:

"Izospan" - produces polypropylene films of all types (A, B, C, D, F). Products:

- elastic;

- UV resistant;

- with a wide range of operating temperatures;

- environmentally friendly.

You can buy "Izospan" DM for 44 rubles/m2, "Izospan" C - 25 rubles/m2, "Izospan" FB - 35 rubles/m2.

"URSA SECO" (). Under the URSA SECO brand, membranes of type A and AM, films B and D are produced. These are high quality products designed to protect various structural elements of a building from steam. Effectively performs its assigned functions throughout the entire service life of the insulation.

Membranes can be purchased from 110 rubles/m2, films in the range of 11-19 rubles/m2 (depending on the density of the material).

"TechnoNIKOL". For the ceiling, a universal film is used, consisting of 3 layers, the top and bottom of which are polypropylene. Price 1 m2 - about 20 rubles.

"Axton" is a trademark of the French company Leroy Merlin. Membranes (type A) and films of types B, C and D are produced. For the ceiling you need to buy membranes (price starts from 21 rubles/m2) and film type B for 15-17 rubles/m2.

In addition, the following companies should be noted:

- "Ecolife";

- Tyvek;

- "Utah";

- "Ondytis".

Sometimes they talk about such criteria as resistance to ultraviolet radiation and the possibility of leaks under the weight of rainwater. Such characteristics have nothing to do with the ceiling.

Installation

The vapor barrier must be done from the inside of the room along with the installation of insulation.

If in the region where the building is located, the winter air temperature is lower than -30, then it is easier to install a vapor barrier layer both above and below. This is a kind of protection of floors from steam and at the same time a way to retain heat.

Now let’s take a closer look at the installation process itself.

The folk way

In ancient times, the peoples of the north, who inhabited the territory of Finland, used a “breathing” membrane - birch bark - to protect the ceiling in the bathhouse.

Nowadays, first of all, it is better to lay the vapor barrier material simultaneously with the thermal insulation material in the sheathing. Therefore, it must be installed first. Then the ceiling frame is secured using self-tapping screws and plastic dowels. After installing the sheathing, a thermal insulation layer is created, after which the ceiling is directly vapor barriered. Please note that each wooden element must be treated with an antiseptic solution and fire retardant.

The installation procedure includes several stages:

- The vapor barrier material should not be nailed, but attached with staples to the outermost element of the sheathing. Be sure to make an allowance for the walls within 15 - 20 cm.

- It is better to unfold the film to the opposite side and cut it with the same allowance.

- The material should be fastened not only around the perimeter, but also on the intermediate slats. One strip is not enough to completely cover the ceiling, so the film must be laid overlapping in strips of 15 - 20 cm. It is recommended to fasten the edges with tape or special tape.

- To ensure a normal level of ventilation, when you install a vapor barrier, leave a gap between it and the ceiling.

The last point can easily be considered one of the most important rules for installing high-quality vapor barriers. For the same purpose, a counter-lattice needs to be installed throughout the frame. It is almost identical to the configuration of the first layer. The thickness of the slats is about 40 cm. Fastening is carried out using self-tapping screws.

It is worth considering in more detail the vapor barrier for baths and saunas. In these rooms, the humidity is always high, and the air is solid steam. If the walls of the steam room are not protected, then sooner or later they will be subject to fungal diseases or rot.

To attach the vapor barrier you will need the following set of tools:

- the material itself (taking into account its capabilities and needs);

- stapler/stapler (for nailing staples);

- hacksaw;

- scissors for cutting metal;

- scotch;

- self-tapping screws;

- screwdriver;

- nails with a wide head;

- hammer.

We invite you to familiarize yourself with: Clay for the stove in the bathhouse

We have indicated the tools that will be useful during different installation methods. And your task is to choose what is needed for a particular situation.

The film is laid from bottom to top with the strips overlapping each other by 10-15 cm. The joints of the strips are glued with tapes such as Izospan KL, KL. Izospan B is always mounted with the smooth side facing the insulation. The places of contact between the sheets and laths of the sheathing, and the counter laths of the air gap are sealed with a special sealing tape. The tape is pressed with the self-adhesive side simultaneously against Izospan B and the abutment surfaces.

Areas connecting to windows, niches and openings for utilities (ventilation, sewerage, water supply) are sealed with Izospan ML proff tape material. The same tape is used to finish joints with concrete and wooden structural elements.

Installation of Izospan B has features depending on which element of the structure needs to be protected.

The installation diagram is shown in Figure 1.

First you need to unroll the roll and cut the ribbons to size. To determine which size of panels is most convenient and economical for installation, it is necessary to measure and mark the walls and ceilings. Then you need to apply the first tape to the internal insulation of the attic or attic (from the ceiling side) with the smooth side and secure it.

The fastening method is chosen which is more convenient for the owner: it can be fastened with a construction stapler or on nails. The first tape in attics must be laid from below, parallel to the floor. For convenience, the tapes can be rolled into tubes with the desired side inward and unfolded as they are secured.

Next, you need to secure the next tapes in the same way, overlapping the previous one with an overlap of about 15 cm. Seal the joints with a special tape such as Izospan KL, KL and mount the lathing for cladding or finishing material on the coating. For ventilation and evaporation of possible condensation, the gap between Izospan B and the cladding should be 50 mm.

Installation proceeds as follows:

- Unroll the roll and cut the ribbons to size;

- secure the first tape with the rough side to the rough ceiling (floor) using a stapler or nails;

- fasten the remaining tapes parallel to the first, with an overlap of 150 mm;

- seal the joints for sealing with the appropriate tape of the Izospan family;

- install the sheathing and lay insulation.

Next, you will need to lay another layer of Izospan B with the smooth side facing the insulation, secure it to the sheathing and seal the joints.

The diagram is presented in Figure 3.

Installation is carried out similarly to the option with interfloor ceilings, with the tapes being laid starting from the bottom, parallel to the floor, also with a smooth surface facing the insulation.

To protect the structures of frame partitions and walls inside buildings, instead of type B, you can use Izospan with the designations C, DM, RS. Installation of these materials is carried out according to the same rules.

Required materials and tools

To vapor-waterproof the ceiling you need to buy:

- vapor barrier membrane type A (AM) - needed to protect the heat-insulating layer laid on top of the ceiling in a ventilated roof;

- vapor barrier film type (B);

- vapor barrier mastic for treating concrete floors outside the room (instead of film);

- double-sided tape or adhesive tape;

- polyurethane (acrylic) glue;

- fasteners: staples, nails, strips;

- construction stapler, if the film is secured with staples;

- hammer;

- roulette;

- construction knife (scissors);

- scaffolding, trestles or a strong table.

Which side to attach the vapor barrier

Laying a vapor barrier on the ceiling causes trouble for more than one craftsman. Many of them do not know which side to attach the membrane and film. We answer: there is no difference. Absolutely, unlike the walls and roof. For pedantic owners who carry out construction and repairs with their own hands, following instructions from “A” to “Z”, we clarify:

- the membrane should always be laid with the smooth side facing the insulation, the rough side facing outwards towards the attic space;

- The film is laid with the light side facing the insulating layer, and the matte side facing the outside, into the room.

To avoid making mistakes when laying a diffusion membrane, there are several tips from experienced craftsmen:

- You need to look at the pictograms - they indicate the outside.

- The outer side of the windproof film is always with a pile, the back is smooth. Determined by the touch of the palm, tactilely.

- The manufacturer's logo is always located at the top.

- The lighter side is placed next to the insulating layer.

- The roll is rolled out on the inside.

For vapor barrier films, it makes no difference how they are laid. If there is still a small pile on it, it is better to lay it with the smooth side facing the insulation, but this is only when insulating the ceiling from below. The fleecy side on top is useless - it does not work as the technologists intended.

Features of the material

“Izospan B” is a translucent film with a two-layer structure. One side has a smooth surface, and the other has a rough surface. Due to the presence of texture, condensation is retained on the surface of the material without flowing down, and evaporates very quickly. Accordingly, moisture does not penetrate into the thickness of the “pie” that insulates the structure. As a result, the formation of fungus on the wood and its rotting, as well as rusting of the metal elements of the protected surface are prevented.