Constructing a roof over a log building is not an easy job, requiring the craftsman to have the skills of a skilled carpenter and knowledge of materials science. The performer will need to first practice making connections. He must take into account the traditional shrinkage of walls made of wood.

In order for a gable roof on a log house to be built flawlessly, you need information about the methods of its construction, including ancient roofing technologies. The information we offer will be useful to both independent craftsmen and customers of construction crews for meaningful control.

Selection of rafter system

The algorithm for fastening rafters is largely determined by the type of rafter system. In the vast majority of cases, the bathhouse is small in size. Such parameters, on the one hand, simplify and reduce the cost of the rafter system, and on the other hand, limit the choice of various options for its arrangement. Currently, the following types of roofs and rafter systems are most often used for baths.

Shed roof rafters

Table. Types of rafter systems for baths.

| Type of rafter system | Brief performance indicators |

| Gable | Such roofs are installed on bathhouses with a length of no more than 6 m; if the dimensions exceed these parameters, then the rafter legs have to be extended, and this has a negative impact on the strength and reliability of the system. The angle of inclination of the slopes is approximately 25°, it is possible to equip a fairly spacious attic space. The truss is assembled from two rafter legs. |

| Inclined single slope | The simplest rafter system, the length of the bathhouse does not exceed 4 m. One end of the rafter rests directly on the wall or mauerlat, and the other on a specially constructed frame. The slope angle is at least 12°. The disadvantage of a pitched roof is the minimum volume of attic space. |

There are quite a few ways to fasten rafters; each craftsman decides on the spot, taking into account the peculiarities of the structure, the wishes of the developers and the qualifications of the contractor. But the most important factor influencing the final decision is that the chosen method of fixing the rafter system should be as reliable as possible.

Roof with hanging rafters

Options for installing a rafter system for a gable roof of a bathhouse

Application of sliding joint

I still suggest cutting down, but not the rafters, but the top crown. Firstly, in this case, the risk of rafter bending is reduced, secondly, the “cold bridge” is reduced, thirdly, the tangential pressure on the mauerlat (top beam of the log house) is reduced, and fourthly, the insulation of the roof in the future is simplified.

The disadvantage of this method is that when cutting down the upper crown of the beam, the height of the ridge decreases, therefore, if in the future it is planned to raise the height of the ceiling, one more crown should be provided. But! Such schemes are only suitable for houses made of wood, since in brick and concrete buildings the mauerlat must be intact in order to maintain its load-bearing qualities.

Fixing rafter legs on a bathhouse made of foam blocks

The rafter legs in such baths are attached to a mauerlat mounted on a reinforcing belt. Accordingly, you need to start work by pouring the reinforcing belt and installing the Mauerlat.

- Install formwork on the walls along the entire perimeter of the room for pouring concrete. For formwork, you can use edged boards approximately 20 mm thick; the boards are fixed to the foam blocks with ordinary nails. The concrete force is insignificant; there should be no deformation of the formwork. Align the top edges of the formwork horizontally.

Important. Before pouring concrete, drill holes in the blocks and install pins in them to secure the Mauerlat. The distance between the studs is approximately 1.5–2 meters, make sure that the holes do not fall into the masonry joints.

Reinforcing belt

- Pull a thread between the outer pins under the level; with its help it is much easier to control the horizontalness of the upper plane of the solution.

- Pour the prepared cement-sand mortar or concrete into the formwork and constantly level it with a trowel. Use thread to control.

Practical advice. When checking the position of the solution, you do not need to lift the thread up; it will stick to the mass and show the incorrect position. The thread should be pulled to the side and released like a string. It is much easier to work not with a rope, but with a thick fishing line.

The thread needs to be pulled to the side

After the screed has completely hardened, install the Mauerlat on it and tighten it firmly with nuts. Do not forget to put waterproofing between the Mauerlat and the screed. It is better to use two layers of ordinary roofing felt, it is cheap and reliable. For the Mauerlat, a board with a thickness of at least 50 mm and a width of 200–250 mm is used. Next, you should begin installing the ceiling beams; it is to them that the lower legs of the rafters will be attached.

Mauerlat installed

Photo of the Mauerlat

Step 1: Install the first soffit board. Its length should be approximately 80 cm greater than the width of the room, 40 cm is required for the overhang on each side. This method of installing rafters is recommended for low baths. Due to the fact that the rafter system is supported by floor beams, the height of the bathhouse visually increases. If the overhang is made from rafter legs, then they fall significantly below the level of the mauerlat and visually reduce the height of the already small facade walls. In addition, attaching the rafter legs to the floor beams is much simpler; there is no need to make complex cuts on the heels. Preparing heels requires not only quite a lot of time, but also a lot of practical experience.

Floor beams

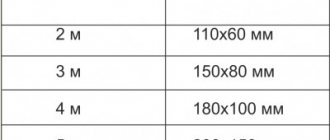

Step 2. Calculate the number and size of rafters. The distance between them should be approximately 60 cm; the following factors influence the specific value:

- sizes of lumber used;

- climatic zone of the bathhouse location;

- characteristics of roofing coverings;

- dimensions of the building;

- the presence or absence of additional struts of the rafter system.

Table of sizes and other rafter parameters

The length of the rafters depends on the angle of the roof, but practical builders use a simplified calculation method - they multiply the width of the bathhouse by 2/3. For example, if the roof width is 6 m, then the length of one rafter leg is 6 × 2/3 = 4 meters. This length provides a roof angle of 30°, which is quite sufficient for all climatic zones of our country, regardless of the maximum level of snow cover.

Calculator for calculating the length of rafter legs

Go to calculations

Step 3. Preparing rafter legs. This is much easier to do on a flat piece of land. Cut the boards to the required length and lay them next to the floor beam. Mark the cutting angle at the bottom and top. Make the blanks and check for accuracy. Everything is fine - use two legs as a template and cut off the rest.

Prepared rafter legs

Practical advice. If, according to calculations, the length of the rafter is 5–10 cm greater than 3 m, then it is recommended to reduce it to 3 m. The fact is that the standard length of lumber is 6 m; there is no need to obtain a large number of scraps of non-standard length due to a few centimeters.

Step 4. Install the outermost floor beams, measure the distance between them and calculate the pitch of the rafters. To check the correct position between the outer beams, pull the rope, and align everything else along it.

Step 5. Screw the floor beams to the mauerlat. It is better to fix them with metal squares and yellow screws; black ones are not recommended. They are made of hardened metal and quickly burst under load. As a result, the stability of the rafter system is compromised. In addition, black self-tapping screws become covered with rust, which further reduces the strength of fixation of loaded components of the rafter system.

Jumpers are fixed to the corners

Experienced builders do not use self-tapping screws, but ordinary nails; they do this for several reasons. Firstly, hammering nails is much faster than screwing in self-tapping screws. Secondly, there is no need to use screwdrivers. Working with them is quite difficult, especially at heights or at the maximum distance from the site. The lower rafters are fixed at the ends of the floor beams, it is quite difficult to reach there, but you also need to hold the screwdriver in your outstretched hand and press it with great force against the head of the screw. Thirdly, nails are made from ordinary carbon structural steel; it has good physical strength. If the loads exceed the maximum stability values, then the nail is slightly stretched and maintains the strength of the connection of the elements of the assembly, and does not burst. Fourthly, bending the tip of the nail on the other side of the board completely eliminates its spontaneous pulling out. Fifthly, the cost of nails is much lower than self-tapping screws, and a large number of them will be needed for the rafter system.

It is preferable to use nails

Step 6. Raise the assembled rafters to the ceiling of the bathhouse and begin fastening them. Before doing this, prepare a temporary walking surface on the floor. Choose durable boards for flooring; they should support the weight of 2-3 people with rafters. It is advisable to nail the flooring to the beams. Never violate safety rules; all their provisions are written based on bitter experience. Remember that no roof or rafter system is worth your health.

Step 7. Install the first rafter on the outer beam. It's easier and safer to do this together. Place the rafter leg at a level and fasten it to the beam with nails. You can use metal squares on the sides. One builder holds the leg, and the second nails it.

Installation of the first rafter

Step 8. Attach the second rafter to the first, the upper ends should rest against each other. Secure the ridge with nails. Keep in mind that nails should be driven in at an angle to the growth rings. This will not only eliminate the possibility of cracking the board, but will also significantly increase the strength of the connection.

Installation of the second rafter

Rafters are tied together with nails

Step 9. Nail a board for the brace approximately in the middle of the rafter. Place the rafter leg in a strictly vertical position and secure the support. This is a temporary element; in the future, the supports will be removed and stationary spacers will be installed instead.

The support is nailed

Step 10. Assemble the same truss on the opposite side of the bathhouse, stretch the thread along the ridge. Take turns collecting the remaining roof trusses. Always make sure that the top corners are positioned exactly along the stretched rope. Do not forget about temporary fixation of elements.

Rafter trusses assembled

The same thing, but from a different angle

Step 11. Install vertical supports under the skates. They must be prepared separately; each one will have to be measured and adjusted. The lower ends of the supports are attached to the ceiling beams using nails or perforated metal tape. The upper end is trimmed into a triangle and inserted between the rafters.

Practical advice. Don’t worry if you were unable to accurately adjust the vertical support; a spread of a few millimeters does not have any negative effect on the rafter system.

A variation of a few millimeters is acceptable

If the length of the rafters is more than 3.5 meters, then it is recommended to make jibs on both sides with emphasis on the lower end of the vertical support. The jibs are fixed using perforated tape.

Experienced builders do not abuse plates, but in all possible cases make ties from boards. Such elements require a little more time, but guarantee the stability of the structure for a long time. One more nuance. If there are remnants of bark on the boards, they must be removed . Over time, bark beetles infest the bark, and they not only damage the bark, but also gnaw holes in the wood. As a result, the boards lose their original load-bearing characteristics, and the roof may sag or completely lose stability.

Bark must be removed from boards

When do you need to make moving connections?

So, we noted that the support nodes connecting the Mauerlat to the boards can have different degrees of mobility: from “0” to “3”. Zero degree - these are rigid fastenings that exclude any changes in the position of the beams.

The Mauerlat is installed when it is necessary to transfer the thrust load from the rafters to the load-bearing walls. This is done mainly in houses made of bricks, panels and blocks. In this case, they try to eliminate deformation and shrinkage of the roof in order to prevent changes in the load on the supporting walls. This is where the need arises for a fixed connection of the rafter system with the Mauerlat.

Another option for a non-joint joint is a rigid fastening of the rafters, reinforced with overlay beams on both sides. Two boards at least a meter long border each rafter leg. One end of such supports is cut at an angle that corresponds to the slope of the roof slope (including rafters). The boards are fastened with a cut to the Mauerlat using long bolts and reinforced steel corners.

We suggest you familiarize yourself with How to attach a cable duct to a concrete wall

The bars are attached to pre-marked places, first one at a time. Then the rafters themselves are mounted close to the overlays on one side, which are immediately reinforced with the same overlay on the other side. There is an option to install two beams at once, and then rafters, but this method is used less often, since it requires more accurate calculations.

Here we come to dynamic support nodes - connections that can change their position. What is it for? Let's remember the physical properties of materials - many of them shrink or swell. First of all, this applies to buildings made of pure wood - timber, logs, etc. Natural wood necessarily shrinks, due to which your roof can not only be deformed, but also completely collapse.

A prerequisite when installing sliding units is to support the rafter frame on a strong ridge beam. Since the supporting lower nodes are dynamic, maximum rigidity should be achieved at the roof ridge. The upper edges of the rafters are sawed down for a tight connection between themselves and the ridge beam, connected and reinforced with crossbars, metal strips, plates and corners. It is better to connect the rafter element already fixed in the ridge to the crown of the log house.

Tools for installing rafters.

When installing rafters on beams using the rigid fastening method, it is important to adhere to certain requirements and eliminate bending, twisting, turns and shifts between elements.

These requirements can be achieved:

- secured with a corner with a hemmed block for support;

- making a cut on the rafter element and fastening this connection with nails and staples.

Using a corner with hemmed support bars, the rafters are placed on the mauerlat. The element itself must have a rigid stop along the load line due to a hemmed beam about 1 m long. It is also fixed on the sides with a metal corner to avoid shifting.

The second installation method is most applicable. With this option, fixation with nails is carried out from the side, at an angle, they are crossed inside the Mauerlat, and a third nail must be driven vertically. This results in a rather rigid assembly when fastening.

In both options, the connections are secured by another fastening of the elements to the wall, using wire or anchors.

At the same roof slope angle, the rafters are prepared using a template, that is, the same size.

The method of sawing and installing the rafter element and sawing the Mauerlat:

- making a connection using 2 nails on the sides diagonally so that they intersect;

- making the connection with one nail, which is hammered in the upper part through all the rafters and into the mauerlat;

- the nails are replaced with a plate with holes;

- using staples, fasten the rafters and the mauerlat;

- the rafters protrude beyond the wall and are secured only with plates.

The connection is made using special fasteners - slides.

Each method allows the rafter elements to move relative to each other.

Installing rafters on a timber bathhouse alone

We warn you right away that this is not the best choice; making a rafter system is much more profitable with an assistant. It is not only safer, but also faster and of better quality. You can independently make a roof on a small bathhouse with light roof trusses.

Step 1. On the ground, assemble all the roof trusses into a single structure. It is impossible to lift the rafters one by one and assemble the truss on the ceiling alone. At the same time, you need to make cuts on the rafter heels.

Assembled roof truss

Washed down the rafter heel

Important. Due to the fact that the trusses are prepared on the ground, it is very difficult to adjust them after installation. This algorithm of work requires increased care during taking measurements and filing.

Step 2: Lift the first roof truss onto the bathhouse and place it flat on the ceiling. Shift the structure so that the overhang is equal on both sides of the structure. It is impossible to do this the first time; you will have to move for a long time from one wall to another to align the ends of the truss.

The first roof truss is being raised

Step 3. Lift it vertically, adjust the position again and temporarily secure it with a side support.

The truss rises vertically

Temporary support secured

Practical advice. It is much more convenient to work with a special carpenter's belt. It has pockets for hardware, compartments for tools and measuring instruments. Everything you need is always at hand. It is possible to hold the truss with one hand and take out the tool with the other and work.

Step 4. Using the same scheme, lift all the trusses one by one and temporarily fix them with various stops. Take your time and work with extreme caution.

All farms are fixed

Step 5. After the trusses are temporarily installed, check their position, if necessary, eliminate any inaccuracies found, everything is normal - proceed to the final fixation of the rafters to the upper crown of the timber bathhouse.

Photos of installed farms

How to do this - choose for yourself: use perforated tape, metal corners, screws or nails . If there are doubts about the strength of the structure, then further strengthen it with braces.

Next, the sheathing is nailed, the parameters of the sheathing depend on the characteristics of the roofing covering.

Lathing

In the spans of the outer rafter trusses, it is necessary to make vertical posts; gable sheathing boards will be nailed to them. If you plan to make an entrance to the attic, then immediately think about the location of the door and nail a frame for it.

Vertical racks

Prices for timber

timber

Methods for installing roofs over a log house

Building a roof over a built log house is not as easy as it might seem at first glance. Such work requires enormous skill, knowledge of materials and carpentry skills. Before you get started, you will need to practice. In this article we will look at methods for installing roofs over a log house and talk about the important stages of installation. Let's hope that the information will be useful for craftsmen and those who are taking on such work for the first time.

Flawless installation can only be achieved by taking into account the shrinkage of walls made of logs. You may need knowledge of ancient roofing technologies and modern installation methods. You need to understand that taking into account the characteristics of the material is not enough to correctly build a roof. There are components to which it is important to pay special attention so that the roof does not deform over time. It is necessary to choose the most rational method of construction. To do this, you should take into account the forces acting on each log and choose the right ways to dampen the action of these forces. Our company’s employees will develop a gable roof scheme taking into account all the features of this material and project.

Features of fastening rafters on a bathhouse made of round logs

The main difficulty in attaching rafters for a bathhouse made of round timber is the difficulty of fixing the lower part of the rafters (heels). It is impossible to firmly fix the flat surface of the board to a round log; the elements only touch at one point. And this does not provide reliable support; the rafter system loses stability. In addition, if the bathhouse is made of ordinary, and not rounded, logs, then the upper crown does not lie in the same plane. As a result, it is necessary to prepare special supports for the rafter legs.

Fastening rafters on a bathhouse made of round logs

There are two options for attaching the rafters to the timber: making cuts in the logs under the heels of the rafters or mounting the roof on the ceiling beams. The second option is considered by professionals to be more reliable and simpler. How is it done?

Step 1. Mark the location of the ceiling on the top crown. It’s better to make marks with a laser level; if you don’t have one, you can use an ordinary water level.

Important. Pay attention to two factors. First, all beams must lie strictly horizontally and in the same plane. Second, logs cannot be sawed to a depth exceeding one-third of their diameter.

Step 2. Drive in nails at the outer marks and stretch the rope between them.

The photo shows a stretched rope

Step 3. Mark the installation locations of all rafter legs. Place the level on the rope and rest the end against the frame. Set the horizontal line and mark it on the top crown of the bath.

Marks are applied

These marks should be used to control the depth of sawing of logs. Thanks to this simple technology, all ceiling beams will be located in the same plane and strictly horizontally.

The log is sawn through

Next you need to work with a small ax

This is what the installed rafters will look like

Further work on fastening the rafters can be continued using one of the methods described above.

Inclined single slope

Differs from flat by increased angle of inclination. Due to the larger angle, flexible tiles can also be used as roofing coverings. Water and snow shed better from a sloping roof, and the risk of mechanical damage is reduced. On free-standing bathhouses, sloping pitched roofs are rarely used; the design appearance and functionality are far from the wishes of customers. Most often, this type of roof can be seen on bathhouses that are closely adjacent to other buildings. Making a roof is not difficult; the rafters rest at one end on the upper crown of the frame, the other end rests on the purlin and headstocks. For the headstocks, side struts made of beams should be installed. All other operations for installing roofing coverings are identical to those described above.

Sloping roof

Shed roof rafter design and pitch

Mauerlat attachment technology

The Mauerlat is one of the outermost elements of a log house roof. It bears pressure from the large weight of the entire roof, which should be equally distributed among the load-bearing elements. The Mauerlat is fastened with rafter elements, which provide this pressure. Mauerlat can be made from solid logs laid around the perimeter, or in meter-long pieces that are placed directly under the rafter elements.

Related article: Important detail: bean bag chair and ball chair for any home (68 photos)

For the manufacture of Mauerlat, only logs, beams and boards with minimum dimensions of 100x100 mm, 100x150 mm and 150x150 mm are used. If logs are used, then one of the sides is cut for maximum contact with the top crown of the log house. The Mauerlat can be secured using several methods.

Scheme of rafters with a sliding support.

When the log house is made of logs or timber, the mauerlat is mounted along the top row and installed on the logs. You can pin:

- using wooden or steel dowels;

- steel staples;

- metal corner;

- using galvanized wire with a minimum diameter of 4 mm.

Overview of fastening fittings for mounting rafters

There are several types of fasteners for arranging a rafter system. All of them are united by the material of manufacture – metal. The most popular types of fasteners are:

- Corners that are used to strengthen nodes during installation of rafters. Corners not only make the fastening more durable, but also increase the load-bearing capacity of the structure. Another advantage is that there is no need to make recesses in the wood, that is, the integrity of the elements of the rafter system is not compromised. The corners are secured with nails with ruff-type protrusions on the leg or with screws.

- Perforated tape, which also serves to give the rafter structure strength and additional rigidity.

- Brackets, which are made of 2 mm galvanized metal and are attached to the wood with anchor bolts, screws or nails.

- LK fasteners, similar in design to brackets and fixed with nails or screws.

- “Sled” fasteners used for installing the truss system of wooden houses in order to protect the roof structure from deformation during the shrinkage of the building.

- Perforated metal plates.

Other types of fastenings that are used when arranging the rafter system are bolts with nuts, self-tapping screws, and wire ties.