Design and principle of operation

Warm film flooring is a fairly simple design. The heating element in the device is a carbon mixture, which is located in the form of strips between a welded heat-resistant film. Electric current flows through copper wires. Each conductor connecting the carbon tapes is covered with a protective sheath.

A special feature of the film floor heating system is the parallel connection. Thanks to this, a failed individual heating element of the structure does not in any way affect the work process of the entire equipment.

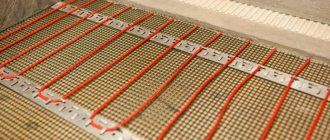

Installation of heated film floor

They produce film rolls 50 meters long, while the width of the floor heating product can range from 50 centimeters to 1 meter. The carbon mixture, which emits infrared radiation, can be located between the layers of film in the form of strips, and in more expensive models the carbon heater is a continuous sheet.

The film that forms the basis of the infrared heated floor is made of strong polypropylene, which does not change shape when heated to 120 degrees. In this case, the thickness of the material, depending on the model, can range from 0.23 to 0.47 millimeters.

They produce film rolls 50 meters long, while their width can range from 50 centimeters to 1 meter

A film-type heating system is used for all finishing floor coverings. Installation is carried out on a rough base. No screed is required after installation. The facing material is laid directly on the film.

An important point in installing this type of heated floors is the low energy consumption. On average, a film heating system consumes 25 to 35 watts per hour.

Calculation of film heated floors

For the efficiency of an infrared heated floor, a correct preliminary calculation of its power is important. Let's give an example in which a heated floor is planned to be used as an additional heat source (that is, a boiler or central heating operates in parallel). In this case, it is enough to cover up to 50% of the floor with film.

To begin with, we determine the useful heating area. The usable area is only its open areas, not occupied by furniture, etc. The picture of the room below shows that the usable heating area is 8.6 sq.m (S = 4.1 x 2.1 m).

Based on the size of the usable area, we select the standard sizes and number of film electric heaters, while it is desirable to cover the entire usable area to the maximum. Here we will use South Korean film with a power of 150 W/sq.m with a width of 500 mm . You will get 4 sections of 4 meters each, that is, 8 sq.m of electric heaters with a total power of 1.2 kW (8 sq.m x 150 W/sq.m = 1200 W). We get a load current of 5.5 A (1200 W / 220 V = 5.5 A).

We recommend drawing up a laying diagram before installation. On it you will need to mark the location of laying the film sections, the distance between the strips, the connection diagram for the film heated floor, including the location of the power wires and the temperature sensor coming from the thermostat.

Note! It is strictly forbidden to lay electric heaters overlapping! There should be 10–20 cm . 50 mm is allowed between the heater strips .

Another very important point. At the site where it is planned to install film heated floors , there must be additional electrical power . Quite often, in its absence and high energy consumption (the system operates in several rooms simultaneously, including as the main one), the problem of network overload . This leads to constant operation of the input machine and other troubles.

In order to avoid such problems in the future, it is necessary to design the power supply parameters of the facility in connection with the additional electrical power of the heated floor.

Below we present the recommended maximum length of South Korean carbon-based film materials depending on the width of the roll and the specific power of the heater.

| Table No. 1. Recommended maximum length of South Korean carbon-based film materials depending on the width of the roll and the specific power of the heater. | |||

| Roll width (m) | Specific power (W/sq.m) | Recommended max film length (m) | |

| 0,5 | 150 | 10 | |

| 0,5 | 220 | 8 | |

| 0,8 | 220 | 6 | |

| 1,0 | 150 | 7 | |

| 1,0 | 220 | 5 | |

Criterias of choice

The models of manufactured warm infrared film floors have distinctive technical characteristics. When choosing a system, there are some factors to consider:

- Film quality and size. The characteristics of the product indicate the characteristics and material of the heated floor. The denser and more layers the film coating has, the higher the resistance to mechanical damage. The width of the roll is selected depending on the design features of the room and its area.

- Power. The value of this parameter is influenced by the size of the heated room and the purpose of the heated floor system itself. For equipment that is installed as the main heating, a fairly high power rating is required.

- Integrity and completeness of the system. When purchasing a heated film floor, you must visually inspect the product to ensure there is no damage. The presence of all elements included in the heating device will also be checked.

It is recommended to purchase a high-quality infrared heating system in specialized stores, where a quality certificate for the product and a guarantee of its use are provided.

Scope of application

Film equipment is widely used for heating various types of premises. The system can act as:

- additional heating device;

- main source of heat.

Also, heated floors can be installed to maintain the temperature of individual areas of the room. Film flooring is most often used for heating;

- living rooms;

- bathrooms;

- utility rooms;

- loggias;

- bathrooms;

- winter gardens;

- public buildings;

- gyms.

Often, film heating systems are used in kindergartens or playrooms. The device has gained such popularity due to numerous positive characteristics, which include safety of use.

Advantages and disadvantages

Warm infrared film-type flooring is considered one of the best floor heating systems. Its main advantages of use include:

- the possibility of installation without any special load on the ceiling due to the low weight of the heating product;

- ensuring uniform heating of the entire floor surface during operation;

- the ability to fully function if individual elements of the device are damaged;

- absence of electromagnetic radiation;

- long period of use;

- economical use due to low electrical energy consumption, if you do not take into account the installation of the system as the main heating;

- ease of installation work.

No screed is required to lay the film, and the topcoat can be used regardless of its type. The system warms up quite quickly without drying out the air.

Among the disadvantages of warm film floors, they sometimes highlight low resistance to mechanical stress and the relatively high cost of high-quality products.

Feedback about use

Forum members and other Internet users left numerous reviews about the use of film heated floors, here are some of them:

Review #1

I installed a heated floor with a reflective screen (heating element power 150 W/m2) and tiled flooring in the kitchen area of a country house. I am pleased with the purchase, since the use of a thermostat allows us to minimize energy costs. During my absence at the dacha, I turn on the system through capacitors and a mechanical relay (programs no more than 3 hours of operation per day).

This allows you to always maintain a minimum positive temperature in the room (in winter it does not drop below +3 degrees). I have been using warm floors for 5 years and have no complaints about its performance. The only drawback is the need for a separate connection using an RCD.

Review #2

Our bedroom is located in the corner part of the panel house; this room has a large window, so in the winter we had to escape the cold by using heaters. We soon learned that such household appliances dry out the air, so we abandoned the heaters and ordered underfloor heating. We have been using this system for more than 3 years and have not found any shortcomings.

Review #3

I live in a high-rise building on the ground floor with an unheated basement, so I constantly feel discomfort from walking on the cold floor covering. Having seen an advertisement on the Internet, I decided to install an infrared floor from the manufacturer Thermo Dar. Ordered goods and installation services. I'm happy with the purchase, the apartment heats up quickly, there is no dampness. Another advantage of this product is the 15 year warranty. The only drawback is the impossibility of installing heating elements yourself.

Review #4

We ordered heated floors from the Kaleo brand. Throughout the winter, this heating system was turned on at 24 degrees; when it got too cold outside, it was switched to +26. The whole family walked around the rooms barefoot. One of the disadvantages of using the coating was the change in color of the floor covering under load (they placed a bag of unnecessary things on the linoleum). The conclusion suggests itself - warm floors cannot withstand high loads, so they cannot be laid under furniture.

Useful article? Add to your bookmarks!

THIS MAY BE INTERESTING MORE FROM THE AUTHOR

Floor insulation

Choosing floor coverings for water heated floors

Floor insulation

Izolon: features, types and common areas of application of the material

Floor insulation

Floor insulation with expanded clay

Floor insulation

Installation of heated floors - instructions

Floor insulation

Warm floor under tiles - selection, installation

Floor insulation

Electric heated floors

Installation features

Laying film for heating floor coverings is not particularly difficult, but connecting the device requires precision and certain skills. Incorrect connection of equipment can cause rapid failure of the entire system. Therefore, if the installation of a film heated floor is planned to be carried out independently, then all actions should be carried out strictly according to the recommended scheme, taking into account all the technological features of the heating product specified in the instructions.

Layout scheme and features

Before spreading the film, you should calculate the parameters of the room. Laying can be done both longitudinally and across the room. It is necessary to place material that emits infrared radiation based on the layout of the room.

Standard installation diagram

If the heating system is used as the main heating, then it will cover more than 60 percent of the floor area. When installing equipment as additional heating, the layout can be done in separate areas. You also need to take into account that the minimum distance from the walls should be 20 centimeters.

To avoid overheating of the system, it is recommended to avoid placing large equipment or large pieces of furniture under them. In this case, the film strips should not be allowed to overlap, and the material should be cut only along the lines marked on it.

It is necessary to spread the film so that the heating elements are directed upward and the copper strips are directed towards the base. To properly install the device, you must follow all installation recommendations specified by the manufacturer in the attached instructions.

Preparing the base

Installation of film type heated floors is carried out on a rough concrete screed. The main condition for installing the equipment is a clean and level base. If the old coating has significant defects, it should be removed. The working surface of the floor should be free of dirt and dust.

Laying foil heat-reflecting substrate

Laying the substrate

Installation of a warm infrared floor requires the use of a special substrate. Heat-reflecting material is spread over the entire area of the pre-prepared base.

The backing should fit snugly against the walls. Scotch tape is used to connect its strips. The edges of the heat-reflecting material are also fixed. You can use a stapler for these purposes.

The film is cut along the marked lines into pieces of the required length

Film installation

The film must be laid according to the pre-planned pattern. Strips of polypropylene material are cut into the required parts according to the specified markings. In this case, the film should be placed from wall to wall in a continuous layer.

After placing the strips, they are fixed to the substrate with tape. All sections of cuts with copper conductors coming out must be insulated.

Laying the film on the substrate

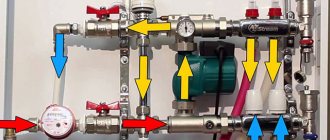

Connection

To connect the contacts you need:

- a strip of copper is secured with a special clamp;

- one side of the terminal should be inside the film, and the other outside;

- for tight adhesion of the contacts, the clamps should be pressed well on each side of the film material;

- Wires are connected to correctly installed terminals - alternating “phase” and “zero”;

- The junction points of the contacts are completely insulated with special bitumen tape.

It is recommended that all areas where contacts are located be placed in pre-cut recesses in the substrate. Placing them this way will avoid the formation of protrusions and provide a smooth surface.

Connecting wires to film panels

Installation of thermostat and sensor

The location on the wall for the regulator is determined before installing the system. It must be located near active electrical wiring. In this case, furniture or other objects in the room should not block the device.

All wires coming from the installed thermostat are placed in the groove. The contacts connected to the film must be located on the side of the control device.

The sensor is secured with tape under the film covering. It should be located close to the thermostat. To prevent the device from protruding above the surface of the film, it is recommended to deepen it into the substrate.

After completing the installation and connecting all the heated film floor equipment, a test run of the system is required.

Thermostat connection diagram

Laying the finishing coating

Floor covering can only be carried out after a complete check of the heating system's operating process.

It is recommended to lay soft finishing coverings, such as linoleum or carpet, on a layer of fiberboard or use other wood material of small thickness. Such protection will help avoid future mechanical damage to the heating equipment.

For other stronger floor coverings, it is enough to cover the film with a thin polyethylene backing.

Important installation questions

The film is laid under most finishing coatings: parquet, laminate, tile (we mentioned additional conditions above). The only note: if the material is soft, like linoleum or carpet, an additional protective layer of plywood or fiberboard is laid on top. This is necessary so as not to accidentally damage the heating elements due to careless strong mechanical impact.

It is not advisable to lay the film under materials that have high thermal insulation (for example, cork). Another significant feature of thermal film is that it cannot be laid in a screed, like other models of heated floors.

The emission of infrared bands is close to the emission spectrum of solar rays. The waves they emit are in an absolutely safe range, so installation of film heated floors can be carried out in any type of room. It is used to heat children's rooms, bedrooms, and rooms where sick and elderly people live.

Instagram mirklimatavoronezh

Instagram proklimat_perm

Possible installation errors

For the proper functioning of the film heating system, perfect accuracy of installation and connection of the entire device is required. In the process of performing independent installation work, mistakes are often made. Therefore, you should know what not to do when installing such equipment:

- lay the film overlapping;

- install one thermostat on two separate circuits;

- attach the film to the base using nails or other sharp fasteners;

- install equipment near other heating devices;

- connect the device without isolating the contacts to the electrical network;

- use a material containing foil as a substrate;

- cover the system with cement mortar;

- install large pieces of furniture in places where the film passes;

- bend the material with the carbon mixture at a right angle.

To avoid damage to the film during renovation work indoors, it is recommended to maintain precise laying diagrams.

Compared to many other floor heating systems, installation of film heating equipment is much simpler. Following the diagrams and instructions provided by the manufacturer, you can install the device yourself. But connecting the system to the network requires certain professional skills. Therefore, the process of connecting all devices must be carried out by a qualified electrician.