Features and types of water heated floors

Piping the water circuit of a heated floor connected to a gas boiler

The water installation differs from other options in that the heat carrier is the liquid flowing through the pipes. In order for it to heat up to the required temperature, you need to connect a heating boiler running on gas or electricity. The circulation of liquid within the system is ensured by a pumping mechanism.

Installation diagrams differ in structure, type of coolant used and requirements for heated premises. Which model is best to choose depends on the characteristics of the internal structure of the home.

For a private home

In this case, it is allowed to install a water heated floor from a gas boiler and use electrical options - cable or infrared. It should be taken into account that each of the models has certain restrictions on implementation. Cable installations cannot be installed under wooden flooring (parquet, boards). Also, some types of wires emit an electromagnetic field that is harmful to residents, but its impact is neutralized by the use of shielding film. When choosing an infrared floor, we must not forget that the coating is thin and breaks easily (with the exception of options made of carbon rods). Heating using underfloor heating can be combined with other forms - solar or conventional heating electrical appliances.

For apartment

Installing a water floor in a city apartment is impossible, since when the system is connected to a riser, the pressure in the latter drops, which worsens the quality of heating for users connected to it. In addition, the risk of leakage and flooding for residents on the floor below increases.

You can install infrared film on a concrete or brick base in an apartment building - it is easy to install and takes up little space.

How to connect the boiler to the floor mains?

Markers are installed at the coolant outlet and return. They show which pipe to connect the supply and return circuits to. For underfloor heating, it is recommended to use equipment with low heating capacity. The coolant in it heats up to 60 0C. Plastic pipes are used for “warm floors”.

Connecting a heated floor to a heating system

Under constant exposure to high temperatures, they can become deformed, so the connection to the boiler is carried out through metal pipes made of galvanized steel or copper.

We recommend: What characteristics does Warmstad underfloor heating have?

The connection unit is made using a threaded method using union nuts. For tightness, rubber inserts are used. A shut-off valve is installed on the pipe to be able to shut off the outlet of hot coolant or cooled water from the floor line. Pipe diameter 26 mm. The circuit is connected to the communication comb. The water “warm floor” from the gas boiler is discharged through the distribution unit.

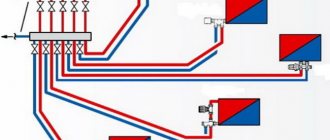

The comb consists of supply and return manifolds. They are tubes that are equipped with air pipes and automatic devices.

The equipment is fixed to the wall. The floor line is led from the supply manifold. The other end of the pipe is connected to the return manifold. The coolant circulates through the floor line. Through the return pipe, it returns to the boiler.

To be able to turn off the comb, valves are installed on the inlet and return pipes. Taps are installed on each branch pipe of the supply and return manifold. To regulate the filling of the water circuit, rotameters are installed. Automation that regulates the temperature of the liquid is installed in the boiler.

To connect the plastic pipe to the manifold, brass adapter fittings are used. They are inserted using the soldering method. The pipe is heated with an expander and the fitting is installed. The plastic cools, securely fixing the adapter; No sealant is used.

When the plastic is overheated by the expander, deformation of the inner layer of the pipe may occur, despite the fact that externally the connecting unit looks within normal limits. The diameter of the pipe narrows. Liquid cannot flow into or out of the line. There is no water circulation. The heating system is not working.

It is necessary to remove the connecting unit and install a new adapter in accordance with technological requirements.

- The system is filled with cold water. For this purpose, there is a tap on the bottom panel of the heating unit. It is traditionally marked with a blue marker. Water comes from a central pipeline. Pre-pressure test the line and remove air from the system.

- Using a piezo ignition, the gas burner is ignited. The water in the heat exchanger begins to heat up and flows from the boiler into the heating system.

- The circulation pump, which is located in the boiler, is mounted on the cold circuit. It pumps coolant through the return circuit into the firebox. The pump operates from the mains.

- The liquid heats up and re-enters the floor line.

This diagram for connecting a water “warm floor” from a gas boiler in a house is the simplest. The thermostat, which is located on the front wall of the unit, sets a certain air temperature in the room.

If the thermal regime exceeds the norm, the thermostat stops the circulation pump. When the air temperature in the room decreases, the pump turns on and the coolant begins to circulate in the floor system.

The principle of operation of a warm water floor from a gas boiler

Scheme of arrangement of a water heated floor and collector.

At the base there are interconnected pipelines with a liquid coolant circulating through them. Installation work on arranging the system involves the need to dismantle the previous floor covering. It is best to install it during the construction of a house or during major renovations.

The system includes:

- heating boiler: gas units are used, as well as those powered by electricity or solid fuel;

- coolant: usually hot water, but in the northern regions of the country the use of anti-freeze liquid is also allowed;

- pipeline for transferring water to and from the boiler;

- a collector that ensures uniform fluid movement;

- a pump that creates forced circulation;

- temperature control device (automatic or manual).

Metal-plastic or plastic pipes can be used for installation. The former have a longer service life.

Warm floor system

Varieties

Floor heating brings unique comfort to your home.

Underfloor heating systems are most often referred to by the general name “warm floor”.

There are two types of such systems:

- Electric heating of the floor slab using an electric heating cable or an infrared emitter placed in a screed or under a decorative covering. A fairly effective solution, but the cost of electricity makes it not very economically profitable;

- Water heating of the floor using circuits laid in the screed through which the coolant circulates. A more complex, but also more profitable solution that allows you to use this system as the main source of heat.

The systems have a similar structure.

If we talk about the electric variety, then this approach is obvious: the main source of heat in the house is water heating radiators, and with the help of heated floors, individual small rooms are heated, for example, a bathroom, a nursery or a hallway. In this case, heating can be turned on only for the duration of the room’s operation.

With this mode of use, you will not go broke on paying bills for electricity supply, but at the same time you will get the opportunity to enjoy the advantages of heated floors. Moreover, the system itself and its installation will be cheaper.

The difference between the water and electric options in monetary terms.

Important! If you want to heat the entire house using a floor system or do not want to overpay for increased electricity consumption, then you are better off choosing a water option. It has more complex installation and more expensive materials, but as a result you will save much more.

Device and principle of operation

The photo shows a design option with a wooden floor.

The design of the system and the principle of its operation in the case of water and electric floors do not have any significant differences. In both the first and second cases, thermal energy is transferred to the floor covering, and then radiated by its surface into the room, warming the air and ensuring normal temperature conditions in accordance with accepted standards.

The operating logic of underfloor heating is simple and clear.

The only difference is in the method of obtaining heat, because in one case, electricity is converted into heat directly in the screed, and in the second it is produced in the furnace of a household heating boiler by burning fuel. Next, the energy is transferred to the coolant, which circulates through the pipes and heats the floor.

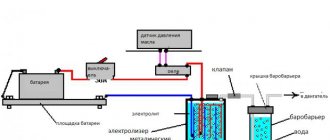

Adjusting the operation of the electrical system is simple: thermostats measure the air temperature in the room and the temperature of the floor screed, and based on this data, the control unit decides to increase or decrease the heater power. Next, the current is converted depending on the decision made.

Connection diagram of sensors and regulators.

In a water system, control is more complicated: the control automation, based on the data received, gives a signal to flow meter valves installed on the coolant supply manifold, and these valves increase or decrease the intensity of hot water supply to the heating circuits. It is also possible to adjust the rotation speed of the heating system circulation pump motor.

Automatic control of a water floor is more complicated.

Important! A water heated floor is a special case of a collector-beam system, the contours of which are laid in a screed instead of feeding heating batteries. This allows for fine adjustment and the most uniform heating of the premises.

Connection features

You can buy a ready-made manifold and connect the supply and return pipes to it.

To install the system, you can purchase a ready-made manifold cabinet, on which the necessary taps are already placed. The supply and return are connected to it. Pipes laid on the floor are connected to the collectors using connecting devices. It happens that the holes have different sections - then transition parts are used.

To cool the liquid, a valve with three strokes is used, through which the supply and return are mixed. It is mounted where the latter exits the collector. In this case, the tubes coming from the boiler are connected to the collector devices on one side, and the branching elements on the other. The drain tap is located at the bottom of the splitter. Instead of a mixing valve, a pump can be used. This option is preferable in case of deficiency of natural circulation.

At low return temperatures, it is recommended to install a condensing boiler.

Installation of additional automation

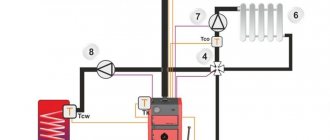

The diagram - boiler - metal circuit - collector - warm floor - is the simplest. It is not complicated by additional equipment.

If several circuits are installed in a house, the coolant in each system must be heated to a certain temperature, then an additional control unit is used. It is a three-way valve with a thermal head and a circulation pump.

Automation will allow you to withstand different modes in individual rooms. The optimal air temperature in the bedroom is 18-20 0C, in the living room 22-24 0C, in the bathroom 30 0C.

The automation is connected to the distribution comb. A bypass is installed between the supply and return collectors. Additional equipment is connected to it. A rotameter is installed at each outlet of the supply manifold. The return outlets are equipped with thermal heads.

- The hot coolant enters the floor line. If the temperature of the liquid in the system rises, the three-way valve closes the outlet of the supply circuit and opens the outlet for the return.

- In the mixing chamber, cold water is mixed with hot liquid from the boiler.

- When the temperature in the water-heated floor decreases, the valve closes the return outlet. Hot coolant is pumped into the floor circuit.

You can connect the underfloor heating system from the boiler yourself. It is necessary to choose the right boiler and determine the water circuit diagram. A separate circuit is drawn for each room.

Additional automation is installed on the distribution comb. Experts recommend maintaining the technology for connecting plastic pipes to collectors.

YouTube responded with an error: The request cannot be completed because you have exceeded your quota.

- Related Posts

- How to install a heated floor in a toilet?

- How to install a water heated floor with your own hands?

- How to lay heated flooring under laminate?

- What are the advantages of Heat plus underfloor heating?

- How to install an electric heated floor?

- How to calculate the length of a heated floor?

Advantages and disadvantages

If the boiler is volatile, if the electrics are turned off, the system will stop working.

The advantages of the system are its reliability, high speed of response to consumer actions (adjusting the degree of heating). Residents will be able to maintain optimal temperature in the house year-round. Using an installation with a double-circuit boiler will allow you to have hot water in the house.

The disadvantages are related to the operating features of the units and the requirements for their installation. If the power or gas supply is interrupted, the system may stop operating. To prevent this from happening, the user needs to pay for resources on time, as well as purchase an uninterruptible power supply if power is often cut off in the area. In addition, installation of the boiler requires a separate room, which is subject to a number of requirements, compliance with which is necessary to ensure safe operation of the system.

Advantages and disadvantages of different types of underfloor heating systems

Electric underfloor heating is no less convenient than water heating, but it is a little simpler in choosing an installation scheme. Since all parts of the heated electric floor are heated equally, there is no need to choose which scheme is best for laying the two-core heating cable.

Today, ready-made floor heating mats, in which the heating cable is laid and secured, are in great demand. The heating mat is designed for installing heated floors without a top cement layer. It is installed in a layer of tile adhesive directly under the selected decorative floor covering. Installation of such a heated floor is simplified and consists of distributing the mats over the floor area.

In addition to using cables and mats for arranging an electric heated floor, you can choose infrared heating films. The most well-proven IR films are those produced in South Korea. They are available in different widths, and their length depends on the size of the room.

The remaining details of connecting all parts of the underfloor heating system are clear to specialists by definition, but for non-specialists, most likely, they will remain a mystery, which they are unlikely to want to comprehend on their own. This matter is too responsible, and knowledge of the school physics course is not enough for it. In addition to knowledge, you will need special equipment, without which it will be simply impossible to complete this work.

Electric heated floor installation.

Safety requirements

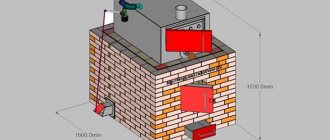

The boiler or socket must be grounded.

The gas heat generator must be installed in a non-residential room with an area of at least 4 square meters and a minimum height of 2.5 m. It must have a chimney. Some boiler models also require that the room have a window with certain dimensions (information about this is available in the accompanying documents). During installation, it is necessary to provide grounding and place the unit on a specially prepared fireproof base.

The walls of the room must be resistant to fire. If necessary, finish with materials that have this property. The distance from the housing to the nearest point of each wall must be at least 0.5 m. Flammable objects should not be placed nearby. It would be a good idea to install a gas analyzer - this will ensure maximum operating safety.

Installing a heated floor with a liquid coolant in a private house will provide year-round heating of the room with the ability to adjust the temperature. To ensure fire safety, a separate room will need to be allocated for the installation of the boiler, which must meet a number of requirements.

Pros and cons of underfloor heating from a gas boiler

Gas equipment is one of the most popular methods of floor heating in a private home. This option has several undeniable advantages:

- Provides uniform, efficient heating.

- Energy costs are minimal - in many cases this is the most budget option.

- Suitable for any coating and coolant.

- Absolutely safe for health (compared to electric floor heating, which creates magnetic fields).

- Such a floor can be easily integrated into an overall heating system, which simplifies the installation process.

This method has no specific disadvantages. The main disadvantages are of a general nature - they are characteristic of both gas and other types of floor heating:

- Warming up takes quite a long time, and it also turns off slowly, so it is impossible to achieve instant heating or cooling of the surface.

- The system relies on electricity, so in the event of an overvoltage or other interruption, the equipment will shut down.

- Installation of the system requires certain skills. However, installing the boiler itself is not particularly difficult. The most important step is connecting the device to the gas supply.

A gas boiler for the floor has quite a lot of tangible advantages and is practically free of disadvantages