Check valve, its design, operating principle and purpose

During operation of the heating system, normal or emergency situations may arise in which the liquid in a particular pipe tries to flow backwards. This can occur when the coolant cools down or the integrity of the pipelines is damaged.

This situation can lead to unpleasant consequences - from stopping heating to failure of the boiler and other components of the system. To prevent changes in flow direction, check valves are used.

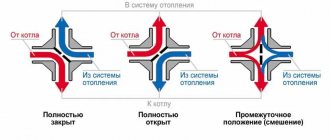

It does not interfere with the flow of liquid in a given direction, and if an attempt is made to reverse the flow, it blocks the pipeline. The valves in the heating system are actuated by various forces:

- spring;

- gravity;

- flow pressure.

Their executive body - a plate, ball or petals, when reversing the flow, fits tightly to the seat and does not allow the liquid to move.

In order for all components to function in the specified mode, the check valve for the heating system must create minimal resistance to flow in a given direction, and operate as quickly as possible when the flow turns.

Types of check valves

All types of devices perform the same function, but may have different designs, different actuators and be driven by different physical principles.

Based on the design and operating principle, there are such main types as

- disk, or plate-shaped;

- ball;

- petal;

- bivalve.

Each type has its own advantages and disadvantages and a preferred area of application.

Disc-shaped

The working body, or valve gate, is a disk attached to a spring-loaded rod. In normal flow direction, the spring is compressed by fluid pressure and the valve opens. As soon as the pressure of the liquid drops or it tends to flow in the opposite direction, the spring expands and presses the plate against the seat, and the valve closes.

A rubber or silicone sealing gasket is placed on the plate (on the seat) to ensure maximum adherence of the disc to the seat and to prevent liquid leakage.

Such devices have gained well-deserved popularity in the design and configuration of household heating systems. They have such advantages as:

- Simplicity of the device. It consists of 5 parts and does not require high precision in manufacturing.

- Reliability. Due to the simplicity of their design, such devices work for years without replacement.

- No maintenance required.

- Affordable price.

There are also disadvantages of such devices:

- High flow resistance when open.

- Susceptible to mineral deposits falling onto the disc and seat. This results in a malfunction.

- Low maintainability. If there is a malfunction, the entire device is replaced with a new one.

- When opening, they create a hydraulic shock. This does not harm the device itself, but can accelerate wear on other dynamic load-sensitive units, such as heat pumps.

There are special designs of disc valves equipped with a smooth opening device. But they cost noticeably more.

Ball or gravitational

In a gravity check valve for heating systems, the main working element that blocks the flow of water is a metal ball. To improve the fit, the ball is covered with a thin layer of elastic plastic or rubber. When the fluid flows through the device in a given direction, it lifts the ball above the seat with the force of its pressure and opens the lumen.

If the flow pressure drops or the direction of movement of the fluid flow is reversed, the ball, under the influence of gravity, falls onto the saddle, presses against it and blocks the lumen. The more the liquid tries to flow in the opposite direction, the stronger the pressure and the more reliable the overlap.

The advantages of this design are as follows:

- Low flow resistance in open position.

- Maximum reliability. The device does not contain rubbing elements and practically does not wear out in the open position.

- High maintainability. The removable cover makes it easy to clean the chamber and working elements of the device and replace the ball if necessary.

The disadvantages include factors such as:

- Large diameter.

- High operating pressure.

- The need to strictly adhere to the orientation of the device during installation. Otherwise, the ball will not rise and open the gap.

High requirements for installation and operating pressure limit the use of such fittings in home heating systems.

Petal

A steel or brass plate is used as a shutter. It is fixed on a spring-loaded axis perpendicular to the direction of fluid movement

The operating principle of a rotary valve is simple. When the liquid moves in the main direction, the pressure force turns the valve, overcoming the resistance of the spring. When pressure drops or flow reverses, a spring forces the valve across the pipe, closing it. There are designs without a spring. In them, the damper returns to its place under the influence of gravity.

This design has its advantages:

- Low price.

- Low hydraulic resistance when open.

- High sensitivity and short response time.

Disadvantages include the presence of moving and rubbing parts. This leads to their inevitable wear and tear and repair or replacement.

Bivalve

Double-leaf valves are a type of leaf valve; their axis is located exactly in the middle of the pipe, and two half-disc petals can be placed along the flow, opening the valve, or under the action of springs they can be located across the flow, blocking it.

These valves have extremely fast response times but create significant flow resistance. They are used in medium and large heating systems with high operating pressure.

Lifting

According to the principle of operation, the valve is close to a disk valve, but differs from it in that the plate and spring-loaded rod are located not along, but perpendicular to the fluid flow.

The pressure force of the flow lifts the plate, thereby freeing up the lumen for the movement of liquid in a given direction. If the pressure drops or the flow tries to reverse, the plate, under the action of a spring, lowers and is pressed against the seat, blocking the gap.

The advantages of this design include:

- Reliability is ensured by a minimum number of moving parts and simplicity of the device.

- Low sensitivity to liquid purity, both mechanical and chemical.

- Maintainability. Through the top cover you can clean the camera and replace faulty parts.

The disadvantage is the need for installation in a strictly horizontal position. This makes the valve inapplicable for vertical sections of pipelines. The design is suitable for systems with natural circulation.

Application area

The scope of application of a particular design is determined by a combination of its design properties, operational characteristics and installation requirements. It is better to select fittings for a home heating system with the help of a qualified and experienced engineer who can perform the necessary parameter assessments and carry out calculations.

Conclusions and useful video on the topic

Video #1. Where to use check valves:

Video #2. How to choose the right shut-off valves for a gravity heating system:

Video #3. How to arrange a heating make-up with a check valve:

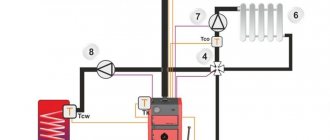

A check valve is a necessary element of complex heating systems. For schemes with one circuit, it is usually not needed, except for arranging the make-up pipeline. But if the system is complicated by the connection of a second boiler, boiler or heated floor, you cannot do without the device.

It is important to select and install the check valve correctly. This guarantees trouble-free long-term operation of the entire heating system.

Would you like to tell us how your heating system has improved since installing a check valve? Do you have information on the topic of the article that will be useful to site visitors? Please write comments in the block below, post photos, ask questions.

Check valves for water: types, design and principle of operation

Initially, all types of check valves were designed with one purpose - to prevent the flow of liquid through a pipeline in the opposite direction. This happens due to the pumping equipment stopping for one reason or another.

Without a backflow valve, water from the system may flow back into the well or well, while the impeller of the pump or water meter will rotate in the opposite direction, which often leads to its breakdown.

All check valves have almost the same operating principle : when the pressure drops below a set limit, a special device is activated, which closes the internal passage for liquid. As the pressure increases, the shut-off device opens and water can flow in a forward direction.

There are four types of locking mechanism:

- rotary;

- ball;

- lifting;

- disk.

According to the type of connection, return flow valves can be with coupling threads, with flanges, wafer-type and with end welding outlets.

The material for the manufacture of the body and working elements of this plumbing fixture can be brass, cast iron or stainless steel. Household valves are most often made of brass; they are durable and wear-resistant.

Cast iron ones are used only on large-diameter main pipelines. They are cheaper, but are susceptible to corrosion. The most reliable and durable valves are made of stainless steel, but they are also the most expensive. They are used in special cases in critical areas of systems.

In the rotary type, the passage in the body is locked by a disc-shaped lock on the rotary lever under the influence of gravity. The water pressure raises the valve, and when the pressure decreases, the valve rotates under the influence of gravity and closes the passage for the movement of liquid in the opposite direction.

The disadvantage of this design is that such a device can only be used on horizontal sections of pipelines. Most often it can be found on large diameter main pipes.

The designers copied the idea of a lifting structure from a valve-type adjustable valve. Instead of a threaded rod, which serves to lift the spool, a spring made of corrosion-resistant steel is installed.

The pressure of the liquid presses on the shutter and lifts it, thereby opening the passage. When the pressure decreases, the spring presses the valve and closes the passage, eliminating the movement of liquid in the opposite direction.

In the ball version, the role of the shutter is played by a metal ball, which can be coated with a layer of rubber. In some models it is spring-loaded, in others it locks the passage under the influence of gravity. This variety is considered the most reliable. It is most often used both in everyday life and at industrial facilities due to its simplicity of design and low cost of production.

In design and principle of operation, a disc-type water check valve is similar to the lifting type. But there is a significant difference: the disc type has a horizontal shutter, while the lift type has a vertical shutter. The horizontal position of the valve reduces hydraulic resistance. This is important for the operation of large-diameter main pipelines.

The leaf check valve has a significant drawback - the valve closes very quickly, which creates the risk of water hammer. Therefore, this type is used in cases where the fluid flow has a low speed. The petal can have one or two wings.

In addition to their main purpose, check valves with a mesh filter at the inlet perform an additional function - purifying water from large mechanical particles. They are used in autonomous water supply systems and are installed at the point of water intake from a water source.

There are combination check valves that have an outlet for drainage and a special mechanism for removing air pockets. The pipe above the spool chamber is an analogue of the Mayevsky valve, and air is released through it. The lower drainage pipe is located after the valve. Through it it is possible to drain water from the system with the valve closed.

Flanged ball check valve - structure, scope of application

In various pipeline systems there is a possibility of reverse flow of the medium. This phenomenon can lead to quite a large number of problems, for example, the pump breaks down or the pressure drops to critical values.

You can eliminate the possibility of such a phenomenon by installing check valves. There are quite a large number of similar shut-off valves; the flanged ball valve is most often used.

It is installed when creating a fairly large number of different systems, both domestic and industrial. Let us consider the features of such a mechanism in more detail.

Operating principle

The name of the valve is due to the fact that a steel ball is used as the main shut-off element. The design features include the following points:

- The main element is the body. In its manufacture, steel or cast iron, as well as some other non-ferrous alloys, can be used. Steel is characterized by high strength, and due to the inclusion of various alloying elements in the chemical composition, corrosion resistance increases. Cast iron has been used for a long period, but such a material does not withstand strong mechanical stress. Non-ferrous alloys are lightweight, corrosion and chemical resistant, and are most often used to create valves for household systems.

- The locking element is made in the form of a ball, which in its original position closes the passage hole. In order for the ball to be in the closed position, a spring is installed at a certain angle.

- When the medium is supplied in the correct direction, the pressure created is sufficient to overcome the resistance created by the spring. Due to this, the passage opening opens.

- When the pressure drops for a variety of reasons (leakage, pumping equipment stops), the spring expands and the ball takes its original position. Due to this, the possibility of reverse flow of liquid through the system is eliminated.

The specific location of the spring determines that during reverse current the spring is not pressed out. In addition, to overcome the force created by the spring, quite a lot of pressure is required, which is not created by the reverse free current.

Valve components

The ball check valve is characterized by a fairly simple design, which determines a long service life. The main structural elements can be called:

- Frame. Recently, monolithic type housings have been produced, which have high strength and reliability. The use of the casting method determines the absence of seams, characterized by low resistance to impact loads.

- Metal ball. The locking element of the valve in question is a ball, which is made of corrosion-resistant steel. The ball has a diameter that is slightly larger than the diameter of the passage hole. In addition, a special seat was created for it, which ensures a stationary locking element.

- The ball is in the closed position due to the spring. It is also made of corrosion-resistant steel, as it can withstand the environment.

- Sealing elements made of rubber provide a high degree of sealing.

Some valves can be serviced if necessary. The maintenance process involves replacing sealing elements that wear out under the influence of the environment.

Access is provided by the location of the cover at the top of the housing, which is secured with bolts. Sealing is ensured by special seals. There are also non-removable designs on sale that are not equipped with a lid. If such a design malfunctions, it must be completely replaced.

The above information determines that the valve design is quite simple and reliable. Various materials can be used in the manufacture of basic elements.

Main advantages

The ball-type valve has become quite widespread due to the versatility of the device. The advantages of such a device include the following points:

- It can be installed in industrial and domestic systems.

- If installation work is carried out correctly, the device can last for a long period without jamming.

- Relatively low cost of the device.

The flange version is common due to its ease of connection. This type of connection can withstand high pressure.

Basic selection rules

Only with the right choice of device can its long-term operation be ensured. When choosing a check ball valve, two main characteristics are taken into account:

- Diameter of the catch passage. It is worth considering that the check valve should not create hydraulic resistance. Otherwise, the pressure in the system up to the valve increases, and there is a possibility of a leak.

- Operating pressure at which the device can operate correctly. When considering a check valve, it is worth considering the minimum and maximum pressure.

Almost all manufacturers indicate these parameters when marking check valves. Due to this, the work of choosing the most suitable design option is significantly simplified.

Another important selection criterion is the type of connection. In the case under consideration, the device has a flange type of connection, but there are also wafer and coupling types. In some cases, valves are installed, which are connected by welding.

Application area

The main design features of the device largely determine its scope of application. A ball check valve is installed in the following cases:

- To eliminate the possibility of reverse flow of wastewater in the sewer system. In such cases, the liquid may contain large impurities.

- On sale you can find versions designed for household and industrial systems.

- The mechanism performs well when the medium is supplied without impurities. The use of high-quality sealing elements allows us to achieve a high degree of sealing.

Installing the valve correctly

To avoid making mistakes when choosing and installing a check valve in the right place in the heating system, listen to these simple recommendations:

- To avoid stray flows in adjacent branches, install petal or disc type products. The former are preferable because they do not create increased hydraulic resistance.

- In the bypass assembly of a gravity system, use a ball valve that has virtually zero resistance.

- For refilling, choose an element with a poppet valve designed for high pressure.

Products with gravity butterfly valves are always placed horizontally with the plug facing up - The gravity type reed valve is always mounted horizontally. Moreover, the head of the service nut must be vertical, otherwise the valve will not close and will begin to leak coolant in the opposite direction.

- Do not purchase fittings with a cast iron body. It is heavier and less reliable in operation.

- Check the correct installation by the arrow on the valve body indicating the direction of water flow.

- You cannot install fittings with a spring lock in a circuit with natural circulation - gravity flow will stop due to high resistance.

Disc and leaf valves require periodic maintenance and cleaning. If solids or deposits become trapped under the seat seal, the non-return valve will lose its seal. The best cleaning method is to remove the element and blow off the adjacent surfaces with a compressor.