Thermal insulation materials

To understand how to properly attach insulation to a wall, you need to find out the features of each sample. All types of heat insulators are used to reduce heat loss in a room. This group includes infrared reflectors and building materials with low thermal conductivity. The latter are in great demand and can be organic or synthetic in nature.

Reflex type

The principle of operation of the reflector is to slow down the movement of thermal energy. That is, there is no absorption and transmission of IR, as is the case with other materials. The reflection efficiency can reach 97-99%. Such indicators are typical for gold, silver and polished pure aluminum. The latter is actively used in the production of reflective thermal insulation of roll or sheet type with foil coating (1 or 2 layers).

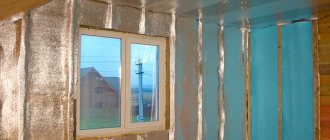

Foil thermal insulation Source stpulscen.ru

Organic material

Here, raw materials of natural origin are used to produce insulation. As a rule, this is waste from the woodworking and agricultural industries. Polymer components and cement are also used as a basis or addition.

Insulation is used in heating conditions up to 150 degrees Celsius. It is relevant for interlayer installation under decorative finishing. Below is a brief overview of samples from the organic thermal insulation group.

Arbolit

The composition includes fine sawdust, planed straw and reeds, and functional additives. The latter include calcium chloride, glass, and alumina sulfate. Cement is used as a binder. At the final stage, the blanks are treated with a mineralizer.

| Characteristic | Meaning |

| Coefficient of thermal conductivity | 0.08-0.12 W/m*K |

| Density | 500-700 kg/cub.m |

| Compressive strength | 0.5-3.5 MPa |

| Flexural strength | 0.4-1 MPa |

Arbolite insulation Source tildacdn.com

PPVC

Polyvinyl chloride foam is made from porous resins that have a foamy structure. In terms of rigidity, the material can be soft or hard, so it belongs to the group of universal heat insulators. The average density is only 0.1 kg/cub.m.

Chipboard

A rigid board made of wood chips contains up to 10% binders and functional ingredients. These can be synthetic resins, fire retardants, water repellents, and antiseptics.

| Characteristic | Meaning |

| Density | 500-1000 kg/cub.m |

| Tensile strength | 0.2-0.5 MPa |

| Flexural strength | 10-25 MPa |

| Water absorption | 5-30% per day |

Chipboard insulation Source yandex.net

DVIP

The material is similar to chipboard, only waste from woodworking or pulp production, straw and corn trimmings are used as a base. The binding component is synthetic resins. Functional additives: flame retardants, water repellents and antifungal substances.

| Characteristic | Meaning |

| Coefficient of thermal conductivity | 0.07 W/m*K |

| Density | Up to 250 kg/cub.m |

| Flexural strength | Up to 12 MPa |

DVIP slabs Source yandex.net

Fibrolite

The material is made from so-called wood wool - these are thin and narrow shavings. The binder component can be cement or magnesium ingredient. Board insulation is inert to chemical and biological activity, has good acoustic properties and resistance to moisture and fire.

| Characteristic | Meaning |

| Coefficient of thermal conductivity | 0.08-.01 W/m*K |

| Density | 300-500 kg/cub.m |

Fiberboard insulation Source twimg.com

PPU

Polyester, emulsifiers and diisocyanate are used to make polyurethane foam. The result is a material with good acoustic properties, inertness to most chemical reagents, and resistance to moisture at a density of 50 kg/cu m. Thermal insulation is applied by spraying, which allows the formation of a seamless monolithic coating in a relatively thin layer. In this case, the configuration of the base does not matter.

| Characteristic | Meaning |

| Coefficient of thermal conductivity | 0.019-0.028 W/m*K |

| Density | 40-80 kg/cub.m |

PPU insulation Source ivteplosten.ru

Mipora

Rigid plastic is made from a water emulsion of urea-formaldehyde resin. To enhance the strength properties, glycerin is added to the composition. The foaming process occurs thanks to sulfonic acid (a petroleum product), hardening - with the help of organic acid.

Mipora goes on sale in the form of crumbly granules or blocks, or a liquid mass. Unlike similar penoizol, the material strongly absorbs moisture and is not resistant to aggressive chemicals. The technical specifications look like this:

| Characteristic | Meaning |

| Coefficient of thermal conductivity | 0.03 W/m*K |

| Density | Up to 20 kg/cub.m |

| Ignition temperature | Over +500 degrees Celsius |

Mipora Source lestnitsygid.ru

See also: Catalog of companies that specialize in home insulation

Expanded polystyrene

The raw material for production is polystyrene, an oil refining product. In its finished form, the material consists of 98% air, since the manufacturing process uses foaming technology. Additionally, fire retardants are added to reduce flammability.

The material is resistant to corrosion and is inert to most chemicals. However, destruction occurs under the influence of ultraviolet rays. Technical properties are presented in the table.

| Characteristic | Meaning |

| Coefficient of thermal conductivity | 0.036-0.050 W/m*K |

| Density | 15-35 kg/cub.m |

| Water absorption | 2% per day |

| Flammability class | G3, G4 |

Extruded polystyrene foam is made from almost the same raw materials, but the technology is different. Thanks to the extrusion method, the result is denser and stronger, lasting approximately 20 years longer. The characteristics look like this:

| Characteristic | Meaning |

| Coefficient of thermal conductivity | 0.028-0.032 W/m*K |

| Density | 28-45 kg/cub.m |

| Water absorption | 0.1% per day |

| Flammability class | G3, G4 |

Expanded polystyrene slabs Source avenue.kiev.ua

Foamed polyethylene

A hydrocarbon substance is used to foam polyethylene. Like expanded polystyrene, the finished insulation consists of approximately 90% air, is inert to chemical and biological activity, and has low water absorption. Thanks to its porous structure, the material has good acoustic properties. The technical indicators are as follows:

| Characteristic | Meaning |

| Coefficient of thermal conductivity | 0.044-0.051 W/m*K |

| Density | 25-50 kg/cub.m |

| Operating temperature range | -40 – +100 degrees Celsius |

Polyethylene foam mats Source prom.st

Video description

Video of how penofol is attached to the walls:

Sotoplast

The insulation is based on fiber filler. This may be a carbon, cellulose, organic or glass component. They are used to make woven fabric with thermoactive resins as a binder (epoxy, phenolic). The outside of the material is covered with film.

The structure of the thermal insulation is cellular (the shape is close to hexagonal). It is sold in the form of sheets of laminated plastic. The characteristics depend on the raw materials used, the amount of binder resin, and the size of the cells.

Ecowool

Paper production waste is used to produce insulation. These are waste paper, scraps and discarded corrugated cardboard, books, magazines, newspapers. The quality of the resulting material depends on the raw materials used. For example, recycled materials produce heterogeneous, low-grade thermal insulation. It goes on sale in crumbly form. Over time, the protective coating shrinks.

| Characteristic | Meaning |

| Coefficient of thermal conductivity | 0.035-0.041 W/m*K |

| Water absorption | 9-15% per day |

| Sound absorption | Up to 9 dB with a 1.5 cm layer |

Ecowool insulation Source tproekt.com

Installation of various groups of insulation

The difference between how to attach insulation to a wooden wall outside or inside is the presence or absence of sheathing. Indoors it is mandatory; thermal insulation is usually fixed to the facade using glue and special dowels. Let's look at methods of attaching thermal insulation using examples of the most popular materials.

Mineral wool

Fiber boards and webs in rolls are characterized by different thicknesses, densities, softness and shrinkage. These points are important, since you need to attach mineral wool to the wall in two ways at the same time, if we are not talking about partitions made of plasterboard or plywood.

The basic technology is installation using lathing. For the supporting frame, you can use a wooden beam or a rack profile for drywall. The pitch between horizontal or vertical slats is calculated based on the width of the insulation used. It should be 3-5 cm smaller. This way the canvas will fit tightly to the supporting structure, which eliminates the formation of cold bridges. Additional crossbars are installed under the slabs. The distance between them is determined by analogy with the basics.

Partitions with mineral wool insulation Source wp.com

Since fibrous materials shrink over time, you need to understand how to attach mineral wool to a wooden wall so that cold bridges do not appear. There are two solutions here. The use of special plastic dowels with a wide head is considered universal. People call them fungi. Rigid stone wool slabs can be glued to a compound that has high adhesion to minerals and the base.

How to properly insulate?

The insulation process itself does not have complicated stages. Almost all slabs are installed according to a similar pattern. There are minor nuances, for example, for external and internal work, as well as when laying on glue or in a frame. The entire process consists of preparatory work, installation of slabs, insulation coating and external finishing.

External thermal insulation

To perform thermal protection on the outside of the house, two methods of installation are used: using glue and in a wooden frame.

The process of thermal protection of the walls of a brick house using an adhesive solution:

The walls are being prepared for laying the slabs. Along the perimeter of the house, a contour for fixing the starting strip is marked with a laser level. Metal profile for supporting the 1st row of insulation boards, secured with dowels. The walls are primed to increase the quality of adhesion. An adhesive composition is being prepared to fix the insulation. The glue is applied uniformly over the entire slab. The plate is carefully pressed against the wall. The plate is secured with dowels. For this purpose, prefabricated holes are drilled through it and fungi are hammered into them, partially drowning the cap into the insulation to prevent the formation of lumps. 5 dowels are installed on one standard slab. After securing the 1st row, the second is made offset by 1/2 sheet, and then installed in a checkerboard pattern. Reinforcement of the insulation surface is performed. The mats are covered with decorative plaster and painted.

With the frame method, a sheathing is made; it can be wooden or metal. The design pitch is chosen to be 20 mm smaller than the mineral products so that they fit tightly into the sheathing. After fixing the slabs, waterproofing and facing material are installed.

The technological process of insulating a brick wall from the outside with mineral wool is in the video:

Internal

Internal work must be carried out in such a way as to prevent moisture from entering the mineral material. Therefore, a vapor barrier film is pre-attached to the wall in the room with an overlap on the adjacent surfaces: walls, floor and ceiling. In this case, all joints are carefully taped with construction tape.

Algorithm for installing mineral slabs inside a brick household:

- Install the sheathing vertically with a step that will allow you to lay insulation boards without bending;

- the slabs are placed in the resulting cells;

- a vapor barrier is strengthened on top with hermetically sealed joints;

- fill the counter-lattice to fix the cladding material.

Tips for insulating a brick wall from the inside with mineral wool - in the video:

Video description

You can see how to insulate a wooden house with mineral wool without sheathing in this video:

Expanded polystyrene

Polystyrene boards are characterized by retaining their shape, since the materials are represented by solid boards. Here, the solution to fixing the insulation on the wall of a wooden house is to use specialized adhesive solutions and plastic mushrooms. Before fixing, the base must be leveled and primed so that there are no voids. To prevent sheets from slipping, a permanent or temporary support bar is installed for the first row. Dowels are used after the glue has dried to prevent sagging.

Facade insulation with polystyrene foam Source lalafo.com

Polyurethane foam

In this case, how to attach the insulation to a wooden wall outside or inside is practically irrelevant. Polyurethane foam is applied to the prepared base by spraying or poured. This requires special equipment in which the individual components are mixed, foamed and blown under pressure.

Polyurethane foam is characterized by high adhesion to most building materials. The foamed dry residue contains a lot of air and for effectiveness a thin layer of up to 10 cm is sufficient. Therefore, it weighs little and does not peel off from the walls under its own weight. In the case of polyurethane foam, the lathing is installed only for the convenience of cutting off excess and installing subsequent finishing.

Installation Rules

As mentioned above, hygroscopic mineral wool quickly absorbs moisture. Therefore, when installing from inside the room or outside on the facade, it is necessary to observe measures to protect it. If insulation is carried out from the inside, then waterproofing is applied along the wall, plus a vapor barrier is applied on top of the insulation itself. Membranes are most often used for this.

If facade insulation is being carried out, then it is best to use stone wool under a ventilated facade with the obligatory installation of wind protection. It is better not to install it under plaster mortars. More dense and moisture-resistant materials are suitable for these purposes.

Learn more about fixation methods

The choice of method for attaching insulation to the wall is determined by temperature indicators, relative humidity, the nature of the materials and bases, and mechanical load. Manufacturers offer various fasteners and mixtures of a universal and specialized nature.

Fasteners for thermal insulation Source derevozashita.com.ua

Lathing

The frame method allows you to solve several problems at once. In relation to thermal insulation, this is the fixation of materials and adjustment of their position. In terms of finishing work, there are more advantages:

● no leveling of the base is required;

● applies to load-bearing structures of partitions with sheet cladding;

● a supporting structure is created for finishing materials of various types, including decorative ones.

Since the created “pie” will not be disassembled for a long time, the rough base must be cleaned of weak elements (finishing, leveling agent, concrete, wood). Destruction and preventive treatment of the surface with antiseptic agents are also carried out. If necessary, perform similar actions with rust.

If a wooden beam is used for the frame, then it is important to pre-treat it with compounds containing anti-fungal and antifungal additives. Installation is carried out only from dry planks. The metal profile must be coated with anti-corrosion protection. As a rule, this is a galvanized coating.

Rack metal profile Source avito.st

About the choice of material

The walls of the building are built according to GOST standards, according to the rules. They must meet the requirements, among which strength occupies the most important place. In addition, they must also be warm. For this, thermal insulation materials are additionally installed. How to attach insulation to a wall is discussed in this article.

We invite you to familiarize yourself with Insulation for walls inside a house or apartment - choice of material, method of laying it

For thermal insulation of brick walls, mainly tile materials are used:

- mineral wool;

- ecowool;

- Styrofoam;

- polystyrene;

- extruded polystyrene foam.

When choosing a suitable material, you should take into account its thermal conductivity, vapor permeability and moisture resistance. The thickness of the insulation directly depends on its thermal conductivity coefficient.

The leading position among materials for insulating walls both outside and inside today is occupied by extruded polystyrene foam. It is cheap, non-toxic and easy to install.

In addition, some manufacturers produce ready-made systems that include everything you need. From the boards themselves to a variety of additional materials - adhesives, dowels, plaster, etc.

Gluing

This technique involves careful preparation of the rough foundation. Loose elements are removed, oily stains are degreased, areas infected with fungi or rust are “cured” and protected with preventative agents. Next, the entire surface is impregnated with primer and dried. The next step is leveling and two-layer priming with a composition with antiseptic additives.

Bonding insulation Source n-dom.ru

To glue slab insulation, you can use ready-made sealants and pastes or dry mixtures. The latter must be mixed with water until smooth before use. Manufacturers indicate the recipe on the packaging.

Let's look at how to attach insulation to a leveled brick wall. The adhesive composition is applied to the slab or base. It is important to observe the recommended thickness of a uniform layer. To prevent the appearance of excess at the ends of the insulator, an indentation of 1-2.5 cm is created around the perimeter. After the composition has dried (after 2-3 days), the “fungi” can be hammered in and finishing can be carried out.

Video description

This video describes how to insulate a base with penoplex using the method of gluing onto polyurethane foam:

Fasteners

Dowels are made of plastic, complete with a metal pin, nail or self-tapping screw, with a thermal head. This variety allows you to choose the best option for attaching the insulation to a concrete wall or wood, to a porous or dense base. In any case, the protruding part is represented by a wide cap, which holds the thermal insulation in a given position.

Attaching insulation to “fungi” Source mycdn.me

Of the nuances of how to properly attach insulation to a wall with “fungi”, only the quantity and direction are implied. The calculation is based on the linear meter of a specific insulator: from 5 pieces (along the perimeter and in the center). The distance from the edges is about 5 cm. To ensure that the “umbrella” fits tightly to the canvases, the dowel is immersed into the base at a right angle. Slight recessing of the cap is allowed.

Other methods of thermal insulation

In addition to ready-made slab, roll or crumble options, there are heat-insulating paint and plaster. The second is applied with a reinforcing mesh to increase strength. Here, the search for a solution to how to attach insulation to a wooden or other wall lies in the correct preparation of the working base. The algorithm of actions is similar to what is performed before gluing rigid boards.

Warm plaster Source remont.bid

Main types of insulation installation

To insulate a building, it is better to opt for external installation of mineral wool. Experts recommend this method as the most effective. One of the common methods is to install slabs with the creation of a ventilated gap. This method has been described below.

There are also other ways to insulate walls from the outside:

- Wet.

- “Well” type.

The wet method consists in the fact that after installing the mineral wool, a reinforcing mesh with plaster is applied to it. After this, the facade of the building is painted. More details about the wet insulation method can be found in the video. In the video you can more clearly see the correct installation of sheets, which will help you complete this process without outside help.

Installation of mineral wool according to the “Well” type is carried out using the following technology: the insulation is mounted between the double wall of the building. To do this, sheets of material are mounted to a brick wall, and then a cladding is made of concrete, brick or other materials. Thus, the insulation is contained in the gap between the double wall of the building.

Briefly about the main thing

Thermal insulation materials have different structures, densities and hardness. This explains the differences in installation technologies.

Depending on the characteristics of the insulation, three methods of fixing materials are used: with lathing, with adhesive compounds or with the help of “fungi” dowels. Most often, fastening is carried out using two methods simultaneously.

No additional fixation is required only for heat-insulating paints and plaster.

Ratings 0

How to firmly attach insulation to any wall

There are 3 main methods for attaching to the walls of a building.

I – sheathing. They create a frame base for ventilated cladding. To do this, choose galvanized metal profiles that are resistant to corrosion and temperature changes.

II – glue. Bonding thermal insulation material has subtleties. First, you need to choose a suitable composition that meets all the requirements. The second is moisture resistance. Further, insulation is rarely simply “set” on glue. Additionally, umbrella dowels are used.

The first type is released in bags. It is diluted according to the instructions on the package. Adhesive foam is produced in cylinders. It does not need to be diluted with water or stirred. Application is carried out using a construction gun.

To fix the thermal insulation, it is necessary to carry out preparatory work. The surface must be cleaned of dust and leveled by applying a layer of plaster.

III – use of dowels. This is the main method for firmly fixing thermal insulation. Dowels are used for both additional and primary fixation.

Each method has its own nuances and features. Before choosing a fixation method, you need to assess the wall surface, as well as compare the factors affecting the materials (temperature, humidity, frost resistance).

To lay mineral wool, create a sheathing of wooden beams.

The distance between the slats should be less than the size of the wool. In this case, the cotton wool will adhere to the base and hold on.

If the thermal insulation is purchased in slabs (it is stiffer), then the slats are filled in a cellular manner.

The wool in the slabs can be glued or dowels can be used. But, the lathing is mandatory.

For lathing, slats are used in height greater than the thickness of the wool. This creates an air gap between the insulation and the finishing coating. This will increase the thermal insulation of the wall.

Penoplex

Penoplex is often used for insulating private houses and apartments at height. To fix it, glue and dowels are used.

We invite you to familiarize yourself with the DIY ventilation deflector

To glue polystyrene foam, a flat surface coated with a primer is required. A support strip is stuffed at the bottom, and glue is applied to the foam sheets. After applying the sheet, you need to hold the material for a while so that the adhesive composition sets.

After the glue has set, holes are made in the sheet for dowels. They will create strength.

Polyurethane foam

This is a porous gas-filled polymer based on polyurethane components. It has a number of distinctive properties, low thermal conductivity. Therefore, it began to be often used in cold regions.

Water and sudden changes in temperature do not affect it. Polyurethane foam is produced as foam. Apply to the surface in 2 ways:

- spraying using equipment;

- pouring - special equipment is used for this and voids must be equipped.

The insulation warranty period is up to 50 years.