What is pyrolysis?

Pyrolysis refers to the process of producing and subsequently burning combustible gas. Pyrolysis is a characteristic process for solid fuel boilers. The fuel is placed in a closed chamber and the amount of air in it is gradually reduced. Firewood or coal begins to smolder. Carbon dioxide released during fuel combustion enters another compartment and is mixed with air heated to a certain temperature. Re-combustion occurs. The main advantage of pyrolysis: it increases the amount of burning time and, accordingly, the amount of heat. In the open air, any fuel burns quickly and produces a minimal amount of heat. In the 50s of the last century, engineers invented a circuit for the latest equipment suitable for pyrolysis. Due to the high cost and lack of justification, development did not begin.

Device

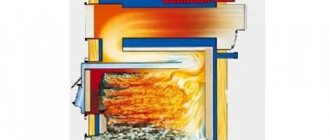

The huge chamber is designed for storing solid fuel: coal, firewood and other flammable substances. Firewood or other fuel flares up, then the air is automatically shut off. For the flame to be intense, air is needed. There is not enough oxygen for intense combustion, and the wood begins to smolder. Wood gas and a lot of carbon are released - ash particles. Air and ash particles are mixed in another chamber and the afterburning process occurs. Both chambers are separated by a special grid on which fuel is stored. The peculiarity of fire in such a device is that it has a reddish tint due to the reaction with carbon.

Installation Features

The pyrolysis furnace should be installed in a utility room, for example, in the basement, if it is used to heat a residential building. It must be equipped with a forced ventilation system. The unit is installed on a special concrete or metal platform. If the installation rules have been followed, the stove will operate on one load of fuel for up to 14 hours.

Manufacturers offer many varieties of units of this type. Factory production guarantees the reliability of the housing, compliance with technological methods and automatic control of the combustion process in both chambers. As a rule, factory models have a high degree of protection against boiling and are equipped with safety valves and automatic air supply regulators.

Principle of operation

The basic operating principle of a pyrolysis boiler consists of the device generating flammable pyrolysis gas from a solid combustible substance. The process occurs at temperatures above 200 degrees Celsius. There is a lack of oxygen. Subsequently, the air is mixed with the remaining flammable gas and afterburning occurs. The processes take place in a specially designated chamber.

Air flows in until the flame burns intensely enough. After this, the boiler switches to gas generator mode. Firewood smolders thanks to an automatic regulator, which, using the firebox, minimizes the flow of gas into the chamber with firewood. There is also an additional supply of air during gas generation, the air reaches the desired temperature and contributes to the secondary combustion of the released gas in the pyrolysis boiler.

The upper chamber is equipped with special holes from which heated air comes out under pressure. The operating principle is such that 90 percent of small particles are involved in the afterburning process. The emission of harmful substances into the atmosphere becomes minimal. The temperature of the flue gases of a pyrolysis boiler is a maximum of 160 degrees. The coolant passes from bottom to top along the boiler, receiving energy from almost everything it comes into contact with, providing effective heating of the room. The boiler efficiency is 85%. Pyrolysis solutions can be called long-burning boilers.

Most boilers operate on any solid fuel: wood, coal and others. Some boilers are electrically independent, so they are suitable for residents of regions and cities where power outages occur. The boiler is equipped with an ash drawer, which is easier to clean. Cleaning takes a minimum amount of time compared to other heat-generating boilers.

Secrets of developing a pyrolysis boiler

DIY pyrolysis furnace diagram.

In order for the boiler device to be brought to ideal condition, it is advisable to perform certain actions. An adjustable boost fan can be installed under the fuel tank. It is designed to pump air directly into the boiler itself. Under the influence of artificially pumped air, accelerated combustion of fuel occurs. All this work can be done with your own hands. Installation of this equipment does not require any special skills.

To increase the amount of heat generated, the automation must work smoothly and accurately, the fuel bunkers must be in optimal positions.

It is possible to achieve an extension of the fuel combustion period if, when constructing a boiler with your own hands, the fuel chambers are separated. In this case, fuel will be burned in one of them, and gases will be collected in the other. When using a two-zone gasification system, it is possible to achieve energy independence of the boiler and a constantly high level of power. The power of a wood-burning stove can be increased by placing grates at the bottom of the fuel bunkers.

A high-quality heat storage device in pyrolysis boilers (as opposed to coal-fired devices) is to install a jumper directly in the combustion chamber. In this case, automation performs its direct function.

The design of the pyrolysis boiler is designed in such a way that there is no need to chop firewood before feeding fuel into it - the main thing is that it can pass through the stove door.

Wood-burning pyrolysis boilers can operate and produce greater thermal energy when using sawdust and peat briquettes. Some boilers can even operate on coal. Installing such a boiler will not require much effort and time. The main thing is to correctly understand the principle of its operation and create a high-quality chimney

It is very important that the chimney has sufficient draft to blow out residual gases. It is not difficult to do it yourself. https://www.youtube.com/embed/uKshq2tUe84

Scheme of work

Many people who are planning to purchase a device are interested in how the device works. The pyrolysis boiler consists of two chambers: afterburning and gasification. Fuel is placed directly into the latter; the chamber is equipped with a special door. Below the gasification chamber there is a special hole for supplying air to the afterburning chamber. It is located below the gasification chamber. The design is equipped with a chimney to get rid of resin and a heat exchanger.

The thickness of the outer layer applied to the boiler depends on its power. It is recommended to choose boilers with a 10% power reserve. To correctly calculate the power, you need to know the total area of the room. For 10 square meters there is 1 kW. Please note: if the room has a non-standard ceiling, you should add up to 3% power to each meter.

Unlike other solid fuel devices, the firebox must be preheated before use. Actions to be followed when working with a pyrolysis boiler:

- At the bottom of the firebox you need to load some small kindling such as wood chips or paper;

- Set the mass on fire using a kind of torch made from the same materials;

- The combustion chamber door should be closed tightly;

- Portions of kindling are gradually added;

- When there is a sufficient amount of smoldering coals at the bottom, you should stop the process of adding wood chips;

At this moment, the temperature inside the chamber reaches 800 degrees Celsius. The main flammable substance must be placed in the chamber.

Features of operation of gas generator boilers

The operating efficiency of a pyrolysis boiler largely depends on the type and quality of fuel. Technically, not only wood, but also coal and even peat can be loaded into the firebox; most modern boiler models are designed to use several types of fuel.

Wood burns in about 5-6 hours, depending on the type. The harder the wood, the longer it burns.

Modern models of pyrolysis combustion boilers can operate on various types of wood fuel: firewood, briquettes, pellets, coal, peat, etc.

It will take about ten hours to burn black coal, and the same amount of brown coal will smolder for eight hours. In practice, pyrolysis technology demonstrates the highest heat transfer when loaded with dry wood. Firewood with a moisture content of no more than 20% and a length of about 45-65 cm is considered optimal.

If access to such fuel is not available, you can use coal or other organic fuel: special sawdust briquettes and wood pellets, waste obtained from wood processing, peat, materials with cellulose, etc.

Before starting to operate the boiler, you should carefully study the device manufacturer’s recommendations regarding fuel.

In pyrolysis combustion boilers, the air supply is regulated by conventional mechanical valves. The absence of complex electronics ensures high fault tolerance of the device

Too wet fuel in such devices is unacceptable. When it burns in the firebox, additional water vapor is formed, which contributes to the formation of by-products such as tar and soot.

The walls of the boiler become dirty, heat transfer decreases, and over time the boiler may even stop working and go out.

If you use wood with too high a humidity for a pyrolysis combustion boiler, conditions will arise inside the device for the formation of tar, which will worsen the heat transfer of the device and can lead to breakdowns

If dry fuel is placed in the firebox and the boiler is configured correctly, the pyrolysis gas produced as a result of the operation of the device will produce a yellow-white flame. Such combustion is accompanied by an insignificant release of by-products of fuel combustion.

If the color of the flame is different, it makes sense to check the quality of the fuel, as well as the settings of the device.

Pyrolysis gases mixed with air burn with an even yellow-white flame. If the color of the flame has changed, you may need to check the boiler settings or fuel quality

Unlike conventional solid fuel devices, before loading firewood into pyrolysis boilers running on solid fuel, the firebox must be preheated.

To do this, perform the following steps:

- Load small dry kindling (paper, wood chips, etc.) onto the bottom of the firebox.

- They set it on fire using a torch made of similar materials.

- Close the combustion chamber door.

- The loading chamber door is left slightly open.

- Add portions of kindling as it burns.

- The process is repeated until a layer of smoldering coals forms at the bottom.

By this moment, the firebox has already warmed up to approximately 500-800°C, creating conditions for loading the main fuel. Do not use gasoline, kerosene or any other similar liquid substances to light the kindling. Before warming up the furnace of a long-burning boiler, you should make sure that the device is ready for use.

A characteristic feature of pyrolysis combustion boilers is a small amount of ash and ash, which facilitates the process of cleaning the device and its maintenance

To do this, check the presence of draft, the tightness of the doors, the serviceability of locking mechanisms and control equipment, the presence of coolant in the heating system, etc.

Then you should turn on the thermostat to make sure that voltage is supplied to the device. After this, open the direct draft damper and ventilate the boiler for 5-10 minutes.

Advantages and disadvantages

The main advantages of a pyrolysis boiler include the fact that thanks to its use you can significantly reduce the cost of firewood. The consumer has the opportunity to ensure maximum long-term combustion due to the operating principle of the boiler. The house is heated, and there is no need to worry about adding firewood. The average burning time of one batch of fuel is as much as 12 hours; you will have to approach the device no more than twice a day. An ideal boiler for burning duration. An environmentally friendly choice, the fuel is burned completely and the emission of harmful substances into the atmosphere is minimal.

Such a device has its disadvantages, the most common include:

- During the cold off-season, firewood consumption increases;

- The ash evaporates into the chimney, simultaneously polluting it and everything around it;

- In the event of a breakdown or incorrect operation, it is quite possible that there will be an overconsumption of firewood, the ash will not evaporate;

- Wet firewood is absolutely not suitable. A lot of energy is spent drying them. They don't smolder.

- Quite a high price;

Advantages and disadvantages of pyrolysis boilers

Now you know what the operating principle of a pyrolysis boiler is. In fact, this is a gas generating unit that produces a large amount of thermal energy. If we compare the calorific value of wood in direct combustion and in pyrolysis, then in the second case it is 10-15% higher. This reduces fuel costs. Let's look at the main advantages of pyrolysis furnaces arising from their operating principle:

Depending on the design features, the afterburner can be located either under or above the fuel loading furnace. In terms of performance, both options are almost equivalent.

- Economical – the ability to save fuel is very important, because a full truck of firewood is quite expensive;

- Increased heat release - the operating principle of pyrolysis boilers allows you to extract more energy from a kilogram of logs than during their direct combustion;

- Long-term work from one stack of firewood will allow you to calmly do your homework, and not sit at the pyrolysis boiler to put another portion of logs into its insatiable firebox;

- Environmental friendliness - thanks to combustion at maximum temperature, the amount of harmful emissions into the atmosphere is reduced;

- The ability to adjust the combustion intensity within fairly large limits - provides more accurate temperature control;

- Ease of maintenance - pyrolysis boilers are equipped with doors for access to the combustion and afterburning chambers, as well as for access to the ash pan;

- Increased efficiency - for some models it is up to 90%. This indicator is typical only for gas units, and even then not for all;

- The ability to heat large buildings - for this purpose, high-power pyrolysis boilers are produced. In terms of their operating principle, they are not much different from their low-power counterparts.

Unfortunately, there are some drawbacks:

- Impressive dimensions - even the lowest-power pyrolysis boilers are distinguished by their dimensions. They have large heat exchangers and two combustion chambers + an ash pan. In addition, equipment often contains water jackets that serve to cool them - their thickness is up to several centimeters;

- Increased requirements for firewood - when using raw firewood, the generation of pyrolysis products can be difficult. Therefore, logs for pyrolysis boilers must be stored in a dry place, otherwise the operation of the equipment will be characterized by low stability - water vapor will interfere with the normal course of the pyrolysis reaction;

- High cost - even if you assemble it yourself, the costs will be high, because this will require good sheet metal. The cost of factory samples ranges from 50-60 thousand rubles and more, depending on the power;

- Some models require connection to an electrical network - their operating principle is to use an electronic control module that controls the operation of the blower fan. To heat buildings without electrification, mechanically controlled pyrolysis boilers are used - they still have the same operating principle.

Most of all, consumers are confused by the high cost of equipment. But if you want to experience savings on fuel and ensure good temperature control when working with wood, you should purchase a pyrolysis boiler.