How and how to finish door slopes in a house and apartment ↑

From the outside, a small gap between the opening and the frame can be closed using platbands - special shaped strips, usually included in the door installation kit. However, from the inside of the room there remains a fairly wide area of exposed brickwork with layers of concrete mortar, and to ensure the proper level of tightness it must be finished not with one, but with several types of materials - insulating, load-bearing and decorative.

Finishing slopes improves the microclimate and is part of the design

According to the installation method, there are 3 options for finishing slopes for entrance doors:

- Applying cement mortar directly to the wall and further plastering it. It is considered the most reliable and cost-effective method, but at the same time the most labor-intensive. To lay out perfectly smooth surfaces, you must have some experience both in preparing the plaster solution and in its application.

- Gluing finishing panels using a suitable adhesive mixture. Finishing door slopes using this principle is more expensive, while the “wet” installation process is quite long (each layer must be allowed to dry), but it is quite accessible even to a beginner in the repair business.

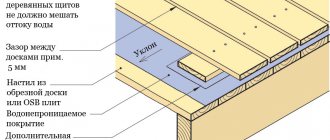

- Fastening finishing elements to a pre-assembled frame. The fastest solution that allows you to achieve a perfectly flat surface, hide telephone or electrical communications, and install lighting equipment in the door block. The downside is the low mechanical strength required to protect the door fasteners from breaking.

It is advisable to isolate the slopes from the concrete walls with a layer of polyurethane foam or mineral wool

In order for the slopes to withstand temperature changes, especially noticeable if the door leads directly to the street, and not to the corridor or landing, it is advisable to install a layer of thermal insulation on the wall: it can be mineral wool, polystyrene foam or its modification - penoizol. If installing insulation does not allow the width of the opening (according to SNiP, the dimensions of the doorway must be at least 0.8 x 1.9 m), cover the slopes with sandwich panels.

Frame slopes are indispensable when the opening is too wide and a large volume of cement mixture is required to seal it. They are also chosen when there are damp walls, or there is no time to do finishing work - plastic or wooden panels themselves look presentable. In order to fix thin sheets, the space between them and the walls is filled with polyurethane foam sealant, which also serves as a heat barrier.

You can choose the shade of the sandwich panel to match the color of the front door

In addition to the protective function, the slopes perform the task of decorative design of the opening. To cover the rough surface, one of the following materials is layered onto concrete or drywall:

- paint – thanks to the varied palette, you can choose any shade, and, if desired, a textured pattern, thereby decorating the hallway space in an original way;

- wallpaper is a good choice for those who, at the same time as replacing a door, are making repairs in the corridor, since using the same wallpaper on the wall and slopes creates the impression of a monolithic surface (a step-by-step algorithm showing how to decorate slopes at the front door with wallpaper is described in the section on finishing operations);

- one-sided sandwich panels - due to the peculiarities of their structure (a layer of extruded polystyrene foam is attached to a sheet of polymer plastic), there is no need for additional measures for insulation and sound insulation of surfaces, and their minimal weight allows them to be attached directly to the wall using an adhesive method;

- plastic panels are considered a compromise option, since, despite the external similarity with sandwich panels, plastic is very fragile, and when finishing deep slopes it is very problematic to achieve uniform rigidity over the entire area;

- MDF is quite durable (withstands medium impact loads without causing scratches or dents) and easy to install material, allowing it to be installed even under conditions of increased operating load;

- laminate or parquet board - a wide variety of colors and textures allows you to choose a tone-on-tone panel with the canvas and door frame, and the high strength, designed for use as a floor covering, determines the long service life of the slopes.

Laminate cladding

Recently, designers, trying to include the doorway into the overall interior picture, use atypical building materials to decorate it - ceramic tiles, mosaics, natural or artificial stone.

Artificial stone in the hallway looks modern

Tiling

How to finish the slopes of the front door from the inside

The luxury of oak and the shine of gold fittings will spoil unattractive slopes; their shape and appearance must be carefully thought out in order to fit organically into the overall environment without loss of functionality.

Cosmetic work begins with repairing the base layer. The plaster will have to be leveled and faced, for example, with plasterboard if the future decor is light. Drywall will not support bricks on its surface. In difficult cases, alabaster is added to the plaster to make it especially durable.

The pattern and texture of the slopes can repeat the design of the walls in whole or in part. The method of gluing slopes is no different from working with walls in an apartment. To fasten laminar panels or MDF, you need to prepare a perfectly flat surface, especially if the slopes are wide. In narrow areas the panels hold up better. At the same time, the mounting foam reliably fixes the decorative material.

In light of modern fashion trends, the design of the entrance door slopes inside the apartment using artificial stone looks stylish and rich. This is a durable decor that does not require special care. A variety of textures and colors allows you to create a unique artistic composition, imitating rough stonework. Compared to natural stone, artificial material is much lighter and reduces the load on the main structure.

Decoration of slopes with decorative stone is carried out in several stages. To create the desired shape in the chosen style, various layout schemes are used, so a sketch is determined in advance. The material is attached to liquid nails or polyester resins.

Wooden slopes in a classic style remain popular today. A wide variety of colors and shades helps to bring any interior to perfection, elegantly and unobtrusively. The disadvantages of wooden slopes include the need to renew the top layer more often than other materials. But the advantages of natural wood far outweigh this drawback.

Peculiarities

After installing the door, you want to relax, but the most important stage is just ahead. After installing the product in the opening, it turns out that the door slopes look, to say the least, ugly, and can spoil the first impression and the joy of replacing the door. A completely reasonable question arises: what can be used to cover the walls to make them look attractive.

The most popular options are to plaster and then paint or cover the space with laminate. Both options are practical, but when working with laminate you will have to do lathing. If you have absolutely no experience in carrying out construction work and want to spend a small amount, then plaster remains the most attractive option.

There are several reasons why you should choose plastering walls. Among the main advantages:

- there is no need to make a lath, which on interior doors will take up part of the space in the passage;

- there is no need to involve specialists in the work;

- low cost of material;

- it takes half as much time as in any other case when designing slopes.

But this method also has disadvantages that are worth knowing about:

- it is necessary to additionally coat the slopes with paint;

- from an aesthetic point of view, not the best option.

Working with laminate requires not only experience, but also patience. Creating a sheathing takes more time, additional tools will be required:

- hammer;

- glue;

- screwdriver

Installation of drywall: 3 ways

This is another easy way to make attractive door frames with your own hands.

Finishing putty

Instead of the adhesive used for plastic, preference is given to conventional finishing putty, which has proven to be a good fixer for plasterboard sheets.

- Careful repeated measurement of all surfaces of the opening is the first necessary step. Markings are applied to the drywall, and the material is cut into blanks with a construction knife (metal hacksaw, jigsaw).

- After trying on all the elements in the opening, putty diluted with water to a paste-like consistency is applied to their “wrong side” in large “slap” patches. The parts are fixed on prepared (primed) slopes.

- If suddenly there is a need to fix them, then use supports - for example, a wooden beam. Having fixed the material, it is left in this state for 10-12 hours. Then the supports are removed and the composition is waited for to dry completely.

- The surface of plasterboard slopes is puttied, sanded, primed and painted.

Polyurethane foam

This material is used if the surface has been well prepared, meaning there are no large depressions (up to 30 mm deep). If there are any, then the potholes are first filled 1/3 with foam. Deeper defects require the intervention of cement mortar or starting plaster.

- A foam snake is applied to the back of the plasterboard blank; its thickness is no more than 10 mm. The part is pressed to the surface, then torn off and placed to the side. The purpose of this step is to wait for the foam to increase.

- After 5-8 minutes, the element is finally fixed and left until the composition hardens for 12-24 hours. The last step is to close the gaps between the drywall and the wall with plaster. Finish the slopes after the material has dried.

Both methods have a big advantage - simplicity and speed of surface design. But there are also disadvantages:

- pre-leveled surfaces are a prerequisite, otherwise ideal installation is impossible;

- there is a risk of bending of plasterboard elements;

- voids left between the wall and the material;

- low reliability of such finishing.

For those who want to get durable and beautiful door slopes, it is better to choose the next, more complex option.

Frame mounting

This method is universal, but also more labor-intensive, but the end often justifies the means. The frame is made of wooden beams or (better) from an aluminum profile. Such slopes can withstand almost any cladding: both tiles and artificial stone.

- Measure the opening - the dimensions of the racks, as well as the horizontal guides. The necessary elements are cut with a grinder or metal scissors.

- In the opening with a pitch of 300-400 mm, holes are made with a puncher into which plastic dowels are inserted. Constantly checking the geometry with a level, the segments are fixed with self-tapping screws. For reliability, jumper elements are installed.

- If work is carried out in the entrance door opening, then the slopes are additionally insulated. In this role, practical mineral wool, glass wool, polyurethane foam (in a very thin layer) or more expensive material - extruded polystyrene foam - are used.

- Plasterboard blanks are fastened around the perimeter, maintaining a distance of 200 mm. The caps are recessed into the skin by 1 mm, but no more. The outer corners are reinforced with perforated corners, they are fixed with self-tapping screws.

Drywall sheets mounted on a frame, polyurethane foam or putty are finished. The seams are glued with serpyanka, the surfaces are puttied, primed, then the finishing material is applied.

What materials can be used?

Next, we’ll talk about building materials used in finishing door slopes based on the degree of demand, price advantages and quality characteristics.

Dye

Decorating slopes with regular paint is the easiest and fastest way, but the aesthetic component in this case fades into the background. The main advantage of painting is the ability to quickly update the coating, as well as replace it at any time.

For painting, you can use water-based emulsion or special textured mixtures. There are many design options in this case. The use of paint is especially important when you want to complete repairs quickly.

Wallpaper

Wallpaper will look advantageous only if the door slopes have a flat base. Wallpaper is usually used when a complete renovation of the hallway is planned. The main advantage is the ability to visually expand the space in general and the doorway in particular, as well as create the impression of a monolithic surface of the door slope.

Gluing wallpaper is not difficult - anyone can handle this task. It is better to give preference to thick vinyl or non-woven wallpaper - they will lie more evenly on the wall surface and will last much longer than their paper counterparts.

Single-sided sandwich panels

Sandwich panels are made of plastic, but unlike PVC panels, their interior is filled with polyurethane sealant, rather than hollow. The main advantages of the material are:

- spectacular external design;

- ease of installation;

- ease of care;

- good thermal insulation;

- moisture and heat resistance;

- no finishing required;

- An absolutely even coating that allows you to create even wide slopes (up to 1.5 meters).

Important Among the disadvantages, it should be noted that over time, sandwich panels turn yellow, and when subjected to mechanical stress, cracks and scratches form on them

Plastic panels

On the construction market you can buy plastic for every taste and color - from plain white to unusual options for leather, wood and other materials. At the same time, installing plastic slopes will only take a couple of hours. The main rule when installing plastic panels, if you decide to trim the door slopes with plastic, is to handle the material carefully, as it is very fragile and can break even from slight pressure.

MDF

When choosing MDF panels for finishing slopes, you should take into account that they will only stick to walls coated with lime-cement mortar. The composition is applied to a surface previously treated with a primer. Special glue is used to attach the panels.

The advantages of the material are:

- laconic design - you can choose MDF panels to match the door leaf;

- high resistance to loads;

- no additional finishing is required - putty and painting, which saves time and money on installing panels.

Among the disadvantages, we note the high cost of the material and the complexity of installation.

Parquet board

There are many options for parquet boards on the construction market, which can be selected to match any type of door leaf. Wenge color models look beautiful and modern. Most often, parquet boards are used to decorate wooden doors or to match the floor covering.

Laminate

Laminate is notable for its strength and durability, which is why it is often used for finishing doors. It is well suited for finishing doors made of natural wood, while being cheap and accessible. In addition, there are options that imitate a wide variety of surfaces - stone, marble, etc., so you can choose a laminate for any type of entrance door.

Tip In addition, laminate is resistant to moisture and detergents, has a low specific gravity and is easy to install. This material can be mounted using either adhesives or short screws.

How and with what to finish the slopes of the front door?

Each method has its advantages:

- If you seal the slope with cement mortar, it will be most reliably protected from mechanical influences, will not let in extraneous sounds and will ensure minimal heat loss. The finished surface will be strong and smooth, but it will not be very attractive in appearance. To make the slope more beautiful, you can use textured plaster or paint it in the desired shade.

- The combination of cement mortar with the installation of finishing materials allows you to diversify the appearance of the products. This finishing of the entrance door slopes is more difficult and takes longer, and is more expensive due to the cost of materials. For the external surface, tiles, stone, panels, etc. can be used.

Minor rule for slopes

Most often, door slopes are finished using plastering. In this case, the surface is first primed and the evenness of the corners is checked. After this, you need to install perforated corners: fixation is carried out using putty.

If the surface is uneven, you can eliminate the disadvantage by installing a plasterboard strip to set the direction.

After this, it is necessary to apply the plastering compound, the procedure is performed from below. Each layer is leveled; the corners installed earlier and the plasterboard strip act as beacons. The most difficult thing to do is putty the ceiling area: for this you use a wide spatula and a shortened rule. As the plaster dries, the surface is primed again and covered with paint, decorative composition or wallpaper.

Method of fastening a slope from GKG

Also, the finishing of door slopes after installing the front door can be done using plasterboard. In this case, individual fragments are drawn on sheets, the dimensions of which are determined in advance through measurements, and installation is carried out using glue or lathing. In the first case, the installation is carried out from above: glue is applied at several points, then the plasterboard part is pressed and fixed with supporting elements so that the composition has time to “set.” Then the walls and the area below are finished, the slopes are also placed on glue, after drying they are treated with primer, putty, and if necessary, decorative decorations are made. In the second case, a wooden sheathing is attached to the wall, and drywall is fixed to it using self-tapping screws.

Choosing a mount on the sheathing is especially important if the rooms are very frozen: insulation can be placed inside for additional protection.

Is it worth making slopes with plaster? the advantages and disadvantages of this method are described in the article Which slopes for windows are better?

PVC slopes and polyurethane linings

Wherever PVC is used now! So the front door can be framed with it. Installation is quick, and the price of PVC slopes is quite low. But this material does not have many advantages.

PVC is fragile and easy to break. Sometimes it’s enough to just lean on it and all the work will go down the drain. The slope cannot be repaired; it will only have to be replaced. And in general, the service life of the material does not exceed a couple of years. Some people cover plastered slopes with plastic, but in reality it looks ugly and cheap.

Plastic slopes

By the way, you can also decorate the slopes with polyurethane overlays, which can imitate stucco. This option looks decent. But the price for such overlays is high. You need to glue the overlays on a flat surface, so you will still have to pre-plaster or cover the ends of the walls with plasterboard.

DIY door slopes - original ideas

How to make original slopes on doors without special expenses? Even the simplest option - painting - can be turned into a fun way of finishing. Alternatively, you can apply two layers of paint: the background layer is applied with a regular roller, and when it dries, a second layer of lighter or darker paint is applied with a texture tool. You can buy one or make one yourself - just wrap a standard paint roller with a piece of suede, so that the material forms waves, bends, indentations, in a word, texture.

- Another effect - colorwash - will allow the slopes and walls to look more airy, soft, if you want. To begin with, the main background is also applied, on top of which a lighter paint, closer to the background, is applied with a sponge or cloth. Using light washing movements or crosswise movements, rub the second layer, due to which a picture of airy lightness is formed. If you don’t have any time to fuss around, use stencils, which you can either purchase ready-made or cut out yourself.

- If you still have wallpaper after renovation, you can cover the slopes with it. This is quite practical, especially if the wallpaper is washable - after all, the doorway gets quite dirty.

- Slopes made of laminate or parquet boards are installed very quickly and look original. Just don’t forget to buy special corners to hide the joints of the dies at the corners. If you think about it, this method is very practical - laminated coating on the floor alone can last about 25 years, and on the walls even longer. Laminate is easy to clean, does not fade and is resistant to mechanical damage.

- Another quick and durable option is slopes made from MDF boards. It should be noted that MDF is still not as durable a material as laminate, but its installation is even simpler - you just need to cut strips in accordance with the width of the slopes, fix them with glue and decorate them with corners.

- Slopes made of artificial stone are more complex in design, but very beautiful and durable. Depending on the shape of the stone and its color, you can achieve the effect of antiquity or, conversely, create modern designs. The stone is attached mainly to a special adhesive base; to adjust individual elements you will need at least a grinder with a diamond wheel. To give a wet effect, be sure to coat the surface of the stone with polymer varnish.

- Ceramic tiles or mosaics look very impressive in a doorway, especially if you choose the right colors and placement. The option is very practical: durable, easy to clean from any dirt, does not attract or accumulate dust.

- Mirror tiles or mirror mosaics will give the doorway greater height and width. A do-it-yourself finishing option for modern interior design; slopes for interior doors look best from this material.

- The use of cork panels will allow you to create a very harmonious finish for the slopes, especially if the hallway has parquet, parquet boards or laminate. To increase the wear resistance of the material, it can be coated with a special elastic varnish for cork.

Before making door slopes, evaluate which materials or decorative elements you already have as a happy owner, perhaps this will give you a fresh idea. It is simply impossible to list all the options - in different parts of the world, designers come up with a wide variety of finishing methods. Surely, somewhere they are already experimenting with 3D slopes or figuring out how to use the free space. Indeed, why not arrange small niches, bookshelves or hiding places in the interior slopes? So don’t limit yourself in your imagination!

How can you finish the slopes?

The choice of finishing material depends on the installation features of the door and its appearance. If the door structure is located in a wall with a recess, in addition to the internal ones, external slopes are formed, which also require finishing. Usually they are leveled with plaster and painted, but if the door opens into a heated dressing room or entrance, it is permissible to install slopes made of plastic, MDF or laminate.

For internal slopes, choose a material that matches the door trim. It could be:

- drywall;

- plastic;

- natural wood;

- laminate or MDF;

- artificial or natural stone;

- plaster.

The most affordable finishing method is plastering with further painting. But if the slope is severely damaged during the dismantling of the old door frame, its use is irrational due to the significant consumption of plaster. In this case, it is more profitable and easier to install finishing materials on the frame.

Stone finishing

Instead of painting, the surface leveled with plaster can be faced with stone laid on glue or its imitation. Despite the considerable cost, such finishing is becoming increasingly popular in modern hallways due to its unpretentiousness, durability and spectacular appearance.

If the door is made of natural wood, it is better to make similar slopes. Wood always looks expensive and fits perfectly into any interior, but it tends to dry out over time and requires careful care.

A more practical and inexpensive solution is panels imitating wood or other materials (laminate, MDF, plastic). They are available in different colors and with a variety of patterns, so choosing the ones you need won’t be difficult. The advantage of installing such panels is to obtain a coating that does not require additional finishing.

Natural wood - a classic solution

For wide slopes, plasterboard mounted with glue or a frame is often used. It allows you to quickly level the surface and achieve its ideal smoothness. The material is covered with wallpaper or painted on top.

Materials for finishing slopes

The slopes framing the entrance to the apartment must correspond not only to the external features of the door, but also to the design of the hallway as a whole. In addition to a purely decorative function, such elements around the door serve as additional insulation. They also cover the joints between the frame and the wall.

For this purpose, you can use various materials or put existing slopes in order. If the door is strong and reliable, but does not stand out in any way in appearance, it is enough to level the slopes with plaster and strengthen them. Such work is usually carried out not only from the entrance, but also in the hallway. Plastered slopes look quite neat. They can be painted in a color similar to the shade of the door itself or to match the wallpaper in the hallway.

It will reliably close the joints between the wall and the door frame, and will also make the walls warmer. Due to this, the slopes will take on a neat appearance. Drywall can be:

- cover with wallpaper;

- cover with paint.

This material has many advantages. The main advantage is that there is no need to level the plaster according to building regulations and then clean the wall. You can trim the slopes from natural wood, if it is suitable for finishing the doorway.

Wood has always been in demand and never goes out of fashion. It combines perfectly with any interior. It can be easily tinted using modern or folk remedies. The tree will serve for many years, maintaining its decorative properties. As a last resort, you can paint the wood to match the color of the hallway.

An alternative to wood can be laminated lining made from fiberboard. It is produced in a variety of colors and imitates the textured patterns of various types of wood. Accordingly, you can choose housing to suit any hallway design. But it is not recommended to finish the slopes on the outside of the door with this material, since it does not last long there.

Another finishing option is ready-made PVC panels. They are made in various widths and in a wide range of colors. The production of such parts and their subsequent sale are carried out by specialized schemes. They have a subway that installs panels. This finishing option looks respectable. It has good aesthetic properties. PVC panels can last a long time. But it is better to place them on the side of the apartment.

On the entrance side, it is better to use 1 or 2 finishing methods, which were discussed above. If you are confident in your abilities, then you can install ready-made slope parts yourself. Another option is to use polymers for finishing on the inside. This is a plastic lining. It can be easily matched to the color of the walls in the hallway. The stores offer a wide range of this material.

Slopes are sometimes sheathed with chipboard panels. They are usually used for very thick walls. But it should be noted that today this finishing method is becoming less and less popular. This is due to the emergence of alternative materials that can replace these massive panels.

One way or another, if material of the required size was found at home, you can use it to design door slopes from the inside. It should be noted that there are other materials that can be used to install slopes on the front door. They can be used to arrange planes around the door. And yet the options that were described above are the most popular.

Options for entrance door slopes

Evaluate the labor costs of each possible finishing option and your material resources. At the same time, decide whether you will hire a specialist or finish the slopes of the front door yourself.

The most common design versions:

- Plastering followed by putty and finishing;

- Sheathing with plasterboard blanks;

- Wood, MDF panels, laminate;

- Plastic panels, lining;

- Decorative rock;

- Vinyl siding.

For example, when replacing old-style boxes, which during installation were caulked with oakum impregnated with a solution, the slopes were significantly damaged. The box often had to be cut down with an axe.

Now the technology and work culture have changed; polyurethane foam, screws, and other modern materials and tools are used. Compare all the nuances and choose how to decorate the slopes of your front door, based on the situation.

If significant damage has been caused to the slopes, then it makes sense to sew them up with suitable materials in order to eliminate the need to work with plaster mortar.

Although plaster is the most reliable, durable, durable (for decades), resistant to any type of damage type of finish. You will have to endure temporary inconveniences, since this is a wet process. Let's start with it.

Installation of plaster slopes

This method is the most commonly used, inexpensive, but creates a lot of dirt. But, nevertheless, working along the beacons, the end result is a smooth and durable surface. Any finishing design is provided - painting, wallpapering, covering with suitable materials, cladding, etc.

At the preparatory stage, protect the canvas from contamination and damage by covering it with plastic film. To prepare the front of the work, begin by cleaning the jambs from poorly adhering fragments of the former plaster with spatulas.

Cut off the protrusions, remove dust deposits, and prime with a deep penetration primer. Since the volume is small, prepare the plaster mixture on site, observing the ratio of the components of the plaster solution.

To complete the work, prepare:

- Cement, sand for mortar;

- Primer;

- Putty composition;

- Trowel, spatula, brush;

- Rule, grater, grater;

- Perforated corners, painting nets;

- Level, tape measure, malka.

To obtain even jambs, fix their position by installing guides from corners and beacons. At the same time, check that the opening angle around the entire perimeter is the same. Plaster is one of the classic options when choosing how to finish the slopes of the front door.

The next step when plastering the slopes of the front door will be to fill the space between the guides with the mixture. Door jambs can be made by analogy with window jambs, the technology is identical. In case of major destruction, the solution will have to be applied in several layers, since the permissible thickness of one is 5-7mm.

Let the first coat set, then apply the second. Remove the excess with a small spoon and take a control measurement of the opening angle.

After finishing, wait until the mortar composition has set and proceed to the puttying processes. Before doing this, prime the base again. Next, apply the finishing coat on the leveled base.

Covering slopes with plasterboard

It is easier and less labor intensive to make the slopes of the front door from plasterboard. For installation, it is advisable to purchase moisture-resistant sheets. This is the entrance door to the home and in winter the temperature difference in the apartment and on the staircase varies significantly.

How does the process of decorating slopes with MDF panels take place?

Step 1. First of all, you need to prepare all the tools. This includes a tape measure, a square, a pencil, a miter saw, a sharp knife, a hammer, masking tape, a screwdriver, and a drill. You also need fastening materials and polyurethane foam.

Tools required for work

Prices for popular models of screwdrivers

Screwdrivers

Step 2. Next you need to take measurements. The procedure is carried out after installing the door - you need to measure the width of the end part of the wall, as well as the width of the doorway. It is better to take measurements at several points vertically and horizontally.

Taking measurements

The width of the opening is measured

Step 3. Now you need to make markings on the MDF planks according to the obtained dimensions. The edge along which the cut will be made must be taped with masking tape. If this is not done, unsightly chips may appear on the panel during sawing.

Marking MDF panels

The edges of the cut are taped with masking tape

Step 4. Using a square, you need to draw an even cutting line.

The cutting line is drawn

Step 5. Using a miter saw, you need to cut the workpieces.

Blanks are being sawed

Step 6. Now you need to assemble the received additions into one design. Use a drill to drill holes for the screws. It is not recommended to screw them in directly with a screwdriver - the fasteners can damage the panels. The holes are made in several pieces at a distance of 10-15 cm from each other.

Assembly of accessories

Step 7. Next, the resulting box needs to be installed in the doorway. You need to install it evenly so that the gaps between the frame and the door are equal on all sides.

The box is installed in the openingStep 8. Now you should make about 10-12 spacer elements from a wooden block.

Manufacturing of spacer elements

Step 9. Spacer elements need to be hammered between the wall and the box. About 3-4 pieces are hammered vertically, and 2 pieces along the upper and lower borders of the box. The block should not stick out; it must be hammered in tightly.

Spacers get clogged

Step 10. Now you can install the platbands. First you need to attach the trim and measure the desired length.

Installation of platbands

Step 11. Next, you need to use a saw to cut the trim to measure at an angle of 45 degrees.

Trimming trims

Step 12. Before installing the platbands, the gaps between the wall and the box must be foamed with foam. It will help further secure the box and provide sound and heat insulation. Excess foam can be cut off with a knife after it hardens.

Gaps are filled with foam

Step 13. Next, you need to secure the vertical trims to the extensions using small decorative nails.

Vertical trims are nailed

Step 14. Now you need to measure and saw off the casing at the top and bottom, and then secure it with nails.

Platband is measured

Step 15. After the structure has been assembled, you need to fix it on the door frame with masking tape for about a couple of hours. Once the foam is completely dry, the tape can be removed.

The structure is fixed with masking tape

Video - Finishing narrow slopes

After the main work on finishing the slopes has been completed, you can begin additional decoration. If they were plastered or decorated with plasterboard, then there is a lot of room for creativity. You can cover the slopes with paint, decorative plaster, wallpaper, draw patterns, attach laminate, stone, tiles and use other materials. The main thing is that they fit the overall style of the interior and meet all the wishes of the home owner.