Here you will learn:

- Pros and cons of induction water heating devices

- DIY induction water heater: diagram

- DIY instantaneous induction water heater

- Induction water heaters for heating

- What you need to know about security

- Conclusion

The modern and most economical device for heating water is an induction water heater. Unlike analogues, it is completely environmentally friendly, does not dry out or burn out air, and meets modern safety requirements. It can be used both as a flow-through water heater and as a boiler for heating a room. The device is usually bought in a store, but we offer an alternative - making it yourself. In the latter case, the device may not have such an attractive appearance, but it will cost much less.

Pros and cons of induction water heating devices

The device has a fairly simple design and does not require special documents permitting use and installation. The induction water heater has a high degree of efficiency and optimal reliability for the user. When using it as a heating boiler, you don’t even have to install a pump, since water flows through the pipes due to convection (when heated, the liquid practically turns into steam).

The device also has a number of advantages, which sets it apart from other types of water heaters. So, an induction heater:

In induction heaters, water becomes hot due to the pipe through which it flows, and the latter is heated due to the induction current created by the coil.

- much cheaper than its analogues, such a device can be assembled independently without any problems;

- completely silent (although the coil vibrates during operation, this vibration is not noticeable to humans);

- during operation it vibrates, thanks to which dirt and scale do not stick to its walls, and therefore does not require cleaning;

- has a heat generator that can be easily made sealed due to the operating principle: the coolant is located inside the heating element and the energy is transferred to the heater via an electromagnetic field, no contacts are needed; therefore, there will be no need for rubber seals, seals and other elements that can quickly deteriorate or leak;

- there is simply nothing to break in the heat generator, since the water is heated by an ordinary pipe, which is unable to deteriorate or burn out, unlike a heating element;

Don’t forget that servicing an induction heater will be much cheaper than a boiler or gas boiler. The device has a minimum of parts that almost never fail.

Despite the huge number of advantages, an induction water heater also has a number of disadvantages:

- the first and most painful for owners is the electricity bill; the device cannot be called economical, so you will have to shell out a fair amount of money to use it;

- second, the device gets very hot and heats not only itself, but also the surrounding space, so it is better not to touch the body of the heat generator during its operation;

- third, the device has extremely high efficiency and heat transfer, so when using it, be sure to install a temperature sensor, otherwise the system may explode .

Disadvantages and advantages

Let's consider the positive characteristics and advantages of induction equipment:

- Heating is carried out in any environment.

- Possibility of producing ultra-pure alloys.

- Rapid heating and melting of any material that conducts current.

- The elements of the device are mounted externally, there are no inserts. This ensures that there are no leaks.

- The induction water heater does not pollute the environment.

- Convenient when it is necessary to heat a certain area of the surface.

- The contact area of the coolant with the surface of the heater is many times larger than in devices with tubular electric heaters. Due to this, the environment heats up very quickly.

- Compact dimensions of the device.

- The equipment is easily configured to the desired operating mode and is easily adjusted.

- It is possible to manufacture a device of any shape (including independently). This prevents local heating and promotes uniform heat distribution.

A simple induction-type heater.

A flow-through heater of this type has practically no disadvantages when compared with devices operating on other principles. The only operational difficulty is that it is necessary to match the inductor with the workpiece. Otherwise, the heating will be insufficient and low-power.

DIY induction water heater: diagram

The device is a transformer with two windings: primary and secondary. The first circuit converts electrical energy into eddy currents, thereby creating a directed induction field, which provides induction heating. In the secondary circuit, the converted energy is transferred to the coolant (in our case, it is water).

It is important to consider the type of material from which the winding is made. Thus, in household models, copper wire is most often used. This material is well suited for heating water in boilers.

In addition to the transformer, the device contains a generator and a pump (optional).

Diagram of a simple induction water heater. As you can see, the device has a fairly simple design and a small number of elements.

Heat generator components and parts

The device includes:

- an alternating current generator that increases the frequency of the current;

- the inductor, which transforms electricity into magnetic energy, is a coil of copper wire;

- heating element, most often its role is played by a metal pipe.

Thanks to this design, energy transfer is carried out practically without losses. Efficiency reaches 98%.

Principle of operation

An induction water heater consists of a generator, a coil and a core, the latter is heated by electromagnetic energy

The device converts electrical energy into electromagnetic energy. The latter, in turn, acts on the core (pipe), which heats up and transfers thermal energy to the water. All these energies are converted by an inductor consisting of a coil and a core. The generator is used to increase the frequency of the current, since with a standard frequency of 50 Hz it is difficult to achieve high heating.

In factory models, the current frequency reaches 1 kHz.

Operating principle of the equipment

Induction heating technology is distinguished by its efficiency and simplicity of its design. Today, two types of induction are widespread:

- Vortex heaters.

- Devices with electronic control and currents in the coil.

In the manufacture of homemade heaters, vortex types of induction are used, which is explained by the ease of their implementation and excellent efficiency. The operating principle of such equipment is based on the transfer of energy to the coolant from a magnetic field. Powerful radiation is generated in a metal conductive inductor. When an electric current passes through a metal coil, it creates powerful vortex currents, with their subsequent transformation into thermal energy.

The heat exchanger of such a boiler can be made in the form of an ordinary column, into which water enters from below under pressure, and induction heating is carried out along its entire height. The heated coolant leaves the boiler through the upper pipe and is directed into the closed circuit of the heating system. Constant circulation of water in the boiler prevents overheating of the elements, which ensures the highest possible safety of using such equipment.

The formation of scale is prevented due to the slight vibration of the coolant as it passes through the heat exchanger, which eliminates the appearance of calcium deposits, and saves the homeowner from the need for any cleaning and other maintenance of induction equipment.

DIY instantaneous induction water heater

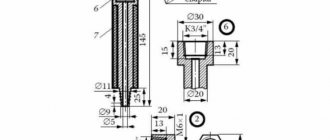

Before you begin installation, you need to stock up on the necessary parts. So, the best option would be a high-frequency welding inverter with a smoothly varying current range . Such a device will cost the least. A more expensive option would be a three-phase transformer, which is the AC power source for the water heater inductor. In this case, you should use a coil of 50-90 turns, and use copper wire with a diameter of 3 or more millimeters as the material.

As a core, you can use either a metal or polymer pipe together with wire (used as a heating element). In the latter case, the thickness of the walls should not be less than 3 mm in order to easily withstand high temperatures.

To assemble the water heater you will need: wire cutters, screwdrivers, a soldering iron and a welding machine if a metal pipe is used.

Installation of an induction water heater

Wrap the pipe with copper wire, making about 90 turns.

There are many options for assembling the device. We suggest trying to assemble the device according to the following scheme:

- Prepare your workplace, materials and tools.

- Fix a small piece of polymer pipe (remember that the minimum wall thickness should be 3 mm).

- Trim the ends of the core to leave 10 cm of wire left for taps.

- Mount a corner on the lower outlet. In the future, the return from the heating should be connected here (if the heater is used as a boiler).

- Place the chopped wire tightly around the pipe. It is necessary to make at least 90 turns.

- Install a tee on the top pipe through which hot water will flow out.

- Install the protective circuit of the device. It can be made from either polymer or metal.

- Connect copper wire to the water heater terminals, then fill the core with water.

- Check the functionality of the inductor.

Recommendations. It is better to install ball valves on all terminals for convenience and ease of dismantling the water heater in case of breakdown. But it is not necessary to fill the pipe with metal pieces, since this does not give the desired effect. Do not forget to leave a window in the housing for access to the control panel of the welding machine.

Popular heater models

Vortex induction heater VIN 7

One of the most popular and sought-after models is the VIN 7 water heater. Its power is 7 kW, which is reflected in the name of the model. Operates from a network of 200 V, frequency - 50 Hz, capable of producing up to 5900 kcal/hour. This is enough to heat a room with a volume of up to 340 cubic meters.

Another undeniable advantage of this model is its compactness. The heater is a cylinder with a height of 620 mm and a diameter of 133 mm. At the same time, it can produce a large pressure of water. The cost varies from 43 to 45 thousand rubles.

Another popular option in the same price range is Edison 4.7. Its power is 4.7 kW and at the same time it produces heat of 3960 kcal/hour. With its help you can warm up a room measuring 240 cubic meters.

Since the industry is evolving so quickly, be sure to consult with a professional before purchasing. It is quite possible that new, more interesting models will be released onto the market by this time.

If you haven’t found a suitable option for yourself, then it’s quite possible to make an induction heater with your own hands. This will save you significant money.

Induction water heaters for heating

Heating circuit, where an induction boiler serves as a coolant heater.

Such a device has proven itself not only as an instantaneous water heater, but also as a heating boiler. True, in this case the welding machine will no longer work as a generator; you will have to use a transformer with two windings . The latter transforms eddy currents arising on the primary winding into an electromagnetic field that is created on the secondary circuit.

In a heating system, the coolant can be not only water, but also oil or antifreeze. That is, any liquid capable of conducting electric current.

An induction water heater boiler must be equipped with two pipes for hot and cold water. Cold water will flow from the lower one; it must be mounted on the inlet section of the line, and on top it is necessary to place a pipe that will supply hot water to the heating system. As a result, water circulates naturally under the influence of convection without a pump.

How to make a heater

Our homemade induction heater from a welding inverter will be slightly modified compared to the prototype to make it easier to manufacture. To create an electromagnetic field outside the inductor, you will need a serious coil with a huge number of turns, and besides, bending a pipe in the form of a coil is not so easy. Therefore, it is better to place a straight pipe inside the induction coil so that it acts as a core.

Logically, the pipe should be metal, but in a homemade installation with a small inductor it will heat the coolant very weakly. So the craftsmen came up with another core device made from a polymer pipe, partially filled with pieces of metal wire. The role of the inductive circuit will be played by a coil of enameled copper wire. Well, a household inverter arc welding machine will serve as a high-frequency current generator. So, let’s clarify the list of materials:

- polymer pipe with a diameter of 50 mm made of cross-linked polyethylene for heating, withstanding coolant temperatures up to 95 ° C;

- steel wire with a diameter of 6 mm;

- enameled copper wire with a cross-section of 3 mm2;

- fine-mesh mesh made of thin metal wire.

The steel wire rod is cut into pieces 4-6 mm long to produce cylinders of different sizes. Then one end of the pipe is covered with a fine mesh and pieces of wire are poured inside. To prevent them from falling out, the mesh must be placed on the other side. An induction winding is made from copper wire over the pipe with your own hands, which will serve as a heater. The number of turns is from 85 to 95, the ends are carefully insulated and connected to the output of the welding inverter, as shown in the diagram:

Now, after turning on the welding machine, the coil will create an electromagnetic field, causing eddy currents to flow in the metal core of pieces of wire rod. It will quickly warm up, raising the temperature of the water flowing through the pipe. Actually, this completes the production of the induction heater; all that remains is to install it in the combustion room and connect it to the heating system.

What you need to know about security

Do not forget that we are dealing with a source of increased danger - an electric heating device, therefore, when assembling and using it, you must follow some rules:

Be sure to use a separate electrical line to connect the induction boiler, and also equip it with a safety group.

- If water circulates naturally in the boiler, be sure to equip it with a temperature sensor so that if it overheats, the device turns off automatically.

- Do not connect a homemade water heater to an outlet; it is better to draw a separate line for this with a larger cable cross-section.

- All exposed sections of wires must be insulated to protect people from electric shock or burns.

- Do not turn on the inductor under any circumstances if the pipe is not filled with water . Otherwise, the pipe will melt and the device will short out or it may even catch fire.

- The device must be mounted at a height of 80 cm from the floor, but so that about 30 cm remains from the ceiling. Also, you should not install it in a residential area, since the electromagnetic field has a bad effect on people’s health.

- Don't forget to ground the inductor.

- Be sure to connect the device through an automatic circuit breaker so that in the event of an accident, the latter will cut off the power from the water heater.

- A safety valve must be installed in the pipeline system, which will automatically reduce the pressure in the system.

Advantages of induction type units

The undoubted advantages of this type of home heating devices include the following characteristics:

- efficiency - the conversion of electrical energy into heat occurs almost completely without significant losses;

- ease of use - constant maintenance of units of this type is not required;

- compact dimensions - induction water heaters are small in size, they can be installed in the heating system in almost any room;

- quiet operation – this equipment operates quite quietly, no noise occurs during its operation;

- long service life - induction units are durable and can operate smoothly for 30 years or more;

- high environmental friendliness - no harmful emissions occur during operation of the device, a chimney installation and a ventilation system are not required.

How to choose an induction boiler

When choosing an induction instantaneous water heater, you need to pay attention to the following characteristics:

- power consumption;

- thermal power;

- the volume of the room that it can heat;

- required network voltage.

It also makes sense to pay attention to the manufacturer. Perhaps the most popular are the products of several companies:

- VIN;

- SAV;

- Geyser;

- Miratron;

- Edison.

All these manufacturers are highly reliable and have a large selection of models.