Almost every house or apartment, along with household appliances such as a TV, vacuum cleaner, microwave oven, refrigerator, etc., has a water heater. There are 4 types of these units:

- liquid;

- gas;

- solid fuel;

- electric.

This division is based on what type of fuel is used to operate the water heater.

There are many reasons that force residents of city houses to install electric boilers in their apartments. The main ones are constant shutdowns of hot water or its heating, but of poor quality. So-called storage tanks are in particular demand. They work according to the following principle: a special tank is installed on the wall, in which water accumulates, and then it is heated for a certain time.

One of the advantages of this type of water heater is its low electricity consumption. In addition, it can be installed very easily without the help of a specialist. But to do this, you first need to familiarize yourself with the features of its operation and installation instructions. In this case, you need to be very careful. After all, if the technology is disrupted, the consequences could be dire. The most terrible of them are the explosion of the boiler and the breakdown of the communication connection.

How does a water heater work?

A boiler explosion is not a common occurrence, but it is quite possible. In order to understand why this can happen and what needs to be done to prevent it from happening, you must first understand the structural features of this unit.

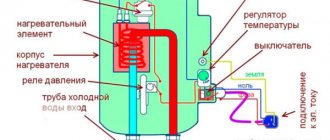

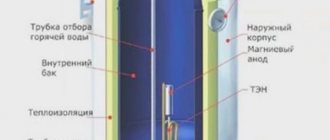

The heating element is of great importance for a water heater. These small tubular elements do a huge job - they turn cold water into heated water to the temperature that the user has set. And therefore, in order for your boiler to work without interruptions, you need to monitor its serviceability. And if this element breaks, you can easily replace it with a new one. You can buy heating elements from us. As a rule, a magnesium anode is purchased along with the heating element; it requires annual replacement.

Any domestic water heater is designed with two shut-off valves. One of them is installed at the cold water inlet, and the other at the hot water outlet.

Another important component for any boiler is a thermostat, thanks to which the unit will not heat up above the temperature set by the user.

In addition, it also contributes to economical energy consumption. Thus, the thermostat for the water heater plays a very important role.

At the inlet of the cold water flow, the design provides two valves: a non-return valve and a safety valve. The first is responsible for preventing water from flowing from the tank back into the cold water supply system. And the second, in case of pressure above normal (if it exceeds 6 atm), will drain water from the system through a special hole.

But don’t be alarmed if your boiler suddenly starts bleeding water. After all, this does not mean that it has broken down or that some other unforeseen situation has occurred. Excess water can also be drained during the heating of the household appliance, since it expands when the temperature rises. So, if the water temperature has reached 90 °C, then the volume of liquid should increase by about 3%. It turns out that in a 100 liter tank after heating there will be 103 liters of liquid. And this “extra” water needs to go somewhere.

Today, high-quality water heaters have a special space for such “excess”, thanks to which water does not leak out of the system. But if it turns out to be not enough, then the liquid begins to flow through the safety valve in operating mode, and not in emergency mode. To make it more convenient, you can put a drain pipe on this valve, which will direct excess water directly into the drain. Or, as an option, you can place any container below.

In order to be able to adjust the pressure inside the system, there is a reducer at the inlet. Water flow pressure not exceeding 3 atm is considered normal for most water heaters and this is taken into account when designing them. And if this mark is exceeded, the liquid flows out of the unit through a specially built-in drain system.

To prevent the heater from exploding, its design includes the following 2 elements:

- valve to reduce intrasystem pressure (safety);

- thermostat.

But it happens that both one and the other malfunction. And then this leads to various accidents during operation of the water heater. For example, an explosion or a communication gap. Let's say you set the temperature to which the boiler was supposed to heat the water, and then, according to the “command” of the thermostat, it was supposed to turn off. But due to the faulty latter, the unit did not turn off and the water in the tank continued to heat up until it boiled. As a result, the pressure in the system increased greatly. All of this could easily be solved with a safety valve. But, as it turned out, it was also faulty. And “extra” water cannot leave the unit. This situation is very dangerous, since due to a malfunction of these two elements, the water heater will either rupture or the pipe will break.

Explosion warning. What should be done?

By following just a few simple rules, you can avoid situations that lead to a boiler explosion, and also prevent other possible emergency breakdowns of the water heating system. So:

1. It is very important to connect the household unit correctly;

2. Constant monitoring to ensure that the water heater is working correctly (no unnecessary shutdowns, normal operation of heating lamps, etc.).

And further. Each boiler has an individual time during which the water heats up to the maximum value. And as soon as this time is over, the thermostat should turn off via a thermocouple. But if the thermostat is broken, the water heater will not be able to turn off and this will lead to its explosion. In such a case, it is necessary to turn it off immediately.

And under no circumstances should you drain hot water. The high pressure that has built up in the water heating system increases the boiling point. Therefore, draining the water will lead to a decrease in internal pressure; unboiled water will boil, forming a lot of steam, and the unit may explode.

Thus, the only thing that is required of you in such a case is to turn off the boiler so that it cools down and wait for a specialist to arrive.

What can cause an explosion?

A geyser, like any gas-powered device, poses a potential danger to users.

Outdated equipment does not respond to overheating, resulting in an increased risk of explosion. It does not contain volatile devices that stop the operation of the boiler when a threatening situation arises or arises

The main reasons why a gas water heater is dangerous and can explode:

- independent connection;

- outdated equipment;

- unauthorized modifications to the heater.

After purchasing an instantaneous gas water heater, you must collect permits for installation. Afterwards, you can install the device yourself and connect the water supply pipes to it. Only GorGaz employees should connect equipment to the gas main and put it into operation.

Equipment installed in Soviet times is not equipped with automation and protection systems, and therefore does not respond to blue fuel leaks and overheating.

An explosion occurs when the gas concentration in the room is 5-15%. If a leak (smell of gas) is detected in the room, it should be ventilated in one burst and an emergency alarm should be called immediately. It is forbidden to turn on the light, strike matches or use a lighter.

For safety reasons, it is recommended to promptly replace outdated equipment with modern devices.

Can a new generation gas water heater explode?

Despite the presence of protective devices in modern technology, new gas boilers can theoretically also explode:

- When there is no water, the empty pipe heats up.

- There is no water circulation in the heat exchanger and it boils to a critical temperature.

Today, even economy-segment boilers are equipped with a security system. The burner will not start until water appears in the coolant and begins to circulate.

All models of wall-mounted boilers currently produced are equipped with various types of sensors for operation control and safety systems, including:

- temperature sensor - water heating is turned off when the set value is reached;

- flow sensor - monitors the pressure in the pipes;

- waste product sensor - monitors the presence of draft in the chimney;

- flexible diaphragm - fixes the pressure in the line (at normal pressure the membrane allows fuel to pass into the burner, if the pressure drops, the membrane returns to its previous position and the gas supply stops);

- ionization sensor - the equipment turns off if the burner flame goes out;

If there is a noticeable smell of gas coming from the gas water heater, immediately turn off the fuel supply and call emergency services. Does it smell like burning? Check the chimney of the gas unit, its condition and the presence of draft.

Why are there explosions today?

In recent decades, people have begun to live much better. There is a massive installation of metal-plastic windows and armored doors with improved insulation, hoods, geysers and other appliances for a comfortable existence.

However, few people realize that such conveniences can lead to tragedy. The media often report cases of explosions of blue fuel in houses where gas water heaters are installed.

The owner of the property is responsible for the gas inside the dwelling. Regular preventive inspection of equipment will avoid disaster and save lives.

In Krasnodar in 2008, a gas explosion occurred in a private house. The reason is a malfunction of the column and a leak. When the gas concentration became critical, one of the residents lit a cigarette and an explosion occurred.

In 2013, a wall-mounted water heater exploded in Volgograd. Due to violation of operating rules, the wall between the bathroom and the kitchen was destroyed.

In 2021, in Borisov (Belarus), an explosion occurred in an old five-story building, the apartments of which were equipped with Soviet-style water heaters. Residents of the house did not notice the leak and did not call emergency services in time.

The reasons for the disaster when using outdated equipment are clear. It is recommended to replace such equipment. If this is not possible, then every weather it is necessary to call gas workers to check its operability and the presence of normal traction. Why do modern geysers explode?

A disaster can occur as a result of a gas leak, as well as at the moment of ignition, when gas flows simultaneously to the pilot and main burner. Hermetically sealed windows and doors aggravate the consequences. But this is only possible if the owner of the equipment interfered with the operation of the device.

Once a year, gas equipment must be inspected by a representative of the gas service, with which the homeowner has an agreement for the supply of gas and maintenance of the equipment consuming it

When operating a gas boiler, you should be careful and adhere to a number of rules:

- when operating the equipment, there must be an influx of fresh air into the room (windows should be kept slightly open);

- It is forbidden to leave a lit burner unattended;

- if you smell gas: immediately turn off the supply of blue fuel, do not use electrical appliances and do not turn on the lights, do not light a fire, ventilate the room and call emergency services.

The equipment must be kept clean and regularly inspected by a technician to identify faults in a timely manner.

Good, and most importantly safe and long-term operation of the unit can only be ensured by its quality

A high-quality boiler differs from a low-quality one by the presence of a pair of thermostats that prevent the possibility of an explosion. The temperature of the first is regulated by the user, and the second is already programmed by the manufacturer at +94 °C. Thus, if the first one is faulty and cannot perform its functions, the second one, as soon as the water heats up to 94°C, will immediately block the system. To remove this lock, you will need to partially disassemble the device.

Use only high-quality boilers. After all, spare parts for water heaters can be from different manufacturers. And your task, when choosing this unit, is to give preference to the one that is assembled from components from trusted companies.

By purchasing a high-quality, expensive emergency pressure relief valve, you don’t have to worry that it won’t work at the right time and the water heater will explode. This boiler element must be constantly checked and replaced approximately every two years. To check the condition of the safety valve, it is necessary to monitor whether it drips while the equipment is heating. If yes, then it is OK.

When installing pipes, both inlet and outlet, use only high-quality metal-plastic pipes. After all, a pipeline made of metal or plastic forms a strong connection with the boiler, which is provided with a thread. And in a situation when the intra-system pressure begins to increase, this connection will not break, but will lead to a rupture of either the water heater itself or the thread. And metal-plastic pipes are connected by fittings that compress the pipe. And, if an emergency occurs, this connection will simply break: the pipe will break out of the boiler, preventing its explosion.

When installing a water heater in a boiler room, do not equip the latter with very durable windows. After all, in the event of an explosion, they will fly out first, thus preserving the walls.

How to prevent an emergency

Follow these simple rules:

- Install equipment correctly.

- Monitor the operation of the device. Look at the panel: the indicators will tell you whether heating continues or not. If, after the time has passed, the heating element continues to work, disconnect the boiler from the network. Don't flush the water! This way the pressure will drop sharply, and the boiling will become even more active. Just wait for the master to arrive.

- Check and replace the safety valve in a timely manner.

- Make connections through metal-plastic pipes. They are mounted through fittings, so the connection breaks when there is excess pressure. Whereas plastic or metal pipes have threads. Then the tank is more likely to explode.

The most important thing is to buy high-quality equipment for your apartment. Its manufacturer provides the proper protection system, so you don’t have to worry.

READ MORE: Soldering the washing machine tank with a hot air gun with an additive

A visual experiment on a heater explosion:

Did the article help you?

Not really

What other problems might arise?

Fixing the consequences of a burst water pipe will cost you much less than the consequences of an explosion of the boiler itself.

But if you try, such situations may not arise. Failure of the pipeline will lead to the flow of water, the amount of which will increase all the time. Next, hot water will begin to flow out of the water heater. Repairing the unit and finding out the reasons for water overheating can only begin after the tank of the device is completely empty and the room is well ventilated. But if the pipes have a reliable and high-quality connection to the boiler, then they may not break. Instead, due to the growing intra-system pressure, the heater itself will explode, bringing with it the following devastating consequences:

- a household appliance can no longer be repaired after an explosion;

- everything around, including doors, furniture, walls, tiles, water and gas communications, etc., can be damaged to the point where repairs will no longer help.

It is very important not to forget that it is much easier to prevent an explosion than to eliminate its consequences later. And to do this, control the operation of your household appliances. And do not forget about regular maintenance and timely repair of the water heater. We provide service and repair of Ariston, Termex, Timberg, Garanterm and other brands.

Thermal protection did not work

https://www.youtube.com/watch?v=_77LiS7L90A

The heating element is equipped with a special button, which serves as protection against overheating. As soon as the indicators exceed the norm, the button is triggered and the heating element is turned off. Due to breakage or low-quality plastic that melts, the protection does not work - the element does not turn off when heated.

The same thing happens as with the temperature sensor: steam inflates the housing and it explodes. Diagnosis and replacement of the element is necessary.

READ MORE: Types and types of coffee capsules, reusable, saving on capsules

The listed problems are typical for storage boilers.

Since the specifics of the work are different, the reasons for the explosion are slightly different.