How to lay linoleum on old parquet

The sequence of actions when laying linoleum depends only on the condition of the old floor covering. Depending on its condition, different methods are used to secure the material to the base, so first you need to carefully inspect all the dies. If the covering is in good condition, you can lay it directly on it. In other cases, sheets of plywood are needed. People who do not know how to properly lay linoleum on old parquet make several mistakes:

- do not use a substrate;

- they forget to eliminate all rotten dies;

- choose a simpler but ineffective installation method.

Each element of the old coating with cracks and fungus must be removed.

In order for the coating to last longer, you need to choose the right option for securing the material.

Laying method on a flat but stepped parquet

Since the tiles of stepped parquet are less than 10 cm wide, a backing must be laid under the linoleum. Such material should not be thicker than the floor covering. In small rooms, the material is not even secured with glue, but is only pressed with baseboards. With this method, it should not “slide” to the side. If the surface is large, you should first attach the underlay to the glue, and then glue the floor covering to it.

A crease appears on poorly secured linoleum

Such work is carried out only after leveling, sanding and priming the parquet. As a result, the surface should be as smooth as if sheets of cardboard were laid.

Gluing the substrate and linoleum occurs almost the same way. First, glue is applied to the base over an area of no more than 2 meters. Then the material is rolled out and the glued area from the wall is ironed. This is necessary to get rid of bubbles.

If a single piece of linoleum is spread over the entire room, it must be smoothed from one of the walls. When you need to secure 2 sheets, perform a few simple steps to hide the joint:

- lay the sheets so that there is no gap between them;

- after this you need to glue the material with transparent tape along the entire length of the joint;

- then carefully cut the tape in the middle and pour in a small amount of linoleum glue;

- at the last stage all that remains is to smooth out the joint and wait a few minutes.

When the tape is peeled off, the joint will become invisible. For a better idea of how the work happens, it’s worth watching a video on the topic.

Preparing parquet for laying linoleum

Option for laying linoleum on worn parquet

If the parquet is worn out and cannot be sanded smooth over the entire area, use sheets of plywood. They are necessary

After preparing the necessary materials and checking the parquet for mold, you need to perform the work in several stages:

- Secure sheets of plywood or fiberboard one by one with self-tapping screws directly onto the old parquet boards. They need to be laid from the far end of the room, moving towards the opposite wall.

- The gaps that form between the sheets must be filled with sealant. This is necessary to protect the old coating from moisture that may penetrate from above.

After sealing the plywood joints, a backing is laid on the material

- At the next stage, the linoleum is laid without glue so that it stretches.

- At the joints near the walls, excess material should be cut off so that there is a gap of about 1 cm, which will then be covered with a plinth.

- To glue linoleum, you need to roll it up near the wall with the window. When applying glue to its inner surface, you should carefully unwind the material and smooth out any irregularities.

- After this, you need to leave the material for a day and only then fix the plinth.

To prevent signs of wear from appearing on the material, the coating should not be exposed to heavy loads during the first week.

Laying linoleum on damaged parquet

Restoring parquet is not always advisable. However, even with serious damage, laying linoleum will hide all the imperfections. The procedure is quite simple:

- Damaged planks are dismantled using a hammer and chisel.

- The subfloor is cleaned and treated with waterproofing, and a sheathing is created.

- Lay sheets of plywood or fiberboard on the floor, fixing them with self-tapping screws to the old ceiling. All cracks are treated with sealant.

- Spread the linoleum, cutting the edges so that there is a gap of no more than 1 cm between them and the wall.

- Linoleum is placed on the base using glue. The composition is applied from one edge, gradually moving to the opposite side. The material must be smoothed, removing any irregularities.

Installation is complete, but the material is not yet secured with skirting boards

How can you lay it?

You can lay the insulating material yourself. When laying soft flooring, it is important to choose the correct thickness of the additional layer. Try to ensure that the thickness of the backing does not exceed the thickness of the front covering, although ideally they should be the same thickness.

READ MORE: Is it possible to put laminate flooring on old parquet?

A smooth surface of the subfloor is a guarantee that the substrate will successfully cope with the tasks assigned to it, one of which is to increase the service life of the coating. The best way to prepare a concrete floor is a self-leveling screed, and a wooden floor is to lay sheet material.

Laying linoleum on a concrete floor

As in the situation with wooden floors, installation is carried out after all repair work has been completed, the room is completely ready and the material has been pre-matured in a rolled out state. Linoleum is laid on a leveled and clean subfloor.

Floor preparation

Leveling a concrete floor for laying linoleum is much easier than leveling a wooden one. Uncorrected surface defects are visually noticeable on the coating and lead to abrasion of the top layer. Before laying linoleum, check the strength of the screed. If the screed is loose, it should be replaced. If the quality of the screed is good, it is enough to level the base with leveling mixtures, plywood, chipboard or by arranging a dry screed.

Preparatory steps for leveling the screed with mixtures:

- The old floor covering is dismantled.

- All bumps or sagging are removed from the concrete base by grinding.

Cracks or potholes are repaired using leveling mixtures.

The surface is sanded, dust-free, and treated with a primer.

The thickness of the leveling layer in the presence of freshly repaired damage must be at least 5 mm. After leveling, the maximum permissible deviation of the floor surface from the horizontal in length or width is 0.2% of the corresponding linear dimension. The clearance between the floor surface and a 2 m long batten is no more than 2 mm. Work begins when the screed humidity is no more than 5%.

Laying linoleum

The processes for laying linoleum on wood and concrete floors are similar, but on a concrete base, linoleum without a base will definitely require a backing. The main functions of the substrate are noise and heat insulation of the floor. Additionally, the substrate will help eliminate minor surface defects, but you should not count on leveling out large flaws.

As a substrate, roll materials made of foamed polyethylene, cork, jute, flax, wool are used, and there are combined options. Substrates made from natural materials are more environmentally friendly and do not shrink.

How best to lay linoleum

To lay linoleum on a concrete floor, there are some ways:

Free installation, used mainly in small (area up to 20 sq.m.) rooms. For fastening, adhesive tape is used, with an adhesive coating on both sides. With this method of flooring, an allowance of 8 centimeters of material is left on the walls. In those rooms that are used very rarely, use double-sided tape.

Particular attention should be paid to the entrance part of the room, this is where the load is highest.

Method of gluing linoleum to the base of the floor. It is designed for rooms with a large area and existing furniture structures that are moved quite often

This method is also suitable for a room where a large number of people are constantly present. After gluing the linoleum, the surface must be given time to dry.

Any installation method requires care and proper cutting of excess material along the base of the wall with a sharp knife.

Having chosen the method that is most suitable for you, you can lay the covering. To do this, you should take the following component materials: linoleum selected in accordance with the interior of the room; welding for gluing seams (hot or cold); glue mixture; ruler, scissors, construction knife and pencil; spirit level to check the absence of surface irregularities; mixture for leveling the base of the floor (if necessary); primer; waterproofing material; adhesive tape used in construction; plinth and a set of fastenings for it.

How to properly care for linoleum

Linoleum is washed from dirt with a rag, a soft brush or a washing vacuum cleaner. As detergents, use a soap solution or warm water with a temperature of no more than +40 °C. Do not use solvents or abrasive cleaners for cleaning.

Care Tips:

- Contact of the coating with the rubber is undesirable. Traces of shoe polish or bitumen-containing substances must be removed immediately, otherwise stains may remain on the linoleum.

- To protect against mechanical damage, place gaskets or put on protective caps under furniture legs.

- To protect the linoleum from abrasion by sand or pebbles brought in from the street, mats or gratings are placed at the entrance.

Types of linoleum

Today, many manufacturers offer two options for flooring: natural - marmoleum and artificial. The first, although more expensive, is eco-safe and highly wear- and fire-resistant.

Artificial comes in four types:

- Polyvinyl chloride is the most common. Made in various colors and textures. It is divided into commercial, household and semi-commercial. Household and semi-commercial products are suitable for residential premises; they can be laid independently.

- Rubber relin based on rubber is used in the finishing of public institutions, on sports grounds, as well as in industries.

- Alkyd or glypthal type of coating, made from alkyd resins, has excellent heat and sound insulation characteristics. However, it is rarely used in residential areas because it is not fire resistant, does not tolerate low temperatures well, and shrinks easily, resulting in cracks.

- Colloxylin or nitrolinoleum has a high degree of elasticity and wear resistance. However, it is highly flammable, so this type of coating is not used for domestic purposes, or in children's institutions.

How to calculate the required quantity

It's actually quite easy to do. The main thing is to calculate the area of the room that you plan to cover

It is important to consider doorways and spaces under windows

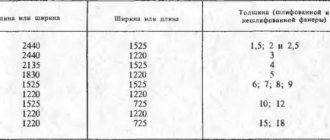

When purchasing, pay attention to the width of the roll to avoid joining. Most manufacturers offer marmoleum with a width of 2 meters, but there are also samples of 2.5 meters

As for PVC coating, there is more choice here, in the range from 1.5 to 5 meters.

Experts recommend purchasing linoleum with a margin of 10 cm on each side. If the material has a pattern, the supply may be larger.

How to level a concrete floor

Alignment can be done in the following ways:

- Stapling. It can only be applied if the defects are minor. With the help of a special building mixture, depressions and cracks are covered;

- Leveling mixture. If there are significant level differences, filling with leveling fluid is necessary. In this case, you can vary its thickness, changing the density during harvesting;

- Installation of wooden covering. Since it is not always possible to lay the covering due to its severe deformation, the best way would be to install an additional structure made of fiberboard, chipboard or dense plywood.

Typically, cement-sand mortar is used as a screed.

Given the importance of the requirements for the quality of the base, before laying linoleum on a concrete floor, you need to check whether it is strong enough and whether the concrete is prone to cracking. This is done using the example of a small portion of a solution of the desired consistency.

They fill a small area with a layer of up to 20 mm. The following deviations from the norm are possible:

- the screed crumbles in your hands - you need to enrich the mixture with cement;

- cracks appear - you need to add sand to the mixture.

However, it should be noted that this screed will take several weeks to dry and shrink. You can level the floor faster and better using modern special self-leveling mixtures.

To get the best possible result, it is recommended to additionally coat the screed with a finishing primer.

If necessary, an additional thermal insulation layer is installed. This is especially true for apartments located on the ground floor or for private houses. The installation technology depends on the type of insulation chosen. It is mandatory to ensure minimal heat loss and reduce the likelihood of moisture affecting the decorative material.

Before laying linoleum on a concrete floor, debris is removed and leveling is done

Particular attention is paid to the joints of concrete slabs. They must be filled with leveling mixture at the same level as the rest of the base surface.

Advice

To protect against moisture, installation of a waterproofing film is necessary. For this you can use polyethylene with a thickness of up to 200 microns.

Concrete base

The main requirements for a concrete floor are evenness and integrity. To achieve this, additional work will be required. It is recommended to level and correct damage using the following methods:

- “Wet” screed + self-spreading mixture.

- Dry screed + wood boards.

The performance characteristics of the future floor also depend on the chosen linoleum. Three types of this material can be found on sale:

- Domestic.

- Semi-commercial.

- Commercial.

The first option is the cheapest, but its durability is sometimes not enough even for ordinary living rooms. The commercial type will last a very long time, but it has a high price and its own design nuances (quite thick). The ideal option would be a semi-commercial type of coating. It has an affordable price, and it can even last for several decades.

Types of linoleum

Linoleums can also have a two-layer construction, when in addition to the synthetic coating itself, there is also a small lining underneath. This option is suitable when there is no substrate between the concrete and the coating, or it is made of wood boards. For laying on additional substrates, a single-layer construction is suitable.

By following these recommendations, you will be able to choose a material that will last a very long time and at the same time look good.

New screed

After choosing materials, you need to prepare the base. One option is a “wet” screed. The application process consists of several stages:

- Cleaning the coating. All debris and dust are removed from the room, leaving clean concrete behind.

- All joints are sealed. For the joints of concrete slabs and for damaged areas, concrete mortar or foam is used. The seams between the floor and walls are covered with insulating tape.

- Water protection. The simplest and most reliable option is film coating. Its strips are connected to each other with tape. The film should cover the entire area, and also protrude slightly onto the walls to reach the level of the future coating.

The film will protect from water

Advice. The “wet” mixture expands when hardened, so damping tape can be glued along the wall.

- The upper level of the screed is determined. The highest section is found along the wall, and 30 mm upward is measured from it. It is advisable to mark the level with a laser level, and then repeat its drawing with thread or pencil.

- Laying beacons. Their function will be performed by sections of perforated profiles, and plastic construction wedges are used for adjustment.

Lighthouses

- Preparation of the solution. The contents of the bag should be poured into a container with water (the proportions are indicated on the packaging), then mix thoroughly. For this, a drill with a special attachment is used.

- Filling. The resulting mixture must be poured between two profiles with a gradual transition to other blocks. It is convenient to remove excess material to the next section using a construction rule.

Applying a “wet” screed

The approximate drying time of the solution should be indicated on its bag. This usually takes no more than 7 days.

Leveling mixture

Small irregularities may form on the surface of the dried screed. For correction, self-flowing liquid compounds are used, which themselves find the desired level and harden.

How to level a floor under linoleum

Application nuances:

- The mixture is poured more or less evenly onto the surface.

- The composition is distributed throughout the room with a spiked roller.

- You need to wait until the mixture evenly covers the base and hardens.

- The final step will be priming. It is recommended to apply it in two layers.

Leveling a self-leveling mixture

This method allows you to achieve almost ideal evenness of the concrete base. It is also distinguished by the ease of performing work.

Methods for laying linoleum on a concrete floor

Options for attaching the covering to the floor largely depend on the size of the room and its purpose.

The correct technology for laying linoleum on a concrete floor is:

- in a free way;

- for glue or mastic;

- on double-sided tape.

Installation of linoleum using the free-laying method, suitable for small rooms with low traffic.

The best option is to lay the covering in one piece, pressing it around the perimeter with a plinth attached to the wall.

In the doorway, the edge of the flooring goes under the threshold.

Along the walls, a technological gap of 0.5 mm is left to compensate for changes in size under the influence of different temperatures.

The adhesive installation method is good for large spaces and high traffic indoors, as well as when cutting material to cover the area with several pieces of linoleum.

In the case of a concrete floor, this method of installation is technically more difficult, but provides the most reliable connection.

Double-sided tape is used for surfaces of any size.

This type of linoleum installation is better than free covering, but with a concrete base, there is no guarantee against deforming shifts.

Laying linoleum on a concrete floor with tape

Before laying out the linoleum, a grid of adhesive tape is made on the concrete surface. The smaller the cell size, the better the adhesion of surfaces.

Lay the roll on top, roll it out, cut it along the walls.

Then we bend half of the canvas and prepare the base for installation by removing the protection from the top of the double-sided tape.

Starting from the middle, carefully straighten the material, smoothing it and pressing it against the strips of adhesive tape.

It is important to immediately lay the linoleum in such a way as to minimize the movement of the adhesive tape at the base, where the coating will hold tighter. You can decorate with skirting boards immediately; in doorways, the material is secured with metal strips or thresholds.

You can decorate with skirting boards immediately; in doorways, the material is secured with metal strips or thresholds.

Laying linoleum on a concrete floor with glue or mastic

When choosing the most reliable method of laying linoleum, think about the selection of adhesive composition.

It depends on the type of coating and the characteristics of the material.

Mastic is good for concrete floors, linoleum with a fabric base, placed on a bitumen mixture.

Baseless coating - for compositions with rubber, dispersion solutions are optimal for linoleum with pile.

There are also many varieties of glue; for residential premises, water-dispersed ones are mainly used, which are easy to use and safe for health.

We lay out the linoleum in the room, bend it in the middle, and apply the adhesive to the floor.

We spread the coating, smoothing and adjusting the position. Repeat for the second part of the room.

In this case, the skirting boards are fixed after the glue has dried, since mechanical impacts on the coating are excluded during this period.

Tools and materials

Laying linoleum on a concrete floor is carried out using the following set of tools and aids:

How to lay linoleum on a concrete floor using glue? First you need to understand the types of adhesives.

Synthetic adhesives (Bustilat) and mastics (Syntolax, Gumilax) on a latex basis are used for interior and exterior work, suitable for PVC coatings, wallpaper, polymer materials, wooden products, etc.

Kawabanga! Plastering walls made of expanded clay concrete blocks: types and features

Water-dispersed adhesive (Homakol, Forbo) for household polymer coatings is perfect for gluing linoleum, carpet, cork tiles, etc. It has good adhesive properties to any absorbent substrate, does not shrink, and is frost-resistant.

About laying linoleum

Linoleum is a floor covering that, in addition to its attractive appearance, has favorable technical characteristics. And the service life of the coating in this case depends not only on its density and wear resistance, but also on the correctness of its installation on the concrete screed.

We calculate the material

When carrying out repairs yourself, you should first of all calculate the amount of linoleum so as not to purchase excess material.

- We measure the length and width of the walls.

- Multiply the length by the width to find the area.

- To the resulting number you should add another 10 cm2 for cutting.

Preparing the base

Preparation consists of the following stages:

- First of all, you need to remove the old coating.

- Correction of uneven floors.

- The final stage of preparing the base is to remove debris, grease and other contaminants.

Regardless of which base you choose, it must be laid on a perfectly flat surface that will not suffer any damage. If base defects are detected, they must be carefully corrected. Otherwise, the new linoleum will not serve you for a long time.

Leveling the concrete floor.

Despite the fact that linoleum is a fairly wear-resistant and durable material, the presence of potholes on the base of the floor will lead to cracking of the coating over time.

There are two common solutions to this problem:

- The most effective method is to level the floor with a thin layer of cement screed. This allows you to achieve a perfectly level base.

- If there are several deep depressions on the base, they can simply be “sealed” with putty, without touching the even parts of the floor. This is the simplest and most economical method, but it is not suitable for foundations with multiple irregularities.

Methods of laying on a concrete base

So, there are several ways to properly lay linoleum on a concrete floor.

Let's look at them in order:

- The flooring is laid directly on the concrete screed, without being fixed to it in any way. This method is an excellent option for small spaces when the load on the flooring is insignificant.

- Laying with gluing on tape. This is the easiest way to achieve reliable fixation of the material on the floor. In this case, you can prevent rapid wear of the coating.

Installation with double-sided tape.

- Gluing using construction adhesive and special mastics.

If we compare all three methods, the last one can be considered the most optimal. Despite the certain labor intensity of the process, this method will be the most effective. And if we talk about rooms with a large area, then this method will be much more effective than gluing it with tape.

Experts advise gluing linoleum to mastic in halls, living rooms, corridors and hallways.

Work technology

As mentioned earlier, laying linoleum on a concrete floor with your own hands is not difficult. After reading some recommendations, it is not difficult to lay such a covering without outside help.

Selection of materials and tools

The concrete field itself is quite cold, so when choosing a covering, pay attention to multi-layer linoleum on a felt basis. This coating is more expensive, but the price fully corresponds to the properties. Based on the size of the room, you should not take the material exactly as measured - it is better to take a few centimeters of stock. If the pattern is large, and one piece will not be enough to cover the entire room, take the material taking into account the fact that you will have to select a pattern.

You don’t need any special tools for DIY installation – just have a brush and rollers on hand. Only at the cutting stage you will need a knife (stationery or construction knife, depending on the thickness of the coating), a square and a ruler for accurately marking the lines.

Having unrolled the linoleum roll, transfer the floor plan onto it with chalk.

When purchasing linoleum, you can ask for it to be cut right in the store, but there is still a chance that you will have to cut it during installation. Cutting is not a difficult process; all errors and uneven edges will be hidden by the baseboards. If there are protrusions, columns, or pipes in the room, it becomes necessary to cut out some sections of linoleum in shapes. For such work, you need to prepare cardboard templates - then errors and irregularities will be minimal.

Before laying, linoleum with an exact pattern must be laid face up, the borders should be joined to ensure the correct placement of the pattern, and fixed with a heavy object to prevent the knife from slipping along the linoleum while cutting the material.

Actually, we have reached the main stage of work. There are several options for DIY installation - for example, in a low-traffic room with an area of up to 20 square meters. m do not require additional fasteners at all - just secure the linoleum with a plinth. For other cases when it is necessary to lay linoleum on a concrete floor, there are three most common, simple methods.

On a concrete screed

Craftsmen recommend making a concrete screed before laying the covering - this will level the base and the linoleum will lie more tightly. Before pouring the screed, there should be no debris or any debris on the concrete floor that could spoil the smooth surface. Pour the cement mixture, level it over the area of the room and wait until it dries completely. Next, it is recommended to carefully clean the surface with a brush and lay the linoleum, which has previously been left unrolled for several days.

We recommend: Do-it-yourself installation of heated floors

Gluing with tape

This method is best used if you need to lay linoleum on a concrete floor, but the coating is not too rough. First, double-sided tape is glued to the prepared, cleaned and degreased floor, without removing the protective film on the other side. The strips of adhesive tape should form a kind of grid - this way the linoleum will hold more firmly. We spread the covering, fold one half and remove the protective film from the tape. Carefully unfold the canvas, then you need to level it, simultaneously pressing it to the floor - with your hands or with a roller. We do the same with the other half of the linoleum.

Using construction adhesives and mastics

It is best to buy adhesives in the same store where you buy linoleum - a consultant can tell you which product is best suited for this type of coating.

There are two types of adhesives, they are divided depending on the gluing method: for continuous and for fixation. The costs of the second are much lower, and application is less labor-intensive. Manufacturers offer the following types of adhesives:

- water-dispersed;

- one-component;

- two-component;

- on a solvent;

- polyurethane;

- for fixation.

When laying linoleum, glue is applied with a notched trowel, roller or brush.

The glue is applied over the entire floor area or pointwise around the perimeter of the room (adhesive for fixation). Due to the properties of moisture resistance and high strength, bitumen mastics are often used when laying linoleum. If the work takes place in a room with a large area, then the use of mastic is a must. In addition, with the help of this material you can isolate the floor from the harmful effects of moisture, level out minor defects and unevenness after concrete screed.

Before applying mastic, the floor must be well primed, the composition is applied to the floor and linoleum - a layer of about half a millimeter for a thin coating, for a coarser one - up to 0.9 mm. When choosing mastic, give preference to well-known manufacturers - their products are of high quality and reliability.

Welding joints

Exactly following the technique of laying linoleum with your own hands is not enough for a good result. Incorrect joining of the panels can ruin the entire appearance of the floor. There are two welding methods for joining linoleum sheets - cold and hot.

The advantage of this type is that it requires a minimum of time and effort. In fact, it is not much different from ordinary gluing. Tape is applied to the joints and cut along the joining line. Glue is poured into the resulting gap; after it dries, the adhesive tape is removed.

Hot welding of a freshly laid coating is not recommended.

Hot welding requires more time and precision when working, but this is justified by the result. The seams become almost invisible, the life of the linoleum is noticeably extended.

For hot welding, you must have welding equipment and a special fastening polymer cord. The work can be divided into two stages:

- Place the cord in the welding machine, heat to 350 degrees Celsius. The side from which the paintings will be fastened does not matter, but is carried out exclusively in the direction of the middle of the room. The melted cord is poured exactly into the gaps, after the product has hardened, the excess is cut off using a sickle-shaped knife (you can also use other types of sharp cutting tools).

- The equipment is transferred to the other side, and the polymer begins to be poured. The center seam should lie on top of what was just applied; after application, repeat the procedure for removing excess with a crescent knife.

It is more difficult to align joints on linoleum with a large pattern - make sure that the pattern matches correctly. And most importantly, this process cannot be rushed.

Types and advantages of linoleum

Depending on the materials used in production, linoleum is divided into types:

- natural;

- artificial.

In the composition of natural linoleum you can find cork flour, lime, tree resin or linseed oil. Most often, felt or jute is used as a base. The presented type of linoleum has two big advantages - environmental friendliness and a high fire safety class.

Artificial linoleum is divided into subtypes:

- made of PVC;

- rubber (relin);

- glyphthalic;

- nitrocellulose.

Linoleum made from polyvinyl chloride is popular due to its low prices and a wide range of colors and patterns. This coating is characterized by a strong odor that disappears over time. In hot weather, toxicity in the material is activated, and linoleum may decrease in size. When exposed to low temperatures, the coating may begin to crack. The rubber type of linoleum is distinguished by a rubber coating. It spreads only in industrial and other non-residential premises due to dangerous fumes. The material is characterized by special strength and resistance to moisture.

The glyphthalic type has high heat and sound insulation properties. The strength of the material is somewhat inferior to PVC coating. It has a short service life and over time, such linoleum changes in size - it becomes shorter along the stripes and longer across them. Brittle, prone to cracks.

Nitrocellulose coating (colloxylin) is spread in non-residential premises, like a gym. The material is durable, moisture-resistant and elastic. It has significant disadvantages - it is highly toxic and fire hazardous in hot weather.

Among the advantages of linoleum are:

- versatility - the selected copy will suit every room;

- undemanding to cleaning - wet cleaning is suitable;

- durability and strength;

- scratch resistance, does not wear off over time;

- levels floors with defects up to 4 mm;

- is resistant to water.

How to properly lay linoleum on a concrete floor: instructions and video

The use of linoleum as a flooring goes back to Soviet and early post-Soviet times, however, with the constant development of technology, production capacity and design, modern linoleum should not be considered a relic of the past - both the quality and visual characteristics of this material have increased. Linoleum is very popular in many office spaces due to its resistance to wear and relatively low susceptibility to mechanical damage; it can and is successfully used in apartments and houses.

Typically, linoleum is laid in rooms with high humidity - kitchens, hallways, balconies and loggias, but due to the variety of patterns it can also be used in living rooms.

Visually, using linoleum you can imitate a stone, tile, laminate or parquet coating, but it is much cheaper and easier to install yourself than any of the listed coating options.

From the traffic jam

To make it, crushed cork bark is used. Cork is an intermediate derivative of wood, which explains the content of lignin and the waste product of the honey bee - wax, due to the presence of cerin. It is these components that give the cork its hardness and resistance to moisture, and its elasticity is due to the unique content of many natural ingredients.

READ MORE: How to insulate the floor on a loggia with your own hands - insulation installation technology

Pros:

- High sound and heat insulating properties.

- Hypoallergenic.

- Good leveling ability.

- Resistant to the formation of rot, mold and mildew.

Minuses:

- Excessive softness, and this is almost always undesirable when working with linoleum.

- There are restrictions on flooring in high humidity conditions.

- High susceptibility to deformation under pressure from heavy furnishings.

- The need for strict adherence to installation technology.

- High price.

Base under linoleum

Before you begin laying the flooring, you must carefully prepare the subfloor. Linoleum is elastic in its structure, and over time it repeats all the shapes of the base on which it is laid.

Therefore, any base before installation must meet the following requirements:

- Durable and smooth surface;

- Solid subfloor;

- No traces of paint;

- No moisture or greasy stains.

Plywood base

Compliance with these conditions will help extend the life of the coating.

On a concrete base

Remember that laying linoleum on a concrete floor is carried out at a temperature not lower than 18C and a humidity not higher than 68%. Before laying, the floor covering is spread out, leveled, and time is given for the material to “settle.” Then they begin cutting the material.

The covering is laid out taking into account the location of the pattern, and a margin of 10 cm is left at the edges. After gluing the coating, the remnants can be carefully trimmed. All seams formed should be positioned away from the window in the direction of the light so that they are invisible. For installation you will need the following tools: roller, knife, ruler.

Preparing the concrete base

There are several options for laying linoleum on a concrete floor, which can be combined if desired:

- Without glue - the method is fast, used in small spaces;

- With adhesive tape - in this case, the linoleum is secured with adhesive tape, which extends its service life;

- Using mastic or glue is the most effective method of installation, and is necessary for large areas.

Installation with glue

The choice of installation option depends on the area of the room and the loads. But to avoid the formation of folds and waves, it is better to glue it. It is also determined in each specific case whether a substrate is needed for laying linoleum on a concrete floor.

On a wooden floor

A wooden floor can act as a base for decking. A linoleum underlay on a wooden floor is not required, since the floorboards retain heat well. Only the floor needs to be prepared before laying. Replace unusable boards, clean them, hammer in all protruding nails and seal all cracks and crevices.

Base wooden floor

After leveling, a primer is applied to the wooden floor, which creates a protective layer against moisture, insects and mold. After the boards have completely dried, you can begin laying the flooring material.

Sometimes plywood is laid on a wooden floor as an underlay for linoleum. In addition, plywood can thus hide all the unevenness of a wooden floor. The plywood is laid offset, cleaned, and the seams are sealed with putty.

Laying without underlay

Laying linoleum is the same as on a concrete floor. In the process, the question arises: is a backing for linoleum on plywood additionally needed, as insulation? Of course, it can be used as an additional measure to extend the life of the flooring material.

See which insulation is best to use under linoleum on a wooden floor. Usually these are soft and loose materials that easily take shape.

Linoleum on linoleum

It is possible to lay a new coating on old linoleum if there are no defects on it and it is impossible to remove it from the floor surface. In this case, the old coating will serve as an insulating layer.

Restoration of defects on old linoleum

If there are flaws or tears on the old coating, restoration is first required. After that, the surface is sanded with sandpaper and a primer is applied. Only after such preparatory work can new flooring material be laid.

For ceramic tiles

When laying linoleum on ceramic tiles, first clean the tiles of all contaminants and seal the seams flush with the tiles. After the leveling solution has dried, you need to polish the surface well, after which the final screed is done. After the screed has dried, the flooring can be laid. It is recommended to lay linoleum on a substrate to avoid sagging at the seams.

Screed on top of ceramic tiles

It is difficult to lay linoleum on glossy tiles. This will require significant financial and physical costs. Therefore, such flooring should be removed rather than covering it.

Preparation and alignment

The instructions recommend the following:

- The old coating must be dismantled and the condition of the concrete underneath must be checked. If you need to cut reinforced concrete with diamond wheels for laying communications, do all the work at this stage.

- Cracks and depressions should be filled with putty, and excess should be knocked down. (See also the article Putty on concrete: how to do it.)

- Remove debris and dust.

- Measure the height difference; if a deviation exceeds 2 mm per square meter, a new floor screed must be poured.

Today, self-leveling self-leveling mixtures are often used to treat floors. They are applied to a previously primed surface.

Advice: when the work of distributing the self-leveling mortar is completed, you need to give it sufficient time to dry, since the linoleum will not let the moisture remaining underneath it pass out, which will lead to mold or rotting.

Preparing the floor for installation

Choosing material

When selecting floor coverings, you need to take into account the fact that concrete is always cold. To provide warmth, comfort and increase sound insulation, multi-layer linoleum is more suitable, the base of which is foamed or insulated with felt, the price of which will be higher than single-layer.

Before going to the retail outlet, take simple measurements so that there is exactly enough material for the entire area of the room. It is best to determine the length of each wall in case it turns out that they are not the same. Then 10 cm is added to the area of the room for cutting.

- if the area does not exceed 6 m 2. leave 2 cm for the allowance;

- when the size varies from 6 to 10 m2. 4 cm is required;

- more than 10 m, which means an allowance of 6 cm.

Advice: when there is a pattern on the linoleum, and one piece is not enough to cover the room, you need to take the material in such a way that it is enough to select the pattern.

If there is any doubt that the seams will turn out perfect, they are “hidden” under the furniture. The covering should be laid perpendicular to the window in the direction in which the sun's rays fall. This will help make the seams and joints not very noticeable, and the surface will look solid.

We recommend: How to cover cracks in a wooden floor

The width of linoleum that our stores offer can range from 2 m to 5 m. If possible, it is better to choose a covering that can be laid in a whole piece.

Services for cutting linoleum can be offered by the store where you decide to buy the material. But it is possible that during installation there will be a need for trimming. (See also the article Insulation for concrete: features.)

It’s easy to cut along the edges, because unevenness and errors will be hidden by the plinth. When laying linoleum end-to-end, you will have to cut carefully and precisely. To get a perfect seam, overlap two adjacent pieces and then cut together to avoid gaps at the joint.

Trimming material near the wall

- knife - a stationery knife is suitable for thin materials, in other cases it is better to use a construction retractable version;

- square;

- ruler.

When there are protrusions (pipes, columns) in the room, you will have to make cutouts in the linoleum for beautiful installation. Here you will need to prepare a pattern made of durable cardboard, with which you can cut the coating.

Tip: For laying pipes and conduits, diamond drilling of holes in concrete with bits of various diameters has proven itself well.

Before performing all activities, linoleum with a pattern is laid out face up and the pattern is joined. To prevent the material from slipping while cutting by hand, weigh it down with heavy objects until the operation is completed. According to the markings, the linoleum is pressed with a ruler and cut off with short movements.

After preparing the necessary pieces, they proceed to installation, which may require a brush, rollers, a knife and a ruler.

Laying options

- If the area of the room is small (less than 20 sq.m.) and there is low traffic in it, linoleum is not glued at all . Simply secure it with a plinth. But material that fits tightly at first can subsequently form “waves” in some places.

Advice: many people ask the question - what to put under linoleum on a concrete floor? Use a backing made of cork, linen, wool or jute.

Wool underlay for linoleum on a concrete floor

- The best choice for large rooms and rooms where there is frequent and intensive foot traffic is the decision to glue linoleum to a concrete base . This process is quite labor-intensive, but the result will fully justify the inconvenience incurred during installation. You can use tape, glue or mastic as an adhesive substance.

Using glue or mastic

When choosing such a “mount” for a floor covering, you should purchase it at the same time as purchasing linoleum. In this case, the consultant will competently select the composition that is suitable for your linoleum.

So, let's look at how to properly lay linoleum on a concrete floor using adhesives:

- It is better to glue linoleums with a fabric base using bituminous synthetic mastic or dispersion adhesives.

- If the base is heat and sound insulating (linoleum on TZI), only dispersion glue is used.

In the photo - how to lay linoleum on a concrete floor using glue

- For baseless, the best choice is mastic, which is based on resins and synthetic rubber.

Adhesives vary depending on the type of bonding they provide. There is glue for continuous gluing or only for fixation.

In the latter case, it is applied faster and easier, and its consumption is not so great, since it only needs to be spread around the perimeter of the room.

- When starting installation, make sure that the temperature in the room where the work is being carried out is not lower than 15˚ C.

- Unscrew the panel and apply glue to the floor underneath it.

Tip: Use a notched trowel, roller or brush for convenience.

- Return the panel to its place, press it well and smooth it with a dry roller.

You can also use double-sided tape, which should first be glued to the floor. The top protective film should remain in place.

After this, the finishing material is laid on top, half of its panel is folded back and only now the protective film is removed, and after that the linoleum is turned in the opposite direction. The second half is processed similarly.