Why is regular maintenance essential?

In addition to the occurrence of emergency situations, the accumulation of scale in a pipeline heating system also sharply reduces its efficiency. Thus, just a millimeter of scale on the inner surface of a heating radiator reduces its heat transfer by 15 percent. Accordingly, in order to achieve a normal temperature in the house, you will have to increase the power of the boiler, and therefore increase fuel costs. In order not to incur extra costs, you need to clean the system.

The accumulated scale on the internal surfaces of the system has a much lower thermal conductivity than conventional metal used to make pipes. Scale is essentially a heat insulator - its thermal conductivity is 40 times less than that of metal. Even a thin layer of scale reduces the efficiency of the heating system to minimum values. Moreover, scale actively interacts with the metal of the pipes, which leads to increased corrosion and even the formation of fistulas.

Before and after washing

In order to improve the quality of operation of the heating system, it is not necessary to wait for emergency situations. Such work must be carried out regularly, usually at least once a year.

Why is it necessary to flush the heating system?

Scale that collects on the walls of pipes and batteries causes numerous problems. Firstly, the mechanical wear of pipes is significantly accelerated. Secondly, the heat transfer of the system is significantly reduced, and this is a negative factor. Thus, experts say that scale 1 mm thick reduces the level of heat transfer by 15%, because The thermal conductivity of scale is approximately forty times less than that of metal. This indicates that even a thin layer of scale damages the metal and can lead to the appearance of fistulas and rupture of pipes.

In addition, key heating indicators change in a negative direction. This means fuel costs rise and efficiency falls. As you can see, the consequences are significant, so flushing heating pipelines and radiators is extremely necessary.

The above can be summarized as follows: the main purpose of heating flushing is to achieve maximum savings in heat and money for the consumer. It is necessary to clearly understand that pipes clogged with various deposits often cause emergency situations. Ideally, flushing heating radiators and pipelines should be done once a year.

Before performing a range of work, you should diagnose the system. The obtained indicators will show the specialist the full picture, that is, he will know the composition and nature of the deposits. Based on the results, the appropriate equipment will be selected, and after washing, it is necessary to perform anti-corrosion treatment of the pipe walls. Thanks to this procedure, the appearance of deposits and scale is prevented for some time.

Heating system diagnostics

To identify the need for hydropneumatic flushing of the heating system, it is necessary to carry out an initial diagnosis. It can be carried out at home, without resorting to the services of expensive specialists. It is based on the diagnostic results that it is necessary to decide on flushing. In addition, after routine maintenance, gently subject the heating system to anti-corrosion treatment - this will reliably protect the walls of the pipelines for the next operational period.

So, the main signs that your heating system needs hydropneumatic flushing are the following:

- Your heating boiler is making unusual sounds that you have not heard before,

- The time it takes to warm up the system to operating condition increases significantly.

- One of the main signs is uneven heating of heating system elements. So, if the pipeline system is hot to the touch, and the radiators are much colder, it is necessary to urgently flush it.

- An indirect sign of a clogged heating system is an increase in energy consumption when the same temperature is reached and in similar weather outside.

How is hydropneumatic flushing carried out and what equipment is needed?

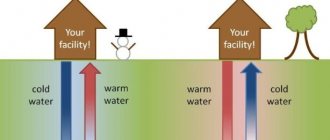

The main essence of hydropeneumatic flushing of a heating system is cleaning the pipeline system and heating radiators using compressed air pressure . In this case, the coolant remains in the system, that is, water. The beginning of this process sharply increases the speed of fluid movement in the system, and compressed air gives the water increased turbulence, that is, uneven movement and the formation of turbulence. Under the influence of a mixture of air and water, scale and deposits formed on the internal surface of the system are loosened, carried away by the water-air flow and removed from the pipes and radiators to the discharge point.

compressor

The discharge point for loosened deposits in this type of flushing is the drain pipe or a specialized tap. If these elements are missing in the heating system, they must be inserted before starting cleaning.

If the heating system with liquid coolant has an elevator, it must be dismantled before flushing to avoid damage.

The air in the heating system is supplied from a compressor to create a powerful water-air flow with turbulence. This device should show a pressure of 0.6 MPa at the outlet. In order to prevent water from entering the compressor receiver from the system, a check valve is installed at the point where it connects to the pipeline system.

A good compressor with a powerful and uniform air supply supplies the pipelines with a water-air mixture, which loosens and knocks down scale deposits inside the pipes. The compressor must operate in a uniform pulse mode, creating not just a constant flow of air, but a series of air-water shocks. This is how the turbulence that loosens the scale is formed.

A smart solution is to use a compressor that can add disinfectants and cleaning agents to the air flow. In addition, such a device must be protected from spontaneous shutdown, be quite compact and, preferably, have an alarm about the level of the flushing liquid being consumed and the displayed pressure parameters.

Standards for flushing heating systems

Before starting cleansing, you need to know about the key techniques, varieties and stages of this procedure. If you don't adhere to the regulations, you can complicate the situation. It is necessary to take into account all the characteristics of this pipeline, take into account the injection of the medium supply inside, in order to avoid the occurrence of fistulas and ruptures, and also use only high-quality equipment

First you need to do initial testing. Symptoms that can be used to determine whether pipes are dirty are determined by several methods.

Depending on the results, you should decide whether cleaning is necessary; You will also need to make calculations: the length of the line to be washed, p of the sphere, which is set depending on the ø of the pipes, as well as the speed of the liquid inside; It is important to divide the pipeline into separate fragments in order to achieve the required rate of water-air solution; The heating system is cleaned, after which it is necessary to determine the need for pressure testing;

The very procedure of flushing the systems, which is necessarily carried out on the eve of the winter protection period, makes it possible to establish the tightness of the configuration. The need for the hydropneumatic method also appears in emergency cases: after assembling the pipeline, radiators and individual heating structures, it is not possible to correctly determine the completeness and tightness of the contact modules.

By following the described scenario and using models that help to establish all the distinctive features of the pipeline, in addition, by performing the necessary calculations, you can flush the OS using the above technology.

Timely cleaning will allow you to avoid emergency situations.

Hydroflushing, how and why

Hydropneumatic flushing of a heating system is based on simultaneously supplying air under pressure in a certain amount and water to sections of pipelines. The water-air mixture that is formed in this case cleans the heating communications thanks to multiple pulses performed by the flushing compressor.

Pulses in pipeline water create small bubbles, which gradually destroy deposits on the walls of heating communication pipes.

In order for the washing process to be successful, it is necessary to perform the following calculations:

- Length of pipelines that will be flushed;

- Air flow and pressure determined based on pipe diameters;

- Water speeds and flow rates.

Important! In order to obtain the required speeds of the water-air mixture, it is necessary to perform flushing in separate sections, that is, in groups of risers or individual risers.

Typical scheme for carrying out work

We recommend: Insulating a wooden house with mineral wool from the outside under siding - step-by-step instructions

Preparation

For the hydroflushing process to be successful, you need to take an individual approach to each heating system and take into account its features.

Ideally, before the process it is necessary to carry out preparatory measures:

- Inspect all heating communications;

- Determine sections of pipelines (risers, groups of risers) that will be washed separately and break them down into stages;

- If necessary, you need to install shut-off valves to block sections of pipelines and remove washed deposits from the heating system;

- Make calculations of air and water consumption to obtain the required result after washing;

- Determine the need for hydraulic testing (pressure testing) of pipelines.

Connected equipment to the elevator

After all the preparatory measures have been carried out, the heating systems are hydroflushed until the water-air mixture becomes lighter. After washing, repeated pressure testing is performed.

The quality of the flushing performed is assessed by the reduction in the hydraulic resistance of the heating system, which is determined after and before hydraulic tests.

Method for cleaning the heating system

A pipe with a diameter of twenty to forty millimeters is inserted into the supply. The pipe is equipped with shut-off elements and check valves. Next, you can begin to supply water and compressed air to the system.

If you had to deal with a small system, then it is possible to supply water and air through existing pipes. If there is excess water, it can be discharged through drain taps or a drain pipe can be specially installed for this purpose. If there is an elevator, then the cone and glass are removed before washing.

Dismantled heating elevator

Compressed air is supplied to the heating pipelines thanks to a compressor, which you can see in the photos and videos in our gallery. The compressor produces air with a pressure of about 0.6 MPa. To prevent the flushing liquid from entering the compressor receiver, you need to install a check valve on the pipeline. Pressure gauges with a scale of up to one megapascal are installed on the supply and return pipes.

Important. The price of the compressor is quite high, but if you have the desire and want to do the washing yourself, you can rent it from a specialized store. This way you will save your money because you are unlikely to need a compressor in your daily life.

The washing itself can be carried out using two methods:

- Flow-through. The heating supply pipelines are first filled with water with the air collector valve open. After filling the pipes, the valve is closed and the supply of compressed air begins. Both the air and water mixture are simultaneously supplied to the pipelines.

Flushing is stopped when clean water begins to flow through the pipe. After this, the water is drained into the drain. This method is used to clean heating and hot water systems;

- Filling method. With this method there is some consistency in actions. To begin with, the pipelines are filled with water and the valve is closed. Compressed air is supplied to the second pipe for fifteen to twenty-five minutes, depending on the diameters of the pipes and contaminants.

After the air supply has stopped, close the valve and drain the water through the drain pipe. Upon completion, the system is rinsed several times with clean water.

Carrying out hydropneumatic flushing of the heating system

How hydropneumatic flushing of a heating system occurs - instructions.

A pipe with a diameter of 20-40 millimeters is installed in the water supply section, which has check valves and shut-off elements. Then compressed air and water are supplied to the system.

If the heating structure is short, then air and water can be supplied through existing pipes. Excess liquid can be discharged through drain valves, or through a specially installed drain pipe. If there is an elevator, then before flushing begins, the cone and glass are removed (read also: “Rinsing the heating system in a private house - instructions and rules for flushing”).

Compressed air is supplied to the pipelines thanks to a special compressor. It creates a pressure of about 0.6 MPa. To prevent the flushing liquid from entering the compressor receiver, a check valve must be installed in the pipeline. Pressure gauges with a scale of up to 1 MPa are attached to the pipes (supply and return).

The prices for compressors are quite high, but if you want to flush the heating system yourself, you can rent the equipment from a specialized store (read also: “What and how to flush the heating system and batteries”). This will help save money - this device is unlikely to be needed in everyday life. Hydroflushing of heating systems can be done in two ways: flow and filling.

With the flow method of cleaning, the pipes are first filled with water, leaving the air collector valve open. It is closed after filling the heating system with water. and then start supplying compressed air. Thus, both water and air enter the pipes at the same time. Cleaning is stopped when clean water begins to flow through the pipe. After this, it is poured into the drain. This method is used to clean heating and hot water systems.

We recommend: GSM module for boiler - functions, models and prices, setup instructions

The filling method is a little more complicated. In this case, the pipelines are first filled with water and the valve is closed. Compressed air is supplied to the second pipe for 15-25 minutes - this depends on the degree of contamination and the diameter of the pipes. After the air supply is completed, the valve is closed and the water is released through the drain pipe. Then the heating system is washed several times with clean water.

Hydropneumatic flushing of central heating systems is very important for efficiently heating your home. Over time, the walls of the pipelines become covered with various deposits, which reduce the transfer of heat to the air and thereby increase heating costs. In apartment buildings, the maintenance of systems should be carried out by housing and communal services - by law, cleaning is required before the start of each heating season, but in practice this requirement is not always met (about

The essence and stages of hydropneumatic flushing

So, what are the rules for flushing the heating system using this method? First, it must be said that this technology consists of supplying compressed air to pipes filled with water. After carrying out such a process, the speed of movement of the water-air mixture increases and high turbulence is created: as a result, deposits are loosened and removed from the system space.

During hydropneumatic flushing, pipes with taps and check valves are cut into the pipeline. In a small system, water is supplied through the pipes available in the heating system. To discharge water, you need to cut a drain pipe into the return pipeline or use special taps. If a system with an elevator is washed, the elevator cup and cone are first removed.

To supply air, you need to use a compressor to flush the heating system, which creates a pressure of 0.6 MPa. A check valve is installed on the compressed air pipeline - its main task is to limit the entry of water into the compressor receiver.

A high-quality compressor cleans the heating system well of all kinds of contaminants. There is no point in buying it for one cleaning, but you can rent it

A few words should be said about choosing a suitable compressor. When making a purchase, you need to focus on the technical characteristics of the product, in particular, the presence of a function for automatically controlling the frequency of formation of mixture supply pulses.

It is good if it is possible to add officially approved disinfectants. The equipment must also provide the following parameters:

- protection against spontaneous activation;

- compactness, mobility;

- presence of pressure level indicator and flushing water flow rate.

And now we will consider instructions for flushing the heating system using the hydropneumatic method. The first option is the flow method - it consists of the following steps:

- the system is filled with water, and the air collector valve is open;

- after filling the valve closes;

- compressed air is supplied followed by opening the drain pipe;

- the mixture is continuously fed into the pipeline, passes through all devices, and then drains.

Flushing continues until clean water flows from the nozzle.

The method of filling the system (second option) is carried out in the following sequence:

- the system is filled with water, the valve closes;

- Compressed air is supplied through another pipe, after 5-15 minutes the supply stops and water and dirt exfoliated during blowing are removed through the drain pipe.

The effectiveness of hydropneumatic flushing is obvious:

- the hydraulic resistance of pipelines and the system as a whole is reduced;

- heat transfer increases, that is, thermal energy is used most productively;

- fluid circulation improves.

It is important to note that hydropneumatic flushing is calculated separately for each system.

Hydropneumatic flushing and pressure testing of the heating system

Heating devices in a residential building are a complex structure connected to an autonomous or centralized network. Long-term and uninterrupted operation of engineering equipment depends on operating rules. If the conditions of use are not followed, the devices begin to become clogged and the quality of room heating decreases. To prevent breakdowns and for preventive purposes, mandatory hydropneumatic flushing and pressure testing of the heating system is required.

The importance of regular maintenance

The accumulation of scale in pipelines not only reduces operating efficiency, but can also lead to an emergency. The smallest amount of deposits, 1 mm thick, reduces the level of heat transfer in an apartment building by 20%. The sediment is a specific insulator that retains energy. Layering can affect the internal surfaces of pipes and heating devices, causing corrosion processes and the formation of fistulas. To improve the quality of equipment operation, it is important to carry out hydropneumatic and hydraulic flushing at certain intervals, at least once a year.

To determine the condition, diagnostics are performed. In apartment buildings, when replacing sections of the centralized network, scale and rust enter the pipeline, which is deposited in the devices. If the analysis is carried out independently, obvious signs include the following indicators:

- Whistling, gurgling and other sounds coming from devices.

- Long period of time for heating.

- Hot state of pipes with cold batteries.

- Increased energy consumption.

- Cleaning is also necessary when replacing the boiler.

When flushing internal heating systems using the hydropneumatic method, carried out by specialized organizations, a special procedure is noted. Equipment is inspected and its technical condition is assessed. Primary pressure testing in an apartment building should show a pressure with a minimum value of 2 atmospheres. This is necessary so that any detected defects are eliminated before work begins.

Professionals draw up a work certificate taking into account hidden procedures, for example, dismantling radiators of a heating system. By identifying the condition of the pipes and the amount of scale, the cleaning method is determined with the customer. Hydraulic technology is most often used, less often chemical cleaning is used. They draw up an estimate and sign an agreement, which includes deadlines for completion. After this, they begin cleaning, then carry out secondary pressure testing. This is necessary to check the functionality of the equipment in a residential building.

Process description

During washing, dirt, deposits, limescale, scale, and rust are removed. To ensure successful cleaning, a number of calculations and preliminary steps are performed:

- Pipeline parameters: length, diameter.

- Air flow and pressure.

- Carrier speed and pressure.

- Measurements of individual groups of risers.

- Checking the presence of shut-off equipment.

- The need to add chemicals for older systems.

- Dismantling equipment that may be damaged by high pressure.

If the pipeline length is short, pipes are inserted at the inlet and outlet. The first is needed for reverse movement, the second is used to drain dirty water. If there are large lines, pumps are connected to the operation to increase the speed of the carrier and in case of insufficient compressor power. There are two methods of hydropneumatic flushing of the heating system:

1. Filling method.

The technology is considered quite complex, since the process involves filling with liquid, then compressed air is supplied every 15 minutes. A compressor is involved in the work. Using water hammer, deposits are removed from surfaces and dirt is lifted from the bottom of the radiators. The coolant with impurities is released through the drain valve of the system. Washing is carried out in several stages until the equipment is completely free of scale. The method is very effective, but difficult to implement, so it is better to entrust the processing to specialists.

Cleaning the heating system involves simultaneously pumping liquid and air through all areas. Before supplying water, it is necessary to close the collection valve; when the compressor is running, unscrew the drain pipe. Passing through all pipes and appliances, the mixture cleans them and then drains. The procedure is carried out continuously until clear liquid comes out. In difficult cases, when washing, chemical reagents are included in the cleaning mixture. An alkali or acid is added to the water, which can dissolve the deposits. Work can be carried out without the participation of a compressor; dirty water comes out when the pump is connected. The amount of funds depends on the length and diameter of the system elements. The method is considered fast and effective, but is not suitable for washing aluminum units, as there is a risk of destruction of the walls from chemicals.

We recommend: Types of window profiles: characteristics, materials, manufacturers

Pressure testing is carried out after cleaning the heating pipes using the hydropneumatic method. The procedure is necessary to identify defects and lack of tightness as a result of washing. The system is filled with water at a slow pace, while the operating pressure should be from 2 to 8 atmospheres, depending on the number of storeys of the house. The parameter is saved for half an hour and checked by connecting a pressure gauge to the inlet pipe. If the meter shows the minimum value, there is a leak that is found and repaired. To do this, drain the water, make repairs, then refill the system until the pressure gauge readings improve.

Cleaning heating pipes using hydropneumatic flushing is a requirement in preparation for the season. Unfortunately, the frequency of the procedure is not always observed, which often leads to equipment failure and an accident on the highway. After choosing a method of implementation, it is necessary to agree with specialists about crimp testing. This will help identify possible defects and places of depressurization.

Hydrochemical flushing of the heating system is cheaper than a complete replacement or overhaul

Heating systems today are firmly connected with our lives. Neither offices, nor enterprises, nor residential buildings can do without them. Therefore, the requirements placed on them are constantly growing, and in connection with growing trends around the world towards saving thermal resources, these requirements are becoming even stricter. Durability, reliability and good heat transfer properties can be achieved if you promptly get rid of scale and other deposits that clog heating systems. Timely preventative cleaning work and hydrochemical flushing of the heating system make it possible to avoid contamination and failure. Scale deposited on the walls of batteries, pipes and heat exchangers causes numerous breakdowns and contributes to faster mechanical wear of pipes and significantly reduces the heat transfer of heating systems. So scale up to only 1mm thick reduces the level of heat transfer by about 15%. Therefore, over time, the cost of fuel consumed increases, and the efficiency of the heating system decreases. Scale and other deposits impede heat flow and create significant thermal resistance, as a result of which the thermal conductivity and temperature of the system decrease, and therefore fuel costs increase significantly. So the thermal conductivity of any scale is more than 40 times less than the thermal conductivity of metal.

BWT solutions for cleaning heat exchangers:

Washing units

Reagents

To get a consultation

Immediately before flushing the heating system, it is necessary to carry out diagnostics and establish the exact chemical composition and nature of the scale. Based on the results obtained, specialists will optimally select the method and equipment for flushing the heating system, and after completing the procedure, they will definitely carry out anti-corrosion treatment of the pipeline to prevent the reappearance of scale and deposits for as long as possible.

There are several technologies for cleaning heating systems: hydrochemical, hydrodynamic, pneumohydroimulsion. Each of them has its positive and negative sides. Chemical flushing of the heating system helps dissolve and remove solid fractional deposits from the system through the use of special chemicals. This cleaning will be effective for flushing a heating system where there is no silt deposits. A special chemical composition is pumped into the heating system, which is prepared depending on the nature of the deposits and the clogging of the entire system. Specialists select the necessary reagents and prepare a solution of the required concentration. The solution dissolves these deposits and simultaneously passivates the metal parts from the inside. In this case, an oxide film is formed on the surface of the metal, which prevents corrosion. Forced circulation of the chemical solution is maintained for the entire calculated time in order for all scale and sediment to dissolve. After removing the remaining active chemical from the solution, be sure to purge the flushed system with air and rinse it with water to remove the cleaning solution and remaining deposits.

Hydrochemical flushing of the heating system is most often used for private houses; it can be carried out at any time of the year and does not require necessarily draining the heating system. You just need to install pumping and tank equipment into the existing heating system and add a chemical solution to the coolant. Thus, the hydrochemical cleaning method, using organic and inorganic solutions with high flushing properties, allows you to remove various deposits from the heating system. Such washing is very effective for pipes, but heating devices may not be completely cleaned, so it is more profitable to carry out comprehensive cleaning - the costs are almost the same, and the efficiency is higher.

As a result of timely and competently carried out hydrochemical washing, the temperature of hot water in the system increases significantly, fuel consumption is reduced, heat losses are reduced, and therefore, at the same cost, the temperature in the room increases. The big advantage of hydrochemical washing is that the process is carried out very quickly with minimal inconvenience for residents. Hydrochemical flushing of water heating equipment and pipelines is carried out only with approved reagents for flushing heat exchangers, which have all the necessary certificates and are absolutely safe for equipment, people and the environment.

Hydropneumatic flushing of heating systems with bottom wiring

In heating systems with a bottom heating circuit, flushing is carried out in a similar way. The system is filled with water through valves 19; 24 and 22, while valve 21 is open.

Next, air is purged, starting from the last, of each heating riser. When flushing along the risers, water can be discharged from each riser through tap 23a.

To divert the air-water mixture from several risers at once, the mixture is discharged into the storm drain through drainage 20 (see Fig. 2).

Hydropneumatic flushing of heating systems is carried out until the discharged water is completely clarified.

- After finishing washing, you need to dump the residual water.

- Fill the heating system and perform a one-time reset.

- Next, fill the system with water and take a sample for analysis.

Hydropneumatic flushing methods

Hydropneumatic flushing of a home heating system is carried out in one of two ways: flow or filling.

Flow-through method of hydropneumatic washing

The system is filled with water, while the air collector valve must be open. After filling the system with water, the valve is closed. Apply compressed air and open the drain pipe. The water-air mixture is continuously fed into the pipelines, passes through pipes and heating devices, and then drains. Flushing is carried out until clean water flows from the pipe. Hot water systems can also be flushed using this method.

Filling method

Fill the system with water, after which the valve is closed. Compressed air is supplied through another pipe for 5-15 minutes (depending on the contamination and volume of the system being flushed). Then the supply of compressed air is stopped, the valve is closed, and water and dirt that have been exfoliated while the system was purged with air are removed through the drain pipe. The system is washed several times until it is completely clean. In systems with overhead wiring, flushing is carried out by supplying water from the return pipeline located below, and the drain pipe is connected to the supply pipeline.

Depending on the design and degree of contamination, the system is washed with risers, groups of risers, sections or the entire system. Typically, a group of two to five risers are washed simultaneously. The remaining risers are turned off. At the end of washing the first group, the risers are turned off and the next group is washed, etc. The washing is carried out until the water-air mixture being removed is completely clarified.

Advantages and disadvantages

Since the end of the 18th century, when Bonnemann proposed the prototype of modern heating systems, until now, the global industry has offered various means for effectively cleaning pipes and radiators. The industrial era has significantly changed approaches to the cleaning process. Manual work and labor-intensive operations have sunk into oblivion - flushing pumps have entered the service of specialists.

Over two and a half centuries, history has offered various ways to remove scale. But today the following operating principles are considered effective:

- Unit for flushing the system with chemical reagents.

- flushing pump for descaling using a pneumohydraulic method.

- Hydropneumatic shock devices for cleaning pipes and radiators.

Experts believe that there is no ideal method, since each method has unique advantages and disadvantages. For example, chemical cleaning is considered low-cost, so it is used most often. But the aggressive solution is not suitable for aluminum radiators, and used reagents need to be carefully disposed of.

Due to the kinetic impact at a speed of 1500 m/sec, the hydropneumatic impact type flushing pump copes well with scale and mud blockages. And, nevertheless, the device will not be able to clean a system with a length of more than 60 m. Specialists use similar units to clean the heating system of a cottage and risers in an apartment building.

The operating principle of a pneumohydraulic compressor is widely used to clean the system from rust, grease and scale. Such devices have excellent reviews for removing silt deposits, since they operate with water-air mixtures and loosen chemical formations at high pressure. However, buying such a flushing pump for the average person is an impossible task. The compressor has an impressive price tag, but pays off well for commercial enterprises.