To make a foundation for a bathhouse, you can use a solid concrete foundation block. This prefabricated foundation made from FBS blocks is one of the highest quality and inexpensive compared to some other foundations. The FBS block includes a reinforced concrete pad and vertical retaining walls made of FBS blocks.

FBS blocks photo

FBS decoding solid foundation block. FBS wall blocks are specially manufactured for the construction of foundations, and they are made in factories using brick making machines. You can make a strip foundation from FBS blocks and a column foundation from FBS blocks, but most often they make a strip foundation since the blocks tend to move relative to each other. Concrete blocks FBS GOST 13579 78 are made of heavy concrete, light and dense silicate concrete with a density of at least 1800 kg/m3. The picture below shows the main FBS blocks sizes GOST 13579-78.

Main foundation blocks FBS dimensions GOST 13579 78

Concrete blocks for foundation

For some reason, concrete blocks for foundations of the FBS brand are always called concrete, although little reinforcement is used in their manufacture.

The abbreviation FBS stands for foundation wall blocks. They are intended for basement walls, because often such a foundation is laid to the depth of soil freezing or immediately for the purpose of constructing a basement under the building. Therefore, walls made of FBS blocks are also the foundation and walls of the basement of a residential building or building for any other purpose.

Dimensions of concrete blocks for the foundation

brand and size of FBS concrete blocks

The construction industry produces a fairly wide range of FBS blocks in thickness and size.

The thickness of the foundation blocks is selected depending on the thickness of the walls of the building. It is permissible to use a block thickness less than the thickness of the wall, but not by much. If in doubt, it is better to choose wider than narrower. For example, the thickness of the future brick walls of the house will be 640mm, and the blocks will be mounted with a thickness of 600m. The brickwork will overhang by 20mm on each side of the block.

And according to the standard size during installation, the entire nomenclature is used, because their installation must be done with bandaging of the seams, and also depending on the size of the foundation.

For example, the size of the foundation is 9 m, which means the following blocks will fit in one row:

- FBS24-6-6- 3pcs

- FBS12-6-6-1pcs

- make the remaining 600mm a monoline insert

- or there is another option: instead of FBS 12-6-6, take FBS9-6-6 2 pieces, then you won’t need to do embedding.

Thus, the number and standard sizes of FBS are usually calculated, depending on the size of the foundation and the width of the wall.

The use of FBS blocks in construction is quite extensive:

- strip foundations of multi-storey buildings

- strip foundations for low-rise buildings with basements

- strip foundations for a bathhouse or garage

- heating chambers during the construction of heating mains

- above-ground single foundations for laying above-ground heating mains

Finishing

Finishing is necessary both externally and internally.

Insulation from outside

If you do not do external finishing, the walls will simply be blown through. So you need to at least prime (with Ceresit ST-17 primer), and then plaster (ST-24) with a layer a little more than half a centimeter thick. You can continue finishing after installing doors and windows. Since aerated concrete is a fragile structure, the frames should be wide and attached to the concrete with anchor bolts as large an area as possible, and caulked with jute or tow. More complex external insulation consists of many elements that are attached on top of the sheathing made. The prepared facade can be covered with plastic siding or decorative plaster.

Insulation of aerated concrete from the outside

Insulation inside

Craftsmen advise covering the steam room and the bathhouse as a whole with foam glass tiles - simply placing them on glue. It is heat-resistant and has low thermal conductivity.

Foam glass is laid like tiles

Then the walls can simply be covered with clapboard.

Covering a block bathhouse with clapboard

A “warm floor” is laid on the floors, and tiles are placed on it.

Warm floor under tiles

Important! Before interior finishing work, you need to install all electrical cables and install taps for the water supply system and drains for the sewerage system.

After laying the tiles, ladders are installed.

Tile with ladder

Let's assume that we have overcome all the difficulties and our bathhouse is ready.

Strip foundation made of blocks

A strip foundation made of blocks in private construction is arranged:

- for a low-rise building with solid walls (brick, gas block) with the base of the foundation laid to the depth of soil freezing

- for a low-rise wooden house or bathhouse with or without a basement, with the base of the foundation laid to the depth of soil freezing

- for any one-story building (house, bathhouse, garage) without a basement, like a shallow foundation

When building any foundation structure, it is necessary to build on the soil.

A strip foundation from FBS blocks can be made for any type of soil, it will only be necessary to apply appropriate structural measures depending on the type of soil and groundwater level.

For example, you want to build a wooden house with a bathhouse, and even a basement. This is a fairly large building.

If you have sandy or rocky (with crushed stone, gravel) soils and the groundwater level is below -3m, then no problem, the design of a strip foundation made of blocks is your most optimal solution.

These soils are not heaving, so under such soil conditions it is possible to construct a full-fledged basement from FBS blocks, which will always be dry.

If you have clayey or loamy soils and a high groundwater level, for example, at 1 m below ground level, then you need to think very carefully before making foundations from FBS, since the basement will have to be waterproofed against groundwater seepage. And clayey soils are heaving and therefore you will have to do:

- monolithic belts along the base of the foundation and along the top of the foundation to strengthen the FBS masonry located in the middle between the monolithic belts.

- fill all foundation cavities around the perimeter of the building with medium-grained sand, which is a non-heaving soil

- coat the side surface of the foundation in contact with the ground with bitumen, thereby reducing lateral buckling forces

- in modern construction, another design solution is used to reduce soil freezing by installing an insulated blind area around the perimeter of the structure

All these activities require an investment of money, so it makes sense to think about the need to build a basement in the presence of heaving soils and a high groundwater level, because for such soils there is another foundation design that may suit you perfectly: a pile foundation with a grillage.

Site preparation for construction and marking

For the construction of buildings, it is better to choose a flat place or with a slight slope to the west, east, south to drain rainwater and prevent flooding of the site in the spring. Cut off all vegetation from the site, remove the turf and carefully level the ground.

Make a calculation, taking into account that the width of the foundation should be approximately 10 cm greater than the width of the bath wall. Mark one of the corners with a 50 cm long peg.

Having placed a right triangle on a peg, measure the length of the longitudinal wall along one of its outer sides, and the length of the transverse wall of the bathhouse building along the other side. At the intersection of the axes, you need to drive in the second and third pegs. Then mark the opposite corner of the bathhouse with pegs in the same way.

Scheme of a strip monolithic foundation.

Using a cord, check the correctness of the markings with diagonal lines - they should be the same (plus or minus 2 cm).

Next, casting of boards and posts is carried out at a distance of 1-2 m from the pegs. The boards should be nailed parallel to the walls of the building, checking the evenness with a batten, at the level of the future floor or at a height of 1 m from the ground. If you have any difficulties at this stage, search the Internet for cast-offs with photographs.

Having completed the casting, apply the axial parameters of the bathhouse foundation plan to its upper edge. Drive nails into the notches and stretch a strong cord between them so that it passes exactly over the pegs driven into the ground. Check all sides of the cast-off in this way - pouring the foundation requires great care and attention! Then, using a plumb line, outline the contours of the inner surface of the base of the building, and the preliminary work will be completed.

Foundation for a bathhouse made of blocks

A foundation for a bathhouse made from FBS blocks with sandy soils and low groundwater levels is a completely acceptable option. Even if you don’t have a house with a bathhouse, but just a small bathhouse, without a basement. You can purchase the smallest blocks with a length of 900mm. Previously, additional prefabricated blocks with a width of 600 mm were produced, but now they are not made. Small-sized blocks can be laid independently, without the use of equipment, in the old-fashioned way: two logs, ropes and a man’s hands.

If you have non-heaving sandy soil, you can safely make even a shallow foundation from blocks. Nothing will happen to it.

In the presence of heaving soils, it is also possible to construct a finely roughened foundation for a bathhouse from one row of blocks, only it is necessary to take the following measures to reduce the forces of frost heaving and strengthen the foundation structure:

- sand and gravel pad 300mm thick

- preparation for 100mm thick blocks of monolithic concrete with reinforcement

- laying concrete blocks on a layer of cement mortar and filling the vertical joints between the blocks with mortar

- monolithic reinforced belt on top of a row of blocks 100-200mm high

- Coating the sides with bitumen

- filling the foundation cavities with sand 100-300mm wide

- insulated blind area

Since many people build a bathhouse on a summer cottage by self-construction and, naturally, do not know what kind of soil they have, it makes sense to play it safe and lay in excess reinforcement rather than strengthen the cracked foundation later.

In case of heaving soils, it is still more advisable to make a monolithic strip foundation for a wooden bathhouse:

- Less likelihood of deformation under the influence of soil heaving forces

- Greater structural rigidity of the foundation

Columnar monolithic foundation

Scheme of a columnar monolithic foundation.

The columnar structure is ideal for dense, heavy soils and small buildings. In each corner of the future bathhouse, as well as under load-bearing walls and capital partitions, holes are dug at a distance of 1.5 m from each other, into which columnar supports (made of metal, asbestos cement, wood, etc.) will then be inserted. If the pillars are chosen with a diameter of 20 cm, then the hole should be dug with a diameter of 25 cm. The pipes should be buried approximately 1 m, and about 40 cm of support should be left above the ground surface.

Sand is poured into the bottom of the dug holes, watered and compacted well. Then a columnar support wrapped in roofing felt is inserted strictly vertically, the space around it is filled 40 cm with crushed stone for stability, and concrete is poured inside the pipe to a height of 50 cm. Then the support needs to be rocked a little so that the concrete solution spreads along the bottom of the hole and strengthens the sand cushion. Insert a reinforcement rod inside the pipe, fill in small crushed stone between the walls of the pipe and the soil, and fill the pipe itself with concrete, leaving 10 cm to the top. After installing the columnar supports, the foundation structure itself can be poured directly.

Construction of foundations from FBS blocks

FBS concrete blocks are laid with ligation of vertical seams.

To construct foundations from FBS blocks, it is best to hire professionals who have construction equipment.

The technology for constructing foundations from FBS blocks is as follows:

- digging a pit to the depth of soil freezing or to the depth of the basement height with the addition of the height of the basement floor structure. The width of the pit should be larger than the dimensions of the foundation so that the blocks can be comfortably mounted.

- cleaning the bottom of a pit or cleaning the bottom of trenches for foundation blocks with horizontal leveling and measuring the design elevation of the foundation base.

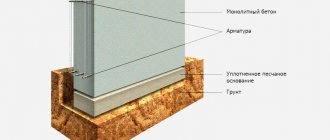

- foundation preparation device: sandy or monolithic, depending on the type of soil, its bearing capacity and groundwater level.

- laying foundation slabs (FL pads) under FBS, which increase the base area of the foundation. They can be laid as a continuous strip or intermittently, depending on the overhead load on the foundation. For low-rise construction, foundation slabs can be replaced with a monolithic slab with reinforcement. It is possible for low-rise construction to construct a foundation from FBS blocks without widening the base, that is, without the use of foundation slabs. Everything is determined by calculations and ground conditions.

- Installation of FBS foundation blocks according to drawings and layout diagrams with ligation of vertical seams (in the middle of the blocks). The blocks are laid using cement mortar and filling the vertical joints.

- Construction of monolithic sections between blocks according to the drawings and laying sleeves for communications.

- Installation of roofing felt waterproofing on the horizontal surface of the top row blocks

- Coating with bitumen 2 times all the side surfaces of the foundation, which will later be backfilled and come into contact with the ground

- Backfilling of foundation cavities with local soil or sand, depending on the heaving of the soil and design decisions.

Transportable baths from SK "Stroyudacha"

A mobile sauna made of timber is a useful structure both for a summer cottage during the summer holidays, and for a suburban area where a family lives year-round. Comfortable and compact buildings will be a pleasant addition and will decorate the site. Their size is small, but this does not prevent you from enjoying bath procedures in comfort. It is worth noting that such a bathhouse can be easily transported. And how useful it will be during outdoor recreation!

See the finished projects on the website, where their cost and equipment are also indicated. Any questions? Contact us by phone numbers listed in the “Contacts” section.

Cement

Cement foundation blocks are used for the construction of various types of structures of single/multi-story buildings (plinths, foundations, and sometimes walls). In addition, they are used in industry in the construction of production facilities, columns, fences, fences.

The main disadvantage of the elements is the need to use special equipment to move the blocks. That is why blocks of 20x20x40 centimeters with a weight of up to 35 kilograms are most popular in private construction - they can be installed by yourself.

The main advantages of a concrete block:

- Stability of the quality of blocks and structures made from them

- Minimum service life of 50 years

- Elimination of errors during the installation process due to the evenness of the blocks

- High frost resistance, non-perception of sudden temperature changes

- No need to construct a sand block

Features of FBS:

- Not suitable for construction on heaving soils

- The need for additional waterproofing

- The appearance of cold bridges at seams

- Can be with or without reinforcement, solid or hollow

- Strength grade – from M75 to M200

- Frost resistance – from F50 to F200

- Thermal conductivity – within 1.1 W/m*C

- Quantity per square meter – 12.5, per cubic meter – about 62.5

- Weight – 28-35 kilograms

- Water absorption – about 6%

- Density – minimum 1500 kg/m3

- Exact dimensions – 188x190x390 millimeters

There is a large selection of blocks available in Moscow and the regions, so purchasing and delivering products to the site in the required quantity and on time is not difficult.

Disadvantages of foundation blocks with dimensions 20x20x40

There are also minor disadvantages of using block building materials:

There are also minor disadvantages when using block building materials

- increased need for cement mortar when doing masonry;

- the need for thermal insulation of foundation blocks associated with increased thermal conductivity.

Despite the shortcomings, the blocks are successfully used for the construction of foundations for various buildings.