The biggest advantage, of course, in cheap laminate brands is the price. Depending on the color you choose, brand and place of purchase, this coating will vary from 400 to 1000 rubles per m2. What will you get? A beautiful and elegant floor that will overwinter on a cold loggia for 5-6 years, but only if force majeure does not occur in the form of rain puddles from a window or melted snow. In this case, the floor will definitely have to be changed, since all inexpensive brands are only moisture resistant.

For the same reason of hydrophobia, you will not be able to use electric or infrared floor heating systems, as there is a high probability of contact shorting.

Expensive brands include all brands of HDF laminate with increased slab hydrophobic parameters. The most famous are the Norwegian Alloc and the German Kronotex. Their price, on average, ranges from 1,500 to 3,000 rubles per m2. These coatings are already much less sensitive to the ingress and penetration of moisture, but the risk of swelling still remains due to the fact that all artificial parquets on a wooden HDF board retain their hygroscopicity.

The best and most functional option is stone SPC laminate, which in its operational parameters is similar to porcelain stoneware, and in its external parameters - similar to wooden boards. Due to the increased temperature resistance and lack of linear expansion, this waterproof laminate flooring will be the optimal choice for finishing not only the loggia, but the entire apartment. Advantages of SPC Stone Floor during renovation:

- SPC laminate is made not on a wooden base, but on a stone one. Due to this, it will not swell from any precipitation that falls on the surface;

- Laying the covering on an area of 5-6 m2 of balcony occurs in just 1 hour without dust and without dirt. You don't need a jigsaw or drill.

- SPC Stone Floor is compatible with all known heated floors and warms up quickly. The first warmth is within 15 seconds.

The only downside is the cost, which, however, is easily compensated by long years of operation, a high warranty, abrasion class 33 and an impeccably beautiful appearance, which is developed by famous designers.

Please note that if you purchase SPC Stone Floor and Caleo at the same time, you will immediately receive a 10% discount on both products.

Should I lay laminate flooring on the balcony along or across?

Let's say that you have already decided to make laminate flooring on your balcony with your own hands, without inviting specialists from Moscow to do this. An important point that you should familiarize yourself with before installation (and this is not in the instructions) is how to install the boards in the narrow space of the loggia: along or across. It all depends on what basis you are going to do this on. If the screed is fresh and the product you choose will be the only topcoat, then the slats are mounted in the direction of sunlight, that is, across the balcony. But if you are planning to cover an old wooden floor with laminate, you should know the following:

- old wooden boards must be firmly fixed

- it is necessary to level the surface of the wood to a flat plane

- any interlocking covering must be laid across the direction of the wooden floor boards

Why such difficulties? This is due to the fact that porous wood quickly absorbs any moisture from the air, while bending and expanding. The natural movement of wood can break the locks of the laminate, which, at best, will cause cracks to appear, and at worst, you will have to buy new material and start covering the balcony with laminate all over again.

Is it possible to have laminate on the balcony - reviews

A few years ago, while doing renovations, on the loggia (ours is about 4.5 meters long), we laid the same porcelain tiles as in the kitchen, so that everything would be in the same color scheme and not too colorful. The fact that we were mistaken was shown by the very first winter and the first frosts. The tiles froze to frost on top and became very slippery. After almost falling over with the laundry in my hands several times, we went and bought carpet to lay on top. We now remove it for the summer, and lay it down again in the winter.

Olga, Moscow region

We made the floors on the balcony from larch. The first three years everything was more or less good. Then the boards began to bend, lose their color, became worn, and the luster disappeared. It seems to be good, after all, the floor is natural, warm, but it had to be sanded and varnished after about 5 years. Now everything is fine again.

We have a spacious one-room apartment, but, as always, there is not enough space. The area was increased due to a small loggia of 2 meters. They were insulated with ecowool. An electric radiator was installed under the windows. The floor was covered with waterproof spc tiles. Only 1 pack was needed. Since we are on the south side, there is enough radiator, we don’t freeze. An Ikea chair and a small table for a laptop were placed on the balcony and the living room was freed up.

We covered the wall under the balcony windows and the floors with laminate. The three remaining walls were simply plastered over. It turned out very cool and inexpensive. It looks modern, smooth and neat. We spent two days working on it, everything is simple - try it too. We chose boards with a chamfer so that when cracks form, they would not be visible. In winter it is quite comfortable, although the sliding effect intensifies in the frosty period and you need to be careful in warm slippers.

Send your reviews and comments to us by email. The email address is being protected from spambots. Javascript must be enabled in your browser to view the address. - they will be useful to other people when repairing and covering the balcony.

Moisture-resistant laminate

The difference between this coating lies in the material and density of the base, which consists not of small wood chips, but of solid wood fibers. In addition, it is pressed and processed at higher temperatures and pressures.

This creates an HDF board of even higher density, which no longer absorbs drops of water. In addition, it is subjected to additional treatment with antifungal and water-repellent mixtures of wax and resins.

High-quality locks, additionally treated with a wax mixture, and ensuring close closure of the boards, also increase moisture resistance. Those. This is a coating whose surface is impermeable to a small volume of water.

Selecting panels for a balcony

The service life of the material also depends on the correct choice of panels. For balconies, experts advise purchasing laminate flooring of class 31 or higher, provided that the balcony is glazed and insulated.

Insulation means the installation of double-glazed windows, insulation of walls, railings of a balcony or loggia. If such events are not planned, you need to pay attention to class 33 laminate, which is characterized by greater resistance to moisture and temperature changes.

Selecting a substrate

One of the purposes of the underlay is to use it to eliminate minor unevenness in the floor and protect the panels from moisture.

The underlay actually eliminates excess noise coming from the laminate itself. The steps become quieter. Sounds from falling objects or shoe soles will be muffled. The above arguments serve as good evidence of the need to use a substrate.

Types of substrates

You should decide on the type of substrate: cork, polyethylene foam or polystyrene foam. A few words about each of them.

1. Cork backing is a natural material. It is made from crushed oak bark. Cork can withstand even the heaviest loads well. It is characterized by depreciation.

Cork flooring is ideal for living rooms, bedrooms and children's rooms. But cork is susceptible to moisture, so it is not recommended for use in the kitchen or loggia. It is also not suitable for “warm” floors. Cork flooring is the most expensive.

2. Izolon is the most economical material. But this is not his main advantage. It has an increased degree of moisture resistance and is intended for rooms with high humidity. This is a good heat insulator.

But it has significant drawbacks. Not durable. Under the influence of loads it is compressed. The service life is short. Over time, the material loses its qualities, shape and collapses.

3. Polystyrene foam backing is excellent value for money. It usually consists of two layers: foil and polystyrene foam itself.

The material has a lot of advantages. It is suitable for rooms with “warm” floors. Easily hides minor unevenness of the main floor. It's easy to install. The price of the product is affordable. The main thing is that it guarantees heat and sound insulation.

Nothing lasts forever in this world. Over time, the polystyrene foam backing wears out. This is its only drawback.

Laminate and warm floor on the balcony

Everyone loves laminate and heated floors on the balcony, with rare exceptions. The simplicity of its installation adds to its popularity year after year. Therefore, questions are increasingly being asked: how to combine heated floors with laminate? Is it possible to do this and lay it on a balcony or loggia? Definitely yes, but there are several very important nuances, compliance with which is a prerequisite for success.

Laminate marking is criterion No. 1.

There are several dozen varieties of laminate, and not everyone can adequately imagine a group of floor coverings paired with the installation of a heated floor. Conventional laminated panels have a number of advantages, but they have one disadvantage that will immediately cover them all. This laminate has a very low thermal conductivity coefficient, so it is neither rational nor wise to use it for heated floors.

Manufacturers, analyzing the latest needs of the construction market, have created a special laminate that is ideally combined with heating. And this is evidenced by the marking, which necessarily indicates the maximum permissible temperature regime.

Important. The manufacturer always indicates the type of heated floor for which the laminate is suitable. You should not experiment and lay a laminate intended for a water floor on an infrared floor, and vice versa.

What affects thermal resistance

You can’t rely only on labeling. This information is sometimes not enough to choose the best pair and combine laminate and heated flooring on the balcony. The next important criterion is the thermal resistance coefficient (TCC). The higher its numerical value, the better the thermal insulation of the laminate.

According to European standards, the CTC should not be higher than 0.15 per square meter. The same applies to the substrate on the laminate, so only the total value will be involved in the calculations.

The resistance level will be influenced by 2 factors:

- - density of the laminate,

- - and the thickness of the laminate.

Laminate and heated floors on the balcony would be an ideal option with a laminate of minimum density and minimum thickness. If the coefficient exceeds the permissible norm, then first the substrate will overheat, and then the floor material itself. This is also fraught with the fact that the heating circuit will fail faster, so it is necessary to carry out a preliminary calculation of the CTE.

Laminate class

Product class is the second most important parameter that you need to pay attention to. The highest class indicates that laminate and heated floors on the balcony will last longer. But at the same time, we take into account that in the case of laying a heated floor, the material will also be subject to a thermal load. As a result, this will lead to almost extreme loads.

Experts call class 32 the best, but besides this, some details still need to be discussed.

Important: The increased strength of the laminate is indicated by its special marking. It shows the temperature range and markings - for electric or water heated floors.

How to choose a laminate for a water heated floor system

The most popular heated floor is considered to be water-based. But you need to be extremely careful when choosing a laminate for it. The material must have the best characteristics. Otherwise, possible temperature fluctuations and high humidity will have a negative impact on its appearance. If the choice was made correctly from the beginning, then the laminate will amaze with its attractiveness for many years.

Why is it worth laying the balcony floor with laminate?

Laminate is a material made from several layers. Boards made of fiberboards (fibreboard) or chipboards (chipboard) are used as a base. The bottom of the laminate is covered with a special water-repellent material, and several protective layers of acrylic resin are applied on top.

Laminate has many properties that make it a suitable material for balcony flooring:

- Resistance to external influences. The balcony, unlike other rooms in the apartment, is most susceptible to weather conditions. Laminate can withstand any temperature changes. This material is not afraid of high humidity, and also does not fade in the sun.

- Protection from mechanical damage. The number of layers of acrylic resin determines how difficult it will be to scratch or push through the laminate. Acrylic resin protects the material well from any mechanical stress.

- Durability. Laminate is one of the most wear-resistant materials. It does not require special care and is not afraid of household chemicals.

Laminate flooring will suit any room decor, as it is available in various colors. For the floor on the balcony, laminate with imitation wood species is most often chosen. You can also purchase material that resembles solid granite or ceramic tiles.

Installation steps

Covering the loggia with laminate is carried out in two main stages.

Installation of sheathing

The preparatory stage, the quality of which determines the reliability of the entire structure.

- Check the evenness of the walls with a lath. Why run it along the wall in a vertical direction? If depressions are found, mark them with a pencil. Knock down the bulges using a chisel or scrape them off.

- Plaster the wall (alternatively, level it with moisture-resistant plasterboard). The latter must be secured in several places with self-tapping screws to prevent the subsequent cladding from collapsing.

- Install a stop at the bottom for the first row of laminate panels.

- Find the horizontal line using a plumb line.

- Select the location of the vertical support structure based on the size of the panels. If the laminate is large, then the lathing profile should run along the edges and middle of the panel. On average, the profile installation step is 40 cm.

- Drill holes with a drill in the appropriate places. Insert screws.

- Start installing the metal sheathing from the outermost elements. Stretch a rope between them as a guide for the intermediate profiles.

- Attach wooden slats to the metal sheathing.

- Lay insulation between the sheathing elements.

Balcony wall lathing

For correct and convenient installation of the laminate on the surface of the room (loggia), you must first install a metal or wooden sheathing. A metal sheathing will cost you 2 times more than a simpler wooden one.

Wooden sheathing

The cheapest and most common lathing is mounted from wooden blocks.

You can easily do this work yourself. Their length should be equal to the distance from the floor to the ceiling. The dimensions of the wooden blocks can be arbitrary, but usually 50*60 mm are used; 30*40 mm. The slats are installed along the entire length of the wall. The distance between them should be 40 cm, then the finishing material will hold more securely.

Then horizontal guides are mounted on the bars; you will attach the laminate board to them. Treat the wooden sheathing bars with an antiseptic to protect the wood from pests and rot.

Metal sheathing

To install the laminate, you will need two types of clamps: with jagged protrusions, they are driven into the sawn-off end of the laminate board and fixed with self-tapping screws to the sheathing or wall, and with a flat protrusion, they press the protruding part of the click lock of the board, securely fixing the laminate and without interfering with the connection with the adjacent board .

The metal lathing is mounted from galvanized profiles. You can purchase a thinner profile.

The load on it will be small, but it will cost much less. It is more expensive than wooden sheathing, but its service life is much longer. The profile fastening pitch is 40 cm.

Installation of the sheathing begins with attaching the outer profiles, they are also called beacons. A string is stretched between them and further installation of the metal sheathing continues along it.

If the profile does not reach the twine, then a small wooden block is placed under it, and if it protrudes beyond it, then this part of the base needs to be cut off. This is done to ensure that the surface after covering is even and smooth.

Then horizontal wooden slats are attached to the metal profile. This is done to simplify the installation of the laminate.

You need to pay special attention to the installation of the sheathing; the quality of your finishing of the balcony walls will depend on how exactly you install it.

Related article: How to attach drywall to a wall: 3 ways

terms of Use

There are a great variety of finishing materials. But not all of them are suitable for cladding balconies. There are certain requirements for balcony building materials. And for good reason. The fact is that there are constant temperature changes and increased humidity. Therefore, finishing materials, including laminate, must meet certain requirements. In addition, to ensure that your laminate flooring lasts as long as possible, follow these rules:

- To prevent clouding and detachment of the laminate in winter, a special temperature regime should be provided on the balcony. Namely, it should not be colder than 5 degrees above zero. Accordingly, it is advisable to glaze the balcony with double-glazed windows and pre-insulate the walls. You can insulate the balcony with polystyrene foam

- Laminate flooring contains wood. High humidity can negatively affect the condition of the material - under its influence, laminates swell. To prevent this from happening, choose a waterproof material for finishing - experts say that only this type can be used on balconies.

- It is recommended not to fasten the material too rigidly, otherwise it may become deformed. It is better to fasten panels not with laminate locks for the same reason.

Requirements for the coating and condition of the balcony

Loggias and balconies are specific rooms that are characterized by significant temperature changes and increased exposure to ultraviolet rays. Therefore, the requirements for the materials used for their finishing are more stringent.

The basis of laminate of standard brands is various wood materials (MDF, fiberboard, HDF), which can swell and swell from excessive moisture. The balcony must be glazed and completely protected from precipitation. Otherwise, it is allowed to use only moisture-resistant, expensive plastic-based varieties.

Moisture-resistant PVC-based laminate

You can safely use laminate flooring on a balcony or loggia only if the room is sufficiently insulated - double glazing and a layer of insulation on the walls and floor are required. The temperature should not fall below +5 , this is the only way to prevent deformation and peeling.

If you are not sure that it is possible to achieve conditions on the balcony that are as close as possible to living quarters, then it is better to consider other finishing options.

Pros and cons of quartz vinyl floor tiles on the balcony

- Warm floor. Unlike porcelain tiles, quartz vinyl laminate is warm, but at low temperatures it is not cold . In addition, it is allowed to use heating systems in conjunction with PVC tiles (heated up to 28°C).

- Water resistance. Quartz vinyl tiles remain stable under changes in temperature or humidity. Direct contact with water will also not harm the floor covering.

- Color fastness. The floor on the balcony is often exposed to prolonged exposure to ultraviolet radiation: quartz vinyl is protected from fading under UV rays .

- Strength. With a thickness of up to 5 mm and a multilayer structure, PVC tiles are very dense and can withstand mechanical and impact loads .

- Frost resistance. Quartzvinyl tolerates frost without consequences : at subzero temperatures, you should not drop heavy objects on the floor.

- Easy installation . Vinyl flooring on a balcony requires less thorough preparation of the base (the area is small, minor flaws are not noticeable).

- Easy cutting . PVC tiles can be cut with a stationery knife or metal scissors - according to any template.

- Easy care. Wet cleaning with detergents without abrasive particles is allowed.

One of the disadvantages of quartz vinyl flooring on the balcony is the relatively high cost of the floor covering compared, for example, with laminate, linoleum or porcelain stoneware (the cost of installation should also be taken into account).

Laying laminate

To raise the floor level on the balcony, logs are used; sheets of plywood or chipboard are laid on top.

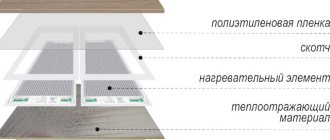

After purchasing the selected laminate and underlay, prepare the surface of the balcony floor for laying the covering. It must be even (differences no more than 2 mm), dry and clean. Installation of the laminated board is carried out after laying polyethylene film and backing on the screed or slab.

The film is needed for waterproofing the floor

Helpful information! Before working, keep the laminate in a warm and dry place for at least 48 hours.

Begin laying from the wall in stripes parallel to it. Other methods are also possible - diagonally or across the balcony. To adjust the size of the coating, the lamellas are easily cut with a hacksaw for metal. To securely fit the boards and secure them in the locks, they are tapped through a wooden block. The finished coating must have mandatory gaps (from 10 mm) from the walls and parapet to compensate for the linear expansion of the material under the influence of temperature and humidity. To do this, use plastic wedges or pieces of the same laminate. In the future, baseboards and thresholds will hide the gaps and protect the laminate from moisture and dirt.

Leave a gap from the wall

Features of using laminate

The material is often used to decorate the entire loggia. It is beautiful, lightweight, and easy to install. In appearance, this finish resembles wood cladding, siding or lining, but is more aesthetically pleasing and less sensitive to fluctuations in humidity and temperature.

Finishing a balcony with laminate is carried out subject to the following requirements:

- Glazing - the finishing material will not withstand direct frequent contact with rainwater and snow. Moreover, the windows on such a loggia can only be opened for ventilation.

- Too low temperatures have a negative effect on the material. We recommend using laminate for cladding only insulated balconies.

- When decorating a loggia with wood or siding, you should maintain ventilation gaps and correctly assess the level of vapor permeability of the finishing “pie”. Otherwise, the dew point will be inside the finish and moisture will accumulate on the back of the boards, the entire cladding will quickly become unusable.

Sometimes they try to sheathe loggias with polyvinyl chloride. This material is resistant to water and is much less afraid of temperature changes. However, its vapor permeability is very low, which leads to a shift in the dew point inside the skin.

Methods of application in the interior

If the balcony is an extension of the residential area, then the choice of interior decoration is of great importance. The main thing is that the additional area is glazed. However, if it is also heated, it is not necessary to use waterproof material, which is more expensive, for cladding the walls and floors.

A large selection of finishing materials allows you to make the appearance of a small room attractive. The range is so diverse that it is not difficult to choose an option based on design and color. This can be an imitation of parquet, natural wood, stone or ceramic tiles. Knowing the characteristics of the material and installation methods, finishing a balcony with laminate yourself does not pose any difficulties, the work will be completed quickly and efficiently. The main thing is that the selected material is fully suitable for the operating conditions.

Do-it-yourself installation of waterproof laminate in the kitchen

Let's consider the technological sequence for laying a waterproof laminate that imitates tiles in the kitchen.

- Screed the floor.

- Lay a polystyrene or polyethylene backing.

- Choose the direction and method of laying the laminate. Calculate joint locations.

- Take measurements. Based on them, trim the coating elements with a reciprocating saw or circular saw.

- Lay the laminate starting from the corner and leaving a distance of at least 1 cm between the wall and the covering.

- Lay the second row so that the pattern matches perfectly.

- Lock the locks by rotating the panel from a 450° position downwards.

- Check the drawing.

- Install baseboards.

Thus, laminate kitchen floors combine high quality, stylish appearance and relative affordability. Installing such a coating is much easier than tiles, even if you are new to renovation. In this case, our recommendations will come in handy.

Installation of laminate flooring on the balcony

The first thing you need to do before laying laminate flooring on the balcony is to level the base. This issue is extremely important, since laminate flooring on an uneven surface will not last long.

There are two main ways to level the floor:

- Concrete screed;

- Use of self-leveling mixtures.

You will have to make the choice yourself - each option has its own characteristics. For example, self-leveling mixtures are much more convenient and practical, especially if the old coating was relatively smooth, but they harden for a very long time, up to a month (read also: “We are leveling the floor on the balcony: screed options”).

In any case, the matter does not end with leveling the floor, and you need to move on. What is good about laminated panels is their extremely simple installation technology, which is due to the locking connection of individual structural elements: the installation of laminated panels almost ends when the grooves and protrusions are aligned with each other.

Naturally, before laying, we must not forget about the need for a substrate, which allows you to insulate the base layer, improves sound insulation and levels out some unevenness of the base. There is no reason to worry about this: the substrate can be laid with your own hands without any problems, so there is no need to call specialists.

In order not to encounter problems in the future, it is worth considering the fact that laminate tends to expand over time under the influence of temperature, so it is necessary to leave expansion gaps between the panels and any obstacles (walls, pipes, etc.). If you do not leave these gaps, the laminate will rest against the walls and break, and the amount of damage will be significant.

Of course, the gaps left need to be masked, for which a plinth and a threshold for the balcony made of laminate are used. Such a threshold for laminate allows you to give the room a good aesthetic appearance and is intended solely to improve the visual qualities of the balcony. That is why the main criterion for choosing skirting boards is their compatibility with laminate flooring.