How to check the heating circulation pump for serviceability

You can check in the following ways.

Ease of inclusion

To examine the performance of the equipment, it is recommended to check whether it is easy to turn on. After seasonal downtime, the condition of the unit must be checked.

To do this, it is recommended that after switching on, listen to the sounds that the equipment makes during operation. If there is no damage, the unit operates quietly .

If you hear various sounds, you will have to check the contamination of parts , the amount of water in the system, etc.

Presence of noise during operation

If the circular pump makes noise, it requires diagnostics or complete replacement. Sounds occur due to malfunction of the rotor or impeller , which can render the entire heating system unusable.

Sometimes noise occurs due to voltage drop . This happens due to imbalance and synchronization, which leads to uneven movement of the coolant.

Attention! Diagnostics are carried out only by a specialist .

If operation is stable, but the device still makes noise, it is recommended to check:

- Is the operating power of the unit equal to the initial values? If the calculations are similar, then the coolant moves too quickly or slowly, which leads to noise.

- Is the motor rotor in a horizontal position?

Bearing operation

Bearings tend to wear out and vibrate heavily.

They are responsible for rotating the impeller, so if the part is no longer suitable for use, it needs to be replaced.

Also, bearings sometimes become damaged and make knocking or squeaking noises. To eliminate the problem, disassembly and washing are carried out.

A special worker does this.

When is a performance check needed?

After another long period of inactivity , the unit needs to be checked; if it is delayed, there is a risk of not only losing heating, but also seriously damaging the equipment.

come to Dmitrovka - I’ll show you and maybe I’ll get the pump in) Otherwise I have extra red Grundfos 20-40 (I’m not sure for the first number, maybe 25) 3500 rubles. I want it for him.

Well, a screwdriver, sort of diagonally, so that it gets into the rotating impeller

Circulation pumps of various types are often used today in country houses and cottages, which makes the operation of autonomous heating systems more efficient and at the same time saves on energy resources. Meanwhile, if such a hydraulic machine fails, the entire heating system stops functioning, which forces its user to choose: use the services of qualified specialists or repair the heating circulation pump with his own hands.

Reasons for device overheating

The most favorable situation is when the temperature of the coolant in the system coincides with the temperature of the pumping equipment. However, it happens that the pumping apparatus begins to heat up above normal: this is a serious signal that problems have arisen in the operation of the device.

The circulation pump overheats for the following reasons:

- Insufficient voltage in the supply network . Because of this, sooner or later the engine will overheat and break down. Therefore, when overheating is detected, the first thing you need to do is check the network parameters: often the problem lies there, and not inside the device.

- Poor bearing lubrication . This leads to their rapid erasure, which creates a real threat of rotor jamming. It is best to renew the lubricant in a workshop, because... Complete disassembly of the heating circulation pump will be required.

- A foreign object got inside the device, causing it to jam . This item could be a piece of limescale or rust.

- System contamination . If the circuit has not been cleaned for many years, its inner walls are usually covered with a thick layer of plaque, which leads to a decrease in the diameter of the tubes. The resistance of the pumped water increases, and the device can no longer cope with the load. To prevent such situations, the system must be periodically cleaned, with the obligatory dismantling of some components (including the pump).

- Installation errors . An indication that the pump is installed incorrectly is if it overheats from the very beginning of operation. Equipment of this type is a complex device, since only specialists can check the heating pump for correct connection.

Modern models of heating circulation pumps are practical and easy-to-use devices. They are characterized by a high degree of reliability, which allows, with proper installation, practically no subsequent maintenance. After detecting overheating or other malfunctions, you should carefully measure your strength before repairing the heating circulation pump yourself. Sometimes it happens that eliminating damage caused by unprofessional disassembly of a mechanism is more expensive than repairing the original defect.

Design, types and principle of operation of circulation pumps

Without knowing the structure of the circulation pump, you will not only be able to repair such a hydraulic machine if the need arises, but also carry out its regular maintenance. The design of circulation pumps consists of:

- body made of stainless steel or non-ferrous alloys;

- an electric motor whose shaft is connected to the rotor;

- The rotor itself, on which the wheel with blades is installed, is the impeller (its blades, which are in constant contact with the pumped medium, can be made of metal or polymer materials).

Circulation pump design

The circulation pump operates, regardless of its design, according to the following principle.

- After applying electric current, the drive motor shaft begins to rotate the rotor on which the impeller is mounted.

- The coolant liquid entering the internal part of the pump through the suction pipe is thrown away by the impeller and centrifugal force to the walls of the working chamber.

- The liquid, which is affected by centrifugal force, is pushed into the discharge pipe.

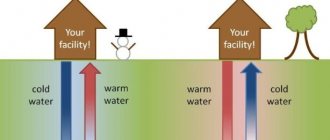

As mentioned above, depending on the design features, the heating circulation pump can be of different types. Thus, devices with a rotor are distinguished:

In private homes, “wet” type circulation pumps are most often used.

For circulation pumps of the first type, which are used primarily to equip household heating systems, the rotor is constantly in a liquid medium. This contributes not only to the lubrication of moving elements, but also to their effective cooling. The main advantages of this type of equipment include:

- low noise level during operation, since the water in which all the moving elements of such a device are located perfectly absorbs vibrations;

- ease of installation (such pumps simply cut into the pipeline), maintenance and repair.

Meanwhile, pumps with a “wet” rotor, if we talk about their disadvantages, are characterized by not very high efficiency, can only be installed in a horizontal position and are very critical of the lack of liquid in the heating system.

Pumps with a dry rotor are installed in separate boiler rooms and are used in systems that heat large areas

The drive motor of pumps with a dry rotor is placed in a separate unit. Rotation from the electric motor shaft is transmitted to the impeller through a special coupling. Unlike devices with a “wet” rotor, pumps of this type are characterized by a higher efficiency (up to 80%), but also a more complex design, which somewhat complicates their maintenance and repair procedures. Circulation pumps with a dry rotor are cut into the pipeline and their housing is attached to the wall, for which a special console is used.

About the choice of equipment and the rules for its independent calculation

The key indicator that determines the efficiency of the circulation pump is its power. For a household heating system, there is no need to try to purchase the highest-power installation. It will only make a loud noise and waste electricity.

Mounted circulation pump

You need to correctly calculate the power of the unit based on the following data:

- hot water pressure indicator;

- pipe section;

- productivity and throughput of the heating boiler;

- coolant temperature.

Hot water consumption is determined simply. It is equal to the power indicator of the heating unit. If, for example, you have a 20 kW gas boiler, no more than 20 liters of water will be consumed per hour. The pressure of the circulation unit for the heating system for every 10 m of pipes is about 50 cm. The longer the pipeline, the more powerful the pump you need to purchase

Here you should immediately pay attention to the thickness of the pipe products. The resistance to water movement in the system will be stronger if you install small cross-section pipes

In pipelines with a diameter of half an inch, the coolant flow rate is 5.7 liters per minute at the generally accepted (1.5 m/s) speed of water movement, with a diameter of 1 inch - 30 liters. But for pipes with a cross-section of 2 inches, the flow rate will already be at the level of 170 liters. Always select the diameter of the pipes in such a way that you do not have to overpay extra money for energy resources.

The flow rate of the pump itself is determined by the following ratio: N/t2-t1. In this formula, t1 refers to the temperature of the water in the return pipes (usually it is 65–70 °C), and t2 is the temperature provided by the heating unit (at least 90 °C). And the letter N denotes the boiler power (this value is in the equipment passport). The pump pressure is set according to the standards accepted in our country and Europe. It is believed that 1 kW of power of a circulation unit is quite enough for high-quality heating of 1 square meter of a private home.

Rules of operation and maintenance

In order not to encounter situations in which the circulation pump installed in the heating system will require repair, it is necessary to strictly follow the operating rules for such equipment, which are as follows.

- If there is no water in the pipeline, the circulation pump cannot be started.

- The amount of water pressure generated must be within the characteristics specified in the technical data sheet of the circulation pump. If the device produces a reduced or, conversely, increased water pressure, this can lead to its rapid wear and, accordingly, failure.

- During the period when the heating system is not in use, the pump must be turned on for circulation at least once a month for a quarter of an hour, which will prevent oxidation and blocking of its moving parts.

- It is very important to ensure that the water temperature in the heating system does not exceed 65°. In water heated to a higher temperature, sediment begins to actively fall out, which, interacting with the moving parts of the hydraulic machine, contributes to their active wear and, accordingly, failure of the entire device.

The circulation pump should be inspected and checked for correct operation monthly. Such measures make it possible to identify malfunctions in the operation of equipment at an early stage and promptly take appropriate measures.

Periodic checking of the circulation pump will significantly reduce the likelihood of its failure during the heating season

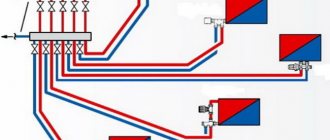

Installation principles and recommendations

How to install the pump? The following tips should be followed:

- Ball valves must be attached to both sides of the pump. They will be useful in the event of future dismantling of equipment during repair work.

- A filter must be installed in front of the pump.

- To remove air that accumulates in the heating system, you need to attach a manual or automatic valve over the bypass.

- The equipment must be installed horizontally. Thus, the pump will be protected from damage if it is not completely immersed in liquid.

- A grounded socket is used for connection.

- Gaskets treated with sealant are used for installation.

- The terminals are located at the top.

Assembling units

Pump installation begins with the assembly of components - main and pump. To assemble the main unit, just connect a 2-inch tap to the connector. Tow is wound onto the squeegee and coated with paint, then the tap is screwed in with an adjustable wrench.

The pump assembly is a little more difficult to assemble. To begin with, tow is wound onto a ball valve (0.75 inches) (over the external thread) and coated with paint. The filter is screwed to the tap. The arrow on it should point in the direction from the tap. If the filter has internal threads on both sides, you will need to connect a nipple to one of them. A connector purchased with the pump is attached to it. Now the inlet part (the one that is attached in front of the pump) is ready.

Assembly of the outlet part consists of screwing the detachable connection onto a ball valve (0.75 inches). Tow is used in the process. Upon completion of assembly, the mating parts of the connections are mounted on the pump using adjustable wrenches and tow. Now you can start inserting them into the heating system.

Pump installation

Before installing the circulation pump, you should perform a number of actions - first of all, install the circulation tap. It is needed to redirect the heat flow to the bypass. The assembled unit is applied to the main pipe.

A marker marks the area in place of which the crane and squeegee will be installed. The pipe is cut off with a grinder, threads are cut or welded along the edges of the pipeline. The detachable connection is unscrewed, the valve and the squeegee are fixed on the pipe opposite each other, the field of which is again combined and crimped with a wrench.

The pump unit is installed in almost the same way as the main unit. First, pipelines are screwed into the taps (threaded elbows, 0.75 inch diameter). The assembled pumping unit is placed against the main line (the main valve should be located directly between the taps).

Holes are cut according to the marks on the highway. Bends need to be welded into them. The main task is to correctly determine the direction of the current. It must be taken into account when installing the circulation pump (usually the unit is fixed to the return pipeline).

The most common faults and their elimination

There are several malfunctions that are most typical for circulation pumps, which are quite possible to fix with your own hands. Such malfunctions can be identified by their characteristic symptoms, without even disassembling the pump or using complex diagnostic equipment.

The pump hums when turned on, but the impeller does not rotate

The reason for the situation when the pump is noisy, but the impeller is motionless, is often due to oxidation of the drive motor shaft. This may occur due to the fact that the hydraulic machine has not been used for a long time. To repair a heating pump with your own hands in case of such a malfunction, you must perform the following steps:

- turn off the electrical power;

- drain all water from the pump and the adjacent pipeline;

- Having unscrewed the corresponding screws, remove the drive motor along with the rotor;

- resting on the working notch of the rotor with your hand or a screwdriver, forcefully turn it, moving it from its dead point.

Disassembled circulation pump

The pump will make noise, but will not work even if a foreign object has entered its interior and blocks the rotation of the impeller. To repair the circulation pump in such a situation, perform the following steps:

- turn off the power supply;

- drain water from the pump and adjacent pipeline;

- disassemble the pump according to the above scheme;

- remove a foreign object;

- install a mesh filter on the inlet pipe.

This is what the circulation pump housing looks like from the inside

The pump is turned on and does not hum or work.

If the turned on circulation pump does not make noise, but does not work, there may be problems with the power supply. To identify the cause and eliminate such a malfunction, disassembling the circulation pump may not be necessary: using a tester, check the level and presence of voltage at the terminals of the device. In many cases, to eliminate such a malfunction, it is enough to correctly connect the pump to the power supply.

If there is a fuse in the design of the circulation pump, then it could blow out due to a voltage drop in the electrical network, which could also be the reason why the heating pump does not work and does not make noise when turned on. To restore the pump's operation, simply replace the blown fuse.

Armed with a tester and a circuit diagram, you can find more serious damage to the electrical part of the pump, for example, burnt out windings

After a short period of operation the pump switches off automatically

If a layer of lime deposits has formed on the inner surface of the stator, the running pump will stop periodically. To solve this problem, it is necessary to disassemble the pump and clean all its internal parts from lime deposits.

What kind of breakdowns occur and how to make repairs yourself

The operation of heating systems implies the possibility of servicing and eliminating many faults by the apartment owners. The circulation pump is no exception: the main thing is to understand its structure and operating principle. You will also need some tools. Before disassembling the circulation pump, you need to make sure that it is connected correctly to the electrical network. All parameters must comply with the instructions in the technical passport.

The most common malfunctions of the heating circulation pump are:

- The device makes noise . The reasons for this phenomenon may be the following: the motor shaft has become covered with rust after winter storage of the equipment, or a foreign object has gotten inside the impeller. To solve the first problem, you will need to disassemble the circulation pump - the pump must be turned off before doing this. After this, the rotor must be turned several times. In the second case, everything is much simpler - the device is disassembled to remove the foreign body. In the future, it is advisable to acquire a protective mesh filter.

- The pump shaft has stopped rotating . First of all, using a tester, you need to check the device for the presence of voltage in it. Another common reason is connection errors. Most models are equipped with fuses that blow out during power surges.

- The appearance of unusual noise . The causes of sounds uncharacteristic of the operation of the circulation pump are often air accumulated in the system. This kind of problem can be solved by cleaning the pipes from air pockets. In order to never return to a similar situation again, it is recommended to equip the upper section of the pipeline system with a special automatic unit. It will independently bleed air as it accumulates.

- The pump stopped starting . The most likely reason is that the power supply has stopped. To eliminate it, you need to check the correct switching of phases and fuses. If everything is fine with this, it is possible that the drive winding has burned out. As a rule, an ordinary user is not able to fix such a breakdown, since disassembling the heating pump is not easy.

- After working for a few minutes, the device turns off . This may occur due to incorrect phase connection of the wires inside the terminal block. Another reason is that the fuse contact has oxidized, which needs periodic cleaning of toxins.

- Strong vibration of equipment during operation . Most likely, the bearing has become loose (it will need to be replaced from time to time). It is better not to carry out such repairs of the heating pump yourself.

How to prepare a circulation pump for the heating season

Before the start of the heating season, in order not to subsequently encounter failure of the circulation pump and its repair, it is necessary to properly prepare the device for a long period of intensive operation.

- You should check that the pump is inserted correctly into the pipeline, focusing on the arrow on the body and the impeller rotation indicator. When installing a new pipeline for installing a circulating hydraulic machine, it is better to choose an area immediately in front of the boiler, where the risk of air pockets is minimized.

- The gaskets and pipes of the pump must be lubricated to prevent them from drying out.

- It is necessary to check the condition of the strainer on the suction pipe and, if it is clogged, clean it thoroughly.

- It is also necessary to evaluate the correct connection of the pump to the power supply network, for which a tester is used.

- You should check the tightness and reliability of the hydraulic machine connecting units.

- You need to perform a test run, the results of which will show whether your equipment is ready for the heating season.

Choosing a pump

To choose the right pump, you should evaluate the characteristics of the product and take into account some recommendations.

- Before purchasing a unit, you need to calculate the flow rate of liquid and coolant, as well as the length of the pipeline.

- The flow rate of the coolant, which passes through all sections of the heating system, is calculated in the same way as the flow rate of liquid in the equipment.

When choosing a pump, take into account the pipe diameter, coolant pressure, boiler performance, water temperature and boiler throughput. The table shows water consumption at a standard movement speed of 1.5 m/s.

| Water consumption | 5,7 | 15 | 30 | 53 | 83 | 170 | 320 |

| Pipe Diameter (inches) | 0,5 | 0,75 | 1 | 1,25 | 1,5 | 2 | 2,5 |