“Heated floor” uses specialized compounds for its work. Although water is used in the majority of cases, antifreeze is also in demand. They are specialized liquids that are resistant to freezing, the base of which is ethylene glycol and propylene glycol. It should also be noted that there are additives that can reduce chemical activity and improve some other parameters.

“Heated floor” system – comfort and comfort in the room

This coolant is poured into the radiator itself and into the communication pipeline. However, before using the composition, it is better to ensure its compatibility with the system. Water is actively used, but its use can lead to:

- corrosion;

- scale;

- precipitation in communications.

In the worst case scenario, when freezing occurs and the boiler stops functioning, the pipes may burst. The use of antifreeze becomes essential in those apartments and houses where people sometimes visit, and therefore there is no opportunity to check the operation of communications. For such a composition, a low freezing point is considered distinctive, which prevents freezing in the event of a boiler or pump shutdown. This is what makes it widespread.

Attention! When deposits occur in the form of sediment in some parts of the system, the batteries are switched off incorrectly, and also when the pipeline structure comes into contact with a surface that is poorly insulated, water freezes. This can also happen if the power of the heating boiler is low, or the room area is large. It is possible to eliminate similar situations if you use antifreeze. In addition, in case of spillage of the composition, it does not pose a danger to humans and the system itself.

The use of ordinary and distilled water

Water is an environmentally friendly and inexpensive substance. It has a high heat capacity, and if necessary or if there is a leak, it is easy to compensate for the lost volume. Also, this liquid in the form of a coolant is used in any communication. But along with such good qualities, there are also significant disadvantages that can harm the system. This:

- The formation of scale on pipes is usually higher due to the presence of salts. If even very small precipitation occurs, this strictly manifests itself in heat transfer.

- Processes that are associated with corrosion due to oxygen in the composition. This leads to the fact that the metal parts of the communication become unusable. However, its content can be reduced if, at the stage of selecting parts, you select parts that have low oxygen permeability or an additional layer.

- Damage to the pipeline in case of an increase in volumes. This occurs when freezing and is considered a physical property from which there is no escape.

- Change the fluid at least once a year. In this case, antifreeze can work for 3–5 years.

Distilled water - environmentally friendly and economical

From what is listed above, we conclude that water is considered a good and affordable option.

Characteristics of "XL Pipe"

The XL Pipe electric-water floor system is installed both in large cottages and in country houses with a small heated area. It consists of the following elements:

- a pipe made of heat-resistant polymer, inside of which there is a heating element;

- the coolant in it is heated by an eight-core cable; it connects to the network;

- the liquid for heated floors is introduced manually; use propylene glycol or antifreeze;

- when heated, the coolant expands, so the tube is equipped with a pressure absorption chamber;

- the inlet end is covered with a silicone cap; it has holes for the electrical cable;

- the ends of the cable are placed in a chamber with insulating material;

- The main line is laid under a screed 4-5 cm deep.

We recommend: How to calculate the power of a heated floor?

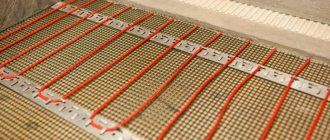

Before installing the main, preparatory work is carried out: leveling the floor surface, laying waterproofing and insulation. A damper tape is reinforced along the lower perimeter of the wall. If mats for “warm floors” are not used, then a reflective screen and reinforced mesh are laid on the insulation. The liquid circuit is attached to it.

All preparatory work is carried out with your own hands. To connect the liquid line, it is recommended to contact specialists.

Pipes are laid in a “snail” or “snake” pattern. The end of the pipe is not returned to the connection point. It is placed in any convenient place on the floor.

When forming a screed, the mesh provides additional reinforcement. Copper wire is attached to the fittings; grounding is carried out.

A temperature sensor is placed between the turns of the cable. It is placed in a protective case. All wires are checked for resistance, connected to the network, and placed in a junction box located on the floor. It is closed with a screed.

The cable to the thermostat comes out of the box. It is installed at a distance of 70 cm from the floor. The end of the temperature sensor and the heating system are connected to it. The thermostat controls and operates the heating system.

Specifics of special substances

In order to choose a liquid for a heated floor system according to the rules, you need to become familiar with all the properties of the composition. A similar substance can be used for other purposes and tasks. First of all, in areas with temporary power and gas supplies, and in fact where there are permanent or long-term shutdowns. In such a situation, antifreeze allows you to keep heat in the communication longer.

The product is also used in non-residential premises with a large area. This is specific:

- warehouse type premises;

- hangars;

- garages.

In such premises, constant temperature changes occur due to the continuous closing and opening of gates.

Antifreeze - quality and ease of use

However, the main feature that such a coolant has is the content of special substances that prevent the formation of corrosive processes. It is due to the additives in the composition that scale does not appear on the walls of pipes and other elements.

This liquid

under the influence of temperature, it does not have the ability to change its own characteristics and physical state. Actually, with the help of this composition, thermal energy is effectively transported throughout the communication. Even at negative temperatures, it does not harden or thicken, does not become wider, and, therefore, cannot lead to the destruction of system components. Such products can work without changing their own state down to –60 degrees C. If necessary, the concentration of the composition can be adjusted by diluting it in a 1:2 ratio with distilled water.

Characteristics of "Unimat Aqua"

Underfloor heating from Unimat Aqua has a different concept. If the coolant in “XL Pipe” is antifreeze or propylene glycol, then for “Unimat Aqua” only distilled water is used.

There is no cable in the pipeline. The coolant is brought to a certain temperature using a heating element. The system is assembled simply, with your own hands. What is included in the Unimat Aqua electric-water heating kit?

- The main line is made of thin propylene tubes. They are laid on a heated area. The “warm floor” system from “Unimat Aqua” is also called capillary.

- The tubes are connected to the control unit. It contains a small pump and a heating element.

- The block contains a thermostat that allows you to set the heating mode.

- The kit includes 2 tees made of heat-resistant plastic, metal bushings and connecting clamps. Using the installation kit, the floor circuit is connected to the control system.

We recommend: How can you make warm floors?

A control unit is installed on the wall. At the top there is an inlet through which distilled water is introduced into the line. There are holes at the bottom for the coolant to exit into the liquid circuit and for its return to the heating element.

- Capillary heating tubes are laid on the rough base.

- Using a tee and metal bushings, the circuit is connected to the control system. The bushings are rigidly reinforced with clamps.

- Connection elements with a square tube cross-section are connected to the water outlet on the block.

- Make an electrical connection between the control unit and the network.

- When the thermostat is turned on, an alarm signal is heard. It means that there is no coolant in the floor line.

- Distilled water is introduced into the liquid system through the inlet at the top of the block. The alarm is switched off.

- Set the temperature on the thermostat and test the thermal regime.

- Cover the tubes with a tie 5 cm deep.

When turned on, water begins to circulate in the floor circuit. The coolant passes through the heating element in the control unit. The water temperature rises in a few seconds.

The liquid passes through the line and transfers its thermal energy to the screed and floor covering. A small pump, which is built into the block, forces the cooled liquid back through the heating element. The coolant circulates through the main line.

The maximum length of one electric water circuit should not exceed 66 m. If necessary, several heating circuits are installed in the room. A control unit is installed for each system.

The liquid electric-water heating system is a good alternative to other types of heating. It does not require access to the central pipeline, so it is installed not only in country houses, but also in city apartments. Permission from the housing department is not required. The heating is autonomous and will save costs on electricity and water radiator heating.

YouTube responded with an error: The request cannot be completed because you have exceeded your quota.

We recommend: How does a water heater for underfloor heating work?

- Related Posts

- How to make a solution for screeding a heated floor?

- How to install PErt pipes for heated floors?

- How to properly install a heated floor?

- What characteristics does a two-core heated floor have?

- How to set up a heated floor?

- How does the underfloor heating calculator work?

Specifics of ethylene glycol-based antifreeze

Liquid

, used in such systems, has not only additives, but also polyhydric alcohols. This significantly improves the quality of the composition.

Main! It is strictly prohibited to use automotive or general purpose antifreeze in such communications.

It should be noted that substances based on ethylene glycol are considered quite dangerous. Moreover, as a heat carrier this product is not ideal. Among the minuses it is necessary to highlight:

- high corrosive activity; specialized inhibitors are used to reduce it;

- ability to foam, this can be compensated for using additives;

- greater fluidity when compared with water;

- poor reaction to overheating.

However, such a composition does not freeze even at very high temperatures, and if this threshold is exceeded, the liquid

is converted into a gel, which does not exclude its increase in volume.

Ethylene glycol based antifreeze

Considering that heated floors are closed systems, the use of this liquid is considered non-hazardous. In open communications, the use of ethylene glycol-based

is not allowed to avoid bad consequences if a leak suddenly occurs.

Is it possible to pour antifreeze into a heated floor system?

For most autonomous heating systems, no matter how the heating is carried out, through radiators or a heated floor is installed in the home, the main heat transmitter is the heated coolant. Most often, the coolant is ordinary water (up to 70% of heating systems used in households), but other liquid media can also be used for these purposes. Water is the most accessible and cheapest coolant. The only disadvantage of this option is that water reacts sensitively to changes in ambient temperature, significantly changing its physical properties.

Another, no less common option with a coolant, antifreeze is a liquid used for heated floors instead of water. Unlike boiler water, antifreeze is a liquid substance made from ethylene glycol and propylene glycol. Special additives (chemical additives) are added to the composition, which reduces the chemical and physical activity of the liquid.

Note: antifreeze, unlike ordinary water, has a low temperature threshold. Depending on the concentration and composition of additives, the freezing temperature can vary from 30 to 65 0 C below zero.

Let's consider various options for choosing a coolant for a heated floor. Which is better, water or antifreeze, how much more practical is one or the other?

When planning the installation of a home heating system according to the “warm floor” scheme, you should not only pay attention to the type of heating devices and the method of laying the heating circuit, but also to the type of liquid that will play the role of coolant. The piping system for heated floors is usually filled with the same compounds that can be used to ensure the operation of radiators. The only caveat is that at the time of purchase you need to determine which composition is suitable for a particular heating method.

Different brands of antifreeze may have different properties, which are determined by the amount and types of additives included in the liquid. For this purpose, it is better to understand in advance the types of non-freezing liquids and find out how this or that liquid behaves in different operating modes.

For reference: By distributing the coolant through the heating circuit, the desired heating effect is achieved - uniform heat transfer occurs across the entire floor surface, due to which the entire interior space of the living space is heated to the required temperature.

It is best to decide on the type of coolant at the design stage. The physical properties of the fluid are included in thermal and hydraulic calculations. Typically, for standard projects, all thermal calculations are based on the use of ordinary water. In the case of antifreeze, it is necessary to make some adjustments to the calculations. It's all about the technological parameters of the equipment.

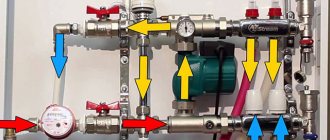

For example: for normal operation of a heated floor with a heating circuit length of no more than 50 m, you can do without installing a circulation pump. If it is necessary to heat large spaces and areas in this way, the installation of a circulation pump is required.

Attention! When working with ordinary water, the performance and pressure parameters of pumping equipment declared by the manufacturer are quite suitable. But in order for antifreeze to circulate normally through the heating system, you will need to purchase a pump with a performance reserve.

In addition, it is necessary to install the circulation pump correctly. The impeller or wet rotor of the pump must be positioned horizontally. Otherwise, a pump for underfloor heating installed in a vertical position will lose up to 30-40% of its power. In order for antifreeze to circulate normally through the water circuit, the pump pressure must be 50-60% greater than in the case of ordinary water. This is the first one.

The second thing that needs to be taken into account is the increased length of the heating circuit and the diameter of the pipes used when working with other liquids. Antifreeze has low heat transfer compared to water, so for the normal functioning of the underfloor heating system, more intensive circulation of the coolant will be required. Not all types of pipes used for the heating circuit can interact with antifreeze. For these purposes, special pipes are produced that have the appropriate diameter and have low reactivity to interaction with chemical compounds.

There is no exact and unambiguous answer to this question. It's all about what you prefer and in what living conditions your autonomous heating system is used. There are a number of aspects that you should pay attention to when choosing one option or another. To do this, it is enough to know the advantages and disadvantages of boiler water and other liquids used as a coolant.

Let's dwell on the benefits of water used in heating systems. Ordinary, untreated water, which we use every day in everyday life, is the most accessible and cheapest option. This is the most important advantage, however, there are other advantages of this option. For example:

- environmentally friendly and completely safe coolant for the inhabitants of the house;

- water has a high heat capacity, which significantly affects the quality of heating of residential premises;

- a quick and affordable way to maintain the required volume of coolant in the system;

- wide scope of application. Water is suitable for almost all heating systems, both open and closed.

Having understood the advantages of water, we should not forget about the disadvantages of such a coolant. Neglecting the physical properties of water can negatively affect the quality of operation of heating devices and the efficiency of the heating system.

If we consider the situations in detail, then when using water as a coolant, the following unpleasant situations may arise:

— water used for domestic purposes contains large quantities of sedimentary impurities, which negatively affects the permeability of the heating system. For heated floors, which are closed-type heating systems, this property of the coolant is not critical, since almost the same volume of liquid circulates along the circuit;

- The abundant oxygen content in water enhances the corrosive effect of metal structural elements. Thanks to the proper selection of pipes for the pipeline, the influence of this negative factor can be minimized;

- freezing of the piping system is the most significant drawback. When exposed to low temperatures, water freezes, significantly increasing in volume. Accordingly, such a state of the liquid can lead to a violation of the integrity of the pipeline;

- frequent complete replacement of the coolant in the heating system (at least once every six months).

Of all the listed disadvantages, freezing of water is the most significant reason why many people prefer other liquids. However, even in such a situation, installing a heating circuit using pipes made of plastic material can solve the problem for some time.

Note: pipes made of polypropylene and polyethylene are least susceptible to destruction due to freezing of the system.

And one last thing. Frequently replacing the coolant in the entire heating circuit is not such a costly thing. You can drain the system every six months and add new water at any time without spending a penny.

As one of the options for using water for heating floors, you can use distilled water. This option is a little more expensive than in the case of ordinary tap water, however, in this case there will be an order of magnitude fewer problems with the functionality of the pipeline.

In all respects, water is an ideal substance for use as a coolant. In some cases, in order to make the heating system more efficient when working with ordinary water, they try to use prepared water. In the process of preparing the liquid, its hardness decreases. Boiling allows you to remove sedimentary impurities and salts from water. Adding small quantities of quicklime and soda ash will improve the performance of the water.

For that category of consumers who have the means and prefer to have expensive heating equipment, the most practical option would be to use antifreeze. This liquid, as mentioned earlier, is made on the basis of synthetic substances, propylene glycol and ethylene glycol. Antifreeze solution is a polyhydric alcohol-containing liquid substance prepared for use in the heating system. By adding special chemical additives, the physical and operational properties of the liquid are improved. The use of automotive antifreeze in the heating system is strictly prohibited.

Important! It should be remembered that antifreeze can be made on the basis of ethylene glycol, a strong chemical poison. When a person comes into contact with this substance, there is a high probability of severe poisoning. If 100-300 ml of this liquid enters the human body, it can be fatal.

The high toxicity of ethylene glycol-based antifreeze, especially as a result of evaporation, can cause dangerous chronic diseases to develop in home residents. Despite the high risk, the use of ethylene glycol-based antifreeze has found its application. Compared to other brands, this composition has an affordable price. Antifreeze brands made on the basis of ethylene glycol have the following crystallization parameters. The intensity of crystallization depends on the concentration of the liquid.

However, if in terms of price ethylene glycol looks more profitable than propylene glycol, then its physical and operational characteristics are far from ideal. Significant disadvantages include the following:

- ethylene glycol-based antifreeze has high chemical activity, which significantly affects the intensity of corrosion processes;

- such a coolant tends to foam under intense heating and increased circulation;

- Antifreeze of this brand has greater fluidity compared to water, which sometimes causes pipeline leaks in the most unexpected places and connections. Due to the fact that the liquid is highly toxic, such leaks are fraught with big troubles;

- due to overheating, ethylene glycol reacts, causing intense precipitation. Due to the rise in coolant temperature above 70 0 C, the heat transfer effect of the coolant is significantly reduced.

Propylene glycol based antifreeze is a safe option. Despite the higher cost, the liquid does its job perfectly. The presence of special additives in the composition can significantly reduce the freezing threshold of the coolant. Almost complete harmlessness allows antifreeze of this brand to be actively used in home heating systems.

Having become familiar with the disadvantages of brands of antifreeze made on the basis of ethylene glycol and propylene glycol, three conclusions can be drawn.

First. For underfloor heating, which is considered a low-temperature heating system, these brands of antifreeze can be used, but careful selection of consumables will be required to install a completely sealed heating circuit. The water circuit in this case is of a closed type, so ethylene glycol will be calm. Without visible harm, circulate through the water circuit.

Second. When overheated, this type of antifreeze loses its basic performance characteristics, so this option is not suitable for heating systems based on solid fuel boilers.

Third. You yourself are able to choose which option to give preference to. There are remedies, use expensive but safer antifreeze made on the basis of propylene glycol. If you want to save money, use ethylene glycol. Only in this case, great care and accuracy is required during operation of the heating system.

For those who constantly struggle with low temperatures in winter, using antifreeze is the best option. In all other options, the safest, most practical and affordable option is to use ordinary water. You can prevent the system from defrosting if you strictly follow the operating rules of the heating system and adhere to the technological parameters of the heating equipment.

Water heating systems - both radiator and underfloor heating - use liquid to transfer heat. And it’s not just water, although it is used in most cases (68% of the total number of systems). Antifreezes are also used - special antifreeze liquids based on ethylene glycol and propylene glycol. They also contain additives that reduce chemical activity and improve some other characteristics of these liquids.

For heated floors, the same compounds that are poured into the radiator system can be used, but before purchasing, be sure to check compatibility with underfloor heating. The properties of antifreeze depend on the additives added and can vary quite a lot, so each time ask for a complete list of properties of antifreeze liquids.

It’s even pleasant to rest on a warm floor, regardless of what it’s filled with.

The type of coolant that will fill the water heated floor must be determined in advance, even before the calculation stage. In the general case, all calculations are carried out for water, but when using antifreeze, everything must be calculated taking into account their characteristics. For example, the overall pump performance needs to be increased by 10-15%, and the pressure generally by 60-65%. The length of the circuits or the diameter of the pipes will also change, since antifreezes have lower heat transfer. In addition, a large length of the system is needed to transfer the required amount of heat. The type of coolant is also important when choosing equipment and pipes: not everything is compatible with antifreeze, and some, on the contrary, can only be used with non-freezing liquids.

There is no clear answer to this question. As always, there are several aspects that need to be taken into account and in each specific case, choose the best option. To make an informed choice, it is important to know all the advantages and disadvantages of each liquid. Let us consider in more detail the properties of each of the coolants.

If you use ordinary untreated water, this is, of course, the cheapest, sometimes even free, option. Moreover, it has other advantages:

- Environmental safety and absolute harmlessness to humans. Ordinary water can do no harm to humans or the environment.

- High heat capacity. This is the only liquid capable of transferring such an amount of heat, and, no less important, capable of releasing it well.

- Easy replenishment of lost volume. After eliminating the leak or evaporating some of the water, you can simply top it up.

- Possibility of use in systems of any type. Including open ones with an open type expansion tank.

There is nothing more environmentally friendly and safer than water

But there are also disadvantages to using water as a coolant. Some of them apply to underfloor heating systems only to some extent and, although they cause some harm, are insignificant:

- Due to the presence of salts in the water, they are deposited on the elements of the system. Even a small amount of precipitation reduces the heat transfer of heating devices. But water heated floors are closed type systems. That is, the same liquid circulates through a closed pipeline. And the limited volume does not contain such a large amount of salts, so we are not talking about serious deposits.

- Due to the presence of oxygen in the water, corrosive destruction of the metal parts of the system occurs. But the oxygen content may be limited. This is done at the pipe selection stage: products are selected from a material with low oxygen permeability or with an additional layer that prevents the penetration of oxygen. In this case, a small volume of water contains a small amount of oxygen, which quickly turns into a bound state and no longer causes any harm to the components of the system.

- When the system freezes, water increases in volume and can damage the pipeline. This is a physical property of water and there is no escape from it. But the situation can be made uncritical: choose pipes from a plastic material that will not collapse when the volume increases. For example, polypropylene and polyethylene have such properties.

- The water in the underfloor heating system must be changed at least once a year. Antifreeze is changed every 3-5 years. But water is free, and antifreeze is quite expensive.

Distilled water is the best option in permanent residences

As you can see, using water as a coolant in underfloor heating systems is a good and very inexpensive option. To make it even more attractive and ensure almost complete safety of the system, you can carry out preliminary preparation of the coolant: soften the water. The easiest way is to boil it in a metal pan with the lid open. In this case, some of the salts will precipitate (unstable compounds of potassium and magnesium). But stable compounds cannot be removed by boiling. You can get rid of them by adding a little slaked lime, sodium orthophosphate or soda ash. But you can do it even simpler: use distilled water. When using this liquid for underfloor heating, you will automatically get rid of the danger of salt deposits. Distilled water doesn't cost much, so it's a good choice.

Antifreezes based on ethylene glycol and propylene glycol are used in heating systems. Typically these are aqueous solutions of these polyhydric alcohols, to which additives have been added to improve their properties.

Only special compounds for heating systems are used. General-purpose or automotive antifreeze should never be poured into a warm water floor!

When choosing antifreeze, remember that ethylene glycol is a strong poison. In case of poisoning, death occurs in 60% of cases, and in the remaining 40% the kidneys are severely damaged. The lethal dose for an adult is 100-300 ml. Not only ingestion of the substance, but also contact with the skin or mucous membranes is fraught with serious consequences. Vapors are toxic, although to a lesser extent: their chronic inhalation leads to irreversible consequences. However, antifreezes based on this ethylene glycol are used. They are sold five times more than those based on the safer, but more expensive, propylene glycol.

Crystallization temperature of antifreeze liquid based on ethylene glycol depending on concentration

Despite all the dangers, ethylene glycol is far from ideal as a coolant:

- It has high corrosive activity (much higher than that of water). To reduce the corrosion ability, appropriate inhibitors are used.

- It has the ability to foam, which is again compensated for by appropriate additives.

- More fluid than water, which leads to problems with leaking connections. Given the toxicity of ethylene glycol, this can be a problem. You need to work with liquid with the utmost caution, wearing protective gloves and goggles. Moreover, all objects and materials that have absorbed the solution also become toxic. They are subject to replacement and destruction.

- Ethylene glycol reacts very poorly to overheating. When the temperature rises to 70 o C, active precipitation occurs, which greatly reduces the heat transfer of heating devices. And this again leads to overheating. After overheating, the properties of the liquid change dramatically, so that further use of antifreeze is impossible. Based on this, it should be taken into account that in systems with solid fuel boilers, antifreeze based on ethylene glycol cannot be used: there 95 o C is more the rule than the exception, and without automation capable of controlling the position or without heat accumulators, the system will inevitably overheat.

Ethylene glycol-based antifreezes are often pink in color.

One of the advantages of using ethylene glycol-based antifreeze is freezing at very low temperatures:

Moreover, if the freezing threshold is exceeded, the liquid becomes gel-like and its volume does not increase. After increasing the temperature, the condition and properties of the antifreeze are restored without any changes. All other properties - low corrosion activity, formation of a protective film, low degree of foaming - this is all due to the presence of special additives that can be added to the same water (if they are compatible with water). Since a warm water floor is a closed system, the use of this type of antifreeze is permitted (prohibited in open systems). But if possible, it is better to fill the system with a composition based on propylene glycol.

Propylene glycol is a safe substance that is approved for use as a food additive in some countries. The properties of this type of non-freezing liquid are also largely determined by the presence of additives, and among the “innate” ones are a low freezing point, not a solid, but a gel-like consistency, which does not harm the system in any way in case of freezing. This substance also has the lowest corrosive activity of all liquids that are used as coolants.

Non-freezing liquids based on propylene glycol are often painted in green colors; many of our packages have the prefix “Eco”

Why then are formulations based on propylene glycol purchased five times less often? Because, firstly, they cost at least twice as much, and secondly, they usually have a higher freezing point. But in systems fired with propylene glycol antifreeze, you can use materials that are less resistant to corrosion, which means you pay less for them.

Crystallization temperature of antifreeze liquid based on propylene glycol depending on concentration

If we talk about the best way to fill the heating system (and heated floors), then, if possible, you should give preference to distilled water. This option is good for not very low winter temperatures or for permanent residence. But if you periodically leave your house or dacha unattended in the winter, then try to fill it with propylene glycol “anti-freeze”. This option, although more expensive, is safe. The use of ethylene glycol composition can only be justified in the case of extremely low temperatures. There is nowhere to go: if there is no safe composition that can withstand winter temperatures, you will have to take what you have.

If the use of antifreeze is unavoidable, it is better to find a safe polypropylene glycol composition

Let us once again draw your attention to the fact that it is necessary to read the system parameters and select equipment taking into account the type of coolant used. If you calculate and assemble the system under water, and then simply fill it with anti-freeze, you will inevitably encounter problems:

- In some cases, if the system is designed for water without a reserve, there will not be enough thermal power. If the reserve was about 20%, then everything will work at its maximum capacity. And all because antifreeze has a lower heat capacity. An option to solve the problem in the case of heated floors is to install a more powerful pump. The speed of movement of the coolant will increase, and with it the amount of transferred heat will increase. But at the same time, when turning on a cold system, do not immediately set the heating temperature to a high temperature: there will be overheating (read about the consequences of this below). Raise the temperature gradually, bringing it to 40-50 o C in a few days (depending on the thermal insulation of your floor, but not higher than 55-60 o C).

- The volume of the expansion tank will be insufficient (it should only be membrane). This problem occurs due to greater thermal expansion. You will have to buy another tank, a larger one, or install a second one.

The size of the expansion tank depending on the volume of the system

To avoid these troubles, when planning, you need to take into account the fact of using antifreeze, choose compatible equipment and chemically resistant auxiliary materials.

Fluid for heated floors must be safe

If the use of antifreeze is unavoidable (low winter temperatures and non-permanent residence in the house), it is safer to use propylene glycol compounds. In terms of their characteristics, they are not inferior to ethylene glycol, although they are more expensive, but they are absolutely harmless. In all other cases, it is better to use water (softened or distilled - your choice) as a coolant for a warm water floor. To insure against defrosting of the system in this case, lay polyethylene pipes in the screed - they normally withstand several freezing cycles. But it must be said that liquid in a heated floor can freeze only at a floor temperature of -5 o C or -10 o C, and this is impossible if the system is stopped even for a couple of days in extreme cold.

Specifics of antifreeze based on propylene glycol

Propylene glycol, for its part, is considered a non-hazardous substance when compared with the previous option. However, the properties of such a composition for the “underfloor heating” system are also mainly determined by additives. At the same time, it is characterized by:

- low freezing point;

- gel consistency;

- minimal corrosiveness.

However, such compositions are in less demand due to the fact that they have a very high cost and freezing point. However, when using this substance in systems, materials that are less resistant to rust can be used, which results in savings.

Antifreeze based on propylene glycol

If the temperature in the region is low during winter, or when people regularly live indoors, it is better to give preference to distilled water. It will provide an opportunity to save your own finances and provide ideal conditions. But, when you have to leave the room unattended for a long time, then propylene glycol antifreeze is a great option. It will hold any temperature and is safe at the same time. It’s better to fork out money once and not worry about the consequences.

Important nuances and subtleties

The components of the “underfloor heating” need to be selected first; it all depends on the liquid used in the future. If you calculate the communication for distilled water and then pour a specialized composition into it, then problems will inevitably arise. Among the main ones are:

- lack of heating power;

- insufficient volume of the expansion tank;

- violation of sealing of fastening connections in the form of threads;

- clogging of narrow pipe passages due to active precipitation;

- destruction of linings;

- occurrence of leaks.

To eliminate similar problems, from the very beginning you should correctly and carefully approach the solution of the necessary task, and specifically provide for the most basic factors. These are the nuances of using antifreeze, indicators for choosing compatible equipment and chemically resistant additives. A similar approach will not only ensure durability and quality of operation, but also the security of all communications.

Pouring liquid into the system

Adding antifreeze is more difficult than adding water. But with the right and competent approach, this can be done with your own hands. To complete the task, you will need a pump or special small equipment that is used for flushing and purging communications.

What do we end up with?

Low temperatures and periodic placement in the house make the use of antifreeze indispensable. In such a case, it is best to use propylene glycol-based

. Although their price is much higher, they are safer and therefore cannot pose any harm to human health or to the surrounding components.

When using water, even in regions with moderate temperatures, it is better to play it safe and purchase polyethylene components as the main components. This will make it possible to eliminate defrosting.