Published: July 21, 2014 (as amended on January 10, 2021) Section(s): Electrical Views: 23538 Comments: 0

The winter kit for household split systems is a number of modifications that allow you to operate the cooling unit in the cold season. As standard, the guaranteed operating temperature range usually starts from -5 (minus five) degrees Celsius. If there is a need to operate the air conditioner at lower temperatures, then it is necessary to install a winter kit on the air conditioner. In this article I will talk in detail about the installation and connection of a winter air conditioner kit using the example of the Haier HSU-09HEK203/R2 split system and the ERKO-01 air conditioning fan control unit. These instructions will be valid for most household split systems of the classic (non-inverter) type. And it will allow you to turn a regular split system into an air conditioner with a winter set.

general information

There are various types of air conditioners available for sale, which differ in their operating properties and operating principles. However, many of them are used only during the warm season, and with the arrival of winter they are turned off.

This is due to the likelihood of condensation occurring inside the equipment due to the effects of temperature and humidity. Modern models of air conditioners are equipped with a powerful drainage system that removes remaining moisture using a special pipe led outside. If temperatures drop below freezing, the tube can become severely frozen, causing an ice block to form. In the future, it will be impossible to remove the condensate outside, which will lead to one of two scenarios:

- Remaining moisture will enter the room, causing the appearance of fungi, mold and dampness.

- Condensation will damage the system.

Exposure to cold is dangerous not only for the internal elements of the air conditioner, but also for the external ones. The compressor, which compresses the working substance that ensures the normal functionality of the device, is at risk of damage and is responsible for its circulation throughout the entire circuit. For balanced operation of the equipment, you need to use a special oil composition, but under the influence of negative temperatures it becomes very thick, and system parts begin to wear out.

When the heating mode is started, the refrigerant should not be cooled, but heated. Otherwise, the heating functions deteriorate and the system is subject to failure. Therefore, the operating mode of the air conditioner in winter is significantly different from summer.

But there is a unique type of device that is suitable for working in cold conditions. This is a mobile monoblock air conditioner, which is a mobile unit with small dimensions and good efficiency indicators. It can be transported to any room or taken to the dacha without performing complex installation. The key components of the device are located indoors, with the exception of the air duct for removing warm or cold air masses. To prevent the risk of condensate freezing during severe frosts, the pipe is connected to a ventilation shaft.

Use in winter

Before you start using your air conditioner in winter, you need to make sure that it supports the appropriate mode. The presence of a heating function is indicated in the instructions or on the body of the device itself in the form of a sun pictogram.

If the equipment can perform heating functions, you should familiarize yourself with the lower threshold of temperature values at which you can start working. Often this indicator is indicated in the instructions.

However, it is important to remember that room thermometers often give incorrect data, so before using the air conditioner for heating, you need to wait until the critical point set by the manufacturer appears. In this case, the device will effectively heat the air in the house with minimal electrical energy consumption.

Modern air conditioners are capable of operating in heating mode at air temperatures above - 5 degrees Celsius . If the values go even lower, it leads to the following scenarios:

- There is a possibility of icing of the condenser or drainage system.

- The power ratings of the device are greatly reduced.

Experts do not advise heating the room in severe frost, since failure to comply with this rule can lead to failure of the climate system. But individual split systems support heating functions even at 10 and 15 degrees below zero. The lower indicator is determined by the type of working substance.

If the temperature drops to critically low levels, you can use an inverter installation. In addition to efficient heating, these devices are equipped with adjustable heating intensity, which allows you to adapt to the current outside temperatures. But inverter-type models are much more expensive than all the others.

We recommend that you read: Floor standing air conditioner without duct

How does an air conditioner work?

The design of any air conditioner does not include any heating elements. When the unit is in heating mode, the heat pump function is activated. That is, the split system pumps gas under high pressure and forces it to condense in the heat exchanger. During the process, freon heats up to approximately 60-80 degrees. Next, the condensate enters the outdoor unit, where it evaporates. This is where the heat is taken and supplied with the air into the room.

Any compressor (inverter or non-inverter) is an important part of a wall-mounted air conditioner. Inside it is oil, which begins to thicken at low temperatures. For proper operation, the ambient temperature must be positive or close to zero. A logical question arises: if the split system is not capable of fully heating, then why do we need a low-temperature kit? For operation in cooling mode! In everyday life there is rarely a need to cool rooms in winter, but in commercial buildings and industrial facilities this function is in great demand.

Operating principle of the air conditioner

To understand why a winter kit is installed on an air conditioner, let’s look at the basic principles of its operation.

A special substance - a refrigerant - circulates in a closed circuit. It enters the heat exchanger of the indoor unit quite cold and when it comes into contact with air, it cools it and heats up. It is in the heat exchanger that the refrigerant boils. It's boiling

is the first of the physical principles that is used to obtain low temperatures when operating an air conditioner.

In the photo: The principle of operation of the air conditioner in cooling mode

Next, the gaseous (namely gaseous) refrigerant enters the compressor, is compressed to high pressure, as a result of which it heats up. In this state, it enters the heat exchanger of the external unit - the condenser. The heat exchanger is blown with outside air, and for more intense heat exchange, blowing is carried out using an axial fan. It is in this heat exchanger that the refrigerant condenses and turns from gaseous to liquid. The hot refrigerant is blown by outside air, gives up its heat to it and thereby turns into liquid. Thus, the second physical process for obtaining low temperatures inherent in the operation of an air conditioner is condensation

.

Liquid, but still quite warm refrigerant (average temperature - plus 40°C) cannot be supplied to the evaporator, since it will not give “cold”, so the refrigerant enters the throttling device (in split systems this is a capillary tube or, less often, a thermostatic valve (TRV)). This is where the third physical process takes place - throttling

, – as a result of which the pressure and temperature of the refrigerant sharply decreases, which then enters the heat exchanger of the indoor unit and the cycle repeats. All these processes can be traced on the ℓgP-i diagram for any refrigerant.

Processes:

1-2 – compression in the compressor; 2-3 – cooling in the heat exchanger of the external unit; 3-4 – condensation in the heat exchanger of the external unit; 4-5 – subcooling in the heat exchanger of the external unit; 5-6 – throttling in the throttling device; 6-7 – boiling in the heat exchanger of the indoor unit; 7-1 – overheating in the heat exchanger of the indoor unit.

Operating principle

If you are interested in the intricacies of installing a winter kit on an air conditioner, instructions and setup rules, you need to fully understand the principle of operation of the equipment, which is based on simple physical laws: thermal energy is absorbed during evaporation, and released during condensation.

We recommend that you read: Window air conditioner

Initially, the system was used only for cooling purposes, but advanced modern technologies have reached such a level of development that climate control technology is quite suitable for heating rooms.

If we talk about the cooling principle, it consists of the following stages:

- The refrigerant in the gas state enters the compressor, where it is compressed under pressure and begins to warm up to high temperatures.

- Then from the compressor the substance enters the condenser, turning into a liquid state.

- As the pressure decreases, the refrigerant enters the evaporator in the indoor unit, where it returns to its original state. As a result of such processes, it boils, “taking away” the thermal potential from the room and traveling back to the external unit. Ultimately, the resulting heat is “thrown out” outside.

- When the working substance in the gas state returns back to the compressor, the cycle is completed.

To use this principle for the opposite task - heating a room, it is necessary to use a special valve. This element rotates the flow to supply warm air masses and remove cold ones.

Operating the air conditioner in winter

complete winter package

Before starting to study the main topic, it should be immediately stipulated that the use of a protective complex makes it possible only to cool the room in cold weather, while heating is excluded. You should not believe the reviews of users who have installed a winter kit for an air conditioner and claim that they have been successfully warming up for more than their first winter. Even if the equipment does not fail immediately, frequent repairs are ensured in any case.

A device that ensures the operation of the air conditioning system for heat at low temperatures simply does not exist, since it is impossible to organize it purely technically.

The fact is that the working substance in the air conditioner - freon - when circulating through the circuit, absorbs heat and releases cold, due to which the air is cooled. If this process occurs in cold weather, then the heat exchanger of the external unit becomes too large or oversized. To eliminate the problem, a rational solution has been found - reducing its size by slowing down the rotation of the fan, which is provided by a rotation retarder or so-called variator. It is part of the winter package for the air conditioner and supports the necessary fan airflow to the heat exchanger.

When the air conditioner operates for heating, the heat exchanger, on the contrary, becomes too small or undersized. A solution to this problem has not yet been found, since it is impossible to enlarge this node purely physically. From this we can conclude that the low-temperature package does not affect the quality of heating in any way and is not capable of providing it.

What actually happens when you start the air conditioner in winter for cold/heat when the thermometer shows below 0°C? For normal heat transfer, the phase transition temperature must be 10-15°C lower than the ambient air temperature. If the thermometer outside shows less than 0°C, then the evaporation temperature will be minus. This causes freezing of the heat exchanger and a drop in performance, since there is a direct dependence on the evaporation pressure.

There is simply a lack of power for normal evaporation, and freon begins to flow into the compressor suction.

Those who allow the operation of an air conditioner in winter without additional equipment run the risk of damaging the equipment, since most often, if the temperature limits set by the manufacturer are violated, a water hammer occurs, the compressor overheats due to freon getting into it, and its final breakdown occurs.

Since it is impossible to increase the performance of an air conditioner when operating for heating in cold weather with any winter set, it is recommended to use heat pumps with a larger heat exchanger to obtain heat.

Causes of malfunctions

Ordinary buyers often go to the HVAC equipment store with complaints that it does not perform a heating function. The most common reason for this phenomenon is purchasing the wrong type of air conditioner . For example, split systems, which are designed for cooling, are widely in demand in warm climate zones. Therefore, they will be useless for cold regions with harsh winters.

Also, the air conditioner may stop working during severe frosts, which indicates damage to the compressor, hardening of the oil, or malfunction of the drainage system. To fix the problem, you will have to use the help of a technician.

If heating a room with an air conditioner is impossible, you should not run to the store and write a complaint, especially if there are no signs of failure on the device’s built-in screen. Often this phenomenon is noticed at critically low temperatures, when the indoor unit needs 10-15 minutes to warm up. Under such circumstances, the room will begin to warm up within a couple of minutes.

Also, all kinds of refrigerant leaks lead to malfunctions in the operation of climate control equipment. A leak occurs when the interblock tubes, where the working substance circulates, are poorly welded. To restore normal operation, it is enough to restore the supply of refrigerant, for which you need to call a specialist.

Even if you become familiar with the basic intricacies of installing an air conditioner with a winter kit and successfully complete the installation, this is only half the battle. In the future, you need to properly maintain the system, monitor its condition and carry out preventive maintenance. The owner of the premises should clean the filters and prevent condensation from freezing in the air duct.

To determine any malfunctions, just monitor the small display screen. On modern devices, it displays any error information as an alphanumeric code. You can decrypt it using the instructions.

If you cannot determine the cause of the breakdown yourself, it is better to call an air conditioner repair specialist to your home. This will reduce the time and avoid errors in system recovery.

What is winter kit

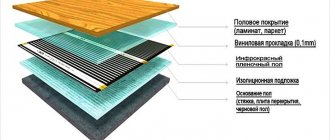

The standard low-temperature kit for non-inverter air conditioners includes:

- Crankcase heater designed to maintain optimal oil consistency in the compressor

- Anti-freeze drain hose heater

- Condensation pressure regulator, or in other words – fan controller

The inverter compressor does not require the purchase of a fan speed controller. The remaining components for operation at sub-zero temperatures for such devices can be purchased separately, as an option.

Composition of the winter kit

Compressor crankcase heater

. At negative outside temperatures, the oil in the compressor becomes more viscous (thick), and when starting, the compressor electric motor may not be able to cope with this, may not start and fail.

Also at low temperatures, the solubility of the refrigerant in the oil increases. Therefore, after starting the compressor, the oil with the refrigerant dissolved in it begins to move through the oil channels of the compressor to all its friction surfaces. During operation, the internal parts of the compressor heat up and the refrigerant boils away from the oil. As a result, a gas plug may form in the oil channel and disruptions in the lubrication system may occur. This will cause the compressor to jam.

A crankcase heater is, in simple terms, a small flexible heating element that is wrapped around the lower part of the compressor (crankcase). When starting the compressor in the cold season, the automation briefly turns on this heater. The oil is heated, which eliminates the above negative consequences.

Condensation pressure regulator

(outdoor unit fan speed regulator). The rapid cooling and condensation of the refrigerant in the heat exchanger of the outdoor unit is facilitated by the temperature of the street air and the intensity of the fan blowing on this heat exchanger. When the temperature outside the window drops, strong airflow leads to supercooling of the refrigerant, due to which it will no longer be able to boil in the heat exchanger of the indoor unit and go into a gaseous state. This, in turn, leads to liquid refrigerant entering the compressor, and the latter may fail.

Of course, there may be a liquid separator in front of the compressor and protection against the ingress of liquid refrigerant is provided in the compressor itself. This can save the device from minor, temporary disturbances, but with constant such operation, breakdown is inevitable.

Installation and connection of the winter kit

fan slowdown device

Before moving on to considering the issue of installing and connecting the winter kit to the air conditioner, it should be noted that it was initially intended for on/off models. In inverter systems, there is no need for a control board, since the variability of fan speed changes is already built into the control module of the external unit. They only require heating of the drainage and compressor crankcase, that is, installation is assumed in a truncated version. Any installation and commissioning work begins with studying the circuit diagram for connecting a winter kit to an air conditioner, which can be found in several places. For most devices, it is printed on the variator board or placed in the installation instructions for the winter package, which is included with the device itself.

Peculiarities

The schematic diagram cannot be the same for everyone, therefore, in each individual case, use the option recommended for a specific model.

Why is that? There are many nuances here. The fact is that split systems operating only on cold do not have a four-way valve, so the process is simplified. In devices operating in heat pump mode, this element is present, which somewhat complicates the installation and connection of the kit to the air conditioner. Depending on the number of fan speed modes, installation can occur either with a phase break or with a neutral break. Some fans have a minimum speed setting that corresponds to the lowest possible speed, so installing a fan speed controller may not be practical.

Compressor crankcase heating and rotation regulator

temperature sensor

So, installing a winter kit on an air conditioner begins with disassembling the casing of the outdoor unit. First, the module is dismantled, then the protective and top covers are removed from the service ports and the front panel is removed.

First of all, the compressor crankcase heating is attached. It is placed on the lower part of the crankcase so that the oil is heated more efficiently. It is necessary to ensure the presence of constant voltage. This will eliminate the possibility of cold starts and oil foaming. Then the rotation regulator is connected to the open circuit of the fan. For start-stop models, this usually requires individual power supply. It is taken from a separately laid wire.

Also, when connecting the winter kit, they provide for the simultaneous activation of the variator with the start of the air conditioning compressor, while it should remain possible to restore the previous split system circuit in the event of liquidation of the modification equipment.

connecting the regulator

The fan retarder has a temperature sensor. It is installed on the condenser coil, located in the middle 1/3 of the upper part of the heat exchanger in the direction of freon movement. Here their optimal contact occurs, ensuring an accurate determination of the condensation temperature. The variator itself is installed and powered, focusing on the circuit diagram for connecting the low-temperature kit to the air conditioner, while it is better to fasten its wires with plastic clamps - this will put less load on the terminals.

After connecting the power, the external unit is assembled, ensuring that all elements are securely secured in their original places. The wires are connected into one assembly with clamps, trying to secure them so that they do not come into contact with the body of the device and the connecting lines of the two blocks. Be sure to check the functionality of the regulator by first starting the air conditioner in cooling mode, and then in heating mode. Readings are taken with a pressure gauge or thermometer.

Drainage heating

Then install the drainage heating, securing it with plastic clamps to the drainage hose, and energize it. As a rule, if the external unit of the air conditioner does not have a power terminal, then an additional power cable is laid along with the interunit cable. If there is a supply terminal, drainage heating, as well as compressor crankcase heating, is powered from it.

At the end of the article, an approximate connection diagram for the winter kit will be given, which is suitable for on/off models. For inverter split systems, equipment is first diagnosed and only then installation is carried out according to a suitable scheme. Some manufacturers produce air conditioners that are compatible with winter sets only of the same brand.

After all installation stages are completed, you can put the air conditioner into operation, but for reliable operation in winter, external protection of the outdoor unit must be provided. In a private house, it can be placed in the space under the balcony, and in an apartment building, the device is hidden under a special canopy that blocks direct access to precipitation.

Before installation, it is necessary to study the product passport with a circuit diagram.

What is a winter air conditioner kit

If you’re already tired of everything and don’t know what else to play, then you can try downloading 1xBet slot machines and enjoy new experiences with the popular bookmaker.

Using an air conditioner to heat your home in winter is possible if you install a winter kit.

It includes the following elements:

- A temperature sensor, which, when the temperature decreases significantly, sends a command to the controller to reduce the rotation speed of the outdoor module fan. Thanks to this, the device is protected from icing.

- To protect the oil lubricant from freezing, a special heater is included in the kit. It constantly keeps the oil in a liquid state.

- In order to prevent the liquid from freezing, a drain line heater is installed in the drainage pipe.

There are low-temperature split systems on sale that are equipped with a winter kit at the factory. They work even at -25°C outside.

How the winter kit works

Wall-mounted air conditioners with a winter kit are already equipped with all the necessary equipment. But you can buy the kit separately and install it yourself.

It consists of three blocks:

- compressor crankcase heater;

- drain hose heater;

- pressure regulator.

The connection diagram for the winter kit for the air conditioner is simple and clear.

The operating principle is as follows:

The temperature sensor is connected to the electronic board. When the outside temperature drops significantly, it reduces the fan speed. As a result, ice does not form inside the unit body. This also protects the oil lubricant in the compressor crankcase from freezing. The compressor crankcase heating only starts if the unit is switched off. Thanks to this, the compressor is always ready to start. If you start equipment with a frozen compressor, it will fail due to freon liquefaction or oil solidification. Heating the drainage line avoids the formation of an ice plug in the tube

Due to this, condensate leaves the device freely at any time, which is important for its efficient and correct operation.

The winter kit is specially designed to solve technical problems that prevent work in frosty weather. If the air conditioner operates in heating mode even at temperatures around zero degrees, the heat exchanger will quickly become covered with frost and air heat exchange will deteriorate. Due to the large temperature difference, the evaporation temperature will decrease, which will reduce the efficiency of the climate control equipment.

All this will lead to the following undesirable consequences:

- The defrosting system of the external unit will operate continuously. As a result, ice forms in the condenser and compressor unit. This will block the fan blades.

- The refrigerant in the heat exchanger will not completely evaporate. If liquid freon enters the compressor, it will cause water hammer and subsequent failure of the compressor.

- The compressor may also overheat, causing its housing to become covered with ice.

Sensor

The installation of the retarder begins with the installation of the sensor. To do this you need:

- select the middle turn of the heat exchanger located between the inlet and outlet tubes;

- attach the sensor to it;

- treat with thermal paste;

- insulate with thermal insulation made of flex.

This installation will protect the sensor from external factors and provide better contact with the heat exchanger.

Variable speed drive

The regulator is installed according to the electrical diagram of the external module and the moderator connection diagram.

When reading the controller diagram, pay attention to the difference in connecting single-speed and multi-speed fans.

According to the diagram (Fig. 1) we connect:

- yellow input cable of the regulator to the corresponding fan terminal;

- We connect the standard orange wire to the black output of the regulator.

With a multi-speed fan (Fig. 2):

- All fan speeds are set to the yellow input cable of the sensor;

- black is connected to the maximum speed.

If there is a heating mode, we connect its wire to the terminal according to the diagram; if not, we insulate it and attach it to the body. We attach the remaining wires (blue, brown), heating wires to the clamps, and supply power to them.

How to install a low temperature kit

Installation of additional options should be carried out by an experienced specialist, since incorrect connection can lead to serious damage.

The low temperature kit, as it is also called, is universal for all non-inverter air conditioners. But for most inverter models, a regulator is not required, and the main manufacturers of split systems offer their own additional options for operating at low temperatures. Of course, it is more convenient to install the winter kit on a removed external unit, since full access to it is required. In this case, its body is disassembled and the connection is made:

- We put the heating element on the compressor crankcase approximately 5 cm from the bottom. We connect its power, preferably through a thermostat, or install a separate machine.

- We screw the pressure regulator block onto the free wall of the housing closer to the connecting blocks of the external unit so that there is access for its adjustment. We connect the regulator according to its diagram. We connect its load “into the gap” of the fan control wire. We connect the additional regulator wire to the four-way valve control wire. We connect the “power supply” of the regulator. Next, you need to correctly install the temperature sensor on the radiator (heat exchanger) to accurately determine the temperature. The entire operation of the regulator will depend on this operation. The sensor should be located on the middle “roll” of the radiator (we determine visually the middle of the heat exchanger). We fasten the sensor using a clamp (for thermal contact it is better to use thermal paste and thermal insulation).

- The drainage should go outside separately from other communications (i.e. we drill a separate hole). At the drainage outlet, you can use a copper tube, to which we attach a heating element with electrical tape. It is also possible to use a heater with a metal-plastic tube in a thermoflex.

Simple instructions for installing a winter kit on an air conditioner

Any installation work begins with studying the connection diagram.

In many devices it is contained in the instructions or printed on the variator board. Each model has an individual scheme.

- We disassemble the housing of the outdoor unit.

- We secure the compressor crankcase heating.

- We connect the moderator to the open circuit of the fan.

- We lay a separate power cable to it.

- We install the temperature sensor on the external heat exchanger.

- Finally, we assemble the outdoor unit.

How to install a winter kit

When it is known in advance that there will be a need to use the air conditioner during the cold season, its modification is carried out simultaneously with installation. The winter air conditioning kit requires special attention when installing the equipment. Further installation of the add-on will be possible only if the external part of the device is fully accessible.

Most often, three components are needed for installation:

- fan speed retarder;

- drain heater;

- compressor crankcase heater.

Installation can be carried out with the help of service center specialists, and if you plan to install the equipment yourself, you must carefully understand all the installation nuances in order to avoid additional problems.

Different equipment models can be equipped with different kits and their installation method will differ, as will the instructions for their installation.

Features of installation of such equipment

The greatest problems arise when installing a condensate pressure regulator. This element is a power regulator, with the help of which air is supplied to the fan motor. The sensor in it is a thermistor. There are several manufacturers on the market.

Sequence of actions when setting up the condensate pressure regulator:

- Determine the required settings based on the analysis of data on expected sub-zero temperatures, as well as condensation values.

- Based on the received data, the controller is adjusted. The temperature minimum will correspond to the value of the “0% speed” parameter, and the difference between the limits will be indicated by “100% speed Dt” on the regulator.

- Connecting power to the fan and regulator, leaving the compressor disconnected, you need to bring the fan speed to minimum.

- To check the correct installation of this unit, it is necessary to heat the pressure regulator sensor.

- In the event that calling a technician from the service center is impossible or the user believes that he can handle installing the winter kit himself, it is necessary to adhere to a certain algorithm of actions. These rules will be common to all brands of air conditioners, but you need to be aware of the likely differences.

- Disassemble the air conditioner housing - the top cover, protective covers and front panel.

- Installation of a condensate pressure controller. A place with a minimum temperature, free from dust and dirt, and where there is no vibration, is best suited for it.

- Remove the walls of the device and the thermal protective casing. Next, a heating device is installed in the lower part of the compressor.

- Reinstall the removed walls and cover, protective casing and front panel.

Secure the heating cable to the drainage pipe. It is connected to the compressor start terminals, because condensation appears in the drain tube when it is running.

Winter maintenance

How should an inverter air conditioner operating for heating be maintained? Apart from ice removal, maintenance is no different from any other air conditioner.

If you do not want to breed mold and mildew, it is enough to clean its filter once every two weeks and wash the impeller twice a year after disassembling the device. All bacteria and fungi that are dangerous to health also accumulate there.

Other types of work, for example, topping up freon or inspecting the external unit, should be carried out by specialists with the appropriate equipment. You better not go there.

Disadvantages and disadvantages of winter heating

Now let's talk about the disadvantages. Don’t think that by choosing a machine with the maximum COP, you will get an ideal heating system that outperforms all others.

A significant drawback of all air conditioners is their noisy operation. There is no escape or relief from the noise.

This is especially annoying in the bedroom. Fortunately, modern inverters have managed to reduce the noise level to 20-30 dB. It's like the rustling of leaves in a slight wind.

In addition to noise, do not forget about the vibration of the external unit. If you have already decided to use air heating in winter, then forget about mounting the external unit on the wall.

Place it only at the bottom on a separate stand with a snow guard.

In summer, when working in the cold, the casing is removed, otherwise the unit will “suffocate.”

Many people place the external unit in the basement of the house. As a result, you get a higher COP, a free refrigerator, and no influence of precipitation. However, the question remains with temperature changes and how they will affect the foundation.

In addition, do not forget about the amount of liquid during defrosting. Over the course of the entire winter season, a small swamp can easily form in your basement.

It is not profitable to use air conditioners for heat in houses with a large area and a large number of rooms isolated from each other. Forget about closed doors with this heating.

To heat two-story cottages, you will most likely need powerful semi-industrial units that cost several thousand dollars. Separate blocks will have to be installed on each floor.

In houses up to 120m2, you can get by with two blocks with a capacity of 9000-12000BTU. In general, with an open plan, count on at least one indoor unit for every 40-50 m2.

At the same time, you still won’t feel the most comfortable heating of the air. Although a thermometer hanging at eye level will show +23C, an unpleasant chill in your legs, especially in distant rooms, will always haunt you.

And for small children this is very critical.

Heated floors are a great improvement over air conditioners in this regard. So, if you have a young family, then most likely you should not switch to heating with air conditioning. If your children are adults or you live alone, then you can safely experiment.

Another disadvantage is that in the absence of a backup heating option, a sudden failure of the external or internal unit will lead to freezing of the entire house.

Of course, you can replace air conditioners with convectors for a while, but what should you do if the electricity is cut off in cold weather?

Buy a powerful generator and switch to a backup source?

But this is again extra costs, unnecessary hassle and a waste of time. Therefore, think through such moments in advance and have at least some temporary alternative.

However, this type of heating is becoming increasingly popular. In general, the main complaints about the unprofitability and unprofitability of heating with air conditioners come from two categories of people:

- who is engaged in the sale, adjustment and installation of traditional heating systems (gas, solid fuel, electric boilers)

- those who bought themselves a cheap Chinese brand

Inexpensive models consume two to three times more than “Japanese” ones with the same thermal power. And they heat normally only when it’s outside down to -5C (the Japanese up to -30C).

Plus they make noise like steam locomotives, and in the end they break down after just a couple of years.

Expensive brands have a MTBF of up to 25 years. Accordingly, the “Japanese” has an average winter COP of 3-4, while the “Chinese” barely reaches 1.5.

To summarize, we can safely say that heating with air conditioning, with a competent approach, has the right to life and can pay for itself in just a few winters.

Even if after this time one of the units fails, replacing it will still be cheaper than connecting, installing, maintaining and operating most traditional heating systems.

Advice from experienced installers

There are some points you need to know in order to install the equipment efficiently.

- It is advisable to install the system in the warm season, since installation at subzero temperatures can damage the equipment.

- A special vacuum pump must be used to remove air from the system so that condensation does not form in it.

- Check for leaks. To do this, the system is filled with liquid nitrogen. It is best to carry out the leak test at the same external and internal temperatures.

- Installation work must be carried out by specialists to avoid breakdowns of expensive equipment.

Sometimes there is a need not only to heat, but also to cool the room in winter. For this purpose, a winter air conditioning kit was invented. Leading manufacturers of such equipment: Ballu, General Climate, Freonix, Midea, Mitsubishi, Daikin.