Expanded polystyrene chips have the following properties:

- thermal insulation (complete filling of the air cushion with small granules in the insulated area removes any cold bridges);

- sound insulation (granules have a rough surface that does not conduct sound vibrations well);

- environmental friendliness (the material is non-toxic and safe for people);

- shock-absorbing abilities (when squeezed, the balls do not lose their structure and quickly take their previous shape);

- performance characteristics (operating temperature range from -190°C to +87°C);

- moisture resistance (lack of absorbent properties);

- fire resistance (granules are treated with a fire retardant substance);

- ease of operation and transportation (light weight and fills the required space as much as possible);

- has no odor and does not cause allergic reactions;

- profitability (relatively low prices for the product and the possibility of reducing prices for other materials by mixing solutions with foam chips).

However, there are a number of restrictions on working with raw materials. Avoid exposing it to a direct open source of fire and do not add it to hot asphalt. Also, if dichloroethane, acetone, benzenes, ketones or their vapors contained in some varnishes and paints come into contact with the material, it is destroyed and almost completely loses its properties. Therefore, it is necessary to strictly follow instructions and safety precautions when working with granules.

Varieties and applications

Foamed foam chips have a white color and an ideal spherical shape, which does not deform under external physical influence. The average size of one granule is 6 - 8 mm.

Granular foam is produced by heating polystyrene at temperatures above 80C and exposing it to isopentane vapor. The finished polystyrene foam balls become very dense and elastic, which allows them to be used at temperatures from -65C to +75C.

Due to many specific properties, this material is widely used in industry. Insulation with foam chips is considered the most reliable cold-resistant method of thermal insulation of floors, walls or roofs. In addition, it is added to construction mixtures and solutions for the purpose of lightening and insulation. Granular foam is used as a filler for upholstered furniture or children's toys, as bulk packaging material, in the production of polystyrene concrete and as a filter component in water purification. The balls are also used as bait when fishing, to lighten structures in unmanned aerial vehicles and when lifting sunken ships.

Different types of foam balls have different physical and mechanical properties. Such properties include dimensions, thermal conductivity, coating density, etc.

Areas of use

Granules are intended for use:

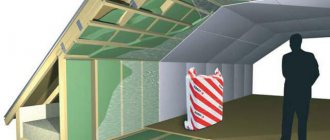

- thermal insulation of walls and ceilings (filling cavities between walls and ceilings);

- for the production of polystyrene concrete (an additive that increases the heat and sound insulation characteristics of concrete);

- as a heat and sound insulating material when backfilling enclosing structures;

- when used in construction heat-insulating mixtures, solutions;

- thermal insulation of pipes in trenches;

- as an imitation of snow on concert, film, and theater venues;

- for use as a filter component in installations for the purification of water and other liquids as a granular contact load for flocculation chambers built into settling tanks;

- for use in the agricultural sector for mixing with soil, thereby loosening and saturating the soil with oxygen;

- as floating bait for catching peaceful white fish carp, crucian carp, tench, bream, roach, etc.;

- as a burn-out additive for the production of lightweight refractory products;

- in the production of frameless furniture: for filling ottomans, mats, bean bags and pear chairs.

The technology for making soft pear-type chairs from foam is very simple: foamed foam granules are stuffed into a pre-sewn bag.

The chair can be any size. These chairs take the shape of a person, which makes their use very comfortable. Children really like these chairs: you can not only sit on the chair, but you can also fight with the chair without consequences - a blow from the foam is not dangerous. Based on practice, insulating a house with foam chips reduces heating costs in winter by 50 percent, and in summer it reduces energy costs for air conditioning.

The low density and fine fraction allows filling the cavity with the highest quality. The service life is unlimited, the crumb does not shrink and does not lose its qualities over time. If we take into account the low cost of the material and all the indicated advantages, foam chips are the most profitable method of insulation.

Also, foam chips are often used in the production of concrete slabs. Such slabs have excellent thermal insulation properties, and the consumption of cement in their production is lower, because the material itself is not an expensive material. After the product dries, it will become much lighter and, in addition to good thermal insulation, will have excellent sound insulation. And such a slab will be less susceptible to moisture.

Materials made from polymers are used not only in construction or industry, but also in some other areas of the national economy. Such insulation as polystyrene foam (expanded polystyrene) deserves special attention. Such products end up in hardware stores in the form of sheets of a certain thickness with standard overall dimensions. Polystyrene foam chips are in great demand among consumers. It has low cost and good technical characteristics. Such products can be used in the furniture industry, as well as for creating decorations in the home. In addition, foam chips are used as insulation for various building structures; they are added to lightweight concrete.

In modern construction and other sectors of the national economy, the following types of polystyrene foam balls can be used:

- primary products. Such materials are produced using a special technology, when polymer raw materials are filled with gas. The result of such a complex chemical process is considered to be the appearance of polystyrene foam balls with a diameter of 1 to 8 millimeters;

- in the second case, unnecessary sheets of foam plastic are processed into individual balls. These pieces are placed in a special unit to obtain small particles.

Granulated polystyrene foam granules description, characteristics, price

The rapid development of technology in the chemical industry over the past 3 decades has created conditions for the emergence of many new materials based on various polymers.

The most famous and in demand of them, without a doubt, can be called polystyrene foam granules. They are made from a gas-filled mixture, the main ingredient of which is polystyrene. Polymonochlorostyrene or polydichlorostyrene are sometimes used. Antiprenes, fillers, and plasticizers are also added to the composition. Foaming of these components occurs under the influence of low-boiling carbons or gas-forming agents. The foam obtained in this way is a moisture-resistant white granule.

Types, application

The products are as follows:

1. Primary. Foaming of polystyrene granules leads to the fact that when heated by steam, liquid or air, they significantly increase in size and transform into voluminous round-shaped balls.

2. Secondary (crushed) granules are the result of crushing waste obtained in the process of manufacturing foam products in special crushers. The shape of such balls is disrupted and only 2/3 of them are round; the remaining number, as a rule, has “chopped” or “broken” edges. However, this does not affect the properties, which remain the same as those of the primary ones.

The size of foam granules can vary from 1 to 8 mm. Based on this, the following types of polystyrene foam chips are distinguished:

- M-15.

- M-25 Light.

- M-25.

- M–25M.

- M-35 Light.

- M-35.

- M-50 Light.

- M-50.

Characteristics, cost

The above types of granules differ not only in size, but also in parameters, and also have different prices:

| Indicators | Granule type | |||||||

| M-15 | M-25 Light | M-25 | M-25M | M-35 Light | M-35 | M-50 Light | M-50 | |

| Diameter, mm | 8-6 | 6-4 | 4-3 | 2-1 | 4-2 | 1,5-1 | 1-0,5 | |

| Bulk density, kg/m3 | 9 | 9-11 | 12-13 | 14-16 | 18-19 | 20-21 | 26-28 | 30 |

| Heat conductivity coefficient, W/m K | 0,053 | 0,050 | 0,046 | 0,040 | 0,041 | 0,039 | 0,037 | 0,036 |

| Compressive strength, MPa | 0,004 | 0,007 | 0,014 | 0,015 | 0,018 | 0,023 | 0,024 | 0,025 |

| Cost, rub/m3* | 1150 – 1750 | 1 880 | 1 960 | 2130 – 2270 | 2 490 | 3 080 | 3 870 | 4 080 |

*As a rule, sellers pack the balls in bags with a volume of 0.1 to 1 m3. It should also be noted that the price of foam balls for wholesale purchases of 3 m3 or more can be reduced by 10-15%.

Application

Considering the above parameters of granulated polystyrene foam, the scope of its use is very wide. It is in demand:

- As a filler for furniture, bedding accessories and children's toys.

- As the main component for the production of heat-insulating building mixtures, mortars and polystyrene concrete.

- When backfilling the enclosing elements of building structures in the form of heat and sound insulation.

- As a filter for wastewater treatment plants.

- For agricultural work. Foam chips mixed with soil loosens it and saturates it with oxygen, thereby increasing soil fertility.

- It is used for catching river, lake and sea fish as bait.

- You can also buy granulated polystyrene foam for decorative purposes. For example, for making artificial snow and so on.

Advantages and disadvantages

Strengths include:

- Excellent heat and sound insulation qualities.

- Good strength.

- Low moisture absorption coefficient.

- Excellent vapor permeability.

- Frost resistance.

- Resistant to combustion. Due to the introduction of fire-fighting additives into the composition of foam balls, they belong to the category of low-flammable substances G1.

- Environmental safety.

- Durability. For 50 years, performance remains unchanged.

Disadvantages of polystyrene foam chips:

- Instability to chemical solvents.

- When used in open areas, it requires additional protection from sunlight, which is a source of ultraviolet radiation.

Advantages and disadvantages of polystyrene foam

Due to its sufficient rigidity and strength, foam plastic can be mounted on any floor base.

In this case, it is not necessary to use a plywood structure, which protects the heat insulator from deformation and evenly distributes the load on the floor, as when insulating with mineral wool.

Due to the integrity of the structure, fungus and mold do not develop . Water is not absorbed by polystyrene foam, which makes it an indispensable floor insulation material in private houses and apartments with high humidity.

Easy to install . Laying foam plastic can be easily handled by a person without repair skills. The main thing is to correctly calculate the material consumption. Increases the service life of any floor covering due to its ability to evenly distribute loads.

Good heat and sound insulator . Polystyrene foam is excellent at minimizing heat loss. Excellent protection against noise coming from neighbors on the lower floors.

Despite the fact that polystyrene foam is harmless and does not have any effect on health, it releases toxic fumes . In rooms with high traffic, during installation work it is necessary to create a reinforcing frame that will protect the heat insulator from mechanical deformation.

Another disadvantage of polystyrene foam is its airtightness. Also, polystyrene foam exhibits chemical activity and is destroyed when interacting with nitrate-containing paints.

Foam chips as insulation

The construction industry very often uses recycled materials, which when combined with other building components produce completely new materials. For example, when combining concrete mortar with foam chips, a very warm and light foam concrete (polystyrene concrete) is obtained, which can be used in the following cases:

1. Insulation of almost any structures.

2. Creation of structures that are lightweight.

3. Filling cavities.

Today, the area of use of foam concrete (expanded polystyrene concrete) is very extensive. Products made from this material can be used both for the construction of non-load-bearing interior partitions and for load-bearing walls.

Foam concrete (polystyrene concrete) is widely used in soundproofing and insulation work. The low weight of foam concrete structures creates minimal load on the foundation. Foam concrete structures are especially in demand for insulating structures without additional strengthening of the foundation.

In terms of environmental friendliness, foam concrete approaches the performance of natural wood. Of course, when building multi-storey buildings, preference is given to brick due to its strength, but foam concrete is an excellent choice for providing thermal insulation.

Proportions for preparing polystyrene concrete:

| Purpose | Cement | Sand | Styrofoam crumbs |

| For load-bearing walls | 1 part | 3 parts | 8 parts |

| For partitions | 1 part | 3 parts | 12 parts |

Preparation of polystyrene concrete

Plaster with foam chips

Polystyrene concrete floor screed

Polystyrene concrete screed for a lighthouse

Foam chips for foam concrete, polystyrene concrete

The modern world amazes with its abundance of various furniture. Among the most unusual pieces of furniture is frameless furniture, which is currently preferred by modern consumers. Those who have ever had the opportunity to sit in this type of furniture feel, first of all, absolute comfort, because... frameless furniture takes the correct position of the human body.

Currently, frameless furniture can be represented by a pear, a ball, a bag or a pouf. It is worth noting that the filler for such furniture is of great importance.

The most popular filler for frameless furniture is foam chips, which help the products maintain the required shape. It is worth noting that frameless furniture using foam chips provides an orthopedic effect. The filler allows you to relax and not just sink into a chair. The material hugs the human figure, giving it a comfortable position.

The advantages of using foam chips for frameless furniture are:

1. Such furniture is not subject to destruction.

2. Foam chips are a safe product that does not emit toxic substances.

3. The material used is not able to absorb dirt, moisture and sweat.

4. The lightness of the products, which means that even a child can move a piece of furniture independently.

5. Foam chips have excellent heat-preserving properties.

Frameless furniture

The use of foam chips for packaging is a very common use of this material. I would like to note that a more convenient material that meets the requirements for transporting fragile goods has not yet been found. The main advantage of using foam chips for packaging is maximum convenience, which allows you to keep the most fragile cargo intact.

Among the benefits of using foam chips for packaging is that it fits any load. In addition, this material repels water, which is simply necessary for transporting goods such as electrical equipment. Do not forget about the fire resistance of the material. When ignited, the foam chips will not burst into flames. And finally, using foam chips as packaging will not add weight to the main cargo during transportation.

Thus, foam chips are not only a material that can keep any type of cargo intact, but also in terms of material, this type of protection is profitable and affordable.

The advantage of all cellular and foam structures is their ability to prevent damage to fragile objects and absorb the possibility of impact. Such materials are easy to mold and have excellent protective and shock-absorbing characteristics.

Previously, paper was used as a cushioning material. Old newspapers, finely chopped or crumpled, were a good, and most importantly, cheap source of cushioning. Fortunately, those days are gone, and today foam chips can be used in great demand for these purposes. It represents a fairly cheap option for using material to provide shock absorption.

Chip foam is considered an effective shock-absorbing material that can recover up to 90 percent of its original thickness after being subjected to stress. Even with the most significant compression, the structure of the foam chips is not disturbed and quickly returns to its previous shape.

Insulation of pipes is an important condition for the normal functioning of any structure. Today, foam chips are often used as pipe insulation.

The advantages of using foam chips for thermal insulation are obvious: 1. Environmentally friendly material. 2. Low thermal conductivity characteristics. 3. High water resistance. 4. The strength of the material, which is confirmed by the fact that foam chips can withstand significant loads over a long period of time. 5. Durability. 6. Ease and simplicity of installation. 7. High degree of resistance to lime, calcareous acids, saline solutions, alkalis and sea water. 8. Fire safety. 9. High resistance to mold and bacteria. Foam chips are not eaten by animals and microorganisms. 10. Wide scope of application.

Main Applications

Foam chips, the use of which is determined by the size of the fraction and the method of production, is widespread in the construction industry.

The main use of “crushed” is the basis for light and warm concrete. When producing polystyrene concrete, a certain amount of granules is gradually added to the solution, and the entire mixture is placed in a concrete mixer. The resulting solution is poured onto the floor, making a warm and light screed. Using a polymer concrete screed not only significantly insulates the floor, but also saves the consumption of concrete mixture, and given the significant reduction in the total mass of the solution, the load on the foundation is reduced.

The second way to use “crushed” is pneumatic insulation. The waste is turned into a liquid composition, which is pumped under low pressure into the interwall space of houses. This method is considered the most effective when insulating old private houses.

It was these structures that were built with an additional air chamber between the inner wall and the outer one. In Soviet times, this was not a tribute to fashion, but a significant saving in building material, since a layer of 10-15 centimeters was equivalent to another row of brickwork. Unfortunately, it was almost impossible to take advantage of the full potential of the invisible layer - the construction technologies of those times did not allow making the air chamber airtight, and in winter the house lost most of its heat precisely because of this design.

The insulation process itself occurs as follows:

- first, experts study the possibility of insulating a house using this method;

- then, at regular intervals, holes are drilled in the outer wall using a hammer drill;

- liquid polystyrene foam is supplied through a hose under slight pressure into the cavity, which fills the space between the walls;

- The holes are closed with special plugs.

Despite the advantages of using molten foam chips in this way, the method has some disadvantages. The most significant of them is the lack of ventilation, which leads to the accumulation of moisture in the form of condensation, gradually destroying the load-bearing wooden structures of the house.

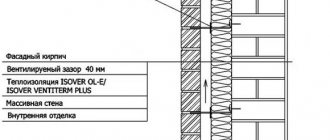

The third popular way to use crushed polystyrene foam is to fill the space between walls with dry granules during construction without mixing with cement mortar . The result is high-quality insulation with the possibility of unhindered ventilation. Compared to standard façade cladding with foam boards, this method is much cheaper.

Main characteristics of foam chips for insulating walls from the inside and outside

Today, the construction market uses materials of various shapes and properties for insulation. One of the most popular is polystyrene foam chips. Thanks to its positive characteristics, the material can be considered the best for turnkey wall insulation in a private home:

- Highly environmentally friendly. Polystyrene foam is non-toxic to people and pets and does not contain harmful chemicals;

- Excellent insulating properties. Due to its roughness, it has good sound insulation and thermal insulation;

- Durability and high shock absorption. When compressed, the granules do not lose their shape and properties;

- Moisture resistance. Insensitive to temperature changes, almost impenetrable to water and air;

- Fire resistance (treated with a fire-resistant solution);

- Immunity to rodent attacks;

- Hypoallergenic, odorless;

- Economical. Low cost compared to analogues, there is a possibility of lower prices for other materials, due to the possibility of combining a solvent with granules.

Insulating walls with expanded polystyrene chips allows you to solve a number of the most pressing problems, because in addition to the simplicity of thermal insulation, this material is very economical to install and of sufficient quality.

Additional uses of granules

Granulated polystyrene foam is used not only in construction, but also in other industries. First of all, this is furniture production. There, the crumbs are used to fill frameless models of armchairs, sofas or poufs.

The next industry is the direct production of foam plastic boards and other configurations, as well as packaging materials and permanent formwork for monolithic construction. Some manufacturers use exclusively “primary”, others add some of the “crushed”.

One of the promising uses of granular foam is as an absorbent for outdoor septic tanks. Tests have shown an almost complete absence of odor and higher efficiency compared to modern bacteria-based preparations.

As an additional direction, granulated raw materials are used for various decorative items. Synthetic snow based on foam plastic has become very popular and quite widespread. One of the hits of the last two or three years has been ball plasticine, the basis for which is fine-grained polystyrene foam and a binding gel.

Disadvantages of polystyrene foam

To make the right decision, in addition to all the positive things, it will be very useful to know some of the negative aspects inherent in polystyrene foam. There are several of them.

Foam plastic is a flammable material

No matter what the manufacturer writes on the packaging, polystyrene foam burns and melts when in contact with fire. Therefore, you need to make sure that the fire does not get close to it. The consequences can be very dire.

This is why polystyrene foam cannot be used on a ventilated façade. Direct contact with air and the void between the insulation and the surface of the facade create all the conditions for good combustion. Emptiness, by the way, works as an additional air draft.

Polystyrene foam releases hazardous substances

During the process of natural aging - destruction, polystyrene foam releases styrene monomer. Its smell can be clearly heard if you put a pack of foam sheets in a closed room. After a while, a characteristic unpleasant odor will appear in the room. That is why you cannot use foam insulation inside residential premises. But, unfortunately, few people know about this.

By the way, this is why you need to insulate a bathhouse with polystyrene foam carefully and carefully. When heated to 90 degrees Celsius, the release of volatile compounds hazardous to human health becomes very large.

Polystyrene foam is hygroscopic

That is, it attracts moisture.

No matter what they say, he does it, although not quickly, but confidently. Therefore, insulating a damp, cold basement with ordinary polystyrene foam would be a very bad idea. It is better to use extruded polystyrene foam for these purposes. It has a different internal structure due to which it does not attract moisture. To test this statement, you can put a piece of regular and extruded foam in water. After a while you will get two materials with different moisture content. One will be heavy and wet, and the second will be dry and light.

Polystyrene foam works as a vapor barrier

This is another serious disadvantage that few people think about at the design and construction stage. It manifests itself especially well in houses that are built entirely from polystyrene foam blocks.

During breathing, a person exhales warm water vapor with the air. This steam must escape from the room. The main direction of steam movement is up and to the sides. The ceiling and walls act as a kind of steam outlet; they “breathe”. A building insulated with polystyrene foam must have good forced ventilation. Otherwise, in winter it will be possible to collect water on the windows with buckets, and the room will be very humid.

Styrofoam is a good home for mice

This is a proven fact.

Small gray rodents live well in ordinary polystyrene foam. For them, this is a kind of paradise - warm, soft and safe. Whatever this happens, it is necessary to limit as much as possible the contact of the insulation with places where rodents can enter. This can be done with mineral wool or metal inserts. Rodents don’t like mineral wool, but they won’t be able to chew through a metal insert. They also do not live in extruded polystyrene foam. In this article we managed to list the main positive and negative properties of polystyrene foam. As insulation, polystyrene foam has a very wide range of positive qualities. But as a material, it has significant disadvantages. Therefore, the use of polystyrene foam in insulating the home itself must be approached carefully and thoughtfully.

By the way, the name itself, “foam plastic,” came to us from the times of the Soviet Union. Then the first import supplier of polystyrene foam boards was a company whose name included the word “Foam”. It turned out like with a copier - the name of the company became a designation for a whole class of copying devices. The same thing happened with foam plastic.