Proper vapor barrier of a frame house

The technology for constructing a frame house, although it appears to be accessible and therefore can be mastered by a non-professional builder, is in fact not such a simple scheme. Each stage of production does not tolerate errors, and all the mistakes can come out quickly enough. This is especially true for the correct vapor barrier of a frame house, because a bad choice can be fatal to the structure.

What is proper vapor barrier

In general terms, vapor barrier is a set of related methods for protecting both the structure and its cake from steam and its next physical state (condensation). The role of events is difficult to overestimate. To understand the importance of vapor barriers, you need to consider two related terms: “breathing walls” and “dew point”.

Breathing walls

There is a strong belief among people that everything around a person should be permeable, everything should “breathe,” including the walls in the house. From the point of view of high-quality frame construction, this is fundamentally wrong.

The thing is that this concept has a completely different meaning. “Breathable” does not mean that the walls provide air exchange. This is an opportunity for the normal removal of vapors from the room, while moisture should be retained in the walls last. And here the vapor barrier plays a decisive role, allowing us to ensure the main principle: reducing the vapor barrier from the inside out. In other words, as you move through the walls towards the street, the possibility of vapor penetration should decrease. When vapor gets into the thickness of the enclosed structure, at a certain moment it turns into a state of condensation, which is destructive for the walls of a frame house. This happens when the vapor reaches the dew point temperature.

Dew point is, contrary to popular belief, not a temperature, but a state at which condensation of water vapor occurs. It is determined by the relative humidity of the air. The goal of proper vapor barrier is to change the conditions inside the structure in such a way as to move the dew point closer to the outer contour of the insulation or to completely eliminate condensation inside the wall.

Correct vapor barrier of a “classic” frame house

By “classical” frame we mean one that is sheathed on the outside with slab material such as OSB to provide it with spatial rigidity, and glass, mineral, and basalt insulation is used as insulation. The problem with such a frame is that OSB has good vapor barrier properties, and if a 9 mm thick slab has a vapor permeability of about 10 g/m2 per day, then OSB with a thickness of 12 mm and above is already an almost absolute vapor barrier.

The wrong choice of internal* vapor barrier will lead to the insulation getting wet in the thickness of the wall, which will worsen its insulating properties and shorten its service life. To prevent this from happening, the vapor barrier must provide greater insulation than OSB.

A simple plastic film can cope with this. Thus, polyethylene with a thickness of 150 microns has a vapor permeability of about 3 g/m2 per day. But a specialized reference film like Izospan D may no longer cope with this task, although sellers promise “fantastic” zero vapor barrier (indicated on the packaging).

The thing is that polypropylene films, although they have lower vapor and gas permeability than polyethylene films, this difference is not an order of magnitude lower, but only 40% lower. However, if we take into account the smaller thickness and density of polypropylene films of the Izospan type (density 105 g/m2) relative to the same polyethylene with a thickness of 150 microns (density 130 g/m2) and the exponential relationship between thickness and insulation, it ultimately turns out that polypropylene the film may be inferior to polyethylene.

"Inverted" frame

This is a non-standard name for a technology in which OSB is installed not outside, but inside the room. It has not found wide spread among developers, although it can be considered logical and even traditional.

The reasons for its less popularity include:

- the impossibility of organizing rigidity between floors or a floor and a pediment;

- formaldehyde emission level. The indicator declared by domestic manufacturers is not trustworthy due to the lack of effective regulation by regulatory authorities.

If the following conditions are met: the house is one-story, the quality of the OSB is trustworthy (there is confirmation of the tests performed and the results obtained), then in this case, in principle, an additional vapor barrier is not required, since OSB is practically a standard vapor barrier.

Vapor barrier of frame house on jibs

In the case when only jibs are used to ensure the rigidity of the frame, and mineral wool is chosen as insulation, then it is advisable to use any film material for the appropriate purpose as a vapor barrier layer. Again, the formed multilayer structure should not violate the main rule about the direction of vapor permeability from inside to outside.

I would like to note the misconceptions that arise thanks to the well-calibrated marketing moves of polypropylene film manufacturers and are then disseminated in all kinds of media and on the Internet. Due to incompletely truthful product promotion and lack of reliable information, a gullible buyer may ultimately suffer. A big question is the statement that polyethylene, in principle, cannot be a good vapor barrier, since along with water vapor it also traps air, unlike films “using innovative special technology.” In this case, the very essence of the vapor barrier is lost.

Vapor barrier with plastic film - pros and cons

Hundreds and hundreds of articles have been written on the topic of the need to use vapor barrier film in the process of insulating roofs, walls and floors. Undoubtedly, this piece of the “pie” is extremely important, and without something as small as film, all the work can go down the drain.

Several types of vapor barriers are known for internal and external use: foil and reinforced films, “breathing” membranes, as well as vapor barrier with polyethylene film.

Despite the great popularity of membranes and the reliability of reinforced fabrics, many people prefer vapor barrier with polyethylene film. And it’s clear why: it does not allow water to pass through, and is much cheaper than other hydro and vapor barrier materials.

What is suitable for vapor barrier

The best option for vapor barrier when insulating a house is special vapor barrier membranes that prevent the penetration of moisture into the insulating layer, protect the structures and finishing of the building from destruction, extend the service life and improve the heat conservation of the house.

There are several types of vapor barrier membranes that are significantly superior to polyethylene films in strength, vapor resistance, and durability:

- Anti-condensation films. They are produced in the form of a non-woven fabric that effectively absorbs and retains condensation on its surface, which then evaporates naturally. The membranes are easy to install due to the absence of the need for a ventilation gap between the insulation and the finishing and are successfully used for the installation of pitched metal roofs, walls and ceilings of both insulated and irregularly heated non-insulated buildings.

- Superdiffuse membranes. Diffuse vapor shielding membranes are included in the insulating “pie” with low thermal conductivity, installing them without a ventilation gap.

- Thermal reflective films. Double-layer vapor barrier membranes with aluminum coating are used in the insulation system of wet rooms, which are characterized by temperature changes: baths, saunas, bathrooms. For example, R Termo Ondutis film reliably screens water vapor, returning 80% of the heat back into the room.

- Reinforced hydro- and vapor barrier films. Multifunctional membranes for protection against precipitation, moisture and condensation, which are used for insulating loggias, balconies, facades and roofs.

What is the difference between vapor barrier and polyethylene film?

Vapor barrier is a material that does not allow even the smallest particles of water vapor to pass through in any direction, has good density, is not subject to the destructive effects of UV, and is easily installed with metal brackets or self-tapping screws. How does polyethylene differ from special film?

Advantages of polyethylene:

- perfectly retains moisture and steam;

- costs less than branded vapor barriers.

Disadvantages of conventional film:

- under the influence of UV radiation it quickly deteriorates (cannot be used for external work);

- the strength of polyethylene is much lower than reinforced or membrane films, it is easier to tear, stretch, and is afraid of punctures and cuts;

- service life is lower than that of specialized vapor barrier;

- Thick polyethylene has sufficient strength, but weighs more than special films.

Accordingly, it is difficult to use such material on ceilings or walls.

Consider the installation of polyethylene film

In fact, the installation of a vapor barrier made of polyethylene film is no different from the process of installing a specialized vapor barrier. Since their main specificity is the protection of thermal insulation and wooden structures from the penetration of steam from residential premises, they are laid in front of the insulation.

This is how plastic film is installed on the ceiling

Wherever the film is used, it is laid horizontally from bottom to top, with overlaps of at least 15 cm.

The joints must be taped with reinforced tape to prevent steam from leaking through the cracks. In addition, another unshakable rule when installing a vapor barrier for any type of “pie” is that there must (!) be a ventilated air between the film and the insulation. If condensation somehow appears there, it will safely roll down the film and will not wet the insulation.

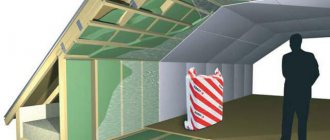

Place of the vapor barrier in the roofing “pie”:

- The roofing covering (metal tiles, sheet iron, slate) protects the interior of the house from climatic and atmospheric phenomena.

- Waterproofing - if atmospheric moisture penetrates under the roofing material, the film will protect the insulation and wooden structures from getting wet. The pairs “roof covering and waterproofing”, “waterproofing and insulation” should not be attached closely. Double-sided conrogrilling is used to provide ventilation gaps.

- Insulation. It is spread in several layers to ensure the required thickness of the casing. The risk of the appearance of “cold bridges” must be taken into account.

- Vapor barrier, like waterproofing, should be located at a distance of 2-3 cm from the insulation to ensure natural ventilation.

- Final finishing of the attic ceiling.

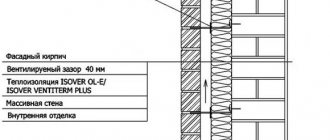

If we talk about internal walls or ceilings, the situation is similar:

- main wall/ceiling;

- lathing or frame made of metal profiles;

- insulation layer;

- vapor barrier film;

- plasterboard or other finishing material;

- final finishing.

As you understand, you can use regular polyethylene, but you need to use it extremely carefully due to its lower density and wear resistance.

We hope that the material was useful to you. We will be grateful if you share it on social networks. The buttons for this are below.

Types of vapor barrier films

If we talk about the main materials from which hydro-wind-vapour barriers are made, then there are two of them:

- polyethylene;

- polypropylene.

For example, the UTA company (Czech Republic) produces multilayer polyethylene films, and the domestic corporation GEXA produces polypropylene films (known under the brand name Izospan).

Also, all vapor barrier films can be divided into:

- single-layer polyethylene;

- specialized multilayer.

A single-layer polyethylene film for vapor barrier does not have a reinforcing layer, and it does not withstand high tensile loads, but even in some current standards, instead of a specialized vapor barrier, polyethylene is “registered” as the main material. And in Finnish frame houses, using “native” technology, 200 micron polyethylene is laid inside the walls to vapor barrier mineral wool.

Watch a video on how to install vapor barriers using 200 micron polyethylene film:

Specialized films consist of several layers:

- Reinforcing layer , which is made in the form of a grid of strips of base material. It is responsible for the strength to mechanical stress when attached to the supporting frame (or sheathing) and during operation of the structure.

- Polyethylene or polypropylene film is the second layer, which is responsible for vapor barrier.

- Lamination on the reverse side is available for most modifications of vapor barrier films. This increases vapor permeability, since the basic principle of operation of a vapor barrier film implies that the thicker the material, the less water vapor will “leak” through a unit surface area in a fixed period of time.

There are universal films that can be laid on either side of the insulation (for example, materials from the YUTAFOL N series).

There are films with an “asymmetrical” structure - one side of them has either a rough or reflective surface. The first option is called “anti-condensation” vapor barrier films. The second option is vapor barrier films with a foil surface (fourth layer), which reflects part of the thermal energy towards radiation.

When installing these types, it is important to know which side to lay the film on the insulation.

How to make a vapor barrier from polyethylene film

A vapor barrier made of polyethylene film creates a vapor barrier, as a result, the warm air of the room does not escape to the street. Such materials serve to protect the insulation from water vapor that forms inside the room. This is how moisture condensation is regulated in the area of the building envelope.

The harm of moisture accumulation in rooms is that as a result, spores of fungi, mold and other bacteria multiply. By using polyethylene film as a vapor barrier, this will be able to resist the penetration of water vapor. The material is made primarily of multilayer polyethylene.

Can film be used as a vapor barrier?

Can a vapor barrier film be used when the budget is limited and the owner needs to save a little during construction? Yes, this option is possible. For both frame and wooden houses, the simplest vapor barrier film is suitable - polyethylene or polyvinyl chloride.

In order for the vapor barrier film to last as long as possible, it is worth knowing what can be done in this case, and what cannot be done under any circumstances.

Firstly, such vapor barrier film must be laid correctly. The diagram shows that a vapor barrier film is placed on the inside of the cake, cutting off water vapor from the interior of the house.

Secondly, the vapor barrier layer must be protected from light. PVC films can still resist sunlight, but polyethylene is very poorly protected from UV radiation.

Third, do not use thin vapor barrier films on vertical surfaces. Thin ones are suitable only for horizontal floors, attics, and ceilings. If the thickness of the film is suitable for a greenhouse, then it is also suitable for walls. This is a simple characteristic of the material.

And finally, you need to fasten the material either with a stapler on large staples through cardboard or PVC spacers, or with small furniture nails. Whether or not to glue the joints, as well as whether to glue the fastening points, decide for yourself. The amount of water vapor that gets into the wall pie through the fastening points is quietly removed through the ventilation gap from the outside of the house.

See more on this topic on our website:

- How to make a canopy over the porch of a house out of polycarbonate Let's see how to make a canopy out of polycarbonate over the porch of a country or city house. Such a canopy will protect you from snow melting during winter or...

- What type of wool can be used to insulate the walls of a house? Do rising prices for electricity and gas make you personally think about saving energy resources? Try to answer this question honestly. If yes, then this material...

- Is it possible to use polystyrene foam under siding? Vladimir Moshkin, Surgut. Question: Hello, fellow builders! Can foam plastic be used for siding to insulate a wooden house? And then some say it’s possible, while others say no….

- How can you insulate an old village wooden house? Despite the favorable climate, buildings made of wood require additional insulation, since in the most severe frosts you can spend a lot on electricity. Among modern residents, suburban…

- How can you insulate a wooden house from the inside and outside? It is believed that a house made of wood cannot allow cold to pass through, because the material from which it is made is a good heat insulator. But there are times when builders are not very conscientious...

Installation of vapor barrier

All further actions are thought through in advance, namely:

- The most suitable type of insulating material is selected.

- Installation work is underway.

- The film used is installed according to certain rules, this allows it not to disturb the structure of the building and other elements.

Most often, a vapor barrier is installed using polyethylene film. Many people don’t even know that there are substitutes for it. Quality indicators are 3 indicators:

- fire resistance;

- high strength;

- low thermal conductivity.

Below are the most common vapor barrier materials:

- Polyethylene with reinforced mesh. It comes either with or without perforated reinforcement. Products with perforations contain small holes that easily allow moisture to pass through. If there is no perforation, then there are no special holes. This material is quickly and easily installed with virtually no waste. Some films have a foil coating to help reflect heat. This coating is most often used in baths.

- Polypropylene. Compared to its polyethylene counterpart, this material is much stronger and UV resistant. Applies to already erected structures. One side of polypropylene is impregnated with cellulose and viscose, which improves moisture absorption. The material is resistant to damage, and the price is affordable for the average buyer.

- Bitumen-based vapor barrier. This is a liquid vapor barrier that is applied to the surface with a roller or brush. Bitumen comes in different forms. Everything will depend on temperature indicators. But if the air temperature is lower than the presented indicators, the bitumen will gradually collapse.

Self-adhesive vapor barrier film

There are other materials used instead of vapor barriers. These are aluminum foil, cardboard, membrane vapor barrier, spunbond, HDPE. They all have their own purposes and directions.

review of materials and recommendations for laying vapor barrier film

Vapor barrier made of polyethylene film - can it be used?

A vapor barrier made of polyethylene film creates a vapor barrier, as a result, the warm air of the room does not escape to the street. Such materials serve to protect the insulation from water vapor that forms inside the room. This is how moisture condensation is regulated in the area of the building envelope.

The harm of moisture accumulation in rooms is that as a result, spores of fungi, mold and other bacteria multiply. By using polyethylene film as a vapor barrier, this will be able to resist the penetration of water vapor. The material is made primarily of multilayer polyethylene.

Why do you need a vapor barrier?

During the insulation process, the temperature affects the inner layer of the polyethylene film. There is still a small amount of water vapor in any room. Sometimes they form water droplets, this happens in certain cases:

- When excess moisture is fixed indoors.

- When the indoor temperature drops. If it decreases significantly, then the steam can no longer retain moisture.

Insulation with films may be necessary if the temperature inside the room is the same as outside. After installing a vapor barrier, steam will no longer turn into water. When the air temperature in the room begins to rise, the steam will disappear on its own.

Vapor barrier material is installed in those parts of the building where contact with cold air is felt most, namely on the floor of the first floor, the ceiling of the top floor or on the walls.

Installation of vapor barrier

All further actions are thought through in advance, namely:

- The most suitable type of insulating material is selected.

- Installation work is underway.

- The film used is installed according to certain rules, this allows it not to disturb the structure of the building and other elements.

Most often, a vapor barrier is installed using polyethylene film. Many people don’t even know that there are substitutes for it. Quality indicators are 3 indicators:

- fire resistance;

- high strength;

- low thermal conductivity.

Below are the most common vapor barrier materials:

- Polyethylene with reinforced mesh. It comes either with or without perforated reinforcement. Products with perforations contain small holes that easily allow moisture to pass through. If there is no perforation, then there are no special holes. This material is quickly and easily installed with virtually no waste. Some films have a foil coating to help reflect heat. This coating is most often used in baths.

- Polypropylene. Compared to its polyethylene counterpart, this material is much stronger and UV resistant. Applies to already erected structures. One side of polypropylene is impregnated with cellulose and viscose, which improves moisture absorption. The material is resistant to damage, and the price is affordable for the average buyer.

- Bitumen-based vapor barrier. This is a liquid vapor barrier that is applied to the surface with a roller or brush. Bitumen comes in different forms. Everything will depend on the temperature

Polyethylene

This is the cheapest and most accessible material. It is conditionally divided into 3 groups:

- non-perforated film;

- perforated look;

- film with an aluminum layer.

Is it possible to use all these types for floor installation? If you are making a vapor barrier on the floor, you can use any type of polyethylene. But each of them has its own specific purpose, like this:

- Non-perforated polyethylene films are used for vapor barrier of a room.

- Perforated material is intended for waterproofing.

- Polyethylene with aluminum coating is mainly used for installing floors in buildings where there is a high level of humidity.

Perforated material

When you come to a hardware store, you will see many names of polyethylene films, it all depends on the brand of the manufacturer. The most commonly sold brands are:

- Polinet. This vapor barrier is presented in one layer and has a non-perforated direction.

- Geotex. Its thickness is 1 layer, without perforation.

- Techno NIKOL - polyethylene film as a vapor barrier with 3 layers, reinforced with a mesh of polypropylene threads.

- TERMOFOL90. Consists of 3 layers reinforced with polypropylene threads and a layer of aluminum.

But this material consists not only of advantages, there are also disadvantages. The most important of them is the low strength of the film. But if installation is carried out carefully, the product will not last 1 year.

Why do you need a vapor barrier in a roofing pie ↑

First of all, a vapor barrier is necessary to protect the insulation from moisture absorption. The thing is that mineral wool and other materials used for insulation tend to absorb water contained in the air. As a result, the thermal insulation properties sharply decrease, mold and mildew appear, and the destruction of the material begins. In addition, due to temperature differences, condensation often forms on the inner surface of the roof, which affects both the insulation and building structures. The living conditions in such a house are deteriorating sharply.

So, the main task of vapor barrier is to protect heat-insulating and other building materials from steam penetration and condensation.

Why you can’t use polyethylene for vapor barrier

The main “disadvantage” of polyethylene as a vapor barrier is that this material does not allow air to pass through - it screens moisture well, but creates a greenhouse effect in the room.

Another fundamental drawback of such a vapor barrier in the “pie” of internal insulation of a house is the flow of condensate over the surface of the film and the accumulation of moisture on the floor. In addition, over time, polyethylene film undergoes destruction, becomes brittle and crumbles into small fragments, and due to its low tensile strength, it is often damaged during installation.

Materials used for protection against steam ↑

As a vapor barrier, you can use materials such as glassine, roofing felt, spanboard, roofing felt, and in bathhouses and other hot rooms - thermofol or foil.

Until recently, the main material for vapor barrier was glassine, but recently more expensive and high-quality film-type materials have become more common. This is due to the fact that glassine, which is based on construction cardboard, does not meet such important parameters as strength and durability.

Vapor barrier with roofing felt is also losing its relevance, since it must be attached exclusively to a rigid flooring, which is made from OSB boards nailed to boards, or from boards connected to a tongue and groove. From an economic point of view (due to the rise in wood prices), it is considered more profitable to install a vapor barrier with film materials that do not require flooring.

Installing a reflective vapor barrier

Canvases with foil are suitable for rooms where you need to retain heat as much as possible. The material is laid with a reflective layer facing outwards. A ventilation hole is placed between it and the finish, which increases the heat-reflecting properties of the foil and eliminates the risk of condensation. Sections of reflective vapor barrier are placed end-to-end and sealed with tape on a metal base.

Vapor barrier materials trap heat inside the house and prevent moisture from affecting the roof, walls and ceiling. The steam barrier in living rooms is installed with the rough side inward, in bathhouses and steam rooms - with the smooth side inward.

Rules for laying vapor barrier ↑

In order to reliably protect the thermal insulation material from moisture, when installing a vapor barrier, you must adhere to certain rules:

- Before proceeding with the installation of the film, it is necessary to thoroughly seal and insulate the raised, protruding elements of the roof. These include antenna mounts, chimneys, ventilation, ducts, etc.

- A vapor barrier film is placed between the room and the insulating layer.

- Most vapor barrier materials are easily attached to a variety of surfaces. Fastening to wooden structures is carried out using galvanized nails with wide heads or staples driven in with a construction stapler. For fastening to concrete, brick or metal surfaces, double-sided construction tape or tape with an adhesive coating is used.

- Since heat from the premises rises upward, the foil vapor barrier film should be positioned so that the applied layer of foil is directed into the room, reflecting heat. A gap must be left between the insulating layer and the vapor barrier, which will provide additional heat retention.

- An important condition for proper vapor barrier is laying the film in a continuous layer - without breaks, cracks or other holes. The joints are made with a ten-centimeter overlap. Places of complex junctions and joints should be additionally taped with vapor barrier tape. In addition to adhesive tape, it is recommended to use wooden slats, which serve as additional protection against tears.

- The film is installed with tension, without sagging.

Despite the apparent simplicity of the vapor barrier process, in fact this is one of the most important stages of roofing. Based on this, you need to either first thoroughly study all the intricacies of the technology, or use the help of specialists.