External thermal insulation value

Insulating a building helps maintain a comfortable microclimate even when the temperature on the thermometer drops critically. External thermal insulation of a house has a number of advantages:

- reduction of space heating costs;

- the walls of the house are less deformed due to temperature changes;

- preventing destruction of the building structure due to the influence of weather factors;

- saving space indoors;

- reducing the likelihood of mold and mustiness on the insulated internal surface of external walls thanks to external facade insulation systems.

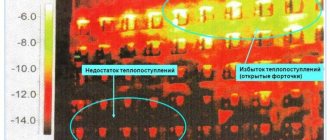

Figure 1. Facade insulation

Recommendations for installing external home insulation systems

If you are going to install the selected thermal insulation yourself, without the help of specialists, then we advise you to take into account several features that will allow you to avoid serious mistakes during installation work:

- At each stage of installation of external thermal insulation of facades, carefully ensure that the surface is not only clean, but also smooth. Even the smallest defects can negatively affect the efficiency of the entire system.

- If you use mineral wool as insulation, this material will have to be additionally secured using dowels with a galvanized tip.

- At the time of application and drying of the plaster layer, it is necessary to strictly maintain the optimal temperature regime, varying between +5C and +25C.

Features of working with facade insulation

The very first difficulty that you may encounter is the choice of material for insulation. Thermal insulation is selected taking into account the individual properties of the construction site. For example, at high humidity, special attention should be paid to the water absorption rate.

Mandatory steps for external insulation of the facade of a house:

- Before starting work, you need to carefully inspect the surface of the walls, clean it of debris and remnants of building materials, and repair cracks and defects. For this, a deep primer is used, which, after drying, is covered with a layer of plaster for exterior use.

- When installing insulation, a load-bearing element is required. It is installed at a height of about half a meter (base profile).

- There are always small gaps between the surfaces of the slab during installation. They need to be filled with a sealing substance.

The choice of material and method of insulation depends on the design of the building and must be selected individually.

Thermal insulation materials for facade design

There are several types of materials for thermal insulation:

- stone (mineral) wool;

- glass wool;

- Styrofoam;

- EPPS;

- polyurethane foam;

- ribbon tow.

Figure 2. Various materials for external insulation of facades

Mineral wool is suitable for buildings located in areas with high humidity, since it has low water absorption. This is a fire-resistant, environmentally friendly material, which also has good sound insulation properties and low thermal conductivity.

Glass wool is an affordable, lightweight material, but it has high water absorption and is harmful to health, which also needs to be taken into account

The cheapest material that holds heat well is polystyrene foam. Among its disadvantages is that it is flammable and therefore dangerous. And small inhabitants of the streets - rats and mice - also like to chew on it. When exposed to sunlight, foam releases substances harmful to humans.

Extruded polystyrene foam is a universal material. Many experts recommend using it not only for insulating the facade of a building, but also as a building material for flooring. The material has good sound insulation and is resistant to moisture and therefore mold does not grow on it.

With polyurethane foam, everything is generally simple - it is sprayed onto the walls. Among the advantages, one can also highlight that after it no gaps are formed and subsequently the use of sealant is not required.

Tape tow allows steam to pass through well, so it does not disrupt gas exchange with the outside world. But at the same time, it also allows water to pass through perfectly and therefore additional waterproofing is required.

Each material has its own advantages and disadvantages, so it can be quite difficult to single out any main one. Different insulation materials can be used for the same building.

Types of facade insulation systems can be divided into wet and suspended.

Which façade insulation system should I choose?

Since the introduction of new standards for building heating technology, quite a lot of manufacturers of facade thermal insulation systems have appeared on the Ukrainian market and their number continues to grow rapidly.

In such conditions, a completely legitimate question immediately arises: which system to choose? In our article we will not consider the variety of insulation systems offered by different companies. We set a more modest task - to compare two facade insulation systems Ceresit MV and Ceresit PPS , developed by the German company.

The materials used in the Ceresit MV and Ceresit PPS systems are produced by the same company under the Ceresit brand. The facade systems Ceresit MV and Ceresit PPS belong to external insulation systems using the “light-wet” method. This means that the insulation is attached to the outside of the building with cement adhesive solutions, then a thin but durable protective layer reinforced with fiberglass mesh is made on the surface of the insulation from the same adhesive solutions, and finally, the decorative finishing of the facade is done with thin-layer plasters.

The word “wet” in this case means that when insulating a building, water-soluble building mixtures are used, as well as ready-to-use primers, plasters, and paints based on aqueous polymer dispersions. And the word “light” means that for insulation, a lightweight thermal insulation material is used, on which a thin protective and decorative layer is applied (the total thickness of the protective and plaster layers is usually from 7.5 to 10 mm), so in total the entire system has a small weight.

The fact that the materials contain water and are applied in thin layers imposes some restrictions on the working conditions with such systems: installation can only be carried out at air temperatures and the surface to be finished from +5 to +30°C. However, this method of insulation has such a combination of positive qualities that the mentioned restrictions do not in the least prevent its widespread use.

Insulation using the “light-wet” method effectively protects the walls of a building from environmental influences (alternating temperatures, frost, precipitation, aggressive substances contained in the atmosphere of large cities).

Facade insulation systems Ceresit MV and Ceresit PPS are durable. Experience shows that their service life without deterioration of technical characteristics and the need for repairs is over 30 years. Ceresit insulation systems can withstand frost perfectly (more than 75 freeze-thaw cycles).

For the climate of Ukraine, this quality is especially important and allows for the effective use of these systems over most of the country’s territory. Finishing facades with thin-layer Ceresit materials allows you to minimize the load on both the wall of the building and its foundation, which plays a significant role in insulating old buildings.

This ensures a high degree of protection of the insulation from mechanical damage. It is especially important to note the very wide capabilities of Ceresit insulation systems when shaping the external appearance of a building.

Application on buildings with a wide variety of architectural styles, reproduction of all kinds of decorative elements on the facade, preservation of the historical appearance of architectural monuments, creation of new modern and original architectural forms - all this is possible with Ceresit systems. Using Ceresit plasters and paints (both mineral and polymer), you can give the façade surface any color and texture.

All this makes the external insulation systems for facades Ceresit MV and Ceresit PPS essentially irreplaceable when solving certain architectural problems. All differences between the Ceresit MV and Ceresit PPS systems are determined by the material used as insulation.

In the Ceresit MV system, mineral wool boards are used as insulation, and in the Ceresit PPS system, expanded polystyrene (styropor) boards are used. The choice of insulation material determines some features of insulation systems.

For example, when insulating with polystyrene foam, Ceresit CT85 glue is used to glue the insulation and create a protective layer reinforced with fiberglass, the facade is finished with both mineral and polymer plasters, and at the height of the first two floors you can do without additional fastening with dowels.

When insulating with a mineral wool board, accordingly, Ceresit CT190 glue is used, the facade is finished only with mineral plasters, and fastening with dowels is mandatory. In the future, we will try to figure out what criteria should be used when choosing an insulation system.

Properties of heat-insulating materials, facade works. Of course, the choice between the Ceresit MV and Ceresit PPS systems is a matter of choosing a heat-insulating material. Its properties determine both the advantages and disadvantages of the insulation system.

Mineral wool board has two main advantages: non-flammability and high vapor permeability. Expanded polystyrene, in turn, differs from mineral wool boards in being cheap (more than 2 times cheaper) and lighter in weight (5-7 times lighter).

But still, since the main property of a heat-insulating material is thermal conductivity, let’s start the comparison with it.

Thermal conductivity. The polystyrene foam and mineral wool boards used in the Ceresit MV and Ceresit PPS insulation systems are almost identical in their thermal insulation properties. Their thermal conductivity according to existing standards should not exceed 0.038 W/(mK).

Vapor permeability. In construction, water has always been enemy number one, contributing to both the destruction of structures and the deterioration of their thermal insulation. Therefore, when insulating facades, much attention is paid to moisture transfer processes.

Excess moisture must be removed from the building, because dryness means warmth and strength. In terms of vapor permeability, mineral wool board and polystyrene foam are very different from each other. Minslab has little resistance to water vapor.

They easily penetrate the building envelope, and condensate is effectively removed. The building “breathes”. In this case, finishing materials, of course, must have high vapor permeability. Therefore, when insulating a facade with a mini-slab, finishing can only be done with mineral plasters or polymer plasters with high vapor permeability, for example, Ceresit CT60.

Expanded polystyrene, on the contrary, has very low vapor permeability and creates great resistance to the penetration of water vapor. This creates a certain problem: in the wall of the building the vapor content will be slightly higher, this will create conditions for its humidification.

But, since the “dew point” is located in the insulation, condensation will not form in the wall. If there is sufficient ventilation in the premises and there is no excess humidity (as, for example, in bathhouses and swimming pools), then the problem is essentially eliminated.

At the same time, the vapor permeability of finishing materials no longer plays such a significant role and the finishing of facades insulated with polystyrene foam (Ceresit PPS) can be done with both mineral and polymer materials.

Fire hazard. Mineral wool boards have another advantage - they do not burn (flammability NG). The basalt fiber from which they are made can withstand high temperatures (up to 1000 °C), while the slabs retain their shape, certain strength and thermal insulation properties.

Therefore, the scope of application of the Ceresit MV insulation system is practically unlimited. Expanded polystyrene boards, unlike mineral wool boards, are combustible materials (flammability groups G1-G4).

This imposes certain restrictions on the Ceresit PPS insulation system and determines the scope of its application. In a number of other cases (for example, for industrial facilities and buildings with increased number of storeys, as well as with increased fire safety requirements), the use of the Ceresit PPS system is possible with additional agreement with the fire services.

When insulating buildings with polystyrene foam, horizontal fireproof cuts should be installed, and edgings made of mineral wool slabs should be made on all sides of window and door openings.

Specific gravity. Expanded polystyrene, unlike mini-slabs, has a very low density. If the mini-slab used for insulating facades using the “light-wet” method has a density of 105 to 180 kg/m3, then expanded polystyrene is no more than 25 kg/m3.

This means that when insulated with polystyrene foam, the increase in load on the foundation and walls of the building will be significantly less than when insulated with mineral slabs. In some cases this is important, for example, if we are talking about old buildings.

Economical. We have already found out that polystyrene foam is somewhat inferior to mineral wool board in terms of vapor permeability and fire safety. However, there is an indicator according to which the championship remains with expanded polystyrene. This is economical.

Expanded polystyrene itself is more than half the price of a mineral wool board. Since the material is very convenient to work with, labor costs when insulating with polystyrene foam are, as a rule, 20-30% lower than when insulating with mineral slabs.

Tangible savings in the construction of systems are also achieved by reducing the number of dowels required for fastening polystyrene foam. Moreover, for fastening polystyrene foam at a height of up to 8 m, dowels are not required at all (for a mineral wool board, fastening with dowels is always necessary), and at higher heights the estimated number of dowels is lower than for a mineral wool board.

The small difference in price for the adhesive masses Ceresit CT85 and Ceresit CT190 with significant areas of facades insulated with polystyrene foam also provides significant savings.

What to choose? Based on the described features of polystyrene foam and minislab, we can decide on the choice of insulation system in each specific case.

The Ceresit MV insulation system (on a mineral wool board) is more expensive, but it can be used on all buildings with virtually no restrictions.

The Ceresit PPS insulation system (expanded polystyrene) is cheaper, but its use is limited by fire safety requirements. In addition, there are a number of objects where the use of the Ceresit PPP system is not allowed at all.

These are buildings with increased fire safety requirements and responsibilities (for example, hospitals, children's institutions, etc.). It is not advisable to use this system in buildings with high internal humidity (swimming pools, baths, hydropathic clinics, car washes, etc.).

Having made the right choice, you will receive a high-quality insulated building facade that will serve you for a long time and provide a decent appearance to your building, and the work on the facades will be inexpensive.

Methods for insulating building facades

For those who have decided to equip a building with an external insulation system, below you can familiarize yourself with the possible options and choose the most suitable one.

Wet facade

The main feature of the wet type of insulation installation lies in its name. All work is carried out using water means for “coupling”. Liquid primer, paints and plaster are used. Even decorative finishing is applied before it hardens. You can learn more about the wet facade from the video.

Ventilated facade

The main feature of this method is the presence of space between the load-bearing wall and the insulation. The gap allows air circulation and moisture removal. Various panels are used as cladding, creating a unique image.

Facade thermal panels

Expensive and “picky” material. It must be installed on perfectly flat walls, because otherwise it will turn out crooked or fall off completely. Among the advantages are the harmlessness and lightness of the panels. The material is very conveniently attached to self-tapping screws, so if desired, the thermal panel can be removed quite easily.

Figure 3. Facade thermal panel

Comparison of facade insulation systems

Each insulation system has its own advantages and disadvantages.

| Parameter/Facade | Wet | Ventilated | Tiled |

| Bridges of cold | Almost not | So many | Average level |

| Durability | Depends on the insulation | From 20 years old | Depends on the insulation |

| System cost | Minimum | Maximum | Depends on the tile |

| Difficulty of installation | Average | High | Average |

| Vapor permeability | Depends on the insulation | Very high | Zero |

| Care | Depends on the plaster | Simple | Simple |

Preparatory stage before wall insulation

In order for the insulation to adhere well to load-bearing walls, to be even and to fit well, you must first carefully prepare the surface.

Fixing the base profile

A necessary procedure used to fix insulation and decorative trim, if necessary, to protect the end. Before the glue dries, the sheets are not stable and can move. For proper fixation, markings must be made first.

Installation of external window sills

An external window sill is also called a sill because of its main function: draining water away from the window. The window sill is an integral part of the building facade and gives the window frame a finished look. If the sills are installed correctly, water will not fall onto the wall surface. The external window sill is fixed directly to the window.

Figure 4. Installation of external window sills