If you want to make your own bunker for a pellet boiler, then you should pay attention to the design of the mechanism for supplying fuel (pellets) to the burner. They can be divided into several types.

The first type is a monolithic rigid twin-screw fuel supply system, which has a rigid structure, the augers are separated by an air pocket to protect the main hopper from the backfire of the pellet burner. The screws are located horizontally one above the other. In such burners, if the User leaves the fuel hopper open, only the lower auger of the burner itself can burn out, and the upper auger supplying fuel from the pellet hopper will not ignite.

It is not difficult to increase the bunker for this type of fuel supply - we increase the height of the bunker walls upward or at an angle of 45 degrees in all four directions, where the dimensions of the boiler room allow this.

The second type is single-screw fuel supply systems. The simplest, most reliable, but also requiring attention from the User of the pellet boiler and its Manufacturer. Because if the boiler does not have an exhaust fan and the bunker is not sealed, then the flame can go in the opposite direction from the chimney and ignite the pellet bunker. However, there is a small caveat here, if the boiler has a two-pass or single-pass convective part (one of the most inefficient pellet boilers), then the resistance of the smoke path is low and, in this case, reverse draft is hardly possible, but again with the caveat that the chimney is built correct and has constant traction. A poorly constructed chimney, if it has cooled down and has no draft, can cause backdraft and the flame from the burner can ignite the fuel bunker along the auger.

When enlarging the bunker for the second type, it is necessary to maintain tightness, that is, we increase the sides of the bunker in any direction, but we seal all connections, or even better, we boil it, and install a sealed lid for filling in wood pellets. It is recommended to install the lid on clamping latches, and a rubber or polyurethane seal is placed at the point of contact between the lid and the hopper.

The third type is twin-screw flexible feed systems, used in mounted or external pellet burners with an external hopper. Such submissions are among the safest, because... have a large air gap between the auger of the external bunker and the auger supplying pellets to the burner for combustion in the boiler.

For this type of supply, non-pressurized fuel bunkers are used, which you can easily increase yourself by increasing the sides or dimensions of the bunker.

When increasing the size of the pellet boiler bunker, do not forget that the higher the bunker, the higher the point you will need to pour pellets into it, i.e. a ladder will appear nearby. Also, in order for the pellets to flow freely down to the auger along the walls of the bunker, it is necessary that the angle of the walls be above 45 (forty-five) degrees, only in this design there will be no pellets hanging in the bunker.

Types of storage facilities for fuel pellets

The consumer is offered three main types of pellet bunkers:

- Standing separately.

- With flat or V-shaped floor.

- Underground.

Each design has its own characteristics and limitations associated with operation.

Free standing bins

Free-standing bunkers are the simplest, but at the same time effective solution to the problem. Typically, a container for storing fuel pellets is already installed on the boiler body, directly connected to the burner by a screw transmission. The operating time from one refill varies from 6 hours to several days, depending on the storage volume.

An additional metal hopper for a pellet boiler increases the battery life to 1-2 months. More recently, models made of plastic have appeared.

During installation, a screw or vacuum pump is connected to a burner or built-in hopper. When solving the issue, take into account the design features of the boiler.

Rooms with flat and V-shaped floors

These solutions mainly use the screw method of loading the intermediate hopper of a pellet boiler house. Pellets are loaded into the bunker through special hatches, or using a twin-screw transmission.

In this case, fuel pellets are loaded into the primary storage room, after which two augers located at a longitudinal angle distribute the pellets evenly along the entire perimeter of the room. The second worm gear is connected to a hopper located on the boiler body.

Another loading option is to use a vacuum pump. The granules are sucked up and poured into storage under air pressure. To ensure uniform distribution of pellets throughout the hopper and prevent them from breaking, special curtains are used.

Underground storage for wood pellets

Fuel is supplied by vacuum or screw transmission.

Where can the bunker be located?

When constructing or choosing a pellet bunker, you determine where it will be located yourself. It can be located in the same room as the boiler, in the next room, it can be located on the street or in another building. It is important that the distance be maintained (10 or 80 meters depending on the delivery method).

Making a pellet bunker with your own hands is not difficult at all.

Regardless of where the pellet storage is installed, it must protect the fuel from moisture: with increased humidity, the pellets are destroyed, and the amount of heat they release during combustion is reduced. Therefore, damp rooms are unsuitable for these purposes. If you decide to install or arrange a storage bin for pellets outside, you will have to take care of its tightness.

Systems for feeding pellets from storage to the boiler

The connection of the external bunker to the wood pellet boiler is carried out by means of a screw (worm) and vacuum fuel transmission. When choosing a connection option, pay attention to several characteristics:

- Energy consumption.

- Noise characteristics.

- Dependence on constant availability of electricity.

By paying attention to the points listed above, you can choose the best option for a private home or industrial premises.

Auger transportation of pellets

A storage hopper with an auger is quite difficult to integrate into existing premises. The use of a worm gear reduces the usable storage area by almost 20%.

Vacuum feeding of wood pellets

Vacuum transportation of pellets from the storage warehouse to the heating boiler bunker is more convenient and efficient. The length of the transport route increases to 30 m, 10 m more than the permissible limit of the screw drive. There are many options for placing storage on the site near the house. It is possible to simultaneously connect several containers at once or increase an existing bunker to 30 m³.

PPB requirements for pellet storage facilities

The boiler room and pellet storage are potentially dangerous premises with a high probability of fire. It is imperative to take preventive measures to prevent a fire from occurring.

Design and principle of operation

The main elements of a pellet boiler are:

- pellet burner - can be retort or torch. The retort is made in the form of a conical bowl, granules are fed into it from below, and combustion air is forced by a fan through the side holes in the retort. The column of fire in the retort burner is directed upward; this should be taken into account when designing.

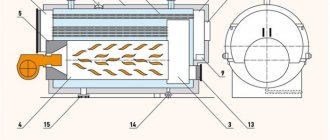

A flare burner is a pipe, from one end of which fuel is supplied, and from the other there emerges a column of flame directed horizontally. Air injection occurs from the pellet supply side.

- fuel bunker - serves for loading pellets; the tank volume of 200-300 liters ensures uninterrupted operation for 3 days.

- transport belt with auger - used to supply pellets from the hopper to the combustion chamber.

- boiler body - made of steel, cast iron or brick. Inside the housing there is a heat exchanger, which consists of interconnected pipes.

- automation - granule supply controller, automatic ignition system, flame presence sensor, draft sensor, temperature sensor.

Pellet fuel, which is compressed granules approximately 10 mm in size, is made from various types of environmentally friendly materials - sawdust, peat, cake, bark.

Materials

To make a boiler with your own hands, you will need the following materials and devices:

- Sheet steel 4-7 mm thick for the boiler body.

- Pipes made of metal or asbestos for the manufacture of a chimney and fasteners for them.

- The material for the bunker can be thin sheet metal, a metal or plastic barrel.

- The auger is of the required length depending on the distance between the hopper and the burner. You can buy ready-made or make it yourself.

- Metal pipes for heat exchanger.

- Electric motor to ensure the operation of the auger.

Auger for feeding pellets from the hopper to the boiler - Fireclay brick for making the body.

- Grate for air access to the burner.

- Automation for starting and monitoring the operation of the boiler.

- Bulgarian.

- Welding machine.

Instructions and recommendations for production

Initially, make a drawing of the device you want to install and buy sensors that will allow your device to work with minimal intervention from you.

The first step in making a pellet boiler with your own hands is to make the boiler body in the form of a fireclay brick box; it should be made horizontal to achieve maximum heating efficiency. In addition to brick, the body can be made of steel or cast iron, but brick retains heat longer.

Next, you should assemble a heat exchanger from square pipes. You need to cut the pipes to the required length and weld them into a rectangular structure. Make holes in the vertical profile for supplying round pipes. Holes must be made in the front pipes for supplying hot and cold water.

Pellet boiler diagram

Cold water is supplied from above, a pipe for hot water is from below. Use metal pipes for supply. Cut ball valves into them. Use a cutting torch or welding torch to cut the holes, then use a grinder to cut the holes. Then you should check the structure for leaks; to do this, plug the bottom hole and pour water into the top hole.

If there is no leakage, install the heat exchanger in the housing, taking into account that the distance between the walls of the housing and the heat exchanger pipes must be at least 1 cm.

Connect a chimney pipe with a diameter of less than 12 cm. The diameter of the pipe should be slightly larger than the diameter of the outlet on which the pipe is placed. Seal the connection between the pipe and the hole. The pipe must be made of heat-resistant material. At the bottom of the housing, install a metal ash chamber with a handle for easy ash removal.

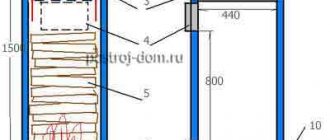

Install a hopper, the bottom of which should be sloping towards the feed. The larger the volume of the bunker, the longer your boiler will operate in independent mode without your participation. To connect the housing and the hopper, you need a metal casing with thick walls into which the auger is installed.

The auger can be made from tire wire or purchased ready-made. The drive to the auger is made through a gearbox from an electric motor. The electric motor is connected to the control unit. A corrugated pipe for feeding pellets is mounted to the auger. Making a homemade burner is quite difficult, since it is not only an ignition element, but also a device that regulates the flame.

Factory pellet boiler burner

To make it, you need to take two square metal pipes with sides of 8 cm, weld one to the other in the form of an irregular inverted letter “T”. The upper vertical part is the compartment where the pellets enter; in the lower part there is combustion and an influx of air for combustion. On the left side, which is connected to the firebox, make a screen.

The upper part into which the pellets are poured must be welded at an angle. To prevent incoming pellets from blocking the air supply, it is necessary to insert a metal plate into the upper structure, the lower part of which is made according to the principle of a comb, the teeth of which are bent into a semi-oval for better air supply. . You can use a burner from a gas can as an ignition element.

How to do

Making containers yourself is not particularly difficult. You can make a frame from a metal corner, cover it with boards, plywood, weld metal of the appropriate shape to the corner, etc. What you need to pay attention to when developing the design is that most bins have at least one inclined wall, which guarantees uniform pouring of granules. There may be more difficulties with a screw device, but you can always buy a ready-made one. It will still be cheaper than buying a branded one. For example, a MAFA Mini bunker with a volume of 300 liters costs 500 euros, a bunker from the same company, but with a volume of 750 liters costs 900 euros.

It’s easy to make a pellet hopper yourself

To manufacture a screw device, you need: a screw of the required length and diameter of 75-100 mm (2), a metal pipe of a larger diameter than the screw (1), a motor that is controlled from the burner (3). We insert the auger inside the pipe, connect the motor, and insert the pipe into the hole in the lower part of the pellet hopper.