Heating a house or apartment in winter and its costs are of concern to almost everyone. A warm water floor, which you can install yourself, will be a good solution to the problem. Pipes through which hot water circulates are connected to the boiler (or other heating system). The advantages of this system: low energy costs and the ability to independently regulate the temperature in the room. It is very important to choose an economical boiler that is most suitable for specific conditions. The most important indicator will be the thermal power of the heating equipment.

- Boilers for heated floors

- Electric or liquid fuel boiler?

- Boiler selection parameters

- How to calculate the power of a boiler for water heating?

- Requirements for installing a gas boiler

Boilers for heated floors

Boilers are divided into single-circuit and double-circuit boilers.

Single-circuit boilers. Single-circuit boilers in the heating system provide only heating of the coolant (only room heating is possible). To expand the scope of application of single-circuit boilers (providing hot water), additional devices are needed:

- storage boilers (providing hot water supply);

- heat exchangers;

- mixing units for heating circuits;

- and other.

Double-circuit boilers are multi-tasking devices: they provide heating and water heating. The second function is performed by equipping the boiler with a built-in flow-through heat exchanger or a built-in storage boiler.

Variety of boilers by installation type:

- floor-mounted (power up to 120 kW);

- wall-hung (power up to 35 kW).

Wall-mounted boilers (most often these are atmospheric devices) are more convenient from an installation point of view and require lower costs.

A boiler with a closed combustion chamber does not require additional space in the form of a separate room. Wall-mounted boilers are equipped with a circulation pump and other equipment for the boiler room. To put it into operation, it is enough to connect the heating pipeline and hot water pipes to it. Boilers with built-in storage boilers of 100 l are a ready-made mini-boiler room

Types of boilers for warm water floors

To equip a warm water floor, boilers running on gas, electricity, solid or liquid fuel are used. Each type has its own advantages. The most economical are gas ones, and the most autonomous are diesel ones.

Gas boilers. The body of gas boilers can be made of steel or cast iron. Steel units are distinguished by their low weight (about half the weight of cast iron with the same power), small dimensions and good maintainability. Cast iron devices are larger and more expensive. Floor-standing gas boilers of the modern generation are suitable for main gas and liquefied gas. The small dimensions of the wall-mounted gas boiler allow it to be placed in any convenient place, and a power of 7-30 kW is enough for a small cottage.

The diesel boiler runs on diesel fuel and is highly efficient and productive. There are no unpleasant odors during equipment operation. Other advantages of this type of boiler include ease of installation, ease of maintenance and control, high efficiency and low fuel consumption. Thanks to a special operating mode based on a gradual decrease in water temperature in conditions of elevated ambient temperatures, liquid fuel boilers are economical and environmentally friendly.

Solid fuel units for arranging water heated floors will be a completely autonomous source of heat supply. They are considered a good alternative to liquid fuel, gas and other types of heating equipment. Fuel combustion occurs according to the following scheme: firewood laid on a grate is set on fire. After this, the boiler door closes and the smoke exhauster turns on. In the inner chamber of the boiler, the firewood is exposed to high temperatures (250–750°C) without access to oxygen. Charring occurs and wood gas is released, which heats the thermal media. Scope of application of solid fuel boilers: residential and industrial premises, agricultural facilities.

Electric boilers are suitable for residential and non-residential buildings equipped with water underfloor heating. The system is connected to the boiler using special equipment and additional devices. The choice of device power is influenced by the area of the room, its condition and other factors. The most optimal power can be selected in rooms with good thermal insulation of walls and ceilings (for example, in new buildings). If there is good thermal insulation, then the manufacturer considers a power of 12 kW sufficient for heating 150 sq.m.

For the tandem “electric boilers - warm water floors”, manufacturers recommend the following combinations:

- heating area 250-450 sq. m - boiler power 36 kW;

- heating area 220-350 sq. m - boiler power 30 kW;

- heating area 140-300 sq. m - boiler power 12-24 kW;

- heating area up to 70 sq. m - boiler power about 6 kW;

- heating area up to 30 sq. m - boiler power 6 kW.

Pros and cons of heated floors. Find out in our article. About infrared warm field. Find out more right now! How to reduce electricity consumption. Find out in our article.

Features of electric boilers

In terms of the degree of autonomy, one of the key criteria on which a boiler is selected, its electric version is in the lead, due to the absence of flammable substances. Having automatic settings, it does not require human intervention, automatically restoring the mode in cases of a short-term power outage. Its reliability, compactness, and affordable price are also attractive.

Installing a heated floor with such a boiler does not require expensive piping, thanks to the initial temperature of the water, which is the coolant, at 25°C. It is enough to mount a collector to connect several circuits.

Connecting a heated floor to the boiler

A modern electric boiler for a warm water floor has three varieties.

- Safe electric boilers operating on heating elements have already received recognition, as they have a fairly simple technical structure. The main weakness of this type of device is the short service life of the heaters, which is compensated by their low cost and simple replacement technology.

- Electrode boilers are a fairly new type of heating equipment, characterized by durability. Compared to the previous analogue, they are more capricious, since flawless operation requires a certain composition of the coolant, which must conduct current. This is due to the operating principle of such a boiler: between two electrodes under an alternating voltage of 50 Hz, placed in a liquid, the movement of ions begins, releasing heat. Positively charged particles move towards the cathode, and negatively charged ions move towards the anode. The electrodes change polarity 50 times per second, so heating occurs quickly.

- Induction models are based on heating a conductor placed in a magnetic field. The role of the core is played by the boiler body in the form of a labyrinth through which water flows. Such a device is reliable, requiring only monitoring of the constant presence of coolant in the system. The widespread use of induction boilers is limited by their high cost.

Related article: Original design of doorways with photos

Environmentally friendly, not polluting the atmosphere of the house with combustion products, the electric boiler is convenient because it can be placed almost anywhere. The only difficulty may be the need for local wiring. Among the disadvantages, there is an increase in energy consumption (consumption per 30 cubic meters ≈ 1 kW/hour). In private households, where frequent power outages are possible, it is advisable to install a combined type, which provides the option of a backup boiler with solid fuel.

Electric or liquid fuel boiler?

To compare two types of boilers, all factors must be taken into account. Despite the cheapness of diesel fuel compared to electricity, an assessment of all costs will show the real picture.

Initial costs for the purchase of equipment and installation costs An electric boiler is a ready-to-use device. A liquid fuel unit will require additional costs for the purchase of a boiler, mounted burner, and fuel storage tank. The difference in consumables is 2.5 times in favor of the electric one.

Installation of an electric boiler will cost several times less, since all the necessary elements for the control and safety of the equipment are built into its body. A liquid fuel device requires the installation of additional devices: a chimney, a fuel tank, and a mounted burner.

Operating Costs Maintenance of an oil boiler requires costs (several hundred dollars per year) for regular maintenance and cleaning. An additional inconvenience is associated with the need for constant orders for fuel delivery. Electric boilers do not require the listed operations.

However, electrical devices also have disadvantages.

- To operate the boiler, several tens of kilowatts of energy are required (1 kW per 10 m2 of area. The ceiling height is up to 3 m, and the room is well insulated). It is not possible to allocate such a volume of electricity in all areas.

- The cost of electricity is high and power outages occur. To protect against frequent power outages, a backup solid fuel boiler is often used.

If water heating is done in a house or apartment within a large city, then electric boilers are the most preferred of all types. This is due to strict environmental requirements and coordination problems.

Having analyzed the situation, we can highlight a number of advantages of electric boilers:

- low cost;

- compactness and light weight;

- easy installation, no chimney required;

- safety (no open flame);

- ease of operation;

- can be installed in any room;

- service is simple;

- environmentally friendly: no emissions and odors;

- silent.

Characteristics of gas models

Modern modifications of gas boilers must be equipped with electronic controls that regulate temperature parameters, ensuring the safe operation of the system.

In order for the automation and circular pump for a warm water floor to work in the event of a power outage, it is advisable to stock up on a local source. Car batteries will provide several hours of operation. In situations where there is a risk of frequent power outages for several days, you will have to purchase a diesel generator.

Compared to the electric model, the gas boiler is a model of efficiency. Its condensation type is especially effective, receiving integrated heat from fuel combustion (explicit energy) and from steam condensation (latent thermal energy).

The principle of operation of the boiler is based on the circulation of the coolant through the exchanger, during which it is heated by the flue gases produced when the fuel burns. During the transfer of thermal energy, the gases are cooled, and at a certain temperature condensation is formed, causing the appearance of additional heat. This feature significantly increases the efficiency of heating equipment.

Gas boilers function flawlessly under conditions of uninterrupted gas supply, without requiring special routine maintenance techniques. In designs that provide an electronic mechanism for igniting the boiler, the operation of the burner is regulated in accordance with the specified temperature values with the removal of all harmful combustion products through forced ventilation. Boilers with piezo ignition, operating automatically, also stop the flow of gas if the flame goes out, but combustion is restored manually.

Related article: Curtains made from leftover fabric are beautiful

Boiler selection parameters

Heating installations, depending on their characteristics, provide different thermal efficiencies and are suitable for a certain area and operating conditions.

- Power. The required parameter is determined by the area of the heated room and the level of its thermal insulation. The manufacturer indicates the area for which the boiler is designed, provided that the building is well insulated. If heat losses are unknown, then it is necessary to choose a boiler whose power is designed to heat an area 25% larger than the actual one. It is not advisable to purchase equipment with excess power, as the device will overheat and break down. If the boiler is installed in an unheated room, it is necessary to involve a heating specialist to calculate the power.

- Possibility of power control. Gas installations may or may not be equipped with a power control system. To adjust the operation of the equipment, automatic mode or manual control can be used. Automatic control systems are more economical. In this case, the user only sets the necessary parameters, and the automation ensures the accuracy and smooth supply of the gas mixture to the burner. Also, when using automation, the frequency of complete shutdown of the burner is reduced, thereby increasing the service life of the equipment.

- Energy dependence. The use of electronics in the control system of electric pumps for forced circulation increases the performance of the boiler, but at the same time depends on the stability of the energy supply and reduces its autonomy.

- Type of water heating. If it is necessary for a boiler (including an industrial gas device) to provide not only a heating function, but also to heat water for domestic needs, it is necessary to choose a dual-circuit model that heats water in flow-through mode. If greater productivity is needed, then you need to go with the cumulative option. Boilers can be built into the boiler or autonomous and connected to the installation. Remote models can have a very large volume (several hundred liters), while built-in ones are limited by the dimensions of the boiler.

What types of units are there for the heating system?

There are several types of boilers. Each has both its own advantages and disadvantages.

Electric

This is a universal boiler that is suitable for heating both residential and non-residential premises. But not every unit is suitable for floor heating.

- Firstly, for a temperature of 26–28 °C you need a boiler capable of delivering a temperature of at least +55 °C.

- Secondly, depending on the type of installation, boilers can be wall-mounted or floor-mounted. Wall-mounted ones weigh little and are attached directly to the pipeline, while floor-mounted ones cannot be hung on walls - they are very massive and can fall, although their power is greater.

- Thirdly, there are single-circuit and double-circuit boilers. The latter are more convenient because they heat water both for heating and for domestic needs.

- Fourthly, the principle of heating. Modern boilers can be connected to the floors directly, classic (outdated) models - only through a mixing unit.

Judging by user reviews, the following brands connect best:

- ATON Electro.

- Barsky Machine Plant Zh7-KEP.

- Baxi AMPTEC.

- GALAN.

Gas

It is the most economical. Gas is an affordable fuel and is allowed to be used in apartment buildings.

Attention

The body of the gas boiler is made of cast iron or steel. A cast iron boiler is very voluminous, heavy and expensive, a steel boiler has medium dimensions, is easier to repair, and is cheaper.

Like the electric one, it can be mounted on the wall (in any convenient place) or placed on the floor (this option is suitable for liquefied gas). A gas unit is preferable if the power goes out frequently in your area.

There are 2 types of gas boilers - convection and condensation:

- Convection - a classic model with one heat exchanger. It is inexpensive, practical, and convenient.

- Condensing is the same as convection, but improved: its efficiency is 15% greater than that of convection (its price is higher).

Solid fuel

This unit has many advantages. For example, it warms the floor so well that you will not find any cool or slightly warm zones in the room. It saves fuel quite well, since the heated screed, turning into a heat accumulator, can release accumulated heat to the space for a long time even after the unit stops operating. However, there are serious disadvantages here:

- At least once a day you will have to load fuel (wood or coal) into the boiler, constantly monitor its supply and store it somewhere (and it takes up a lot of space).

- Clean by hand and often.

- Regularly check whether the chimneys are clogged or whether the ventilation system in the house has deteriorated.

- When the power of the unit decreases, the efficiency of the entire heating system drops sharply.

- Additional protective devices must be designed and installed.

Important

Experts do not advise installing such equipment: not everyone can monitor it all the time (and you need to monitor it day and night) and control the temperature.

How to calculate the power of a boiler for water heating?

It is necessary to calculate the required power of heating equipment to select the correct boiler. The approximate required power for heating a country house is calculated based on the following data: to heat 10 m2. area, 1 kW of power is required, that is, it is assumed that the specific power is 100 W/m2.

The calculation is quite rough, and it is suitable for a brick house with low heat loss: the building must be well insulated, the ceilings must be no more than 3 meters high, metal-plastic windows with double glazing.

To increase the life of the heating system and thermal reserve, it is necessary that the coolant temperature be at the level of 65–75°C. To do this, the boiler power (under ideal conditions) is increased by 20–25%.

Any additional load requires an increase in power. In the case of providing hot water using a storage boiler, it is necessary to add another 30-40%. If in the future it is planned to expand the heated area, install a heated water floor, or a heated water pool, then the boiler must be purchased immediately with a capacity designed for further changes.

If a heated floor is planned as an element that complements radiator heating and increases living comfort, then its heat output is considered to be no higher than 50 W/m2.

Connection to the heating system

The comfort of heated floors, which create a uniform thermal background throughout the entire volume, is difficult to overestimate. They acquire particular relevance in autonomous residential buildings, and are used even in apartments where it is possible to install local heating equipment, since connecting a water-heated floor to the heating system coming from the central boiler room is prohibited for several reasons:

- low quality coolant;

- exposure of pipes to significant hydraulic resistance;

- the risk of destruction of system elements from water hammer.

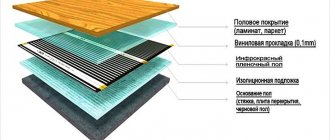

Using your own heating system requires the presence of a mixing unit that lowers the temperature of the coolant, since when heating a house the liquid heats up to 75 ÷ 90°C, and for the floor ≤ 50°C is allowed.

Related article: Is it possible to additionally paint non-woven wallpaper?

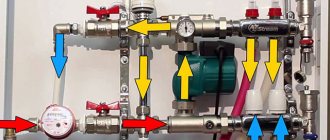

Manifold - connecting the heated floor to the heating system

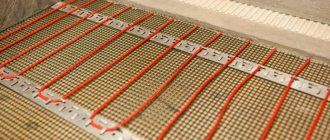

The sequence of work includes several stages:

- Simultaneously with the sensor, the circulation pump is securely fixed to the inlet pipe.

- A mixing valve (preferably a three-way valve) is connected to the warm pipe of the heating system.

- The output of the check valve installed on the outlet pipe is connected respectively to the heating return pipe with a branch leading to the mixing valve.

Requirements for installing a gas boiler

Premises requirements:

- A separate non-residential premises is required for the boiler room.

- The ceiling height in the room is at least 2.2 m.

- Room volume based on 7.5 m3 per boiler.

- The floor area per boiler is 4 m2.

- Doorway width from 80 cm.

- The size of the window is determined by the calculation: for every 10 m2 of area - a window measuring 0.3 m2.

- There must be a hole for air flow (8 cm2 per 1 kW of boiler power).

- The boiler must be installed at a distance of at least 0.1 m from walls that are plastered or the wall decoration is made of non-combustible materials.

- Installation of devices near fire-resistant walls is permitted if they are insulated with roofing steel laid on an asbestos sheet with a thickness of at least 0.3 cm.

Communication requirements

- Characteristics of the electrical network: single-phase current, voltage 220 V, current 20 A. An individual circuit breaker is installed. Grounding is provided.

- A shut-off unit is installed on the gas main, one for each boiler.

- Water supply and the possibility of connecting it to the heating and hot water supply (DHW) systems of the building.

- The sewerage system provides emergency drainage from the water supply and boiler systems.

- Communication parameters (gas pressure in the gas main, water pressure, etc.) must comply with state standards.

Design and principle of operation of a gas boiler

Now let’s look at the diagram of a gas boiler:

Gas boilers come with a closed and open combustion chamber. In the second case, exhaust ventilation is always forced. With forced ventilation, the design is more complex, so we will consider this option (see diagram above; diagram is clickable).

So, the device of a gas boiler with forced ventilation.

Everything is in the case.

The boiler in the diagram can heat water for both hot water supply and the heating system at the same time. Therefore, it has five outlets at the bottom: 1 - gas supply, 2 and 3 - supply and return of the heating system, 4 and 5 - outlet and water outlet for the water supply system. The specific connection diagram for each pipe should be looked at in the passport for a particular boiler model.

Wall-mounted boilers can be with or without an external heat exchanger. This heat exchanger serves precisely to heat water for hot water supply. (In the example given, this is exactly the boiler.)

Let's look at how a gas boiler works.

Cold water enters the boiler (rightmost pipe). A safety unit is installed here (in the diagram it was called a “hydraulic module”), which is built into wall-mounted gas boilers.

Further along the coolant, also inside the boiler, is a circulation pump. An expansion tank is connected in front of the pump using a tube.

Next on the tube is a temperature sensor (there are three of them in the boiler: on the return, on the supply and on the chimney for exhaust gases).

The coolant then passes through a heat exchanger, where it is heated by a gas burner. And then it moves into the heating system.

In the center of the boiler there is a gas fitting, which includes a safety unit that controls gas pressure, the presence of flame, and exhaust gas removal. If something does not correspond to the set parameters, the safety unit shuts off the gas supply.

From the listed gas valve block, gas flows to the burner.

Exhaust gases enter the chimney. In the model shown, a fan is installed (at the beginning of the chimney) for forced removal of gases.

Boilers with forced ventilation do not require a high chimney pipe; it can simply be brought out to the side, through the wall.

In the example shown, the chimney is coaxial - “pipe in pipe”. Air enters the boiler through a wider pipe, and combustion products are discharged through a smaller pipe.

Well, boilers with natural ventilation need to install a pipe above the roof ridge in order to create good draft.

Now a little about heating water in a gas boiler for hot water supply.

Cold water from the water supply goes into the boiler through the corresponding tube. It also has its own security system that monitors the presence of water flow. There is also a valve for recharging the hot water system: if necessary, we open it, and water flows from the general water supply system.

So, cold water goes into a heat exchanger made in the form of flat tubes. And in the heat exchanger, the water is heated by the coolant from the heating system. But the coolant and water for hot water do not mix: the heat exchanger is designed in such a way that there is no direct contact, and heat is transferred only through the walls of the heat exchanger tubes.