A feature of modern sauna stoves is their heating temperature, which can reach 400 degrees. An important indicator of the efficiency of the furnace is instant heating of the body and maximum heat transfer.

The entire heating process is accompanied by the release of infrared radiation, which is distributed on surfaces adjacent to the furnace. Under the influence of high temperatures, the wooden structure of the bathhouse can char or ignite.

This is why it is so important to ensure that wooden surfaces are reliably insulated from the heat of the stove. A protective screen and casing made of fire-resistant materials are suitable for this.

Do you need protection in your bathhouse?

Protecting the walls of the bathhouse from the heat of the stove is not always required. For example, you can provide a distance between the wall and the stove, which will allow you to achieve fire safety without additional protection. The fact is that at some distance the IR rays emitted by the furnace begin to dissipate, which significantly reduces their impact on nearby surfaces.

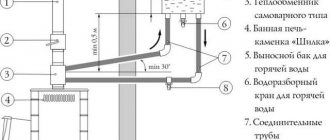

The distance from the stove to the wall in the bathhouse varies depending on the type of stove:

- 0.32 m or more - the distance for a stone oven with quarter-brick masonry;

- 0.7 m or more is the required distance between the wall and the metal furnace lined with fireclay or brick from the inside;

- 1 m or more is a safe distance for an unlined metal furnace.

At first glance, it seems that creating such a distance is much easier than installing additional protection, but this is fundamentally wrong. Maintaining a safe distance is only advisable in large steam rooms, but in small private baths, the stove, including the indentations, will occupy most of the room, so it will be much easier to use insulation.

When is fencing required?

The answer to this question lies in the way heat is distributed from any type of furnace. There are 2 such ways:

- Direct heating of the air in the steam room.

- Transfer of heat to surfaces using infrared radiation.

For a bathhouse, the first method is preferable, when in the process of heating the steam room, the air is first heated, and the wooden shelves, walls and floors receive heat from it. If necessary, the hot dry air in the steam room is moistened, this is called “steaming”.

Installation diagram of a protective screen for a furnace.

Infrared radiation is emitted by all heated surfaces, including the hot walls of a sauna stove. Considering that the burning temperature of firewood reaches +600°C, the outer surface of the metal walls warms up to +300°C. It emits such a powerful stream of infrared radiation that people taking bath procedures can get skin burns.

Sauna stoves in the mid-price category are equipped with a steel convection casing, which simultaneously acts as a protective screen. More expensive cast iron products are finished with slabs of natural stone or salt bricks: mineralite, soapstone and other rocks. But budget and homemade steel stoves do not have such a screen.

A screen for a sauna stove is necessary in the following situations:

- when the hot firebox body is not covered from the outside with a steel convection casing, and the stove is located in an open place;

- if the stove is equipped with a casing, but stands close to the wooden wall cladding;

- if the factory screen is made of thin metal and does not protect well from radiant heat.

Not only people, but also wooden walls need to be protected from hard radiation, as stated by fire safety rules. Therefore, a heater installed close to a wooden wall must be protected from it by a fireproof barrier. Brick is best suited for this purpose.

Metal protective screens

On the construction market, the most common metal protective screens are made of steel or cast iron. Many manufacturers of iron furnaces provide thermal insulation for their products, providing them with special casings.

Choosing protective screens is quite simple, because depending on the side of the furnace to be insulated, you can purchase a front or side panel. Installing such screens will also not cause difficulties, because the manufacturer provides special legs that can be easily attached to the floor.

Next we should talk about the installation rules. The panels themselves are installed at a distance of 1-5 cm from the stove, but a distance to the adjacent wall is also required. Protective screens reduce the radiated temperature to 80-100°C, which allows them to be installed 50 cm from a parallel wall.

Fireproof materials for baths

Thermal insulation is the most important point when organizing a bath, so the essence of the procedure is based on heat. When organizing thermal insulation, it is important to consider what surfaces you are treating - single-layer insulation is suitable for floors and walls, but double-layer is required for the ceiling, to which all the heat rises. Thermal insulation of saunas is carried out using the following fire-resistant materials: mineral wool with heat-reflecting foil, stone wool, glass wool with aluminum foil, expanded polystyrene or foam glass.

Insulation can be carried out both externally and internally. Thanks to the use of fire-resistant slabs for baths and modern materials, insulation from the inside is considered the most optimal, which allows simultaneously solving the functions of hydro- and vapor barrier.

Brick screens

The furnace fence in the steam room can also be made of brick. A brick screen can be installed on all sides of a metal furnace, forming a protective lining. Also, such a screen can only be installed between the flammable surface and the stove, representing a protective wall.

Having decided to lay such protection, use solid fireclay bricks, for the binding of which you can use clay or cement mortar. Typically, half-brick masonry (120 mm) is used, but due to lack of material, quarter-brick masonry (60 mm) is suitable. When using the latter installation method, remember that the thermal insulation properties of such a screen are reduced, so the distance to the wall should be increased.

This finishing of an iron stove in a bathhouse is also carried out in compliance with certain rules:

- In the lower part of the shield it is necessary to provide special openings that will ensure air convection between the furnace wall and the brick;

- The height of the brick wall should exceed the height of the stove by 20 cm, but it is often built right up to the ceiling;

- Maintain a distance of 5-15 cm between the stove and brick screens;

- There should also be a distance of 5-15 cm between the flammable surface, for example, a wall and a brick protection.

Heat resistant cables

Choosing a non-flammable cable for steam rooms is a fairly responsible procedure that affects not only the operational reliability of the installed wiring, but also the safety of people in the bathhouse.

Since the temperature inside the steam room can reach plus 170 degrees (with a humidity level of up to 90 percent), the cable products installed in it must have the appropriate characteristics. For these purposes, it is recommended to select special samples of waterproof and heat-resistant cable products in a non-flammable sheath, the quality of which is confirmed by certificates.

Non-combustible wall coverings

The second option for protecting walls from fire is special sheathing, which is made from non-combustible materials. The working element of this protection, which reflects IR rays that are dangerous for flammable surfaces, is a reflective material, for example, stainless steel.

There are also decorative finishing options that preserve the aesthetic purity of your bath. One of the advantages of this method is that protecting the walls in the bathhouse from the stove will not only prevent fire, but also retain heat inside the room.

How to protect the walls of a bathhouse from the heat of a stove - technologies and materials

When planning the construction of a bathhouse, it is important to remember to create safety indoors. First of all, this concerns fire safety. By melting the bathhouse, the stove can be heated to 300-400°C, which significantly exceeds the combustion temperature of the wood from which the bathhouse is most often built.

All the heat from the stove is released into the room, but the main heat is absorbed by nearby walls, which leads to their charring and fire. It is extremely important to avoid such consequences, so in this article we will tell you in detail how to insulate a stove in a bathhouse from the wall.

Reflective wall cladding

You can assemble this version of protective casing yourself. To do this, you will need a non-flammable thermal insulation material, which will be discussed in more detail below, as well as a sheet of stainless steel.

Stainless steel can be replaced with a cheaper option - galvanization, however, when heated, it can release harmful substances, so we strongly do not recommend using it. When starting work, secure the insulation to the wall, and then cover it with a metal sheet.

To ensure that such thermal insulation for a sauna stove is as productive as possible, polish the metal surface. This will allow IR rays to be better reflected back into the steam room, and the reflected rays will be better perceived by humans.

You can use the following materials as thermal insulation:

- Basalt wool is absolutely safe for baths. It retains heat well, in addition, it is highly hygroscopic and does not burn at all;

- Basalt cardboard is a good option for a bathhouse. It consists of thin sheets of basalt fiber that retain heat well and do not burn;

- Asbestos cardboard is a strong and durable heat insulator, which is also suitable for a bathhouse;

- Minerite for baths is also an excellent material. Non-combustible plates are specially manufactured for shielding hot surfaces in baths and saunas;

Before covering the wall near the stove in the bathhouse, familiarize yourself with the correct technology for its construction. The most important thing is the installation order and compliance with the gaps.

The ideal design has the following structure:

- Wall;

- The ventilation gap is 2-3 cm;

- Insulation 1-2 cm;

- Stainless steel sheet.

Remember that the total distance from the wall to the stove must be more than 38 cm. For fastening, use ceramic bushings that will help form ventilation gaps. If the distance between the wall and the stove is minimal, then it is necessary to use two layers of mineralite slabs, between which a gap must also be left.

Internal impregnations

The main reason for using special impregnations in baths and saunas is increased levels of humidity and temperature, which can cause destruction of wooden ceilings, walls and shelves.

When choosing an impregnating material suitable for these purposes, the main attention is paid to the quality of the composition, after application of which the wood should not lose the ability to “breathe” freely.

You should also distinguish between the types of compounds used to protect shelves and benches from similar materials used when treating walls and ceilings in a bathhouse.

Impregnation for shelves

The protective agents used to treat shelves, based on their effect on the color of the wood, are divided into colorless and colored. The first includes impregnations of various compositions, bleaching mixtures, varnishes and waxes. Varnishes for the protective coating of shelves in saunas and baths must be subject to strict selection, during which special brands that release toxic substances when heated are eliminated.

Typically, for benches and shelves in a bathhouse, water-based compounds are used that penetrate well into the wood structure.

Colored coatings are used in cases where darkening of previously treated areas is observed. In this case, only the tarnished parts of the surfaces are subject to coating, but if desired, they can be completely treated.

As for specific samples of protective material, acrylic varnishes from these or “Belinka” are suitable for treating baths and saunas. All of them are made on a natural basis and have a large selection of color shades.

Protective coatings for walls and ceilings

Impregnations intended to protect walls and flows in the bathhouse must have an organic base and have water-repellent properties.

Modern processing agents have universal properties and are able to protect surfaces from moisture and thermal heating, as well as from the destructive effects of fungi and insects.

Depending on their base, all known types of protective impregnations are divided into water-based and oil-based preparations. Complex (combined) compositions, produced in the form of paints and varnishes, are also very popular, providing protection for the finishing materials of the bathhouse from moisture fumes and microorganisms.

Some of them have additional features such as fire resistance and the ability to repel dirt.

Bath waterproofing

Waterproofing is necessary so that the building materials from which the bathhouse is built, as well as the layers of insulation placed on it, do not get wet and do not lose their protective properties. Waterproofing can be done either using roll insulation or using special water-repellent coatings.

It is especially important to carefully consider the waterproofing of the floor, since this is where a lot of water will flow. For this purpose, a leak-proof concrete floor with a backing made of waterproofing material is often used. Another option is to make a leaky floor with special gaps where excess water will drain.

Bath vapor barrier

The fireproof materials that you used for heat or waterproofing can have vapor barrier functions, or special layers separately designed for vapor barrier can be used.

For example, if you chose fiber insulation without foil, then you will need to make a vapor barrier with an aluminized film. To treat the ceiling, you can use a granular layer of expanded clay. And from the inside it will be very useful to protect the bathhouse or sauna with special reflective thermal insulation. If the construction of a bathhouse is taking place in the northern regions, you can use double-sided foil thermal insulation of the bathhouse with an internal filler made of basalt wool.

It is very important to ensure that the connections are airtight and not to use foamed polymers for vapor barriers.