Rocket stove made from a propane cylinder: drawings, photos, videos. Step-by-step making of a stove from a gas cylinder with your own hands.

In the last article, we looked at the process of assembling a camp-type rocket stove; the design of a rocket-type stove allows us to obtain the maximum possible output of thermal energy by burning pyrolysis gases that are formed during the primary combustion of wood.

A rocket stove can also be used for heating rooms, cottages, garages; in this article we will look at the design of such a stove made from gas cylinders.

In order for a rocket-type stove to effectively heat a room, it is necessary to additionally make a chamber for afterburning pyrolysis gases, in this way the heat transfer of the stove will significantly increase and fuel consumption will decrease.

As a container for afterburning pyrolysis gases, you can use a regular propane gas cylinder, the diameter of the cylinder is 300 mm, the height is about 900 mm, such a container is best suited for making a rocket-type stove with afterburning pyrolysis gases.

Is there any danger?

Many people associate gas stoves with direct danger and to a certain extent they are right. The fact is that liquid gaseous fuel can burn at a certain speed. If the burner is not designed correctly, it may leak, which is dangerous to human life and health.

Gas stoves for summer cottages with a cylinder are also included in the dangerous category. However, in order for the operation of such a heating unit to be as safe as possible, liquid fuel is odorless, but for safety reasons a small amount of a characteristic fragrance is added to it.

Heating equipment can be connected to a boiler or pre-installed communications

As an alternative to a gas fireplace, you can use a more affordable and easy-to-install electric one.

Important: gas stoves for a summer residence will be completely safe to use if the burner is designed according to all the rules and is fully operational. In this case, the gas will burn completely under any operating mode or supply intensity. Also, soot and soot will not form or settle in the inside of the burner.

Interesting to know: gas stoves are also highly economical. They are suitable for any conditions, their operation is allowed even at medium latitudes. At the same time, the efficiency of such fireboxes increases to the maximum, in contrast to solid fuel brick stoves, the efficiency of which decreases by 8-15 percent.

Gas stoves for home use are very popular among summer residents, as they are able to heat a small space well. At the same time, the gas itself, due to the fragrance called mercaptan included in its composition, allows you to sense something is wrong in time in case of a leak. This component causes lacrimation, has a pronounced, characteristic odor, and is safe for health.

Do-it-yourself gas forging furnace

Hello everyone, today we will look at a simple blacksmith furnace design.

This stove runs on gas and can be powered from a gas pipeline or a cylinder. The good thing about such a furnace is that the steel heats up quickly, and the furnace instantly reaches the desired temperature when compared with electric furnaces. The homemade product is assembled like a table; the stove is equipped with legs with wheels that will allow you to move it to the right place. The author used ready-made burners for production. If you are interested in the project, I suggest you study it in more detail! Materials and tools used by the author: List of materials:

- corner; - round pipes; — wheels for trolleys; - Sheet steel; — heat-resistant cement; - fire-resistant brick; — gas hoses, taps, fittings, etc.; - two gas burners.

List of tools:

- welding machine; - vice; - Bulgarian; - roulette; - band cutting machine. Furnace manufacturing process:

Step one. Legs

First of all, the car decided to make legs for a homemade project, the material needed would be pipes, the author used round ones, but profile ones would also be quite suitable, whoever has what. We cut the pipes at right angles to the same length; the author used a band cutting machine, but if desired, you can do it with a grinder. We weld wheels from the cart to the ends of the future legs, which can rotate around their axis 360 degrees. So that the wheels can be replaced, it is better to make brackets for them and secure them with screws and nuts.

Next, we assemble the base; the author used sheet steel as the main material; its edges can be bent to form a box. If you don't want to bend it, you can cut the steel and weld it. The author welded pieces of a massive corner as two side walls of the box. As a result, thanks to the corner, the stove had an excellent shelf.

Having made the box, we weld the legs made earlier to it at right angles.

Step three. Making the upper part of the furnace

Next we make the upper part of the stove; the author also welded it from sheet steel. The length of the structure is made such that two refractory bricks can be laid in a row. There should also be space for pouring heat-resistant cement.

We install two pieces of steel pipe vertically in the upper part, through which the combustible mixture will be supplied to the furnace.

Step four. Thermal insulation

Thermal insulation is placed in the upper and lower parts. We plug the gas inlet holes in the upper part of the stove with paper or rags so as not to brick them up. Well, then we put heat-resistant cement into the body, the mixture must be evenly distributed and compacted well. As for the base, we also put a heat-resistant composition into it. To save money, you can pour a suitable dry insulator like mineral wool onto the bottom of the housing, and then make a screed on top from a heat-resistant compound. We level everything well and leave to dry.

Finally, the author laid heat-resistant bricks in the upper part on the sides, which holds the insulating layer and also insulates the side parts. For bricks, you can weld stops to the body so that they do not fall out. After that, we put the halves one after another and the oven is ready.

Step five. Connection and testing

We install burners through the pipes on the stove and connect the gas pipeline to them. Each burner has a separate tap; if desired, you can turn on only one burner. We also make sure to install one common emergency valve in front of the burners. You can light the stove, first the author made the mixture rich so that the fire burns slowly and smoothly. In this mode, steam began to be released from the cement, and the oven began to dry out. Well, then the furnace can be gradually brought to full power. The author turned out the torches in such a color that in the daytime they are not even visible, only the hum is heard.

We try to heat the steel in a furnace, the author succeeds easily, that’s all, the homemade product is ready. In such a furnace you can easily melt aluminum, anneal steel and much more.

Do not forget to paint the stove with heat-resistant paint, since with frequent temperature changes the metal quickly oxidizes. I hope you enjoyed the project and found some useful thoughts. Good luck and creative inspiration if you decide to do this again, don’t forget to share your ideas and DIYs with us!

SourceBecome the author of the site, publish your own articles, descriptions of homemade products and pay for the text. Read more here.

Why gas?

Gas heating stoves for the home have many advantages. First of all, this is the affordable cost of natural gas itself. Maintenance of a liquid fuel device is cheaper than a solid fuel unit with similar power and functionality.

The advantages of this fuel also include:

- There is no need to load or prepare fuel. To start heating, simply turn on the heater;

- Warming up of the premises reaches its peak already 1-2 times after switching on. While to warm up a room using a wood-burning fireplace with your own hands, it will take about 3-4 hours;

- The particular effectiveness of such devices is achieved when installed in a bathhouse;

- A gas cylinder lasts for a long period of use, unlike coal or logs.

biofireplaces are safer, but less efficient than gas variations

Interesting to know: stoves with afterburning gas, like other simpler models, belong to the environmentally friendly variety. The fact is that during operation, the fuel burns almost completely, does not break down into elements harmful to nature, and reaches the stratosphere in smaller quantities.

Purchase or DIY?

A gas heating stove can either be assembled with your own hands or purchased in a ready-made, assembled state in a specialized store. Each of these options has its positive and negative sides.

Basic moments:

- It is strictly forbidden to use homemade gas equipment and devices in accordance with the safety rules prescribed by the Russian Ministry of Emergency Situations;

- The cost of high-quality, powerful heating equipment capable of heating a large house is about 800 dollars or more;

- The most budget-friendly, at the same time very high-quality, functional devices are domestically produced;

- An affordable, but less powerful option is mobile units, which have small dimensions and appropriate weight, allowing them to be moved from one room to another and transported.

The gas stove has a visual similarity to classic wood-burning fireplaces

The firebox can be framed in the required color and style

Important: gas ovens cannot be installed with your own hands, since in order to conduct gas and the necessary communications you must have knowledge, experience, and tools. In this case, the gas service specialist must confirm his work with appropriate documentation, and upon purchase the device itself is provided with a certificate indicating its suitability for use.

It’s interesting to know: since it is unacceptable to install gas kitchen stoves with your own hands, all you can do yourself is to additionally equip the device with a burner. It is important to remember that for these purposes only supercharged burners are allowed to be used. The use of atmospheric burners is strictly prohibited for household appliances!

Materials for making stoves

Homemade gas furnaces are built from stone, brick, or a metal structure is welded. Stone and brick structures take longer to heat up, but retain heat for a long time. Metal stoves heat up very quickly, but cool down just as quickly. Some of the simplest and most compact gas furnaces are metal ones. By covering such a structure with brick, you can ensure that it retains heat longer.

Choosing a gas stove

Portable gas stoves are more efficient. However, in order to make the right choice that will fully meet your expectations, we recommend that you familiarize yourself with the following information:

- A gas stove for the kitchen and home should be made exclusively of metal or cast iron. Only these materials can increase the efficiency and efficiency of the device;

- It is not recommended to gasify brick stoves made by yourself.

Bulky wall-mounted stone stove in the interior of the house

Interesting to know: gas heating stoves can be made of brick. However, in this case, the masonry must be of the highest quality, and the firebox is carried out almost continuously. In order for such a unit to be effective, the brick must be laid not massive, but small. In this case, the chimney system must contain various channels (for example, a Swedish or Dutch fireplace). The few advantages of this type include the creation of a healthy microclimate in the room, since the brick structure “breathes” well.

Design

A gas stove consists of a housing, a fuse, which is necessary to stop the gas supply in case of extinguishing, a sealed gas chamber, a thermostat and a chimney. Gas baths do not need to be warmed up periodically, so they can be turned off immediately after

use. The principle of operation of the stove is simple - gas is mixed with air before entering the firebox. Gas is supplied to the burner using special gas pipes.

Gas infrared ovens

Gas infrared ovens are highly efficient. They are suitable for heating a summer house, private house or standard apartment. Their features include:

- They heat the rooms fairly quickly and evenly;

- They have small dimensions;

- Thermal energy spreads throughout the room and does not go only to the ceiling or floor;

- A comfortable temperature is formed, the air does not dry out;

- To achieve fast heating and maximum efficiency, the design can have a ceramic finish;

- The cost of such heating equipment is affordable;

- Mostly, models are equipped with an open combustion chamber.

The built-in gas fireplace is installed in a pre-prepared niche

Main elements and components of gas boiler equipment

Interesting to know: gas bread ovens are very popular today. They have proven themselves positively in both small and fairly large industries. Gas ovens with electric ovens are designed for wicking. Some models are additionally equipped with a hob on which you can cook food and heat water (analogues of standard stoves). Gas baking ovens with an electric oven are considered the most efficient and functional.

In kitchen heating stoves, about a hundred or more baked goods can be cooked at a time. Since such devices are quite economical, they do not require industrial gas or electricity to operate. Thus, you can install the devices at home with your own hands and open your own business.

Interesting to know: gas furnaces for firing ceramics, which are widely used both at home and in production, are no less popular. In order to heat small parts, the elements can be assembled with your own hands. To do this, use a simple tin can.

How to make a stove from a gas cylinder with your own hands - two options with drawings

Despite the large assortment of heating devices, many land owners show interest in homemade stoves. What is this connected with?

Firstly, such a device is quite simple to make.

Secondly, you can choose any design, depending on the installation location and the specifics of further operation.

Thirdly, a stove assembled with your own hands will cost almost nothing.

Fourthly, with its help, not only the heating problem is solved, but also the disposal of most of the garbage that constantly accumulates in the local area (dacha area).

Fifthly, you don’t have to spend money on “fuel”, be it gas, electricity, briquettes or other. After all, no one will give anything for nothing.

It turns out that there are more than enough “advantages” of independent design, as well as options. One of the simplest is a gas cylinder stove. This solution is in many cases better than others, since this container is stronger than an ordinary iron barrel or pipe assembly (which means it will last much longer) and is more compact (and therefore more versatile in installation). Let's consider 2 simple models that differ in the type of fuel used.

Option A - furnace in production

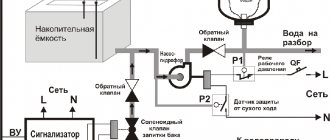

This design has a number of advantages. Firstly, a stove made from a cylinder of standard dimensions (50 l) provides heating of up to 80 m² of area. Secondly, it is quite simple to “attach” the external circuit of the water heating system to it. For example, like this:

This stove is well suited for heating small utility rooms (workshop, garage) or a country house.

Design features. The cylinder must be selected according to the wall thickness. For such a high-pressure vessel it should be in the range of 10 - 15 mm. Thinner walls reduce durability, and thicker walls reduce heat transfer. For smoke exhaust pipes, this parameter is within 2 – 3 mm.

Manufacturing procedure

The technology is easy to understand from the drawings, especially since all linear dimensions are indicated on them. Therefore, we will consider only its individual nuances.

Preparing the body

- First of all, it is necessary to dismantle the valve, after which the vessel is thoroughly rinsed.

- Marking is done, since the “top” will have to be cut off.

- Next is filling the bottle with water. Many articles that describe this technology do not indicate why this should be done. But the meaning should be understood. Cutting the container is done with a “welder” or “grinder”. In both cases, the process is accompanied by an increase in temperature in the work area and sparks. Therefore, water is a guarantee that the cylinder will not ignite or explode during operation.

- To make it stable and cutting off the “lid” is not difficult, it is advisable to dig the container into the ground.

- At a distance of 5 - 10 cm from the top cut, a “window” is cut out for the smoke exhaust pipe. As a rule, a product with a diameter of 110 mm is used.

- To arrange the blower, another “window” is cut out in the lower part. You just need to think about installing the door. Another option is to weld the hinges.

Installation on a stand

It is clear that the stove should not touch the floor. Therefore, it needs to be raised a little. How is at the discretion of the master. You can make a “pedestal”, for example, from a corner, you can weld stand legs.

Chimney installation

Here are only general recommendations, the rest is clear. You just need to take into account that combustion products will heat the pipe, so it needs (in the case of passage through the ceiling) high-quality insulation (asbestos sheet, for example).

- The horizontal section (from the stove) is about 40 - 50 cm.

- Vertical - at least 2.5 - 3 m (to ensure proper traction).

Assembling the fuel "tank"

A piece of pipe is used as such a container. Its length must exceed the height of the stove body. The “tank” is welded to the bottom of the cylinder. Access for welding is through the blower.

Making the lid

A hole is prepared in advance for the passage of a pipe through which the mining will be poured.

Disadvantages of this design

This must be taken into account during operation of the stove.

Oven operation

Before pouring the waste, it should be filtered. The presence of impurities will lead to the fact that the injectors will constantly become clogged, and in this case there is no need to talk about combustion stability.

Furnaces during mining can make quite a loud noise, and this must be taken into account when determining the installation location.

The work process is accompanied by increased formation of soot (soot). Therefore, the smoke exhaust system requires more frequent maintenance (cleaning).

Option B - wood stove

The design of such a stove is much simpler.

It is advisable to install it for summer cottages, since with its help you can solve the problem of recycling most of the garbage - paper, cardboard, so-called “dry wood” (branches, grass, leaves). If it is assembled for a utility room, then the cylinder should be oriented not horizontally, but vertically. This way you can save a lot of space.

But the operating principle is the same.

Assembly Features

The balloon will have to be cut off either from one or both ends. What the difference is will become clear a little later.

Making grate bars. The easiest option is to drill holes in the bottom of the resulting barrel. Then on the front (front) part of the stove there will be only 1 door - for loading “fuel”. And it is enough to cut the balloon on one side.

You can also make the grate in the form of a lattice. For example, weld it from a reinforcing bar. Another option is a sheet of iron with drilled holes. This “mesh” is welded to the sides of the barrel. This is why you will need double-sided cutting of the cylinder in order to more reliably “grab” the grate.

But that is not all. A rectangular window is cut out in the bottom, oriented along the longitudinal axis of the stove. Ash will be removed through it. So that it is collected in some kind of “container”, and does not accumulate under the cylinder, corners are welded from below, along the edges of the window. You will get a “sled” along which the loading box will move.

A more complex design involves the presence of 2 windows on the front cover. One is for loading garbage, the second is for regulating draft and removing ash. It is clear that in this case the bottom is not drilled.

What to consider

- The doors must close tightly. To do this, it is advisable to strengthen a heat-resistant cord around their perimeter (for example, from the same asbestos-cement fiber).

- The diameters of the holes must be selected so that large fractions do not fall into them.

That's all, actually. If the principle is clear, then the reader will decide for himself which scheme is more convenient for him to assemble the stove.

Additional Information

A gas stove for heating a private home must have a special certificate, the validity of which is checked before installation. The following details must also be taken into account:

- Determine the required power. To do this, sum up the area of all the rooms of the house or apartment that you want to heat. On average, about one and a half kilowatts of power are consumed per square meter;

- The premises must have ceilings with a height of at least two meters and an area of about 7-10 cubic meters;

- The firebox must be framed with a metal plate;

- If you want to use automatic blowing, the fireplace is additionally equipped with power from the electrical network.

Modern gas stove in high-tech style

The principle of connecting a gas fireplace with a water circuit

Heating unit with decorative firewood

Gas heating stoves for summer cottages stand out against the backdrop of electric, wood-burning fireboxes. They are light in weight, do not require the assembly of an additional foundation, and are highly powerful. The installation requirements for such a unit are also minimal. It can be placed both in a private house and in a standard apartment.