When carrying out construction work and repairs, it is often important to use universal connecting elements. A handy alternative to small nails and glue is a staple gun. Depending on the model, the device can be used for a wide range of jobs.

Principle of operation

The design of a construction stapler is extremely simple. Using muscle force (in mechanical models) or a motor (in electric models), the spring is raised upward. When the uppermost position is reached, the spring sharply expands. This force is enough to drive the staple/nail. When the lever is lowered, a new one replaces the old staple/nail and the process repeats.

It turns out that to hammer a nail you don’t need to make several targeted blows with a hammer - you just need to place the stapler where you need it and pull the trigger, your other hand remains free. It is convenient, fast and simple, which is why the tool has become so widespread. There is a misconception that a construction stapler can only hammer, but there are models that resemble a stationery stapler. They work with staples and are able to bend their legs, which is why they are used in the furniture industry and in decorative work.

A stapler is also called a stapler, tacker, nailer, staple gun, and staple gun.

The main advantages of a construction stapler:

- nailing materials does not take much effort and time, the process is automated and is carried out many times faster;

- the second hand remains free;

- installation can be carried out in the most difficult to reach places;

- vibration is not transmitted to the material, so you can easily work near glass elements without the risk of breaking them;

- the variety of fastening elements gives the tool versatility;

- safety. Unlike working with a hammer, you don't have to worry about hitting your fingers.

Staples for furniture stapler

After purchasing a staple gun, it is better to immediately stock up on consumables. Staples come in many different types. They differ in sizes, which each manufacturer labels independently. Based on material used, staples are divided into:

- aluminum, suitable for working with soft materials;

- copper for soft wood;

- steel, suitable for any materials, but rusting over time;

- stainless steel;

- galvanized.

Depending on the type of work, you can purchase staples of different shapes:

- U-shaped ones

are considered standard and are used more often than other varieties. - U-shaped ones

are needed to secure the cable. - T-shaped ones

are used when the fixation should not be noticeable.

Scope of use of a construction stapler

The simple principle of operation and the ability to get rid of a hammer and nails allowed the construction stapler to become an almost indispensable tool for any construction and finishing work. As you already understood, this tool performs two main functions:

- nails one material to another if the stapler is loaded with nails;

- connects parts by bending the legs of the staples.

The scope of use of a construction stapler is very wide. Here are just a few examples of jobs where this tool can be used:

- fastening furniture upholstery and making drapery;

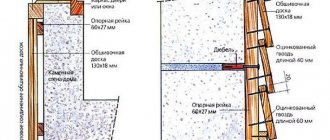

- creation of lathing and frames;

- installation on the frame of sheet materials such as chipboard, fiberboard, plywood, tin;

- installation of lining, siding;

- installation of insulation, insulating membranes;

- fastening of carpets;

- installation of floors made of tongue and groove boards;

- installation of bitumen shingles and roofing material;

- attaching canvases to the frame;

- fastening power cables;

- assembly of wooden pallets;

- arrangement of film greenhouses;

- installation of glazing beads on wooden windows.

Electric staplers are much more functional than mechanical ones, but they are also more expensive. As a matter of fact, the type of energy that powers the stapler is the key criterion for dividing staplers into types.

Which construction stapler to choose from the variety offered?

The choice of stapler should be based on the following factors: frequency and intensity of use, operating conditions, and the types of work you intend to perform with the tool. The type of fasteners you plan to work with is also critical.

For use in workshops and workshops with a heavy production load, a pneumatic stapler is best suited. An electric stapler is also suitable for work in a workshop if the workplace has the ability to connect to an electrical outlet and does not require super-high performance. If you plan to work in open spaces and on sites where there is no access to the network, choose a cordless or mechanical stapler. For exclusive home use, it is best to buy a mechanical stapler. It will do an excellent job with “amateur” work and will be very inexpensive.

Mechanical stapler

A mechanical stapler has the simplest device, hence its advantages :

- durability, because there is nothing special to break;

- complete autonomy. Since no network connection is required, work can be done anywhere. You also don’t have to worry about the battery running out;

- compactness and minimal weight, because the design does not contain batteries, wires, etc.;

- simple maintenance. From time to time it is necessary to lubricate the spring;

- low cost, therefore, for rare household jobs, as a rule, mechanical models are chosen.

A mechanical stapler is not always operated by hand - stationary models are used in production, the release lever of which is pressed by the foot.

The disadvantage of mechanical staplers is the need to apply force, i.e. You won’t be able to work with such a tool for a long time, so if you expect to pick it up often and use it to work with hard materials, then it’s better to look towards electric models.

We mentioned earlier that the heart of the stapler is the spring. In a mechanical tool, the spring can be of two types:

- twisted or torsion bar . The main advantage is lower price. This design is used in hobby-class instruments, as it has a lot of disadvantages;

- plate or spring. Free from all the disadvantages of a coil spring. It is easier to build, and its returns are lower. This type of spring is used in professional instruments. The downside is the higher price.

To reduce recoil in a mechanical stapler , the design includes a lot of solutions. The most common are handle linings with shock-absorbing properties. Manufacturers are also working to create cases that distribute the load more evenly across the entire palm. The lower the recoil and the lower the noise level, the more technologically advanced the tool you have.

Many models are equipped with a double strike function, shock force adjustment and other additional functions, which you can read about below.

Staples, nails and pins can be used as fasteners in a stapler. Most models are designed to work with U-shaped staples of a certain thickness and width, while the length of the legs can vary. More specific are staplers with a round groove in the working part; U-shaped staples are inserted into them. Scope of application: installation of power cables.

On the farm, and even for professional use, a universal tacker is more useful, which works with both different types of staples and nails.

Separately, as a type, it is worth noting staple hammers. The bracket flies out not when you press the handle, but when you hit the surface with the tool. The accuracy of fasteners suffers, but you can work faster and use less force, which is why for some areas of construction this is an indispensable tool.

Maintenance and repair

Types of staples for construction staplers.

Each type of stapler has a staple block that is secured inside or outside the tool. Once the supply of staples is depleted, the unit must be replaced with a full one. All models have easy access to the unit and instructions for proper replacement.

If a blockage or breakdown occurs, the easiest way to figure it out is with a mechanical stapler. Such a mechanism can be repaired by simply replacing a few screws in the structure or changing a part. The housing is very easy to assemble and disassemble.

Electric and pneumatic staplers are subject exclusively to warranty or professional repair and maintenance due to the complexity and design features. A person who does not have the skills and experience in repairing special equipment will not be able to repair it themselves or at least determine the cause of the breakdown.

Electric stapler

In an electric stapler, a motor does everything for you, which drives the spring. This means that you can use a stronger spring, which will give a stronger blow. It will be possible to use larger fasteners. Therefore, the scope of use of an electric stapler is much wider. The downside is dependence on the outlet or the need to monitor the battery charge. Batteries make the device heavier, and wires limit the working area.

The maximum staple length in mechanical staplers is 10-15 mm, in electric staplers it is 25 mm, but there are models that can drive pins up to 50 mm long. The performance of electric staple guns is up to 20-30 beats per minute. It is difficult to develop and maintain such speed in a hand tool.

Depending on the characteristics of their work, electric staplers are divided into:

- network . They work from the network, i.e. they have a cord, which limits the operator’s mobility, so they often have to work with an extension cord. Such a tool can cause electric shock - special attention should be paid to how the manufacturer implemented the protection. Ideally, the case should be plastic with protective rubber pads on the handle, and the cable should have two layers of insulation;

- A cordless stapler is more mobile, but due to the presence of a battery, it weighs more than a network device, and even more so than a mechanical one. On average, one charge is enough for 1000 shots. The second disadvantage after weight is the need to charge the battery and the possibility of it being completely discharged at the most inopportune moment. When purchasing, be sure to pay attention to the battery capacity, but it is better to divide the autonomy declared by the manufacturer by 1.5. It’s great if you have the opportunity to purchase a second battery. In terms of performance, cordless models are not inferior to mains models, and often surpass them, providing a rate of fire of up to 30 strikes per minute and the ability to drive nails up to 30 mm long.

The functionality of electric staplers is much wider than their mechanical counterparts:

- the impact force can be adjusted stepwise or smoothly;

- automatic reusable blow and blow with two staples make some types of work more efficient;

- the shot function from pressing on the tip turns the stapler into a staple hammer;

- many craftsmen will like the fastener removal function;

- some models are equipped with a depth sensor;

- For safety, safety locks and protection against accidental descent are provided.

How to insert staples into a stapler?

Installing a new charge in the device is not difficult:

- The device is locked to prevent accidental operation.

- The magazine cover is removed from the rear.

- Next, the pusher spring is removed.

- The staple charge is installed with the legs facing down.

- All manipulations are done in reverse order.

- After removing the safety, you should try to shoot blank several times to check.

Today, thanks to a wide range of models, staplers with a slightly different charging method may be found.

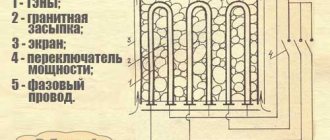

Pneumatic stapler

These are the most powerful and productive devices. The design is somewhat different from the electric and mechanical tackers. Here, instead of a spring, a pneumatic cylinder is used, and the main working force is compressed air. The whole thing is activated by pressing the trigger or pedal. The last option is typical for stationary models.

The main advantage of pneumatic staplers is their highest productivity. These are devices that are used more in production than for construction and finishing work. However, recently you can increasingly find equipment of this type on construction sites. The downside is the need to use a compressor to obtain compressed air, which means additional costs and noise, and the hose limits movement. The operating pressure varies between models, but on average it is 4-8 bar.

The average productivity of a pneumatic tack is 60 staples per second, which is twice as much as that of an electric tool. This staple gun can hammer staples 50 mm or more in length. At the same time, the device is compact and weighs only slightly more than a mechanical stapler.

Like electric models, pneumatic devices are equipped with a number of additional functions, including adjustment of impact force, multiple impacts, etc.

Types of staplers

The first step is to decide what type of staple gun you want. According to the type of driving force, construction staplers are:

- Mechanical. They are operated by hand force, have low productivity, and a small number of staples that can be “tucked” into it. With such equipment it is quite difficult to work with hard materials - you have to make a significant effort. But mechanical staplers are small in size and weigh little, which allows you to work in awkward positions. Their low price is also attractive, although there are models with a rather high price tag.

- Electrical. The staple flies out when the trigger is pulled, but the trigger mechanism is powered by electricity. There are models that run on mains power, and others that run on batteries. Naturally, productivity is higher than that of manual staplers, but prices are significantly higher, especially for cordless staplers. Also larger in size. Moreover, for models powered by mains power, the cord interferes and limits movement, while for battery-powered models, the weight and bulky handle cause inconvenience - the battery is usually attached to it from below. But the physical effort is minimal.

There are a lot of construction staplers. There are only three “drives” - they can work using the power of hands, electricity and compressed air

- Pneumatic. The driving force is compressed air, under the influence of which the fasteners or nails fly out of the magazine. They also have high productivity and a large magazine that can hold a large number of staples or nails. But the hose from the compressor (and the noise from it) interferes even more than with electric models. Moving with such a unit is problematic. So this type of stapler is more suitable for professional use in a specific place.

If you need a construction stapler for one-time work - only during the construction or finishing of a house or apartment, choose a mechanical or electric one. Mechanical works in any conditions, electric only in places where there is electricity. Even battery-powered models require periodic charging. Yes, you can buy a second set of batteries for them and while one is working, the second is charging. But charging also requires electricity.

Pneumatic staplers are purchased mainly in workshops for professional use. For one-time work this equipment is too expensive and very noisy.

Fastener type

There are staplers designed to work only with a certain type of staples, there are those that can work with different staples, and there are models that shoot both staples, nails, and pins. Before purchasing, you should definitely pay attention to this characteristic, having previously assessed the nature of your own work.

The main types of fasteners used are presented in the table.

The most popular are U-shaped staples of type 53 and 140. Such fasteners are used for furniture upholstery (in this case, staples up to 8 mm long are suitable), as well as for various types of work with drywall, plywood, etc. (the length of staples can reach 16 mm).

When it is necessary to attach a cable, use U-shaped clamps . Where to use nails is probably already clear to everyone, but pins are used where it is necessary to obtain the most aesthetic fastening, without protruding heads.

The staples are usually collected in groups of 50-100 pieces, they are fastened together, which simplifies transportation and handling, but does not in any way affect the ease of separation from one another during operation. Staples may have sharp or blunt ends. The first ones fit into the material more easily, so you will have to put in less effort to drive them in.

Most staples are made of steel; brass is used much less frequently.

Types of construction staplers and their prices

The staple gun is divided into:

Mechanical (manual) stapler

It operates by hand, has a compact size and light weight, has a small magazine capacity and low productivity.

In addition, with such models it is quite problematic to fasten materials to a solid base.

Mechanical construction staplers can be conventional (with a coil spring) or spring (with a leaf spring).

The first is the simplest, cheap, with an adjusting screw located in the upper part of the body, on the opposite side of the tip.

Price 350 – 800 rubles.

Leaf spring tools are more expensive, but have less recoil, are more powerful, last longer, and are easier to cock.

The cost can reach 2.5 thousand rubles and more.

Electric stapler

A more productive option, where the electric motor is responsible for cocking the spring acting on the firing pin.

The electric stapler, depending on the energy source, can be mains-powered (powered from a household electrical outlet) or rechargeable (with a removable battery).

All of them are larger and more massive compared to the previous version, and in the former the operating radius is limited by the long cable, so you often have to use extension cords, while the latter are inconvenient due to the bulky handle to which the battery is attached, as well as the overall massiveness.

The average price is from 1200 to 6000 rubles, and good battery options will cost 15 – 25 thousand rubles.

Pneumatic stapler

Powered by compressed air supplied from a compressor.

There are no springs, and the fasteners are inserted into the material under the influence of gas pressure.

The performance of pneumatic staplers is much higher; they also have greater reliability, magazine capacity and impressive impact force.

On the other hand, all the problems in operating such a construction stapler are generated by the compressor: noise, bulkiness, and most importantly, the limited length of the hose.

The price of a gun without a compressor is 2 – 3 thousand rubles.

Like almost any tool, a construction stapler is divided into the following classes:

Domestic

It has a small working life, is made of low-grade materials, has extremely limited functionality, and is not designed for intensive, frequent use.

Professional

A high-quality tool designed for long-term intensive use, it has advanced functionality that increases ease of use and productivity.

Industrial

It is mainly used by craftsmen in production areas where high productivity and fault tolerance are required, and mobility is not of particular importance.

A good example is a pneumatic stapler, which is comfortable to work in one place.

It should be noted that mechanical staplers are divided into several types:

Classic stapler

Works with staples no longer than 16 mm.

For example, he is able to attach upholstery to the wooden frame of a sofa, a mosquito net to a window vent.

Cable

Designed for fixing cables (including electrical) on various surfaces using special brackets, the length of which depends on the thickness of the wiring being laid.

Their cost is about 5-6 thousand rubles.

Universal

Capable of working with both conventional U-shaped staples and T-shaped and nail-type fasteners (nails, pins, studs).

On the packaging of such models and on their body, as a rule, they write: “3 in 1” and even “4 in 1”, with corresponding pictures.

Hammer

It is a long handle, at the end of which there is the mechanism itself, which is triggered by the inertia of the blow.

This type of stapler-hammer is used where accuracy is not important, for example, when fixing flooring or insulation.

There are also special construction staplers designed for specific jobs, for example:

Furniture

This is usually the name for any construction stapler, however, there are models created specifically for installing wooden frames and furniture upholstery.

Upholstery

Only for installing upholstery material on various substrates.

They come in two types, some options pierce the material and bend the staples (effective for joining fabric materials, bending the edges of canvases), while others pierce the upholstery and wooden base, and with the fasteners recessed.

For fastening the lining to the sheathing

Uses special staples driven at an angle.

Roofing stapler

For fixing soft roofing materials, insulation, insulation.

Can be equipped with a retractable blade.

What else to consider when choosing a construction stapler?

When choosing a stapler, also consider the following nuances:

- If you plan to work with materials of different hardness, be sure to choose a model with penetrating force adjustment . This option is provided in almost all mechanical staplers, but it is still better to clarify this point before purchasing. By turning the adjustment wheel, you can fine-tune the impact force so that the staple or nail is exactly flush with the surface, without sinking too much into it or rising above it. When working with pine, for example, you can use minimal force, but chipboard will require maximum force;

- Naturally, it is worth taking into account the key characteristics of the device. These are the rate of fire, weight, cord length for network models, battery capacity for battery models, operating pressure for pneumatic models;

- In devices operating from the network, the length of the cord is important. Minimum – 5 m. Once again we emphasize the importance of high-quality insulation;

- The double strike feature allows you to almost completely avoid missing staples. In this case, if during the first blow the staple or nail is not completely immersed in the surface, the next fastener element is not supplied, but an additional blow is made to the staple;

- all other things being equal, the best stapler will be with a collapsible body , i.e. assembled with screws rather than rivets. Such a tool is easier to maintain, since it can be disassembled at any time for cleaning or lubrication;

- the smaller the angle between the lever and the body in the initial position, the more convenient it will be to work with the tool, especially if it is necessary to carry out fastening by weight;

- if you need to fasten staples/nails at a clearly defined distance from the edge, then take a closer look at models with guide elements, stops and hooks;

- Staplers with a protruding nose are well suited for working in hard-to-reach places;

- The shockless release function makes transporting the stapler more convenient and safe. Thanks to it, the device can be simply folded, while inadvertent operation will be excluded;

- The convenience of operation is also affected by the design of the store. More convenient will be the one where the magazine with fasteners is inserted, as in a stationery stapler. Push the magazine through the slot hole is not so convenient and fast. The magazine viewing window is a useful option that allows you to easily monitor its condition;

- What distinguishes a household construction stapler from a professional one is not only the price and set of functions, but also the material used. Inexpensive appliances for home use are usually made of plastic (don't worry, plastic can be durable and reliable too). Professional models are made of metal - it is heavier, but much more durable. Plastic is used only as protective linings;

- The name of the manufacturer is a guarantee of quality, and for staplers, like other equipment, this rule works 100%. Among the most famous brands we note Bosch, Intertool, Einhell, Metabo, Sparky, Sturm.

More about impact force

Often it is this characteristic that is decisive when it comes to determining which construction stapler is better. Generally speaking, mechanical models have the smallest impact force, followed by electric ones, and the most powerful ones are those that run on pneumatics. However, in addition to this, in each category there are devices that work more and less efficiently. Let's try to figure this out.

The easiest way to calculate the impact force is by the longest staple length that the stapler can drive. Usually this characteristic is indicated in its technical data sheet. For example, they write like this: the length of the staple is from 4 to 14 millimeters. We should be interested in the maximum value - it is this that determines the force of the taker’s blow. Let's assume that we have two models in front of us, the first of which has a staple length varying from 4 to 10 millimeters, and the second from 4 to 14 millimeters. Naturally, it is better to take the second model.

It should be noted that the maximum length of the staple depends to a large extent on the material being processed. For example, staples 14 millimeters long fit into soft pine wood just perfectly, without any effort. But with oak or particle boards you will have to tinker - here it’s good if you can drive the staples to a depth of 12 millimeters. So it should be remembered that as the hardness of the material increases, the impact force becomes somewhat weaker, and the depth of driving of consumables becomes less.

If you are not particularly experienced in such work, and you are purchasing a stapler for infrequent home use, feel free to buy a model capable of driving staples 12 millimeters long or a little more. That's enough for you.

TOP 6 best construction staplers

STANLEY Light Duty 6-TR150L

Inexpensive and quite functional stapler. It works from muscular strength and has an adjustable impact force. The body is made of aluminum and equipped with ergonomic handles. The stapler can accommodate both staples (size 53, length 6-14 mm) and nails (size 300, length 12-15 mm). The manufacturer has taken care of convenient access to the store. Even professional builders praise this stapler. The only complaint is the inability to work with nails without heads. Costs about 1400 rubles.

Gross 41005

A distinctive feature of this model is the spring spring, which makes it much easier to interact with the device. The stapler works with nails (8-16 mm, type 300, 500) and staples (8-14 mm, type 36, 53), and is equipped with a mechanism for adjusting the impact force. Thanks to a small protrusion at the base of the device, you can work with it in the most difficult to reach places. The model costs about 1,200 rubles and is very popular with users.

BOSCH HT 14 0.603.038.001

Another good option if you need a mechanical stapler. The model is as simple as possible, but has an adjustable impact force, can drive staples (4-14 mm, type 53) and nails (up to 14 mm, type 41). Users note that the design uses a coil spring. Cost – about 1200 rubles. A little expensive for this model, but if the name of the manufacturer is important to you, then you can consider the device, because it is assembled of very high quality.

BOSCH PTK 14 EDT 0.603.265.520

A high-quality network stapler that provides productivity up to 30 staples/min. The magazine can accommodate staples (6-14 mm, size 53) and nails (11.4-14 mm, size 48). The device weighs a lot - 1.1 kg. The noise level is average – 95 dB. There is an adjustment of the impact force, an indicator of the degree of filling, and the ability to hit with two staples at once. However, some complain that the model jams the other half of the staples in the store. The cost is about 6,000 rubles.

Hammer HPE2000C PREMIUM

The device is powered from the mains, has a decent rate of fire (30 strikes/min), works with staples (15-25 mm) and nails (15-32 mm). There is an adjustment of the impact force. Price – about 4200 rubles. Masters complain that sometimes there is a shortage.

Rating of construction staplers

When understanding how to choose a construction stapler, the advice of professionals will come in handy. The masters included the following brands in the rating of the best models:

- Bosch HT 14

is a mechanical type device for fastening soft or thin materials. Cost – $17. - Stanley 6-TR250

is a mechanical device with an ergonomic D-shaped handle and adjustable impact force. Cost – $29. - Hammer HPE20

– electric construction stapler for nails or staples with a cord length of 2 m. Cost – $31. - Metabo DKG 80/16

is a pneumatic device with reduced vibration levels. Cost – $121. - Ryobi R18N16G-0

is an electric battery model, the main task of which is driving nails during construction and installation work. Cost – $212.

Why doesn't the furniture stapler work?

The main malfunctions of a furniture stapler may be associated with improper operation, selection of staples, or design features of a particular model:

- If the staples are not completely clogged, then you need to either adjust the tool and tighten the spring, or remove the jammed staple from the magazine and continue working.

- Often, if the staples are not clogged at all, you need to lubricate the head of the staple clamping mechanism.

- When the staple gun produces several staples at a time or they constantly get stuck, this indicates a malfunction of the striker. Its shape may be damaged or there may be a crack.

Why does a furniture stapler bend staples?

Another common problem is the situation in which a furniture stapler bends the staples; every experienced craftsman knows what to do. The problem can be solved in two ways:

- Purchasing more durable staples, since the existing ones do not match the density of the material.

- Using staples with shorter legs. The shorter they are, the easier it will be for the fastening material to enter the surface.