Design Features

A stove for a cauldron from a gas cylinder in finished form.

Unlike a pan with a flat bottom, which heats up unevenly, the cauldron distributes heat over its surface. However, this effect can be achieved when the fire's flame covers most of its outer surface. This cannot be achieved by using a flat stand or tripod installed over a fire; a special hearth or stove must be made.

It is better to build a stationary brick structure, but if this is not necessary, you can get by with a simple structure made from a regular gas cylinder. There are also more complex home-made structures, which are constructed from car rims or steel pipes with a diameter of at least 250 mm and a wall thickness of 3-5 mm. However, they all turn out to be bulky and not very convenient to use.

Selection of furnace design

Stoves for a cauldron made from a pipe or a gas cylinder are made according to the same design, the only difference is in the material of the workpiece. In the future, we will talk about making a stove from a gas cylinder. The instructions are also quite applicable for stoves made of pipes.

When choosing a design for making a stove, consider the following factors:

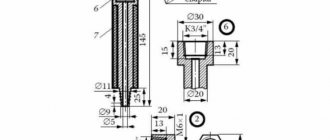

- The cauldron should fit 2/3 into the neck of the stove so that the flame heats it evenly. Therefore, choose the diameter of the pipe or cylinder that matches the desired volume of dishes. For a ten-liter cauldron, a size of 450 mm or more is suitable.

- A stove with a chimney is good for semi-enclosed verandas. If you like smoky dishes, make a design without a chimney and use it only outdoors.

- The most convenient boiler level height is from 90 to 100 cm above the ground.

Advantages of a stove made from a gas cylinder

A stove from a cylinder can be moved from place to place.

A metal stove is almost impossible to manufacture without welded seams, which during operation are quickly destroyed under the influence of external climatic factors and heating of the walls to high temperatures. Therefore, for such structures, empty gas cylinders are most often used, which have suitable geometric dimensions and are practically ready-made containers for the firebox. After a little modification, the gas cylinder becomes an ideal stove for cooking in a cauldron. If you have certain skills, such a stove can be made in an hour.

A self-made stove for a cauldron from a gas cylinder has a number of advantages:

- guarantees a tight fit and uniform distribution of heat (heat) along the walls of the cauldron;

- ensures complete combustion of wood and the most efficient use of heat;

- allows you to easily move the product from place to place.

Making a stove for a cauldron does not require virtually any financial costs - you only need a gas cylinder, and the summer resident will find everything else in his own workshop.

When choosing a gas cylinder for a stove, we focus on 2 parameters: volume and diameter. It should be taken into account that part of the volume will be occupied by the ash pit of the stove and the bottom of the cauldron itself. Of the entire range of cylinders (5-50 l), the most suitable is a 50 l cylinder. It can accommodate a large firebox and a convenient ash pan.

Manufacturing of gratings

The grill serves as a stand for the barbecue. It is a mesh of 5 mm rods. These rods are inserted into several slots, which run in one row along the two edges of the hole for the cover. Of course, the slots are sawed in advance with a grinder.

Also, the slots can be used for planting skewers, as shown in the photo of a barbecue made from a gas cylinder with your own hands. Therefore, the optimal width and depth of the channels is 10 and 15 mm, respectively.

For convenient preparation of shish kebab, you can weld a metal tray next to the hole under the lid.

Consumables, oven fittings and tools

To make a stove you will need a 50 liter cylinder.

To make a stove for a cauldron you will need:

- old gas cylinder 50 l;

- pipe with a diameter of 100-150 mm;

- steel sheet - 0.5 m²;

- steel corners - 4 pcs.;

- door hinges;

- grate;

- fire door;

- ash door.

Tools you may need:

- welding machine with electrodes;

- grinder with a set of cutting and grinding wheels;

- electric drill with a set of drills;

- a set of plumbing tools (hammer, chisel, pliers, etc.)

- hard brush with steel bristles;

- roulette;

- marker.

Before sawing, the cylinder must be untwisted to release the remaining gas.

Scale and sparks flying in different directions when welding and cutting metal can damage the retina of the eye and/or the skin of the worker. Therefore, before starting work, you need to prepare a set of protective equipment:

- welding mask;

- protective glasses;

- closed shoes;

- suit made of thick fabric;

- gloves.

Working with hand-held power tools requires compliance with the safety rules set out in the relevant labor protection instructions.

Making a stove with your own hands

To make a stove for a cauldron from a gas cylinder with your own hands, several mandatory operations are performed.

Preparing the balloon

It is necessary to release the remaining gas from the container. Open the valve and keep the cylinder in this state in air for several days. Then turn off the tap completely and pour out all the contents from the container. A similar result can be obtained if you rinse the balloon several times with warm water.

Cutting the cylinder to size

The top of the cylinder is cut off and a hole for the door is cut.

After filling the cylinder with water and turning the tap all the way, begin cutting. It is necessary to carefully, preferably along the weld seams, cut off the upper and lower parts, thereby obtaining a blank for the stove with a height of at least 45 cm. If the cuts are uneven, the smoothest one is trimmed with a grinding wheel and made into the top of the stove.

Then they try on the cauldron: if it fits 2/3 into the cylinder, this part of the work can be considered completed. If the cauldron has a larger volume, use a grinder to make vertical cuts to a depth of 5 cm every 7-15 cm along the upper edge. If necessary, they are folded so that the cauldron goes in 2/3 of its diameter.

Flushing

It is necessary to thoroughly rinse the inner surface of the resulting workpiece several times, first with an aqueous solution of bleach, and then with a soda solution. This will get rid of unpleasant odors.

After the inner surface of the workpiece has dried, they begin plumbing and welding work: installing a chimney, doors, and fittings. Next, the stove is calcined, thus eliminating any remaining unpleasant odors, and at the same time the tightness of the chimney and installed doors is checked.

It doesn't hurt to paint the outside of the stove with black paint if it's rusty. Even after some of the paint has burned off, the stove will look neater.

DIY construction of wood-burning stoves from gas cylinders

The structure of a wood-burning stove is incredibly simple: a chimney, a combustion chamber with a grate (grid) and a vent. A gas cylinder produces a compact and fairly safe design. It quickly heats up itself, while heat immediately begins to flow through the walls into the heated room, and just as quickly heats the hob for cooking or heating food.

Scheme of a potbelly stove made from a small gas cylinder

Any metal stove has a significant drawback - burning out of the sides of the firebox. Regardless of the thickness of the steel, the walls will sooner or later end up with holes. This must be strictly monitored, otherwise it won’t take long for things to end in a fire.

Preparing for work: tools, materials and cleaning the cylinder

To build a wood-burning stove from a gas cylinder yourself, you will need:

- Grinder with wheels for cutting and grinding metal.

- Welding machine and electrodes for it.

- Drill with drills.

- Stiff brush with metal bristles.

- Chisel, pliers, tape measure, marker and hammer.

- One or two balloon containers.

- Chimney pipes.

- Sheet of steel for the ash pan and doors.

- Grate box and metal corner for legs.

Extremely important! Before starting work, it is necessary to empty the container of residual gas. Even its minimal volume, coupled with fire or scale formed when cutting metal, can lead to an explosion.

A vertical potbelly stove can be made with a removable stove and removable grates.

First, you need to prepare the tools and all the necessary components. But the main thing at this stage is preparing the cylinder. There could be gas left in it, which must be gotten rid of before you start cutting the metal with a grinder and welding.

Even a hint of propane should be removed from the container. To do this, you will have to unscrew the valve and fill everything inside to the brim with water. And then dry it, leaving it outside for a couple of days. If you have difficulty unscrewing the tap, you can use a hammer to knock it out

Potbelly stove - fast, simple and warm

This stove model from a gas cylinder can be assembled with your own hands in both horizontal and vertical versions. In the first case, the firebox and blower doors will be located in place of the tap, and in the second - at the very bottom of the body. Accordingly, at the other end you will have to weld a pipe for the chimney.

Cut a 50-liter cylinder to make a stove with your own hands

The doors can be made round from pieces of metal cut into a cylinder or straight from a sheet of steel. The first option involves welding the hinges directly to the body and door leaf, and the second involves pre-fabricating the frame from steel corners.

In a horizontal structure, in place of the bottom of the stove, you will have to cut a hole with a grinder and weld the grate bars, or simply drill holes in the balloon wall. Then you will need to make an ash pan in the form of a rectangular box and weld it in the right place. If a vertical model is chosen, then the grate bars will have to be welded inside the cylinder, and another door will have to be cut for the blower below the firebox.

Instead of grates, it is enough to drill holes in the housing with a drill

In the end, all that remains is to mount the legs from the corners and the chimney, having previously cut a hole for it of the appropriate diameter. To increase draft and heat transfer, the chimney pipe should be made elbow with a horizontal section of a couple of meters.

Oven for a round cauldron - uniform heating of the surface and delicious food

In addition to a heating stove, a gas cylinder makes a good stove for cooking. To do this, on a vertical potbelly stove it is enough to weld a flat steel sheet on top or make a separate heater for the cauldron. Moreover, the second option is even easier to do than the first.

Important! The cauldron has a round bottom so that the heat is distributed evenly. The fire from burning wood should cover the entire bottom, and for this it is better to make the stove open at the top, without a chimney.

The cauldron must be immersed in the cylinder as much as possible

. In fact, you will have to make a vertical potbelly stove without a top. It is better to make the cut at a distance of 20–25 cm from the valve. The cauldron should fit two-thirds inside the cylinder body. If its diameter is larger than the section of the cylinder, you will need to use a grinder to make vertical cuts in the walls and bend the resulting petals outward. Everything is extremely simple.

How to improve a cauldron stove

A cauldron stove can easily be turned into a universal hearth. To do this, purchase a special cast iron plate with removable rings.

The maximum diameter of the hole in the stove with the rings removed must correspond to the dimensions of the cauldron. The best option is that the stove ring covers the cauldron right up to the handles.

When purchasing a stove, pay attention to the presence of a central plug. This part is needed when the stove is used to heat a room. Such a plug will not allow smoke to spread and will not disrupt draft.

To increase fire safety, it is recommended to equip the stove chimney with a spark arrester. It can be made from an ordinary tin can with a large number of holes that can be made with a nail.

How to use the oven correctly

For ease of carrying, the handles are welded in.

When operating the stove, you must follow certain rules:

- The stove should be installed on a thick sheet of metal, which will provide additional fire safety for the structure heated to a high temperature.

- Limit access of children and animals to the heated fireplace.

- Do not place the oven near flammable objects.

- To avoid condensation on internal surfaces, use only dry firewood.

- Do not use the stove to burn construction and household waste.

It is strictly prohibited to pour liquid petroleum products into such a furnace. Only solid fuel can be used.