Explanation in simple human language

The problem with corrosion of faucets and heated towel rails is that you have plastic pipes going to them, but the riser in the house is made of metal pipes. Metal pipes are all grounded, in new houses through a potential equalization system, in old houses - in the basement to the ground loop. When using plastic pipes, you break the metal connection between the riser pipes and the metal mixer or heated towel rail. Therefore, you break the potential, on the riser you have one - ground, on the heated towel rail - another. It's called potential difference. What appears between different potentials? Current - provided that a conductor appears between them, and such a conductor is the water flowing through the pipes. When water moves through pipes, micro-friction of various media occurs - water and metal, and what happens during friction? Remember the ebonite stick? That's right - tension, i.e. potential, the one in the riser is equal to the potential of the earth (grounded), and the one in the heated towel rail hangs on it by itself, and through the water between different potentials, stray currents arise, and as a result, corrosion. Water definitely has excellent electrical conductivity.

In our experience, Mario heated towel rails resist stray currents best; for this occasion, we are giving a 10% discount on any water model. When placing your order, simply enter promo code mario10 and receive a 10% discount.

ALL YOU NEED TO DO is to ensure a reliable metal connection between the riser pipes and the metal terminal devices (mixer, heated towel rail). Simply put, ground your heated towel rail to the metal pipes of the riser, the potential will equalize and the current will have nowhere to flow.

Why haven’t similar difficulties arisen before?

Strange as it may sound, progress has become the reason for the emergence of such a problem as potential difference in engineering systems. Namely, the widespread replacement of metal pipes with plastic ones. As long as the hot water supply, hot water supply and heating pipelines were completely metal, no difficulties arose. And there was no need to separately ground each radiator, faucet or heated towel rail either - all pipes were grounded centrally in the basement of the house, in two places. And all metal appliances in bathrooms and toilets automatically became safe and protected from stray currents.

The transition to plastic changed everything: on the one hand, pipelines began to last longer, and on the other hand, there was a need for additional protection of plumbing equipment. And here it’s not only about the pipes themselves, because in terms of conductivity, metal-plastic is close to traditional metal, but also about the fittings - connecting elements. More precisely, in the materials from which they are made and which cannot provide electrical contact with the aluminum “core” of the metal-plastic pipe.

Video

On the YouTube channel, Vyacheslav Yankevich published several good videos on how to ground a heated towel rail. Below we present two of them.

What are stray currents and the reasons for their occurrence in scientific language

The reasons for the occurrence of stray electric currents in the heating and water supply systems are very different - from the absence or improper grounding of electrical appliances directly connected to the riser of the heated towel rail, such as a washing machine, electromagnetic filter, circulation pump, to the proximity of the railway and tram tracks.

Stray currents arise not only from external, but also from internal sources, namely due to a short circuit. Theoretically, with proper construction, there should be no short circuits in the system, but in practice it turns out differently. In some places, the welding joint is replaced with conventional bends or a piece of pipe is replaced with metal plastic, so stray currents arise, and all this leads to electrical and electrochemical corrosion.

When the entire riser consists of metal pipes, and in apartments they are replaced with plastic ones, stray currents arise due to different types of pipes. All this happens because all metal pipes are grounded during construction. In new houses, for example, grounding occurs through a potential equation system, and in old houses in basements - along a ground loop. And when installing plastic, this metal connection between the pipes and the heated towel rail is leveled, and stray currents appear. Consequently, the already existing potential is broken: it turns out that there will be one on the riser, and another on the heated towel rail.

Another common cause of electrocorrosion is the potential difference between two different materials in close proximity to each other, especially black and stainless steel.

Also, damage to this plumbing is caused by stray currents that arise in the event of poor wiring insulation, a network break, or if someone (maybe even on another floor of an apartment building) connects the neutral wire from the electrical network to the heating system for personal gain. Damage is also possible if grounding is done to the heating system. The place where the charge penetrates the body of the heated towel rail undergoes a chemical reaction: it inevitably leads to damage to the product. These problems are solved by grounding the heated towel rail or potential equalization.

Before you buy a water heated towel rail, read this article; it will be useful to know this before your bathroom renovation is completed.

Stray currents in a heated towel rail: how to eliminate, grounding, protection

High humidity in the bathroom has more than once had a negative impact on household appliances.

This attribute of the bathroom is an integral part of it. The heated towel rail is capable of not only efficiently performing its intended functions, but also fitting into a logical overall interior. In order to prolong its life, many people buy devices made of stainless steel. The heated towel rail not only performs its main function, but also logically decorates the interior

Device related issues

If you own a stainless steel heated towel rail, then you are familiar with the problems called “stray currents” and galvanic corrosion, and it is unlikely that you will be able to avoid them.

It’s easy to identify them: if small spots the size of a match head begin to appear on your stainless steel device, which not only rust, but also spread further, know that these are stray currents in the heated towel rail. How to fix the problem and is it possible? The answer will not be long in coming.

Noticing a leak in the device, many owners complain about a low-quality product. Mostly, such conclusions are not true, since the cause of the malfunction lies in an electric current that can destroy the pipes of your heated towel rail. Destruction is affected by:

- electrolyte water, including salts and minerals;

- presence of high temperature;

- stray currents.

Mostly, the problem of currents arises as a result of poor-quality wiring, when networks break. When a charge enters the device, a chemical reaction occurs, leading to breakdown or damage to the heated towel rail.

Determination of stray currents

All technical devices that come into contact with water are sooner or later subject to corrosion, one of the types of which is considered to be stray currents that arise in the ground, which is used as a conductive medium. Corrosion is caused by metal devices being buried underground or on the surface. Sometimes stray currents can appear as a result of emergency leaks.

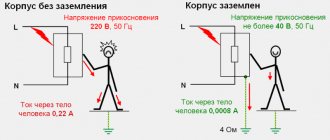

Sometimes stray currents are defined as zero pulses that exist in all ungrounded metal structures. The nature lies in the potential difference in grounded structures in different parts of the building. To get rid of stray currents, you need a potential equalization system.

Thanks to it, a person will protect himself from electric shocks. You can create a system at the time of construction, when the connection of metal pipes and the zero bus of the input distribution device occurs. This process is called galvanic contact.

Old buildings and houses differ from new ones in that all water risers are made of metal. The risers are connected to grounding bars located in the basements. Regarding the new building, the metal water pipes there are connected using a system that equalizes potentials.

Thus, water flows through metal-plastic and polypropylene pipes. By doing similar installation work with the water supply, you can interrupt the connection between the heated towel rail and the metal riser, which is why corrosion occurs. The phenomenon is called potential difference.

Grounding the heated towel rail is necessary to prevent the occurrence of currents

Therefore, a prerequisite for metallic structural elements is grounding, which prevents the occurrence of currents.

Why does current leakage occur?

For any action there is a specific reason that is easy to determine. Most often, current entering the heated towel rail is caused by factors that experts recommend eradicating without fail if you did not do everything perfectly during installation.

- Unprofessional use of the electrical supply system. When pipeline systems are specifically used as zero working conductors.

- In case of incorrect connection of sterilizers, washing machines, hydromassage baths, shower cabins, water heating boilers, dishwashers that connect the pipeline systems to the building's power supply.

- Damage to the cable line or electrical equipment that occurs during use.

- In case of weakening, burning and mechanical damage to conductors.

When a radical restructuring of the power supply system occurs, a three- and five-wire circuit to the electrical equipment must be introduced. It is not worth explaining to an adult why it is dangerous to deal with electric current. But it probably won’t hurt to remind you that water can conduct dangerous voltage.

So, its conductivity will deliver current to the “unwanted” place. The conductivity of water will not protect against electric shock. Touching a damaged heated towel rail means receiving a noticeable electric shock that can kill an elderly person.

Is it possible to secure a heated towel rail?

The advantage of stainless steel heated towel rails is their unlimited service life. Their shine is caused by polishing during manufacturing. Features of heated towel rails:

- they are resistant to mechanical stress, unlike devices made of copper and brass;

- any damage in the form of scratches can be eliminated with mastic and a felt cloth;

- Seamless devices, which are guaranteed for 20 years, can withstand currents.

The heated towel rail is resistant to mechanical stress

However, even such durable devices are subject to electro-corrosion, which can only be determined with the help of professional instruments.

To eliminate stray currents, it is necessary to ensure a reliable metal connection between the riser pipes and the metal end devices. In simple words, the process is called grounding the heated towel rail. All that is required of you is to ground your device to metal pipes. Grounding will get rid of stray currents immediately: potential equalization will occur, and the current will not be able to “leak through.”

When all the pipelines were made of steel, the problem of grounding the batteries never arose. This is explained by the grounding of each pipeline, as an extended element, in two sections of the basement. In addition, previously the bathroom was grounded using separate conductors, which provided an electrical connection to the water supply.

How does grounding happen?

Having found out all the physical features of stainless steel devices and the causes of problems in them, it’s time to figure out how to ground a heated towel rail. It is not difficult to do this yourself even for a beginner in such work.

The simplicity is associated with the design of the heated towel rail models themselves, which are adapted for connection to a grounded outlet. If the socket is built into the bathtub itself, then provide it with a special housing that protects it from liquid and moisture. For this model, it is enough to install the socket and close it with a cap.

How to ground a water heated towel rail according to the diagram? Follow the suggested order and you will succeed.

- First, you should carefully check that the heated towel rail is securely attached to the riser pipes.

- Then carefully analyze the material of the pipes related to the hot water supply system. When steel material is detected, grounding is preferably not required. With metal-plastic analogues, the situation is the opposite: despite their current conductivity, the circuit is interrupted at the area where the fittings are connected. For such models, provisioning is required as much as possible. After examining the plastic material, proceed to the next step.

- Using a conductor, connect any metal elements in the room.

- Start making a grounding jumper: connect the wiring from the distribution panel to the conductor.

- Secure the grounded wire to the coil using a special clamp.

- Operate your device without any problems.

How to ground a heated towel rail?

Unfortunately, grounding is not a panacea and does not provide a 100% guarantee that the heated towel rail will not leak, but we have another option to protect the product - the polymer coating of the heated towel rail.

The dryer is connected to the heating system through a metal-plastic pipe (diagram below). The fact is that a metal-plastic pipe has an aluminum layer inside that conducts currents, but at the point where the fitting is connected there will be a break in the electrical circuit. Therefore, it must be grounded to the DHW riser or ground loop.

The need for grounding

In multi-storey buildings of the old (Soviet) model, metal heating risers are initially grounded in the following cases:

- The heated towel rail is connected to the heating system via a metal pipe.

- During the reconstruction, an individual heating system was installed.

If all the pipes are made of steel, grounding the batteries would not be a problem since all pipes are usually grounded in two places in the basement. In addition, the bathroom is grounded by separate conductors that are electrically connected to the plumbing system.

There is a need for grounding the heated towel rail in the following cases:

- The device is connected to the heating system through a metal-plastic pipe, which is equipped with an aluminum layer that conducts currents. However, a break in the electrical circuit occurs at the fitting section.

- The house riser is made of metal-plastic pipes.

Grounding schemes for polymer risers.

By default, an electric heated towel rail assumes that this device will be connected to a grounded outlet.

To ground a stainless steel water heated towel rail, the sequence of actions is as follows:

- We connect with a copper conductor with a cross-section of at least 2.5 sq. mm.

- We make a grounding jumper: we connect the conductor and the wire on the distribution panel.

- We secure the grounding wire to the heated towel rail pipe with a special clamp.

Simply put, you need to ground the heated towel rail to the metal riser pipes or ground loop.

Causes

Many who have installed a heated towel rail at home have encountered the problem of electrocorrosion of the device. One of the main causes of corrosion is stray currents. To cope with this problem, it is enough to ensure a strong metal connection between the connection riser pipes and the heated towel rail pipes. That is, it is necessary to ground the pipes.

Another cause of corrosion can be water. But not in terms of its chemical composition, which will negatively affect the condition of the pipes, but the fact is that water, when circulating through the pipes, rubs against them, thereby generating a certain amount of current, which can also lead to corrosion.

Another factor causing stray currents in the heated towel rail can be an unscrupulous neighbor who, in order to save his day, put a magnet on the water meter and connected to the heating system, now the cubic meters of water are counted in the opposite direction, the currents accumulate in your heated towel rail.

Protection of pipes from stray currents

Metal pipes are still popular, although they are being replaced by more modern analogues. The main task is to combat corrosion. One of the reasons for its formation is stray currents. Protection against them is based on different principles.

What effect does current have?

The problem is relevant in those sections of the pipeline that are laid under railway tracks, highways and city roads. Stray currents created on the soil surface follow the path of least resistance. Since metal is an excellent conductor, charged particles pass through it and return to their starting point.

Pipe wrapping for protection

This destroys the pipes as the particles take metal molecules with them. Constantly exposed to electricity, the walls of the pipe become thinner

To eliminate the problem, it is important to choose the right methods for protecting products from current.

general information

Protection of underground pipes is divided into passive and active control measures.

- Active is characterized by the installation of a device that generates a counter electrical signal.

- A passive measure is insulators. The task is to choose the right materials and take into account a number of properties.

Stray currents cease to be dangerous if comprehensive pipe protection is carried out. Experts recommend coating products with polymer compounds - this prevents metal corrosion.

Protection by tapping

What should be done?

To protect the pipes, a cathode station is installed. This installation supplies some potential to the product body. So the stray currents are compensated; they meet on their way a charge of opposite sign and a larger value. The pipe ceases to be the area of least resistance.

Another method (less expensive) is to completely isolate the pipes from the ground (done during the construction phase). Protection is implemented in the form of mastic, powder, enamel shields, etc. Insulation is also carried out using adhesive polymer tapes, as well as using a primer. The main condition for their use is that insulating materials must be thermally resistant, not subject to rapid rotting, with high strength and good dielectric properties.

We advise you to study Active antenna for car

There is also a more radical protection of the pipe - replacement with plastic products. Then the lines will last for many years, there is no need to change such analogues, they are resistant to external factors and are an excellent dielectric.

There is something else…

Stray currents are dangerous in those regions where electric transport is provided. The problem is not always relevant. In some parts of our homeland, residents get along just fine without insulating underground pipes and use the highways for many years.

What are stray currents?

Stray currents are currents that arise in the ground, which is used as a conductive medium. But this is too general a definition. In the case of heated towel rails, stray currents appear as a result of electricity leakage from the wiring as a result of a wire breakdown. The lost current tends to places with low potential, that is, to any metal structures.

Stray currents are dangerous because they cause metal corrosion, which leads to leaks and wear of the heated towel rail. Another dangerous factor is that a device with stray currents is unsafe for humans. Because there is a high risk of getting an electric shock.

To protect yourself from these two factors, you need to do the following:

- Grounding, that is, to ensure a strong connection between the water supply or heating pipes with the heated towel rail. Then the stray currents will disappear and the corrosion process will stop.

- Create a system that will balance the potentials of all pipes.

Grounding can protect the heated towel rail from corrosion

Stray currents are a common phenomenon and, moreover, dangerous for humans. Therefore, as soon as you notice this feature in your heated towel rail, you need to fix it: by calling a specialist or yourself

Relationship between stray current and corrosion on metal

Due to the presence of water and dissolved salts in the ground, any metal structure in the soil is susceptible to corrosion. But if the metal is also exposed to stray currents, then the process becomes electrolytic in nature. According to Faraday's law, the rate of an electrochemical reaction directly depends on the current flowing between the anode and cathode. Consequently, the rate of corrosion of a metal pipe (laid in the ground) will be influenced by the electrical resistance of the soil, as well as the complex nature of the processes occurring in the cathode and anodic zone.

We advise you to study All about fusesAs a result, the metal structure, in addition to normal corrosion, is exposed to leakage currents. This can cause the formation of a galvanic couple, which will significantly accelerate the corrosion process. In practice, there have been cases when a section of a water supply system pipeline that was subject to galvanic corrosion failed after two years, with an estimated service life of 20 years. An example of such an impact is presented below.

Pipe after exposure to stray currents

Indications for grounding

In fact, all engineering systems are grounded at the construction stage of the building. A grounding system is created. In old houses, a potential equalization system was used. This system implied the connection of the metal parts of the system. Today, the widespread use of plastic pipes calls this method into question. As a result of the use of plastic inserts, the metal connection of the system breaks, which leads to the occurrence of stray currents.

It seems that the problem can be solved by using metal-plastic pipes, since such pipes contain aluminum film. However, we must not forget that metal-plastic pipes are connected mainly by soldering. To ensure the tightness of the soldering of metal-plastic pipes, it is necessary to clean the joint from aluminum foil, that is, that same metal connection disappears.

New houses are equipped with a special grounding circuit in the electrical panel. This greatly simplifies the grounding of the heated towel rail. In addition, the use of such a circuit is the only possible method to ensure grounding of all systems with parallel use of plastic pipes.

Grounding of the heated towel rail is necessary:

- In a new house with a metal-plastic heating riser. The main pipeline is always made of metal, so there is a high probability that stray currents on the way to the main will get into your heated towel rail.

- After renovation in an old house using metal-plastic pipes. In old houses, as already mentioned, the potential equalization method was used. The result of such repairs is a violation of the grounding system, which means it needs to be provided with a new one.

- Connecting the heated towel rail to the network using metal pipes.

Measurement methods

To check for the presence of BT, devices are used to determine their presence and size. The set of measurements includes:

- testing the voltage and direction of current along the sheaths of main cables;

- finding the potential difference between points: underground communications - rails;

- measurements in individual sections of the railway of the insulation value of the rails from the bedding;

- analysis of the degree of energy leakage from cable sheaths into the ground.

Important! Measurements at railway facilities are carried out during hours of highest train traffic density.

BT measurement kit

The use of a BT protection complex and correct calculation of the potential will minimize the negative impact of currents. An important role is played by the precise determination of BT localization sites. Electrocorrosion protection of objects reduces the cost of repair and replacement of deteriorated pipelines and other underground communications.

Methods for grounding a heated towel rail

There is actually only one way to ground a heated towel rail: using a grounding wire connected to the grounding circuit in the electrical panel. When using plastic in the installation of a heated towel rail, each metal element of the system is grounded. For this:

- The wire must be stripped and then bent into a loop shape.

- The paint is removed from the pipe, and then the stripped part of the wire is placed against the metal part of the pipe.

- The loop is secured with a metal clamp.

- These loops go around all metal parts of the structure.

- The wire is routed to the electrical panel in the entrance and connected to the ground loop.

There is only one way to ground a heated towel rail

In old houses where a grounding loop is not provided, you will have to make do with metal pipes so as not to break the loop that equalizes the potentials of metal structures.

Innovative technology for protecting heated towel rails

Electrocorrosion is considered the biggest problem with stray currents. The heated towel rail is already exposed to a fairly high degree of risk. Due to the fact that hot water passes through the pipes, salts accumulate on the inner walls, interfering with the passage of the coolant. Due to the effect of electricity on water, the effect of galvanic corrosion occurs, when the loss and deposition of salts accelerates, and the corrosion processes of the metal also intensify, in other words, rust begins to affect the pipe many times more strongly.

Taken together, all these factors lead to rapid failure of the heated towel rail. Usually the manufacturer talks about 5 years of service, but a stainless steel heated towel rail can in fact withstand 20-30 years of use.

However, manufacturers of heated towel rails have tried to anticipate this fact and make more expensive products with corrosion protection. This product is advertised as protection aimed specifically at electrocorrosion, but in fact the innovation also protects against salt deposition.

To preserve the heated towel rail, the manufacturer coats the inner surface of the pipe with a special polymer. Thus, electricity from the pipe cannot affect the water. At the same time, the inner surface becomes smooth, which prevents the deposition of salts, which means that such a coating protects the pipes from overgrowing.

But don’t think that such innovation is a panacea. We must not forget that stray currents are not only electrocorrosion, but also a danger of electric shock. From the point of view of corrosion activity, the coating will really protect the heated towel rail. But for your own safety, it is better to ground the heated towel rail.

Source

Why is my heated towel rail leaking?

There are two main reasons why heated towel rails rust and leak :

- The weld seam is the weak link of any metal structure. Welding stainless steel requires high qualifications and strict adherence to technology. Its violation (overheating, poor treatment of the seam after welding, etc.) leads to a violation of the anti-corrosion properties of the metal.

- The quality of stainless steel and its thickness in modern heated towel rails, unfortunately, leave much to be desired.

Some manufacturers of heated towel rails, in order to protect against electrocorrosion, coat the inside of the pipes with polymer coating to prevent direct contact of water with the metal.

Yes, this slightly increases the service life, but does not completely solve the problem. If stray currents are present, they enter the heated heated dryer not only with the water carrier, but also through the connecting nuts of the water supply. Such heated towel rails can also leak. Hot water acts as a catalyst for oxidation and corrosion affects the weld, and then the pressure of the circulating water damages the polymer coating in this place and a leak forms.

READ ALSO: Chrome-molybdenum Pipes What to Cook

It is not without reason that the well-known Russian company that produces heated towel rails with internal polymer coating strongly recommends grounding them under the threat of denial of warranty (in the first case, a leaking heated towel rail will be replaced, but they will strongly recommend grounding it and will warn that the second time they will refuse to replace it due to electrochemical corrosion) .

Causes of electrocorrosion

Once installed, a stainless steel heated towel rail can serve without interruption for a long time. However, if a metal grounded riser is cut in the bathroom or an old heated towel rail is replaced with a new one (with a metal-plastic or polypropylene line), then the grounding is disconnected. Metal-plastic or foam-propylene futores break the conductor chain, and at the same time water acts as a kind of electrolyte, which together leads to the appearance of stray currents.

The potential difference between plastic and metal can arise not only due to renovation work in the apartment, but also for the following reasons:

- improper organization or lack of grounding in old houses;

- close location of electrical wiring and current-carrying lines in relation to the water supply;

- accumulation of static electricity on plastic water pipes as a result of water friction.

All these processes are almost impossible to control - especially in apartment buildings. Violation of the rules for installing or servicing the water supply system by operating organizations can lead to damage to all engineering equipment, including the heated towel rail in a single apartment.

Signs of electrical corrosion on a heated towel rail

Electrochemical corrosion on a water heated towel rail begins with the formation of small red spots that gradually increase in size. Over time, the corrosion process becomes more intense. Rust spots not only expand, but also deepen into the metal, forming black spots on the pipes on the outside and inside. Under the influence of stray currents, the entire surface of the heated towel rail is damaged, and leaks appear on the welds, which only worsen the problem.

It is worth adding that rust has good “helpers”. First of all, these are various impurities that are present in tap water. Chlorine, oxygen, magnesium and calcium salts negatively affect the metal and significantly accelerate the corrosion process. An important role in the deterioration of the heated towel rail is played by the high temperature of the water in the hot water supply (up to 70 degrees), which increases the onslaught of electrocorrosion.

How to eliminate stray currents in a heated towel rail

High humidity in the bathroom has more than once had a negative impact on household appliances. This attribute of the bathroom is an integral part of it.

The heated towel rail is capable of not only efficiently performing its intended functions, but also fitting into a logical overall interior. In order to prolong its life, many people buy devices made of stainless steel.

The heated towel rail not only performs its main function, but also logically decorates the interior

Damage caused by electricity – Stroim24.info

It all starts with small spots and ends with pipe failure

Electrocorrosion of pipelines is a rather unpleasant phenomenon. And it’s not just about the appearance of the pipes: the development of corrosion processes gradually leads to a violation of the integrity of the walls and connections. So over time, both the reliability of the pipeline and its service life will decrease.

To understand how to deal with this phenomenon, you need to understand its nature. That is why it is necessary to understand the most important practical aspects of electrical corrosion of plumbing pipes. This is what we will do.

Main features

A device such as a heated towel rail is often made of stainless steel. This material is highly resistant to rust, which is why the service life of such products is much longer than that of conventional steel heated towel rails.

The first signs are visible on the welds - over time the problem will worsen

But still, sometimes we can observe how pipes that should not rust become unusable. Typically the process develops according to this scenario:

- First signs. Rust appears on the surface of a stainless pipe in the form of small spots. As a rule, the spots do not exceed the size of a match head and are located in groups.

Source: https://evroterm32.com/bluzhdayuschie-toki-v-polotentsesushitele-kak-ustranit/

How to protect a heated towel rail from electrocorrosion

Stray currents are zero currents that are present in unzeroed or ungrounded metal components of a plumbing system. Since they appear due to potential differences, the best solution to eliminate them is to ground the heated towel rail.

If the DHW riser and its outlets are made entirely of metal, for grounding it is enough to connect it to a PE bus located in the nearest electrical panel. For the connection, a copper wire is used, which is attached to the riser using a clamp or a bolted tab. To increase the safety of the bathroom, other metal objects in the room, such as a bathtub, are additionally grounded.

In the case where the riser and its outlets are made of plastic, a metal insert is mounted between the ball valve and the heated towel rail. Next, a grounding clamp is placed on it, and then connected using a copper wire to the PE bus in the electrical panel. If you have a combined riser, you will also need a metal insert, but initially the broken metal parts of the pipe are connected with copper wire, and only then the grounding element is laid to the PE bus.

There are other ways to get rid of stray currents:

- Potential equalization allows you not only to prevent electromechanical corrosion, but also to avoid electric shock due to gross mistakes by electricians or theft of electricity from neighbors. For this purpose, a special box is installed in the apartment, inside of which there is a grounding bus. Copper wires are drawn from all current-carrying elements of engineering systems (including gas, ventilation and heating) to the box, and then the grounding bus is connected to the PE bus in the apartment electrical panel. If the wiring in the apartment is made of polymer pipes, then grounding wires from mixers and taps are additionally connected to the box.

- Buying a heated towel rail with protection against stray currents - from the inside, these devices are treated with a special polymer composition, which forms a dielectric coating with protection against stray currents. Although such equipment is more expensive, it has a longer service life and does not require grounding.

- Replacing a water heated towel rail with an electric one - such devices are characterized by autonomous operation, that is, they are not connected to hot water pipes or heating systems, and therefore do not suffer from electrocorrosion. The only thing is that due to the high humidity in the bathroom, their connection must be made through an automatic device and an RCD with mandatory grounding.

Electrochemical corrosion, which develops when the heated towel rail is installed incorrectly, can lead to its premature failure. Therefore, when purchasing equipment, you should assess the situation in advance and take measures to prevent corrosion processes.

Source