Types of Home Piping

Depending on the location, communications can be internal or external. Street pipelines are most susceptible to freezing, and if the owners left for the winter and did not drain the water, home systems may also freeze.

A typical water supply design in private buildings consists of a well or a well, an underground pipeline connected to internal communications. The source of water supply can be a central pipeline or a common well for several houses.

Water pipelines are made of various materials: steel, cast iron, thermoplastics, chrysotile cement, fiberglass, etc. The most popular pipes in private construction are polypropylene, polyethylene, and metal-plastic pipes. They are durable, inexpensive and easy to install.

Why do pipes freeze?

The risk of water freezing in the pipeline exists regardless of the material of manufacture. But in steel structures, active ice formation begins earlier than in plastic ones. This is due to the high thermal conductivity of the metal, which cools much faster in the cold.

Freezing of water in a pipe is observed at temperatures from -7°C. Provoking factors:

- laying the pipeline above the soil freezing level or in the open air;

- non-compliance with the slope, due to which the pipes are constantly in a filled state;

- improperly functioning taps, taps and valves that delay the outflow of water.

A very unpleasant phenomenon is pipe rupture, which is caused by the expansion of water during the transition from the liquid phase to the solid phase. In this case, you have to replace the damaged area, which is not the easiest thing to do in low temperatures.

What to do when the water supply is frozen: 3 ways to defrost plastic pipes without digging

The water supply needs to be laid wisely and ensured that it functions smoothly all year round. But if mistakes were made during installation, they will have to be corrected at the most inopportune moment. One of the worst consequences of poor plumbing is freezing water. Let's look at 3 proven methods for defrosting plastic pipes.

Winter, as always, comes unexpectedly! Let's imagine a situation - you wake up in the morning, there is biting frost outside, and no water flows from the tap. An inner voice tells you that the pipe is frozen. What to do?

Often the water supply freezes underground, as well as in places of contact with the foundation and reinforced concrete structures. It is not possible to warm up the pipe from the outside in such places. Here you have to operate remotely, inside a thin water pipeline.

The principle of defrosting a water supply is the supply of coolant to the ice plug. This is very difficult to do. It is not enough to pour boiling water from a kettle inside - it will do nothing. The coolant must be supplied continuously until the ice plug is completely thawed.

Where to start?

For those who use a well, first of all, you need to make sure that the ice plug is in the pipe and not in the pump or in the street water tap.

This is done simply: the electric pump is disconnected from the water supply and turned on - water starts flowing, which means there is ice in the pipe. It happens that the tap in the well freezes. Warm it up with a hairdryer. If there is no result, then the problem is in the pipe and you need to choose a convenient way to fix the problem and get to work.

It will be useful: Profiles for drywall: sizes and types of plasterboard, manufacturer of starter and flexible, rack Knauf, what are there

Correct styling

Proper installation will help avoid serious problems such as water freezing, loss of permeability and pipe rupture. The basic requirements are specified in SP 31.13330.2012, which also apply to private housing construction.

Depth

According to building regulations, it is recommended that water pipes be laid below the ground freezing level. Based on the results of long-term observations, special maps or tables are compiled in the coldest months of the year.

The depth of the pipeline depends on the climatic conditions in the region and the composition of the soil at the site. Loams and clays freeze less than sand or rocky soils. So, in the Moscow region this value is in the range from 1.35 to 2 m, in the Krasnodar Territory - 0.3-0.5 m, in Surgut 2.2-2, 9 m.

Slope

When laying, you must strictly observe a reverse slope of at least 0.001 towards the well or insertion point. On flat terrain it can be reduced to 0.0005.

This means that the height difference for each linear meter of length should be at least 0.5-1 mm. Even with such a small slope, the water will spontaneously flow back into the well or main line and will not stagnate, creating conditions for the formation of ice.

Causes of pipeline freezing

Often the cause of freezing is an error in calculations at the construction stage. The most severe case is the freezing of an underground water supply. It is difficult to find a water pipe underground, and in frozen ground there is a very high risk of damaging the plastic. There are several simple rules that, if followed, will help to avoid problems during operation:

- the smaller the pipe diameter, the deeper the trench;

- when laying a water supply system, take into account soil freezing in the harshest winter;

- if it is impossible to dig a trench of the required depth, provide thermal insulation;

- To prevent water from stagnating, lay the pipe with an inclination towards the source.

It will be useful: Design of a living room with two windows: no room decoration, 2 photos and three, panorama in a private house, corner interior

Usually the pipeline freezes in border areas, between the ground and the air, between the air and the wall. The use of plastic pipes can only partially solve this problem. Although the thermal conductivity of plastic is lower than that of metal, additional thermal insulation is required.

How to avoid freezing pipes

But what if it is impossible to bury the pipe below the freezing depth? For example, the site may have rocky soil that is difficult to develop. Also making it difficult to penetrate are structures buried in the ground - reinforced concrete slabs, foundations, communication routes that cannot be penetrated or bypassed.

The most common reason is high groundwater level. The soil on the site can be so damp that water begins to appear literally at a depth of two shovels. It is not possible to dig a 1.5-2 m trench and lay a pipe there.

Important. For these cases, various methods of installing a pipeline with insulation are provided. They will help prevent water from freezing even when laid at a very shallow depth.

Thermal insulation with “shells”

Manufacturers produce shells for pipe insulation from various materials - polyurethane foam, foamed polystyrene, mineral wool. PPU and PPS shells are used for laying in the ground. They reliably protect structures from freezing, do not rot, and do not corrode in a humid, aggressive environment.

For ease of installation, some products are equipped with a tongue-and-groove lock. An additional outer layer of foil reflects heat rays and reduces the likelihood of channel freezing.

“Shells” are produced in a wide range of sizes and shapes, so choosing suitable thermal insulation for communications, even of complex configurations, is not difficult. During installation, the shell is placed on the water conduit and additionally secured with fastening tape.

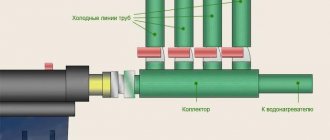

"Pipe in pipe"

This method is often used when laying pipes outdoors: at the entrance to the house or between nearby buildings, for example, a cottage and a bathhouse. The method provides not only good thermal insulation, but can also be useful if an ice plug has formed in the water supply. Hot water is poured into the gap between the pipes and patency is restored in a matter of minutes. Everything is convenient and practical - no need to look for a blockage or dig a hole in frozen soil.

For installation using the “pipe in pipe” method, non-pressure plastic sewer pipes with a diameter of 110 mm are used. The water pipe can first be wrapped with thermal insulation, and then inserted into the channel. A good insulating effect is achieved by using polyurethane foam (polyurethane foam), which is pumped into the gap between the pipes, having previously made holes along the length every 30-35 cm.

To minimize heat loss, the design is made even more multi-layered. It may consist not of 2, but of 3 pipes. If in such a “box” you additionally install thermal insulation from some porous material, for example, foam rubber or a substrate for laminate flooring, the pipeline will not freeze even in the most severe frosts.

Foil materials

Effective thermal insulation of water supply and sewerage systems - cylinders laminated with foil or foamed polyethylene films with a metallized layer. The materials reduce heat transfer to the surrounding space by reflecting infrared rays from the metal surface into the pipe.

The products consist of layers of insulation and aluminum foil. The thicker it is, the stronger and more resistant to damage. Mount the films with the foil side facing out. When laying, use a special metallized tape, carefully sealing all joints with it.

Heating cable

Cable pipe heaters are becoming increasingly popular in private buildings. They are installed both outside and inside water supply networks.

Laying can be carried out not only at the stage of laying communications, but also along already buried pipelines. This is often the most acceptable way to get rid of regular freezing without laborious dismantling of pipes.

To heat water supply and sewer networks, a polyolefin-coated cable is used, which is resistant to aggressive environments and mechanical damage. When laying wires inside the pipe, products with insulation made from food-grade fluoroplastic are used, which is safe for health and does not change the taste of drinking water.

According to the type of regulation, cables can be self-regulating or resistive, the latter can have one or two cores. The temperature regime and power level are selected depending on the pipe diameter and purpose.

Installation is carried out in the following ways:

- spiral winding;

- installation outside along the pipe;

- internal gasket.

Self-regulating cables are able to change the degree of heating with temperature fluctuations. The colder it is, the higher the power consumption of the product. Sold in coils of measured length, you can cut the required amount.

Resistive heaters have constant parameters that do not change depending on environmental conditions. Manufactured in fixed length sections. If you need to cut the conductor, you will have to apply the coupling yourself.

Important. When laying a heating cable, it is advisable to carry out insulation so as not to waste heat on warming the surrounding space.

In order to save energy, you can turn on the power only when the pipe lumen is blocked with ice, and do not use heating the rest of the time.

Video - installation of a self-regulating heating cable inside a pipe

Thermal insulation paint

Liquid insulators are new generation coatings. Thermal paint creates a thin protective layer on the surface of structures, replacing traditional insulation several centimeters thick.

This effect is explained by the very low thermal conductivity of the composition. It contains tiny balls of glass, ceramics or polymers with a vacuum inside, which effectively prevent heat transfer. The content of heat-insulating microspheres reaches 80%, the rest of the volume is occupied by an acrylic or latex binder.

The paint is applied with a brush to the surface of the pipe in several layers. According to manufacturers, the service life of the coating reaches 12-40 years.

Ready-made thermally insulated pipes

You can significantly simplify your task if you install pipes in a factory-made protective shell. Manufacturers produce products for plumbing, sewerage and heating installations with one or more functioning channels, as well as an additional heating cable. Insulated communications can be installed both outside and inside the house.

The corrugated coating provides design flexibility, which greatly simplifies the process of laying even complex pipeline configurations with a small radius of curvature. To avoid shell deformation, the installation technology provides for the installation of a soft sand cushion. A special adapter is used to connect to a regular pipe.

Insulation methods

In order to properly insulate the pipes running from the well to the house underground, it is better to do this at the stage of laying the water supply. Otherwise, you will have to dig a trench again, lay insulation, and so on.

This process not only takes a lot of effort and time, but is also quite costly in terms of finances.

Of course, when laying a water pipeline from a well to a house, you can use special microflex pipes, which are already equipped with protection, but it very often happens that it is necessary to insulate an already laid water supply system.

In this case, there are several alternative methods that allow you to heat the external water supply with minimal effort and cost.

So, in order to prevent the water supply from freezing in winter, you can insulate it using a heating cable.

Video:

In this case, when the cable is turned on, the surface of the pipe itself is heated, which prevents the water from freezing.

You can also insulate water pipes using air.

In this case, it is necessary to use polystyrene foam or basalt insulation to create a kind of umbrella that will trap warm air coming from the ground.

To do this, a special receiver and check valve should be embedded into the system, which will be responsible for the pressure in the pipes.

This method is especially relevant for a water supply coming from a well, since in this case a submersible pump is installed in the system, capable of creating the necessary pressure.

In any case, before deciding on the principle of insulating an external water supply system, it is necessary to carefully study the properties of each method and choose the most suitable one.

More details about the insulation of underground water pipes are described in the video below.

Video:

Anti-freeze taps

A common reason for the lack of water in the pipeline is a frozen tap. This is especially true if water for domestic needs in winter must be collected from the yard or used for irrigation during periodic frosts. A tap that is installed in the ground is called a hydrant. It is a piece of pipe up to 1.2 m long with a lever at the top and a valve at the bottom. There is another pipe of smaller diameter inside.

One end of the hydrant is connected to the water main, the other is above the ground and serves to supply water. When the handle is lifted, the valve of the inner tube, connected to the lever via a rod, is activated. After lowering the handle, the valve shuts off the access of water, and the remaining water flows through the external pipe back into the water supply. This way, no liquid remains in the hydrant, which means there is no risk of it freezing.

The design and principle of operation of a tap connected to a home network are similar to an underground hydrant, but with some differences. The structure is laid in the wall. At the outer end there is a valve and spout, at the other end there is a check valve with a stem. Product length from 15 to 60 cm for walls of various thicknesses. Since the shut-off valve is located in the positive temperature range, the faucet does not freeze even in severe frost.

By turning the valve, the valve opens and water flows into the spout. When the handle is rotated back, the pipe lumen closes. The remaining liquid is spontaneously removed and the pipe remains empty.