Installation of Baxi gas boilers

Almost all gas boilers have the same basic design: natural gas flows through the gas valve to the burner nozzle block, then is ignited by an electric spark through the electrode. Using a heat exchanger, the heat from combustion is then transferred to the heat carrier. The heat exchanger is located above the burner.

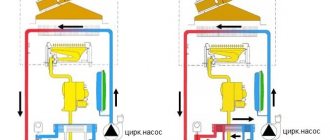

Gas boilers differ in the presence of a second flow-through heat exchanger, which is necessary for preparing water, as well as in functionality.

The most common options are:

- 1 heat exchanger and indirect heating boiler.

- Two separate heat exchangers. 1 – for preparing water, 2 – for the heating circuit.

- Combined heat exchanger for heating and water preparation.

Gas boilers can be divided into turbocharged, atmospheric, and also with an open and closed combustion chamber. Equipment with an open chamber takes air from the combustion room. All safety standards and regulations must be observed in the premises. In some countries it is prohibited to use this type of gas boiler.

A turbocharged boiler does not require a chimney, unlike an atmospheric one. In the first option, combustion products are forced out of the combustion chamber by a fan through a coaxial chimney. This gas boiler is suitable for installation in an apartment.

The following processes occur in a gas boiler: switching the flow of hot water, heating water, removing combustion products and monitoring safety.

An electronic board is necessary to control and monitor the safety of all equipment. The electronics operate according to the set values and, in the event of failures, stop the operation of the gas boiler.

Baxi Main 24 boiler does not turn on

Potential on metal parts of the boiler can also cause problems with electrical components (the body and metal parts must be reliably grounded).

If, for example, there was a power surge in the network, the fuses could have blown, the serviceability of which can be assessed visually and, if necessary, replaced independently, but only with the fuses that come with the boiler (usually they can be found on the lid). If the fuses are intact, you also need to inspect the parts of the control unit itself for damage.

Damage to the electronic board can only be repaired by a qualified technician.

In other cases, most likely the user will receive a code on the display or other boiler indicators, by which it will be possible to understand in which specific boiler unit the problem occurred.

Thermal energy is transferred to the coolant into the heating or hot water circuit through heat exchangers and a circulation pump. Accordingly, a common malfunction is poor circulation in the hydraulic circuit.

Due to their design features, bithermic heat exchangers are difficult to clean from deposits and most likely you will have to buy a new one.

An obstacle to movement in the circuit can also be a pump breakdown, an air lock in the heating circuit, a lack of pressure in the expansion tank, low pressure in the system, clogged filters, or freezing of certain sections of the pipeline.

On modern boilers, depending on the model, flow sensors and pressure gauges are installed, and if problems are detected, the owner will receive the corresponding fault code.

Why is it necessary to ground a gas boiler?

The safe operation of a Baxi gas boiler is only possible if the device is properly grounded. It is necessary to organize grounding taking into account the current PUE standards.

Before starting the gas boiler, you should check that the connection is correct. The operating instructions state the following: if the requirements are not met, the gas boiler will be void of warranty.

When installing the equipment, the inspection company must check the quality of the grounding. Most often, in apartment buildings, residents buy an apartment with a working gas boiler and do not think about the quality of its connection. Problems may arise over time due to improper grounding. Therefore, it is recommended to check the quality of grounding and installation of the gas boiler before starting use.

Do not forget that this equipment is a gas installation and a high-risk unit. There are times when a fire occurs due to negligence in safety.

It is worth paying special attention to the boiler control electronics. Almost all models are equipped with a security and control system. An electronic board that includes various components is responsible for this. This element has the highest cost and accounts for about 30% of the total cost of a gas boiler. If there is no grounding, the board may break and error e35 may appear.

The operation of the gas boiler is controlled using automation. It includes actuators and various sensors. If the connection to the network is incorrect, a failure and emergency stop of the equipment may occur. In some models, the polarity of the connection must be observed.

Using a tester, the grounding is checked: there should be no potential between the neutral wire and the phase, and the operating voltage between the ground and phase terminals should be 220-230 V. In addition, to check the grounding of metal parts of the equipment, you can use a special indicator screwdriver.

Flame ionization electrode

A flame sensor is installed on the burner of a gas boiler and is necessary to monitor the presence of a flame. The electrode on the control board is connected to the connector. The flame sensor in some boilers can be combined with an igniter.

There is an air gap between the burner and the electrode, which prevents the passage of current when the boiler is not working. When gas burns, the control board records the flow of microcurrents through the flame. The value should be in the range of 0.5-5 µA.

Incorrect operation of the electronics may be caused due to the presence of various parasitic interferences and potentials on the parts.

What to do if error e35 remains?

If no methods help resolve the error, you may need to replace the board. Some models of Baxi gas boilers have installed boards that are sensitive to external interference and power supply standards. In the picture below you can see the features of the boards that work correctly.

The cause of error e35 on Honeywell boards may be increased sensitivity to humidity. Due to accumulated dust, this error may appear. For Bertelli boards, simply rinse the surface with isopropyl alcohol.

Gas boiler Baxi mainfour 240f error e35

In this series of gas boilers there are 2 types of control board: 1 different and 2 interchangeable. Visually, you can distinguish the type of board by the color of the display panel. In mainfour 240f gas boilers, the board does not have a flame modulation control circuit and also has a gray panel.

Gas boiler Baxi ecofour 24 error e35

The most versatile gas boilers are the Baxi Mainfor and Ecofor series. The difference is the secondary plate heat exchanger for heating water. Mainfor boilers have 1 heat exchanger for heating water and heating. Most often, the cause of error e35 is improper grounding of the equipment, so the recommendations for elimination are almost the same.

Many manufacturers include universal boards in their equipment, so different boilers have interconnected boards and can be installed on different series. In order to make the correct installation, you need to configure the board to work on a specific boiler using the configuration menu.

What does the baxi boiler signal about - error e35 and how to fix it

Recently, there are practically no places left where there are no gas distribution lines. Therefore, gas boilers are widespread, including appliances from the Italian company baxi. When installing gas equipment and its operation, various problems may occur. For example, when installing a baxi boiler, error e35 is quite common, but it is easy to fix.

Advantages and disadvantages of Baxi Eco Four 24F

Wall-mounted boiler "Baxi"

Baxi is an excellent boiler option for ensuring a comfortable temperature in an apartment or country house. The company of the same name produces equipment for hot water supply and heating, ranking third in the world in popularity. It has a wide range of products and affordable prices.

The Baxi Eco Four 24F model is widely used among buyers. It is a design that combines a double-circuit boiler and a water heater. When designing, the designers made this model “smart”. So if any problems occur, the boiler itself displays errors on the panel, and the user can only fix them.

Like any other heating equipment, Baxi gas heaters have a wide list of advantages.

Advantages of boilers

- The production technology ensures a high degree of boiler safety during operation.

- Double-circuit wall-mounted boilers are environmentally friendly. The main share of emissions in them is carbon dioxide, which is well absorbed by green spaces.

- Baxi equipment runs on liquefied natural gas. It is automated, so it can function without interruption for a long time according to a given program. Baxi Eco Four 24F boilers are designed in such a way that they do not stop operating when the gas pressure decreases.

- Low noise level during operation, high performance and ease of operation. All parts are made of high-quality materials, which ensures a long service life of the units.

- An affordable price that attracts buyers, as well as a modern and stylish design that allows you to integrate the boiler into any interior.

Flaws

Among the disadvantages of Baxi equipment are the constant need for power supply, as well as increased sensitivity to voltage surges - despite the installed overload protection.

Important! To protect yourself from unexpected power outages, you should use stabilizers that have batteries built into them or connected to them.

Operating principle of the Baxi Eco Four 24F unit

The outside of the metal combustion chamber of the boiler is covered with a fairly thick layer of heat-insulating material. A copper heat exchanger is placed on top of it. The burner is located at the bottom of the combustion chamber.

When the temperature in the room decreases, the thermostat automatically activates. It transmits a signal to turn on the pump, which provides a vacuum in the return pipeline. This leads to hot coolant entering the supply line. The pressure indicator when water enters is no more than 0.45 Bar.

Error e35 in Baxi Eco Four, MAIN four and Fourtech

This error can be described as a stray flame. A combustion signal comes from the ionization sensor until the board sends a signal to open the gas valve.

This error can be caused in a Baxi gas boiler for the following reasons:

- The gas valve is not sealed. After the signal to open the valve is turned off, the presence of a flame is detected.

- Moisture has entered the electronic board of the gas boiler.

Error e35 can occur accidentally in a gas boiler. To solve the problem, you can hold down the “R” button to reboot the equipment. If after this the error does not disappear, then you should look for another cause of the failure.

One of the causes of error e35 may be a malfunction of the electronic board or its incorrect operation.

You can resolve this error as follows:

- Install an isolation transformer.

- Check the network parameters, which must comply with the standards. It is necessary to check the absence of potentials between the ground, zero and pipes.

- Install a special interface device.

Advantages and disadvantages of the Baxi Eco Four 24 f boiler

The Baxi ECO Four 24 f boiler from the Italian brand is considered a leader in the Russian market. The unit has a simple design, is available in white colors and is compact.

ECO Four heating equipment is presented on the market as single-circuit for heating and double-circuit for heating and domestic hot water needs. Combustion chambers are available in both open and closed types.

The Baxi ECO Four 24 F model has gained popularity among buyers; with its small size, the Baxi boiler can heat rooms of 240 m2 and provide hot water to a family of four people.