Where are modern heating elements used?

As mentioned, they are an integral part of industrial and household appliances. They can be found in electric stoves, frying cabinets and ovens, electric kettles, heating appliances, water heaters, electric coffee makers and many other machines. Replacing a heating element can be either simple or very complex. It all depends on the technology where they are used. A wire with high electrical resistance is used as the basis of the heating element. In most cases it is made of nichrome. So what electric heating elements exist and are currently widely used?

Open nichrome spiral

The oldest heating element is, perhaps, an ordinary nichrome spiral. Once upon a time, homemade electric stoves, water boilers and “goat” heaters were in use. Having nichrome wire at hand, which one could “get hold of” in production, making a spiral of the required power did not present any problems.

It was known what diameter the wire was and what length was required to wind the spiral of the required power. These magic numbers can still be found on the Internet. The figure shows a table that shows data on spirals of various powers at a supply voltage of 220V.

Calculation of the electric spiral of the heating element

Everything here is simple and clear. Having set the required power and the diameter of the nichrome wire available at hand, all that remains is to cut a piece of the required length and wind it onto a mandrel of the appropriate diameter. In this case, the table shows the length of the resulting spiral. What to do if there is a wire with a diameter not indicated in the table? In this case, the spiral will simply have to be calculated.

Infrared heating elements

When functioning, they generate infrared rays into the environment. In this way, heat is distributed in a manner that is safe for humans. Infrared heating elements contribute to gradual and uniform heating of the room (but the area where they are directed is considered a priority). Thanks to this property, they are used not only at home, but also in industrial and laboratory conditions. In addition, these devices have a low operating temperature (60-65 degrees), which allows the use of infrared heating elements as a drying device for fruits, vegetables and mushrooms.

Wet and dry heating elements

Such a heater is in direct contact with water, which is why such a heating element is called “wet”. The service life of a “wet” heating element is within 2...5 years, after which it has to be replaced. In general, the service life is short.

To increase the service life of the heating element and the entire boiler as a whole, the French company Atlantic developed a “dry” heating element design in the 90s of the last century. To put it simply, the heater was hidden in a metal protective flask, which prevents direct contact with water: the heating element heats up inside the flask, which transfers heat to the water.

Naturally, the temperature of the flask is much lower than the heating element itself, so the formation of scale at the same water hardness does not occur as intensely; a larger amount of heat is transferred into the water. The service life of such heaters reaches 10...15 years. The above is true for good operating conditions, especially the stability of the supply voltage. But even in good conditions, “dry” heating elements also exhaust their service life and have to be replaced.

This is where another advantage of the “dry” heating element technology is revealed: when replacing the heater, there is no need to drain the water from the boiler, for which it should be disconnected from the pipeline. Simply unscrew the heater and replace it with a new one.

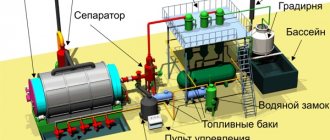

The Atlantic company, of course, patented its invention, after which it began to sell the license to other companies. Currently, boilers with a “dry” heating element are also produced by other companies, for example, Electrolux and Gorenje. The design of a boiler with a “dry” heating element is shown in the figure.

Boiler with a dry heater

By the way, the figure shows a boiler with a ceramic steatite heater. See below for the design of such a heater.

Carbon lamp

It is a vacuum tube made of quartz glass. Inside there is a radiating element, which is made of carbon (carbon-containing) fibers twisted into a bundle. Sometimes it is also called a spiral, but this is incorrect. Despite the fact that carbon fiber appeared relatively recently, it has successfully gained a place in a number of technologies, including in the manufacture of heating elements. When voltage is applied, instant heating occurs. Thanks to the fibrous structure, the radiation area is increased, which leads to increased heat transfer. This, in turn, allows for significant energy savings (compared to using a nichrome base).

Infrared heaters

The difference between this type of heaters and other devices is that they do not heat the air directly, but the surfaces of the home environment: furniture, walls, the floor of the house, etc. Heated surfaces, like heat accumulators, give off heat to the air, creating comfortable conditions. This principle of operation allows you to choose infrared heaters not only for heating the space inside the house, but also outside - in the gazebo, on the terrace.

Infrared heaters are perhaps the best of all options for a summer residence, despite their higher cost. This device runs on either gas or electricity. Can be installed on the ceiling or wall. The gas version, like all combustion-related devices, is less safe and more difficult to install.

Advantages

- Rapid increase in temperature in the operating area of the device.

- Infrared heaters operate silently.

Flaws

- Higher cost compared to the heaters described above; infrared heaters cost from 2000 rubles.

Ceramic infrared emitters

They are ordinary heating elements, which are placed in a ceramic housing. The shell is heated by heat, and then the external environment. Due to the large area of the ceramic heating element, space heating is carried out in an accelerated mode (compared to a heating element). Also, due to their size, they are often called panel infrared heaters. They can be concave, flat or convex. The operating temperature of the ceramic heating element usually ranges from 700-750 degrees. Their parameters can be selected for all cases. There are individual specimens that boast significant parameters: for example, the open type is designed to quickly heat a room and can heat up to 900 degrees above zero!

Fan heaters

The most affordable and easiest to use are heat fans, which are usually tabletop or floor-mounted. When air passes through the heating elements of the device, any room is quickly warmed up. The heating elements in the fan heater are made in the form of:

- Electric open spiral with temperatures up to 800 degrees.

- An electric heater in the shape of a tube with a temperature of over 200 degrees.

- Ceramic tiles with temperatures up to 200 degrees.

Heat fans with ceramic heating elements provide a cleaner air supply, without the emission of combustion products. The devices are popular due to their low cost and ease of portability. They almost instantly heat the room to the desired temperature.

Fan heaters are economical: 1 kW of device power can warm up a room of up to 20-25 m2.

In addition to these characteristics, their advantages include the presence of a thermostat, which instantly turns off the device if it overheats.

The disadvantages of heat fans include their noise and ability to raise dust in the room.

There are also other types of heaters such as blowers or heat guns. The system of such a heat gun uses heated coils and a powerful fan. Leaf blowers are very effective in cold areas such as garages.

Quartz and halogen emitters

They are a sealed vacuum tube made of quartz glass. Inside there is a spiral made of metal with high resistance. Essentially, these are halogen lamps with a tungsten filament inside. Depending on the design, emitters are divided into two types:

- With medium wave.

- With shortwave range.

In the first, the spiral is made in a star shape. In the second, a filament is located inside a quartz tube. But why were the different designs created? The fact is that halogen emitters, which are supported by a filament, can heat up to a temperature of 2600 degrees. These elements are highly powerful and have a very short response time. Where are these benefits applied? They are necessary in short cyclic processes, which nevertheless require the high power density that the specified heating element can provide.

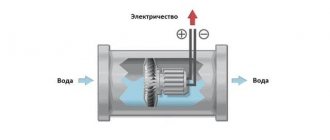

Connecting and checking heating elements

When connecting the heating element, a wire of suitable cross-section must be used. Here everything depends on the current flowing through the heating element. Most often, two parameters are known. This is the power of the heater itself and the supply voltage. In order to determine the current, it is enough to divide the power by the supply voltage.

A simple example. Let there be a heating element with a power of 1 kW (1000 W) for a supply voltage of 220 V. For such a heater, it turns out that the current will be

I = P/U = 1000/220 = 4.545A.

According to the tables located in the PUE, such a current can be provided by a wire with a cross-section of 0.5 mm2 (11 A), but in order to ensure mechanical strength, it is better to use a wire with a cross-section of at least 2.5 mm2. This is the wire most often used to supply electricity to sockets.

But before making the connection, you should make sure that even a new, just purchased heating element is in working order. First of all, you need to measure its resistance and check the integrity of the insulation. The resistance of the heating element is quite simple to calculate. To do this, you need to square the supply voltage and divide by the power. For example, for a 1000 W heater this calculation looks like this:

220*220/1000=48.4 Ohm.

The multimeter should show this resistance when connecting it to the terminals of the heating element. If the spiral is broken, then, naturally, the multimeter will show a break. If you take a heating element of a different power, then the resistance will naturally be different.

Insulation integrity check

To check the integrity of the insulation, measure the resistance between any of the terminals and the metal body of the heating element. The resistance of the filler-insulator is such that at any measurement limit the multimeter should show a break. If it turns out that the resistance is zero, then the spiral has contact with the metal body of the heater. This can happen even with a new, just purchased heating element.

In general, a special megohmmeter device is used to check insulation, but not always and not everyone has it at hand. So checking with a regular multimeter is quite suitable. At least such a check must be done.

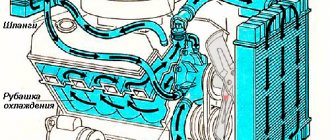

As already mentioned, tubular electric heating elements can be bent even after being filled with insulator. There are heaters of the most varied shapes: in the form of a straight tube, U-shaped, rolled into a ring, snake or spiral. It all depends on the design of the heating device in which the heating element is supposed to be installed. For example, in the instantaneous water heater of a washing machine, coiled heating elements are used.

Some tubular electric heating elements have safety features. The simplest protection is a thermal fuse. If it burns out, then you have to change the entire heating element, but it won’t lead to a fire. There is also a more complex protection system that allows you to use the heating element after it has been triggered.

One of such protections is protection based on a bimetallic plate: heat from an overheated heating element bends the bimetallic plate, which opens the contact and de-energizes the heating element. After the temperature drops to an acceptable value, the bimetallic plate unbends, the contact closes and the heating element is ready for operation again.

Silicone heating elements

Structurally, they look like this: an etched heating film or wire is placed between two layers of silicone. Despite the strangeness, in this way you can obtain an element that will allow you to obtain a variety of parameters for the finished equipment. To increase mechanical strength, reinforcement is made with textile glass fiber. Characterizing them, it should be said that such heaters require little time to heat up and cool down. They can accurately maintain the temperature of the heating element using a sensor and thermostat. Their sizes are small: the smallest are only 0.7 millimeters thick. This fact allows them to be used in various fields: from heating barrels of paints or oils to aerospace vehicles.

Silicone heating elements are characterized by increased resistance to the negative effects of dampness and moisture. Therefore, they are used in laboratory equipment, catering, and in general in any cases where it is necessary to protect equipment from condensation and freezing. The only limitation is the temperature of the working environment: in most cases it should not exceed 200 degrees.

Open Coil Heaters

They are a spiral heating element that must be installed in special insulating grooves or mounted on brackets. Heat is supplied through convection or radiation.

Advantages: simple circuit, fast heating, moderate cost and ease of repair.

Disadvantages: low electrical safety, possibility of short circuit, poor protection against mechanical damage.

Examples of devices with an open spiral:

- dry heating elements,

- micanite heaters with open spiral,

- wire heaters,

- Heating elements for annealing furnaces.