Types of coolant

Water is the most popular and accessible coolant for water heating circuits. However, due to its use as a coolant for aluminum heating radiators, the metal begins to rust, and scale and deposits appear inside the pipes. Therefore, such systems require periodic flushing and cleaning. Also, during winter shutdowns, there is a real danger of freezing: in such cases, it is necessary to drain the water. If this is not done, freezing of the liquid will certainly lead to rupture of pipes and batteries.

All this indicates that, in addition to correctly calculating the power of the batteries for the room, it is important to use exactly the coolant that is not afraid of freezing and chemical interaction with metal walls. It is important to keep in mind that such special solutions do not have a negative impact on human health when the circuit leaks. We are talking about antifreeze: this coolant is not afraid of low temperatures, which is facilitated by additives and additives dissolved in the liquid, which act as inhibitors of corrosion and mineral deposits.

Conditions for using coolant

When choosing antifreeze for aluminum radiators, you need to remember some conditions for working with it. These rules are mandatory for use; they will make the operation of the circuit not only more efficient, but also safer:

- The heating system must be equipped with a more powerful circulation pump than is required for conventional water heating. If the length of the circuit is quite large, then it is necessary to install an external installation of the circulation pump;

- installation of a special expansion tank is required, that is, a capacious expansion tank, the volume of which will be approximately twice that required for a traditional water circuit;

- It is recommended to use large-volume aluminum radiators, as well as heating pipes;

- you cannot install automatic air vents; when using antifreeze in the system, you can only install manual taps, for example, Mayevsky;

- When making detachable connections, you can use sealing gaskets only made of paronite, chemically resistant rubber, or Teflon. Many experts advise using linen winding, which is sealed with a sealant that is resistant to ethylene glycol (if a coolant based on it is used);

- It is not recommended to dilute antifreeze with water, but if this is allowed by its composition, then you can only use purified, distilled water. Melt and rain water are absolutely not suitable for this;

- Before pouring antifreeze for aluminum radiators, it is necessary to carry out preparatory work. The entire circuit, including the boiler, should be flushed with water. The timing of replacement is regulated by antifreeze manufacturers, but experts recommend doing this once every two to three years; you cannot leave the coolant in the system for a longer period of time;

- After antifreeze is poured into the system, you should not immediately put a very large load on the boiler, that is, put it at a high temperature. In this case, it is recommended to increase the temperature gradually so that the coolant has time to warm up smoothly. Such a liquid has a lower heat capacity than water, so this condition must be strictly observed.

Special mention should be made about the water coolant. If in cold weather, for various reasons, the boiler is stopped for a long period, then it is necessary to drain all the hot water that may be there from the heating system in order to prevent rupture of the pipes.

Heating a home: how to choose a coolant for a radiator? When choosing antifreeze or any other coolant for a heating system, numerous factors must be taken into account. This must be done at the design stage of the entire heating system, since the water system is not suitable for the use of antifreeze.

If the temperature in the cold season in the general circuit does not fall below five degrees Celsius, then it is best to prefer a type of coolant such as water, but all salt compounds must be removed from its composition as much as possible. When the temperature in the house is expected to drop to sub-zero levels, only antifreeze can be used, since the water will simply freeze under such conditions. To avoid freezing, you can completely drain all water from the heating system, but there is one serious drawback. The fact is that the radiators will fill with air, and this will lead to corrosion in the presence of high humidity.

There is another way to avoid freezing by using water as a coolant, but for this it is necessary to build in special electric heating elements, which will be controlled using temperature sensors or an installed remote control. This option allows you to maintain the temperature level in the system above 5 degrees Celsius, but the cost of the heating circuit increases many times, that is, it is cheaper to immediately install a system designed for antifreeze. When choosing the required antifreeze for the circuit, you should pay attention to the following characteristics:

- extremely low temperature that can be maintained by the coolant;

- the composition of the liquid, its purpose, that is, for which system it is intended;

- purpose of antifreeze. Is the coolant intended to work in aluminum radiators, how does it interact with plastic pipes, rubber, steel elements, etc.;

- length of time for using antifreeze;

- coolant safety. You should pay attention to how safe the liquid is for humans if it is necessary to drain it after its service life has ended).

But the color of antifreeze for radiators does not matter at all, it simply shows what brand the liquid belongs to.

The choice of coolant when installing a heating system is a fairly important part of the operation of the entire circuit. The efficiency of home heating, its safety, and service life depend on the right purchase. Today, for aluminum radiators, which are becoming increasingly popular, several types of coolants can be used. This is ordinary water, antifreeze based on various components and a special mixture of water and ethyl alcohol. The choice of coolant largely depends on what conditions of use of the system are observed, since it is not always possible to fill it.

Pros and cons of aluminum radiators

The popularity of aluminum batteries is explained by the following advantages of the products:

- Light weight. The weight of one section does not exceed 2 kg.

- Cheapness. Aluminum is a common metal that is easy to process.

- Easy installation and maintenance. The coating is heat-resistant paint that is easy to clean.

- Excellent decorative characteristics.

- High level of heat transfer. This is facilitated by additional ribs with thin walls. According to this indicator, aluminum radiators are almost 3 times superior to conventional cast iron batteries.

- Compact sizes.

- Fast response to temperature switching due to the low thermal “inertia” of aluminum.

Weaknesses of aluminum radiators:

- Very sensitive to the composition of the coolant (hardness, mineralization). Poor water quality often causes equipment failure. Therefore, deciding which antifreeze is best for a radiator must be taken seriously.

- Tendency to corrosion. Design, installation and repair must be carried out very carefully.

- Working pressure restrictions.

- High probability of formation of air pockets due to the chemical activity of the metal with salts dissolved in water

The choice of coolant for aluminum radiators must be done very carefully.

Comparison of radiators by coolant type

Comparison of characteristics of water and antifreeze:

| Parameter | Water (distilled) | Antifreeze (on average) |

| pH level | 7 | 7,5-9 |

| Freezing temperature, °C | from -35 to -65 | |

| Boiling point, °C | 100 | 104-108 |

| Density, g/cm3 | 1 | 1,04-1,075 |

| Viscosity, mm2/s | 1 | 5,8-7,1 |

| Heat capacity, kJ/(kg*K) | 4,19 | 3,5-3,7 |

The efficiency and durability of a heating system is determined by many parameters. It is also very important to decide which coolant to choose for an autonomous heating system, taking into account the efficiency of its operation, as well as the characteristics of the radiators. If we are talking about a centralized heating system, then it is necessary to select radiators taking into account the characteristics of the circulating coolant.

The choice of coolant is determined by the following main factors:

- viscosity and thermal characteristics;

- chemical activity of the coolant in relation to the radiator material;

- freezing temperature of the coolant;

- safety of operation.

Types of coolants

The most common coolant in centralized and autonomous heating systems is water. Its popularity is explained by its general availability, low cost, environmental safety, and good thermal characteristics. However, there are also a number of significant disadvantages.

The presence of dissolved salts in water leads to the formation of scale on the internal walls of radiators. As a result, heat transfer is significantly reduced, the flow diameter of radiators is reduced, which impairs coolant circulation.

Another disadvantage is the rather high freezing point of water (0 °C). Freezing water leads to the destruction of radiators. Therefore, if interruptions in the operation of the system are possible, it is recommended to use a non-freezing coolant for heating radiators - antifreeze.

The freezing point of antifreeze can reach -65 °C. This is enough to operate the heating system in almost any conditions. In addition, even when frozen, it turns into a gel-like state, which does not lead to destructive consequences for radiators.

The operating temperature of antifreeze is about +75 °C, which is also quite consistent with the parameters of most heating systems. The use of antifreeze has a beneficial effect on the service life of gaskets, seals and other non-metallic elements of the system.

Today, antifreezes based on ethylene glycol and propylene glycol are most often used in heating systems. Ethylene glycol has optimal thermophysical characteristics, but is a strong toxin. Therefore, antifreezes based on propylene glycol, which is a harmless substance, are most widely used.

When using antifreeze, it is very important to control its acidity level. For most radiators, a pH level of 7-8 is recommended. If it is exceeded, the metal of the radiator can quickly corrode.

Compatibility of various types of coolants with radiators

All types of modern heating radiators can be used with both water and antifreeze. However, there are a number of factors that must be taken into account when choosing coolant and heating radiators.

High-quality cast iron radiators are less demanding on the chemical composition of the coolant due to the significant thickness of their walls. Corrosion threatens them only when the recommended pH level of the coolant is exceeded. In addition, due to the low thermal inertia, the dependence of the heat transfer from the radiator on the coolant temperature is small. These factors contribute to the use of any coolant in cast iron radiators.

However, there is a significant limitation due to which antifreeze is very rarely used for these devices. The volume of one cast iron radiator section can reach 1.5 liters. Considering how much antifreeze is required to fill the system, the use of this type of coolant turns out to be economically infeasible. In addition, cast iron batteries are most often used in centralized heating systems, where water is used as a coolant. On the other hand, in such systems, high-quality water treatment is of great importance to prevent the formation of scale on the walls of radiators.

Cast iron radiators Ogint are a bright representative of this category of radiators, combining modern design and the advantages of traditional cast iron radiators. The radiators are manufactured in full compliance with GOST 31311-2005 and are covered by a 2-year warranty.

Steel radiators are the most sensitive to the quality of the coolant. To fill these devices, either soft or distilled water or high-quality antifreeze is used. The coolant for aluminum radiators must meet the same requirements.

Antifreeze as a coolant

When solving the problem of which coolant to choose for aluminum radiators, it is important to find a specific composition intended specifically for the intended use.

It is important to consider the following disadvantages of antifreeze liquid for aluminum radiators:

- Low level of thermal capacity (inferior to water by almost 115%).

- A circulation pump is required. Without it, the system will not work due to the high viscosity of the antifreeze, which creates additional obstacles to the movement of the coolant along the circuit.

- Noticeable increase in volume when heated.

- Very high fluidity (50% more than water). Because of this, special attention has to be paid to welded (solder) and threaded connections.

- The toxicity of some compounds. We are talking, first of all, about ethylene glycol antifreeze, which must not be used in combination with hot water supply.

Ethanol compounds

The significant cost of this antifreeze for aluminum radiators often becomes a serious obstacle to its use in private autonomous systems. The composition can be obtained from distilled water and 40% ethanol (ethyl alcohol). The quality of such a solution is superior to the factory analogue in certain parameters. The matter mainly concerns its low viscosity (although compared to water it remains quite high). There is also a decrease in fluid fluidity, which makes it possible to be less demanding on the connecting areas.

The use of homemade ethanol antifreeze for heating radiators has a beneficial effect on the safety of the rubber sealing gaskets that are present in any circuit. It is recommended to dilute alcohol with hard water: in combination with ethanol, it will become a serious obstacle to the formation of scale on the inner walls. In this case, you cannot do without solid sediment, but you can easily get rid of it by flushing the system. In cases where the percentage of ethyl alcohol in water does not exceed 30%, it will not evaporate.

Due to the fact that the coolant for aluminum radiators is similar in its characteristics to water, its boiling point is approximately the same as that of water. This suggests that when the temperature reaches + 85-90ᶷ, no steam release will be observed. Thanks to ethanol, the thermal expansion of water is reduced by an order of magnitude, which allows the system to more comfortably tolerate lower temperatures in the room.

What proportions to use

It is important to understand that to lower the freezing point it is necessary to increase the percentage of ethanol in the solution:

- When the indicator drops to -10.6 degrees, ethyl alcohol must be present in an amount of at least 20.3%.

- When the temperature drops to -23.6 ᶷ degrees, the share of ethanol increases to 33.8%.

- At a temperature of -28.7 degrees, alcohol is added in a volume of 39% alcohol.

- At a temperature of -34 degrees - 46.3%.

It should be taken into account that one liter of 96% ethylene contains 960 ml of anhydrous alcohol. Therefore, to obtain a 33% solution, you will need 96/33 = 2.9, that is, 2.9 liters of distilled water. That is, to make a 33% solution you need one liter of ethyl alcohol and 2.9 liters of distilled water. The antifreeze obtained in this way for heating can be safely poured into a circuit with aluminum radiators, because it will retain its fluidity even at -22 degrees below zero.

There are certain restrictions on the use of homemade and factory-made non-freezing coolants for bimetallic radiators:

- It is strictly forbidden to use antifreeze in heating circuits with electrolysis boilers.

- Antifreeze cannot be used in open heating systems. We are talking primarily about toxic ethylene glycol compounds.

- It is not advisable to allow the liquid temperature to drop below -20 ᶷC. This significantly deteriorates the quality of the additives used, which provokes the formation of scale on the internal walls.

- In systems with antifreeze, it is prohibited to use flax tow placed on the paint. Under the influence of ethyl alcohol, it quickly disintegrates, which leads to depressurization of the connection. It is best to use Unipak plumbing paste in such cases.

- Antifreeze liquids have a destructive effect on galvanized elements.

Special coolant

What is he like in general?

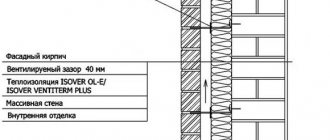

Connection examples: 1) drain valve; 2) plug; 3) entrance; 4) exit

Note on the image. Depending on the method of supplying fluid to the batteries, as shown in the top image, the degree of heat transfer may change.

- The most used and in demand coolant throughout the world for water heating systems is, of course, water , but its use leads to metal corrosion, as well as the formation of scale and sludge, therefore, there is a need for periodic flushing and cleaning of the system. In addition, you do not have the opportunity to turn off the heating in the winter without draining the coolant, since the water, of course, will freeze and what is called “defrosting the system” will occur - pipes and / or radiators burst - simply put, it comes out out of service.

- From all this we can conclude that it is important not only to correctly calculate the power of the batteries for the room, but you should also use a coolant that does not freeze and enters into a chemical reaction with the metal . Such special liquids have one important property, which is indicated in the instructions and you need to pay attention to this when purchasing - in the event of a system leak, such a coolant does not in any way affect the health of the human body.

Antifreeze as a coolant

Note. Antifreeze, which can literally be translated into Russian from English as “anti-freeze”, is used to name liquids that do not freeze at low temperatures, as a general concept for such drugs. But in this case, there are special additives or additives - they serve as inhibitors of corrosion and mineral deposits.

Radiator operation and mounting

But be that as it may, when choosing antifreeze for aluminum heating radiators, you should choose exactly the composition that is specifically intended for this purpose, since the manufacturer specifically provides for all the nuances of the intended use.

But one should not look at such a coolant as some kind of panacea - it, quite naturally, has its drawbacks:

- Compared to water, its thermal capacity is 115% lower;

- It is impossible to start the system without a circulation pump, since antifreeze has a high viscosity and circulation will be inhibited;

- Liquid expands greatly when heated;

- Its fluidity is 50% higher than the fluidity of water - this forces us to pay special attention to welded (solder) and threaded connections;

- When using ethylene glycol antifreeze, it is impossible to connect a hot water supply system, but only one circuit for heating, since they are poisonous.

Ethanol based antifreeze

Note. If you do not have the opportunity to purchase a sufficient number of such mixtures for a heating system with aluminum radiators, you can make them yourself, but for this you will need distilled water and 40% ethanol (ethyl alcohol).

Ethanol based antifreeze

The high price of such coolants may not allow their use for your own autonomous system, and then you will need forty percent ethyl alcohol and distilled water, which will allow you to prepare the necessary liquid yourself.

It is noteworthy that this composition is to some extent even better than the factory one, since its viscosity is much lower, but at the same time, it is in sufficient proportion higher than that of water, and in addition, the fluidity also decreases, which makes it possible to lower the requirements to a certain extent to welded (solder) and threaded connections.

In addition, it should be noted that when using such compounds, the rubber seals (gaskets), which you will use in any case when installing the circuit, are not damaged.

Here you should also pay attention to the fact that it is best to use hard water when preparing the composition - it, together with ethanol, does not allow scale to form on the inner surface of the walls of pipes and devices.

Of course, in this case there will definitely be solid sediment, but it can be easily removed by flushing the system with running water. If the content of ethyl alcohol in water does not exceed the 30% barrier, then alcohol evaporation will not occur - the liquid will behave exactly like ordinary, clean water.

Distilled water

Due to its identification with ordinary water, the boiling point of such a coolant is approximately at the same level as water, therefore, if the liquid is heated to 85-90ᶷ, then there is no abundant release of steam, since there is no boiling.

Finally, ethanol significantly reduces the thermal expansion of H2O, therefore the risk of pipes and/or batteries bursting when the system defrosts is significantly reduced.

Proportions

Pictured: ethyl alcohol

It should be taken into account that a certain decrease in temperature must be accompanied by an increase in the percentage of ethanol to distilled water, so if the thermometer drops to -10.6 ᶷC, then the content of ethyl alcohol in the total composition must be at least 20.3%.

If the temperature drops to -23.6 ᶷC, then 33.8% ethanol will be required, at a temperature of -28.7 ᶷC - 39% alcohol and at a temperature of -33.9 ᶷC - 46.3%, respectively.

But that's not all - one liter of 96% ethylene contains 960 ml of anhydrous alcohol, therefore, in order to get a 33% solution, you need to divide 96/33 = 2.9, that is, 2.9 liters of distilled water.

This means that to obtain a 33% solution we need one liter of ethyl alcohol and 2.9 liters of distilled water. This composition will serve as an excellent coolant for a circuit with aluminum radiators, which will not freeze even at -22.5 ᶷC.

Red antifreeze

But this composition, that is, the antifreeze, the preparation of which we described, and any other, in certain cases is strictly prohibited, therefore, you will have to take into account certain factors:

- The use of antifreeze in heating systems using electrolysis boilers is strictly prohibited.

- The use of antifreeze in open heating systems that use ethylene glycol is strictly prohibited, as it is toxic.

- It is not recommended to lower the temperature beyond -20 ᶷC, as this reduces the quality characteristics of the additives used - scale will appear on the inside of the walls.

- When using such coolants, it is not recommended to use flax tow placed on the paint, since ethyl alcohol easily corrodes it and the connection will depressurize. Unipak plumbing paste is well suited for this.

- Also, in such cases, galvanized pipes, pipes and fittings cannot be used in the system.

Results

Discussions on the topic of whether it is possible to pour antifreeze into aluminum radiators brought very specific answers. Responsibility for choosing a coolant lies entirely with the owners of the household. When considering various liquid options, one should keep in mind one more feature of systems filled with antifreeze coolant. If the operating temperature regularly exceeds the limit of +70ᶷ degrees, it is better to refrain from using antifreeze solutions, because because they have a very high expansion due to the alcohol content. This is fraught with pipeline ruptures and damage to heating devices.