Let's start with the most interesting thing - what is a beautiful bathhouse made of timber, by what criteria and who evaluates it, on the basis of which a bathhouse can be assigned this “status”. By what criteria will we determine the beauty of a bath?

Beautiful baths made of timber

Beautiful bathhouse made of timber

Bathhouse made of profiled timber

Bathhouse made of profiled timber

The beauty of a bath does not depend on its size, as some owners think. There may be a small bathhouse that is perfect in all respects. Or maybe a huge building, reminiscent of an ordinary barracks and indicating a complete lack of sense of reality of its owner. It also happens the other way around, of course.

Beautiful small sauna

Price. In this case, it is not worth saving; beautiful buildings are not created from low-quality cheap materials. But in everything you need to observe moderation - a “golden toilet” in a bathhouse is also not a sign of beauty. Each item or element of the bath should be made taking into account generally accepted standards.

Construction and finishing require high-quality materials

Beauty concept. This is a very conditional definition, some like tall and thin women, while others prefer short and plump ones. Who can give an objective assessment of beauty? Objectively, no one, and rightly so. Hence, a beautiful bathhouse made of timber should, first of all, please its owner, and not those around him. It’s very nice when your ideas about beauty coincide with the opinions of others; if they don’t coincide, listen to your voice. In the end, you are building a beautiful bathhouse to please yourself, and not to provide food for empty speculation to various “experts and critics.”

VIP – sauna made of laminated timber

Project of a one-story Finnish bathhouse

Interior of a one-story Finnish bathhouse with a veranda

Interior of a Finnish steam bath

Layout of a one-story Finnish bath

Taking into account the above, we will present to you, in our opinion, several beautiful bathhouses made of timber. We don’t hope that absolutely everyone will like them; everyone will have their own opinion. And this is very good, otherwise architects would be left without work, and all baths would be “twin brothers”.

Bathhouse 6x4 with veranda

Bathhouse appearance

Bathhouse, rear view

Bathhouse layout 6x4 plus veranda

House project

The first step with which you need to start building a house from timber or a bathhouse with your own hands is developing a project. This is the most interesting stage of construction, during which you can give free rein to your imagination and ingenuity. Developing a project from scratch in a special office will require a lot of expenses, so it is better to spend a few days on the planning yourself.

So, the project must include a diagram of the future house with all the details. You need to indicate where it will be located, what materials will be used for construction, where they will be purchased, at what cost, and much more. All, even unimportant aspects of construction must be indicated in it.

Results

In the article, we specifically selected several completely different designs for beautiful baths, going from simple to complex. In this way they tried to give general directions to modern designers and architects. A beautiful bathhouse is the fruit of the labor of many professional specialists; not only architects, but also engineers, technologists and, of course, designers work on the project. The highest quality materials and advanced technologies are selected, and solutions are selected for each individual case. Most of the projects are exclusive, designed for individual orders. Of course, each developer can make his own changes, but this must be done carefully and competently. Unprofessional changes in complex projects can negatively affect the strength of the load-bearing elements of the bathhouse. If you want to make your own edits, then it is better to change only design solutions and not touch engineering and architectural developments.

And one last thing. Everyone dreams of a beautiful bathhouse, but as surprising as it may seem, most “dreamers” can make it a reality. This will require persistence and the ability to choose the best solution for yourself. In this case, as many different factors as possible should be taken into account.

The foundation is the key to durability

The foundation is the basis of any house or bathhouse. The reliability of the building will directly depend on its quality. The foundation is the support of the house, which consists of:

- Sand pillow;

- Ground;

- Frame made of reinforced structure;

- Concrete;

- Holes for ventilation;

- Waterproofing.

There are several types of foundation:

- A strip foundation is a reinforced concrete strip that stretches along the entire perimeter of the house. This tape is laid under all walls of the building;

- A columnar foundation is erected in the form of pillars located at all intersections of walls and at points where there is a large load. This is an economical and reliable option that can only be used for houses with low weight, for example, the construction of a house from laminated veneer lumber is often carried out on this type;

- Pile foundation is a structure consisting of piles. Most suitable for large buildings.

Laying the foundation requires a lot of attention, as this is one of the main processes in the construction of a log house or bathhouse made of timber.

Construction Features

To assemble a log house from a calibrated log, you just need to correctly measure the depth of the longitudinal gutter and saw down the bowl for bandaging at the corners. The almost ideal cylindrical shape greatly simplifies the marking process. Moreover, you can always replace the log with another one; they are almost the same in diameter.

The main feature of constructing a bathhouse from a log is the simultaneous assembly of all the elements of the box as the number of crowns and the height of the walls increases. Simultaneously with laying, joints and cracks are packed with jute or dried moss. Even technological cuts must be sealed with linen cord and oil putty.

Assembling a hewn log bathhouse is much more difficult; each log has to be adjusted individually, taking into account the curvature of the trunk and the quality of the cut groove. The assembly of a log house with an uncut root part of the trunk is considered especially chic. Visually, a chopped bathhouse box looks more stylish, the corners are warm and very hard, but in order to assemble such a lock, the cutting accuracy must be maintained at 2-3 mm per log size.

This is how windows are made in a chopped bathhouse

Wall assembly

Laying the first crown of timber

Wall beams usually have cuts at the corners for proper installation. It is not so easy to build the walls of a log house from 150x150 timber, but on the Internet you can watch a video by professionals that shows everything. So, laying the walls begins with the first crown, which needs to be given great attention.

Firstly, be sure to take care of waterproofing. If it was not laid during the construction of the foundation, then you should think about it before laying the beams. It is necessary to lay roofing material on top of the base in two layers, and then lay longitudinal boards treated with bitumen. Only after this can the first crown be laid.

Options for assembling the walls of a log house 150x150 or a bathhouse made of timber:

Assembly in the floor of wood. To do this, you need to make holes in the timber for the dowel. A dowel is a spike made of wood or metal that can be used to connect beams to each other. Holes must be made in the corners and along the length of the beam, the distance between them must be at least 1 meter. Next, the first crown is laid, with insulating fiber on top of it, and then the laying of the next crowns begins. The dowels must be driven in starting from the third row of beams. You can watch a video on similar installation for better familiarization;- Connection of timber along the length. The standard length of the timber is 6 m. In cases where this is not enough to build a house, you can use a special assembly technology. The ends of the beams must be cut in a certain way so that they can be connected to each other into a locking structure. It will also need to be fastened with dowels, starting from the third crown;

- Assembly with main tenon. To use this technique, it is necessary to make a tenon on one of the beams, and a corresponding groove on the other. During connection, they must fit into each other, creating a corner of the log house or bathhouse. With this method, the first crown is still made into the floor of the tree, this way it is possible to achieve greater strength. The crowns are connected by dowels.

Sauna made of calibrated logs

Of all the options and designs for log saunas and steam rooms, sauna houses made of rounded and calibrated logs are most widespread. In fact, nothing has changed in the process of harvesting and selecting logs for felling.

The material for building a bathhouse from calibrated timber, debarked or hewn logs is selected according to the same rules:

- To build a bathhouse, only the lower quarter of a pine or larch trunk is used, where there are no branches or crooked areas;

- The half-difference between two diameter measurements in the perpendicular direction should not exceed 10 mm. In this case, the deflection of the trunk in an undried state should not be more than 5 mm for each meter of length;

- The diameter of the log for the bath is selected within the range of 210-250 mm. For the construction of saunas for the southern regions, where in winter there are rarely frosts worse than minus 20°, it is allowed to use calibrated logs with a diameter of 150-180 mm.

For a chopped sauna you need a log dried to a strictly defined standard.

Important! The conditions for choosing material for a chopped bathhouse are more than stringent, and given the fact that logs are often discarded due to defects and past diseases, the cost of harvesting increases several times.

Therefore, such a method as building a bathhouse from calibrated logs appeared. Essentially, this means that the dried part of the trunk is subjected to special processing on a trimming or sizing machine. The workpiece is cut or sharpened with a special tape or a set of cutters, as a result the log acquires an ideal geometry, absolutely the same diameter along the entire length of the workpiece, which greatly simplifies the process of laying the walls of a log house.

Only a small part of the surface is removed on the machine, whereas when sawing timber, the most valuable parts of the trunk are lost

Upon completion of the barrel calibration procedure, the almost finished log is subjected to longitudinal milling, that is, part of the surface is cut off in order to obtain a rounded support groove. The transverse size of such a rounding is selected depending on the air temperature. For a bathhouse in the northern regions, the width of the groove should be at least 16 cm, for the middle zone 12-14 cm is enough, for those who decide to build a bathhouse from calibrated logs in the southern regions, you can use a standard calibrated log 150 mm with a notch of 8 cm.

A groove is cut along the workpiece, thanks to this, chopped baths are not only more durable, but also much warmer than timber ones

The bathhouse box turns out to be very even, all the logs placed in the crowns fit perfectly against each other, so a bathhouse made from calibrated logs turns out to be quite warm and durable. The second indisputable advantage of using rounded material is the expressive and at the same time modern appearance of the building.

Roof of the house

After the height of the walls has been brought to the desired level, you can begin to cut the roof with your own hands. This is a difficult process, which you can see with your own eyes in the video. The roof structure for a log house or bathhouse can be of any type. The best and most common option is a gable roof. It consists of two elements - the rafter structure and the roof.

The rafter structure is the basis of the roof. Rafters are its constituent components, the fastening of which is carried out using staples and nails. If you plan to install heating or gas in the house, then you need to provide holes for the pipes.

The next step is laying a vapor barrier film, on top of which you need to sew counter battens, after which the sheathing is installed. Afterwards, the material from which the roof will be made is selected, and then the process of laying it begins.

What timber can be used to build a bathhouse?

The choice of building material for a bathhouse directly affects what characteristics the finished structure will have. Therefore, you need to pay attention to its quality.

- Before purchasing, you must carefully inspect the timber for damage. It should not have cracks or other serious defects. You should not take risks and purchase material even with minor damage, because after a few years this can lead to serious problems - the tree will begin to rot and completely collapse.

- You also need to make sure that there are no blue spots on the surface of the wood. If you notice such a defect, know that there is rot inside the material, most often caused by pathogenic microorganisms. Therefore, such material should under no circumstances be used to build a steam room or any other structure.

- Also pay attention to ensure that the beams do not show visible signs of damage from beetles and other pests.

- A sign of high-quality building material for a bathhouse is a perfectly flat and smooth surface. Expect problems if you agree to purchase material with distortions or other damage. Already at the stage of laying the crowns, you will see why you should not have chosen this material.

Floor installation

Building a log house with your own hands is not an easy task, and you need to be careful. Otherwise, living in the building will be inconvenient and uncomfortable. So, you should definitely consider installing the floor. Most often they are made double, with a heat-insulating layer placed between them. In the process of making the floor, edged boards are used.

It is hemmed from the bottom. When hemming, all stitches must be carried out evenly and accurately, otherwise after a short use, the boards will begin to tear off. Also, to install the floor, a cranial beam is used, which will be attached to the logs.

Modern coatings can be used to install the floor. They will cost a little more, but they can change the interior and design of the entire house.

Bathhouse made of large logs

One of the possible options for constructing a bathhouse box is to use debarked and ground blanks of large diameter. If you build walls from Siberian pine or cedar, and their diameter often reaches 50-60 cm, the result will be a very warm and, most importantly, durable room. On average, hand-cut bathhouses made from large logs last for 40-50 years, no less.

The large size of the workpiece gives the bath an unusual look

For steam rooms and saunas in Arctic cold conditions, log houses are built from large-diameter logs, most often the famous Canadian red cedar. The diameter of the chopped log can reach 110-140 cm, resulting in a very warm room, but such baths are recommended to be built for dry and very cold climates, otherwise the outer surface of the walls will quickly become covered with cracks due to fluctuations in air humidity.

Log houses made from large logs require the use of construction equipment

Log houses are assembled by cutting the corners “into the bowl”, this is due to the high cost of the logs and the desire of the builders to save material as much as possible; sometimes the root parts are not even cut off.

Door and window openings in a log house

In order for a person to enter the future house, it is necessary to install doors. To allow light to enter a building, windows are needed. However, it is not possible to simply install both windows and doors - special openings are required.

Openings can be made in two ways:

- In the process of making a log house or bathhouse. This is a complex technique, since it is necessary to calculate in advance the correct location of the windows. The beams are selected in a special size and laid so that there is an opening;

- After the construction of the log house. This cutting method must be carried out with a plumb line to mark the places where the sawing will take place. The process is completed using a chainsaw. In a specialized video you can see all the nuances of the work;

The next step in the design of door and window openings is the frame. Thanks to it, you can strengthen the opening and ensure the free placement of the beams. The main purpose of the casing is to preserve the shape of the openings after shrinkage.

Laying the first and subsequent crowns of the bathhouse frame

Laying the first crown of the bathhouse frame.

The first crown is assembled on a previously prepared waterproofing layer, which is laid on the foundation. When installing the first crown, special attention must be paid to the correct placement of the timber, since it is used as a guide when installing the remaining crowns, the ceiling and the roof. The bars in the crown can be connected in various ways. When assembling the first crown, a level is used; all beams must be in a strictly horizontal position. In the corners, the beams of the first crown are connected by metal brackets made from reinforcement with a cross section of 10-12 mm.

To assemble the first crown, a beam with a size of 200x200 mm is used, for the overlying ones - with a section of 150x150 mm. After assembling the first crown, floor logs are cut into it, and at the same time a beam is laid, which serves as the basis for the internal partitions. All crowns are laid evenly, a sealing material is laid between them, which also serves as insulation. All crowns are fastened together in the vertical direction with devices called dowels. A dowel is a pin made of metal or wood. To install the dowel, a hole is drilled in the timber with a slightly smaller diameter than the dowel itself. The fastener is inserted into the hole and driven in using a sledgehammer.

To give the structure additional rigidity, brackets are used to connect adjacent crowns.

Finishing a timber house

Finishing a house or bathhouse from a log house is an essential part of the DIY construction process. There are only two options for the development of events - leave the outer walls unchanged, treating them only with protective varnish or covering them with decorative elements. This is a difficult choice, because the wood texture looks beautiful and attractive, but I also want to try modern finishing options. For decoration, you can use clapboard, siding or block house.

The interior decoration of a log house comes down to two processes - mandatory and additional. The first option includes flooring, as well as installation of windows and doors. Additional features include the design of a certain interior and style in the house.

How to get rid of resin in a bath

All chopped boxes made from debarked logs have one significant drawback: when the walls inside the chopped bath are heated, resin and resin sweat out onto the surface. You can get rid of it in several ways:

- Warming up the surface with a hairdryer and removing traces of oleoresin with a spatula and a wire brush. The method is quite effective, but slow; in order to free the walls of the bathhouse from resin, it will take at least a week of painstaking work;

- Wash with a mixture of alcohol and turpentine. Removing the resin is faster, but then the walls have to be washed and sanded with a scraper;

- Cleaning the surface with an abrasive nozzle. You cannot heat the wall; you can quickly sand dry logs, and thereby remove the layer in which pests may remain.

Mechanical and chemical treatment of walls

Among other things, the walls of a chopped bathhouse become smoother, which makes it easier to treat the wood with protective varnishes and impregnations. If the log is not cut carefully, then splinters and sharp ends of the fibers may remain on its surface, and grinding removes all defects. In fact, grinding can also be used to combat fungus, but mechanical treatment cannot fully replace chemicals.

Plumbing, electricity and heating

If you wish, you can take care of all the benefits of the modern world. The first of these is water supply. It can be of several varieties - autonomous or centralized. Centralized water supply will come from one main pipe. The advantages of such a connection are the ease of installation work, the disadvantage is the dependence on the central water supply. The autonomous option has several advantages, including the fact that water is supplied at will.

An important point, which includes the construction of a house from profiled timber or another type, as well as a bathhouse from timber, is heating. It can be presented in different forms - installing heating yourself, using portable equipment or installing heated floors. There are several options from which you can choose the one that suits your taste and budget.

Today it is impossible to do without electricity. Laying the wiring will not leave any difficulty, as well as installing switches and sockets. However, when carrying out this work, do not forget about fire safety rules.

Making a log house with your own hands is considered a difficult task, the execution of which will require a lot of effort and time. It will be more difficult to build a comfortable and convenient log house without special skills or little experience. It is recommended to use the help of specialists and always be prepared for additional costs.

Bathhouse made of debarked logs

It is clear that additional processing of the log simplifies the construction of the bathhouse; often carpenters only need to make the correct cuts on the corner locks, and even then, craftsmen often have to work with a chainsaw rather than with an axe. Therefore, true connoisseurs of the steam room prefer baths made of chopped logs that have only undergone debarking. This is the most complex and time-consuming project to manufacture, but the demand for such buildings is growing quite quickly, and there are reasons for this.

Advantages of a hewn bathhouse made of debarked material

Almost all owners of saunas and steam rooms made of chopped logs note a brighter and somewhat brutal appearance in comparison with boxes made of calibrated material. A bathhouse made from a rounded cedar trunk, even without painting and varnishing, looks like a toy made of pencils. Another thing is a log house made of debarked logs; the bathhouse looks natural and quite impressive.

In addition to appearance, a bathhouse cut from a debarked trunk has quite tangible advantages:

- Walls are easier to fit in corner locks;

- The surface of the log retains most of its dense outer shell;

- The structure of the bathhouse material, chopped from debarked material, practically does not lose resin and resin.

During the process of wall shrinkage, the inter-crown gaps “stick” with resin

As a result, it turns out that a log bathhouse can last for several decades, which is almost twice as long as a building made from calibrated material. The difference arises in the processing method. The machine removes bark and part of the sapwood unevenly, its thickness at different points of the workpiece is different. The main thing is that when rounding the workpiece, the outer layer containing most of the resins, resin and protective substances is removed. Therefore, it is necessary to treat the surface with impregnations and regularly seal cracks and joints at corners.

Disadvantages of debarked logs

Of the significant disadvantages, only two can be cited. Firstly, you have to remove the bark and plan the surface of a pine or cedar trunk by hand; the work is very hard and requires professional use of a scraper.

You can’t build a log bathhouse alone

Secondly, you have to fight with the resin remaining on the surface of the trunk, wash it off and clean it from the inner surface of the walls of the steam room and dressing room, otherwise the smell and evaporation of the resin resin will not allow the steam room to be heated to the desired temperature.

Furnace structure and interior decoration of the bathhouse

Each Russian bathhouse has a stove to heat the room and create an appropriate microclimate in the steam room. A small stove, fueled by wood, can heat a fairly large room.

Correct design of the stove in the bathhouse.

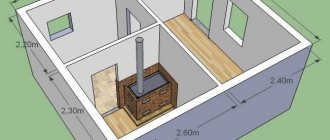

When constructing a small stove, it requires a special approach to construction and special knowledge. Creating such a furnace has a large number of nuances. The location for the furnace is selected in advance, at the project development stage. For construction, you need to prepare a concrete foundation; in addition, the base for the furnace can be created using red brick. The location of the stove must be taken into account when installing the roof and ceiling.

Thermal insulation material is installed inside and the final finishing of the premises with finishing material is carried out. The insulation between the beams is compacted using a spatula. During the finishing work, a fire-resistant brick wall is built, which separates the stove from the wooden surfaces.

In the process of finishing the interior of the bathhouse, communications are connected - centralized water supply and drainage.