Updated: 04/22/2021 16:53:15

Expert: Andrey Nikolaevich Kuznetsov

*Review of the best according to the editors of expertology.ru. About the selection criteria. This material is subjective in nature, does not constitute advertising and does not serve as a purchase guide. Before purchasing, consultation with a specialist is required.

Modern heating systems of private houses are equipped with circulation pumps. Thanks to this inexpensive device, it is possible to quickly and evenly heat the coolant in different parts of the house, saving heat energy. The main task of the device is to move liquid in a closed loop. The device operates from an electrical network, so the pump will only be useful if there is a current of 220 V. When choosing a circulation pump, you need to know several important points.

How to choose a circulation pump

- Varieties

. There are two modifications on sale that differ in design. Models with a dry rotor are distinguished by their high efficiency (up to 80%), but they require regular maintenance, their service life is short (3-5 years), and they produce a lot of noise during operation. Pumps with a wet rotor have an efficiency of 50%, but they do not require maintenance, their service life reaches 10 years, and the equipment is practically inaudible during operation. For those who are sensitive to noise, it is better to give preference to models with a wet rotor. - Productivity

. Different heating systems require a pump with optimal performance. The homeowner needs to know the power of the boiler installed in the system. If a 40 kW heating device is operating in the circuit, then the pump must provide a throughput capacity of 40 l/min (2.4 cubic m/h). - Lifting height.

The next important characteristic of the circulation pump is the pressure (lift height). Experts recommend sticking to a simple formula. For 10 m of pipeline, a pressure of 0.6 m is required. It is easy to calculate that for a heating main 100 m long, a circulation pump with a lift height of 6 m is suitable. - Adjusting the flow rate

. A very useful option in the pump is the ability to change the speed of water movement. Some models are equipped with a mechanical switch for 2-3 positions. The user selects the optimal mode based on the room temperature. More modern devices are equipped with electronic regulators that change the speed automatically. The maximum rate should not exceed 1.6 meters per second. - Power

. Each circulation pump has an electric motor with a certain power. The thinner the pipes in the heating system, the greater the motor power should be. Otherwise, the pump will not be able to overcome the hydraulic resistance in the line. For small circuits, power up to 100 W will be sufficient, and complex systems are equipped with models with motors of more than 150 W. - Coolant temperature

. Each heating system has its own temperature regimes. If when using a gas boiler the water is heated to +80°C, then in systems with a solid fuel boiler the coolant reaches a temperature of +110°C. It is important to pay attention to the lower temperature limit in case of irregular heating of the house in winter. Homeowners fill the system with antifreeze, which does not freeze in cold weather. In this case, the pump must remain operational at -10°C. - Materials

. In order for the pump to work for a long time to the owner’s delight, you should find out what materials the critical components and parts are made of. The body should ideally be cast iron, and the impeller and impeller should be made of high-quality plastic. - Connection size

. When inserting a circulation pump into the main line, it is important to consider the diameter of the pipes. Straight pipe threads are designated in inches, for example G1, G2 or G3/4. The connecting size is also indicated in the pump characteristics.

We have selected 11 of the best circulation pumps for our review. All of them have received approval from the expert community and have earned high marks from consumers.

General calculations

It is necessary to determine the total heating capacity so that the power of the heating boiler is sufficient for high-quality heating of all rooms. Exceeding the permissible volume can lead to increased wear of the heating device, as well as significant energy consumption.

The required amount of coolant is calculated according to the following formula: Total volume = V boiler + V radiators + V pipes + V expansion tank

Boiler

Calculating the power of the heating unit allows you to determine the boiler capacity indicator. To do this, it is enough to take as a basis the ratio in which 1 kW of thermal energy is enough to effectively heat 10 m2 of living space. This ratio is fair in the presence of ceilings whose height is no more than 3 meters.

As soon as the boiler power indicator becomes known, it is enough to find a suitable unit in a specialized store. Each manufacturer indicates the volume of equipment in the passport data.

Therefore, if the correct power calculation is performed, there will be no problems with determining the required volume.

To determine the sufficient volume of water in the pipes, it is necessary to calculate the cross-section of the pipeline according to the formula - S = π × R2, where:

- S – cross section;

- π is a constant equal to 3.14;

- R is the inner radius of the pipes.

Having calculated the cross-sectional area of the pipes, it is enough to multiply it by the total length of the entire pipeline in the heating system.

Expansion tank

You can determine what capacity the expansion tank should have by having data on the coefficient of thermal expansion of the coolant. For water this indicator is 0.034 when heated to 85 °C.

When performing the calculation, it is enough to use the formula: V-tank = (V system × K) / D, where:

- V-tank - the required volume of the expansion tank;

- V-syst - the total volume of liquid in the remaining elements of the heating system;

- K – expansion coefficient;

- D – efficiency of the expansion tank (indicated in the technical documentation).

Currently, there is a wide variety of individual types of radiators for heating systems. In addition to functional differences, they all have different heights.

To calculate the volume of working fluid in radiators, you must first count their number. Then multiply this amount by the volume of one section.

You can find out the volume of one radiator using the data from the product technical data sheet. In the absence of such information, you can navigate according to average parameters:

- cast iron - 1.5 liters per section;

- bimetallic - 0.2-0.3 l per section;

- aluminum - 0.4 l per section.

The following example will help you understand how to correctly calculate the value. Let's say there are 5 radiators made of aluminum. Each heating element contains 6 sections. We make the calculation: 5 × 6 × 0.4 = 12 liters.

As you can see, calculating the heating capacity comes down to calculating the total value of the four above elements.

Not everyone can determine the required capacity of the working fluid in a system with mathematical accuracy. Therefore, not wanting to perform the calculation, some users act as follows. To begin with, fill the system to approximately 90%, after which the functionality is checked. Next, the accumulated air is released and filling continues.

During operation of the heating system, a natural decline in the coolant level occurs as a result of convection processes. In this case, there is a loss of power and productivity of the boiler. This implies the need to have a reserve tank with working fluid, from where it will be possible to monitor the loss of coolant and, if necessary, replenish it.

Rating of the best circulation pumps

| Nomination | place | Name of product | price |

| The best inexpensive pumps for the heating system | 1 | VORTEX TsN-32-6 | 2 070 ₽ |

| 2 | Leberg GRS 25/4 (180 mm) | 2 350 ₽ | |

| 3 | Grundfos UPS 25-40 180 | 4 800 ₽ | |

| 4 | VORTEX CN-25-6 | 2 020 ₽ | |

| The best circulation pumps for heating in terms of price-quality ratio | 1 | GILEKS Compasses 32-80 | 5 852 ₽ |

| 2 | WCP 25-80G (180 mm) | 4 590 ₽ | |

| 3 | Wilo Star-RS 25/4-180 | 4 800 ₽ | |

| 4 | DAB EVOTRON 40/180 | 10 108 ₽ | |

| The best circulation pumps for high-performance heating | 1 | DAB A 110/180XT | 20 600 ₽ |

| 2 | Grundfos UPS 32-80 180 | 12 250 ₽ | |

| 3 | Wilo Star-Z 20/7 CircoStar | 12 876 ₽ |

How to install the pump?

The pump can be installed on the pipe without cutting. For this purpose, outlet pipes are provided in the housing. The disadvantage of this installation is that if the equipment breaks down, you will have to dismantle the pipe. It will be difficult to remove the device.

In order to be able to replace the pump without complications or carry out repair work, ball valves, bypasses, and union nuts are used to connect to the pipe. First, the working block is assembled. After this, it is installed in the pipe.

We recommend: Pros and cons of steam heating without a pump

During repair work, taps block the access of water to the pump. The liquid begins to flow through the line to the boiler under the influence of gravity: it is necessary to install the condensate line above the slope.

In hardware stores you can purchase a ready-made unit with a circulation pump for steam heating. It is connected to the main line without additional complications. When choosing, you need to pay attention to the possibility of connecting the working unit. It can be designed for vertical or horizontal connection.

When choosing a circulation pump, take into account the operating temperature range and the maximum permissible pressure. Pay attention to the type of motor, its size and installation length. All electrical equipment must be well protected from water. When purchasing, you need to check the air exhaust system. This is especially important for steam heating. When the pump becomes airy, its operation will stop.

YouTube responded with an error: The request cannot be completed because you have exceeded your quota.

- Related Posts

- What types of steam heating radiators are there?

- How does a steam-heated furnace work?

- Which wood stoves are suitable for steam heating?

- How to organize steam heating of a garage with your own hands?

- How does a low pressure steam heating system work?

- Features of steam heating in a private house

The best inexpensive pumps for the heating system

Low-cost circulation pumps can handle small heating systems or water supply lines. Among the inexpensive models there are many worthy examples. Here are the best ones.

VORTEX TsN-32-6

Rating: 4.8

A very tempting purchase for heating systems in a private home is the VORTEX TsN-32-6 pump. It perfectly combines affordability and excellent technical characteristics. Thanks to the high power of the electric motor (90 W), the pump creates a lifting height of 7.5 m, and the productivity reaches 9 cubic meters. m/h. The device can operate in a wide temperature range (-10...+110°C), it is durable and reliable. The cast iron pump housing is also reflected in the weight of the equipment (3.8 kg).

You can rarely find negative reviews on thematic forums; most often these are isolated cases of marriage. In general, domestic consumers are satisfied with the technical characteristics and low cost of the pump. The model becomes the winner of our rating.

Advantages

- affordable price;

- good pressure;

- high performance;

- reliable design.

Flaws

- Pump breakdowns are noted during the warranty period.

Temperature

In terms of importance, among the characteristics of circulation pumps, the first is the maximum possible temperature in the water system.

Manufacturers of expensive products indicate an indicator of up to one hundred and thirty degrees.

Budget devices can withstand up to 90 °C. In fact, the devices can withstand temperatures 10-20 degrees less.

If your house has a system designed for such heating, you can purchase a cheap pump, and in the case of a solid fuel boiler, you should proceed from the temperature parameters to which the water is heated.

The best circulation pumps for heating in terms of price-quality ratio

Pumps with good pressure and performance are capable of maintaining the required level of coolant circulation in a one- or two-story house. The following models have the optimal combination of affordable price and good technical parameters.

GILEKS Compasses 32-80

Rating: 4.9

The circulation pump JILEX Compass 32-80 has an excellent ratio of cost and technical characteristics. Thanks to a powerful electric motor (245 W), the pump creates a maximum pressure of up to 8 m, providing a throughput of 8 cubic meters. m/h. The model works perfectly in heating systems of private houses (up to 3 floors). The kit includes fastening nuts protected from corrosion. A three-speed switch allows you to save energy by choosing the optimal mode for your heating system. Experts gave the model first place in our rating.

Users have no particular complaints about the operation of the pump; it has the best price-quality ratio. The device operates reliably, silently and efficiently.

Advantages

- saving heat and electricity;

- high-quality assembly;

- silent operation;

- reliability.

Flaws

- not detected.

WCP 25-80G (180 mm)

Rating: 4.8

The WCP 25-80G (180 mm) pump is practically in no way inferior to the rating winner. It is suitable for installation in single-pipe or two-pipe heating systems. The model is equipped with a powerful motor (245 W), which provides performance from 0.5 to 8.5 cubic meters. m/h and pressure from 0.5 to 8.0 m. The pump is well made, the cast iron body and aluminum motor make the device durable. Thanks to the three-position control, users can choose the desired operating mode. The strengths of the pump include its compactness, which simplifies its installation.

Overall, homeowners are pleased with the pump's reliability, affordability, and durability. The product failed to surpass the leader in the rating due to loud noise at maximum speed and low-quality plastic.

Advantages

- compact dimensions;

- light weight;

- three-position regulator;

- affordable price.

Flaws

- noisy work.

Power

Heating systems of private houses operate under pressure of three to four atmospheres. Such options are only possible for two-story buildings. The most common option is one and a half to two atmospheres.

In any case, you need to pay attention to the power indicator of the device. And yet, it is very important what material the pump body is made of. The best option is cast iron. Cheaper products are made from polymer materials.

Pump installation: stages and nuances during installation

The first thing to do is drain all the liquid from the heating system. Then, if necessary, the pipeline must be cleaned. In accordance with the connection diagram, work on installing equipment and fittings must be carried out. When the installation of the heating system is completed, fill in water , after which excess air is removed from the pump.

This is done by opening the central screw. Please note that before each switching on of the unit, it is necessary to carry out air removal work. When a circulation pump for heating is purchased, you need to decide on the place where it will be installed. Experts recommend installing this equipment on the return line in front of the boiler. The thing is that air can collect at the top of the boiler during operation if the pump is installed on the supply side. This may cause it to be drawn out of the boiler, causing a vacuum to form, causing that part of the boiler to boil.

If the pump is installed in front of the boiler, then water will be pushed into the heating installation . The consequence of this will be the creation of air space and the installation will be completely full. In addition, with this installation option, the pump will operate at lower temperatures, which will have a positive effect on its service life.

Having selected the installation site for pumping equipment, then create a bypass or outlet. The need for it is due to the fact that in the event of a breakdown or when the electricity is turned off, thanks to it, the operation of the entire heating system will not stop and there will be an opportunity for the coolant to pass through the main pipeline thanks to an open tap. When installing a bypass, it is necessary to remember that the diameter of the pipe should be smaller than the diameter of the main pipeline. When the bypass is ready, proceed to the main stage of work on installing the unit.

The heating pump shaft must be completely submerged in water. If it is only partially immersed in the coolant, this will lead to a reduction in equipment performance by 30%. In the worst case scenario, the work area becomes faulty.

In addition, the installation also includes the installation of a terminal box with a top location.

In addition, ball valves are installed on both sides of the pump. During the operation of the equipment, they will be required to perform maintenance on the pump and dismantle it if necessary.

The system must also include a filter. It will protect the unit from mechanical particles. Once inside its structure, they can adversely affect the operation of the pump.

A manual or automatic valve must be installed on top of the bypass pipe line. It is necessary to release air pockets at certain intervals.

Equipment structure and principles of its operation

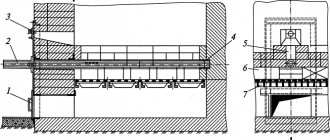

If we talk in detail about equipment such as a circulation pump, then its main purpose is the forced circulation of warm water in a closed-type heating system. The pump design consists of a stainless steel housing and a steel rotor screwed to it. Some pumps use a motor instead of a rotor. The impeller is secured to the motor shaft .

It is this that ensures the release of coolant. The pump operates thanks to an electric motor. The installation, operating as part of the heating system, pulls water from one side and then throws it into the pipeline. This is achieved due to centrifugal force. Its occurrence occurs when the impeller begins to rotate. The pressure created by the pump must easily overcome the hydraulic resistance of the pipeline, radiators and other elements that make up the heating system.