Answer

What to do if you notice rust on a reliable old cast-iron battery that has been tested for years?

Is it worth changing it or is there a chance that the battery will still serve? And if this is a new cast iron battery, what should you do in this case?

Let's figure out what causes rust on a cast iron radiator.

So, one of the main qualities of cast iron is its corrosion resistance. During operation of the radiator, its surface becomes covered with so-called dry rust and corrosion practically does not proceed further. For this reason, cast iron radiators are very durable - it takes a lot of time for the thick wall of the radiator (which is exactly what a quality product should have) to rot through.

Has rust appeared on a cast iron battery?

This means the battery is simply damaged. It could be a small crack that is leaking a little. Or a shell formed during casting. In this place, the battery wall turned out to be thinner, and, accordingly, it succumbed to corrosion more quickly.

Of course, a small leak in the battery can be repaired by cold welding. By the way, there are “masters” who advise doing exactly this. They even sell special anti-rust paint for batteries. But if you simply cover up and paint over the rust, the consequences of such a “repair” can be very sad. After all, if in the middle of the heating season the battery breaks, it will not seem like much to either you or your neighbors. Not to mention the fact that you will be left in the cold without heating.

Therefore, if you notice rust on the battery or on the connection of sections, then there is only one way out - replacing the radiator.

Focus on quality

And to avoid the excruciating pain of wasted money, choose high-quality radiators from well-known manufacturers. For example, cast iron radiator Аdarad Оttoman 475 or radiator Аdarad Nostalgia 800/180. After all, a stingy person, as you know, pays twice: the first time when he buys cheap Chinese radiators, and the second time when, after a year or two, he replaces them with new ones, having previously flooded his neighbors.

In addition to all the advantages inherent in cast iron radiators, these batteries also have an excellent appearance. These radiators are guaranteed to last you at least 50 years. No rust and no leaks.

How to Determine When Battery Flushing is Necessary

If your heating system consists of ordinary metal pipes and a cast iron radiator, and it has not been flushed for a long time, and you are not going to change it before the start of the new heating season, then the battery should be flushed.

Let us clarify: this should be done BEFORE the start of the heating season, and not when everything is already turned on, and suddenly it turns out that the battery does not heat well.

Do-it-yourself washing technology

You can rest assured that you will not be able to complete this procedure alone: cast iron batteries are bulky and heavy. But if your hands “grow from the right place,” you can do it quite well with an assistant.

So, how to rinse heating batteries yourself?

The technology is as follows:

- Drain the heating system. In a private house you can do this at any time, in an apartment building - when you find a plumber and agree with him so that he gives you the key to the basement where the tap is located.

- Unscrew the battery from the pipes and remove it (when performing this operation, it is necessary to have an assistant!). This can be difficult if the connections are welded. You may need to use a cutter or other device to heat the coupling.

- Inspect the radiator. Perhaps it is better not to clean it, but to replace it with a new one?

- The radiator will need to be flushed with plenty of water. If you are going to do this in the bathroom, place some kind of tray underneath to avoid scratching the tub.

- Proceed to flush the battery. To do this, you need to turn it upside down, close the hole at the bottom, and fill it with water (preferably warm). Then the water needs to be released. The battery is turned over so that the water washes away the flakes of rust and scale. If water does not help, and if you have a cast iron radiator, you can use a special liquid. It cannot be used for aluminum appliances.

The battery is leaking - what to do?

Almost every house and apartment has cast iron radiators, thanks to which it is always warm and cozy in cold weather. The service life is several decades, this is so long that almost everyone takes their work for granted, without thinking at all about the fact that they need to care for the battery.

Of course, when an incident occurs in the form of a leak, everyone begins to cut off the telephone numbers of the housing office and private repairmen. If this happened on a weekend, everything is somewhat more complicated. The average apartment resident has no idea what or how to do if a cast iron battery starts to leak.

Please note that if employees of the management company or heating network, during a scheduled inspection, will be able to identify and fix the breakdown in time, but this must be done on time and in advance.

A breakdown causes a lot of trouble if it happens in winter and there is already water in the system . Below we will tell you how to provide first aid to a battery and not leave your family without warmth and comfort, without flooding your neighbors.

Remove rust from radiator

There are several ways to remove rust from the metal surface of a radiator.

The simplest is mechanical, that is, we take a battery, take metal brushes and sandpaper and clean off all the rust and the layer of previous paint.

(Of course, the method is very long and difficult, but the most effective). You can also use the sandblasting method.

But, sometimes there are cases when the mechanical method cannot be used when we use mechanical compounds:

- We prepare a solution (500 ml of water, 105 g of ammonium, 100 caustic soda, 400 g of 40% formaldehyde, then add another 500 ml of water), to this solution add 10% sulfuric or hydrochloric acid (100 to 3). The part you need, first of all, degrease (for example, with gasoline) and allow to dry, after which the rusty parts should be dipped in the resulting solution for 20-30 minutes, then rinsed thoroughly with hot water.

- Use tin chloride (dip rusty parts in it) then rinse and let dry.

- Fish oil (apply it to the problem area and leave it for several minutes).

- If there is little rust, you can moisten cotton wool with kerosene and use it to wipe off the rust.

- Clean off rust with machine oil and charcoal.

Home remedies (using what you have on hand):

- Vinegar + citric acid (1:1) and apply to areas, leave for a couple of hours.

- Baking soda (mix with water to form a thick paste) and apply to areas for 20 minutes, then wipe off with a wire brush (the procedure may be repeated).

- Coca-Cola (dip battery parts in Coca-Cola and leave for a while).

- Ketchup. Apply ketchup or tomato paste to the rust stain, leave for 10 minutes, then wipe dry.

- Foil (using it, you need to scrub off the rust from the radiator).

Radiator paint

The choice of paint is a very important aspect, because the final result will depend on the choice.

First of all, the paint should:

- Withstand high temperatures (at least 100°C);

- Be resistant to mechanical stress;

- Have protection from an aggressive environment;

- Don't be toxic.

The following types of paints are available for sale:

Acrylic enamels. They are made from organic solvents, so when the paint dries, they emit a characteristic solvent smell. When dry, the surface becomes glossy and shiny.

Advantages:

- High service life;

- Colors remain bright and do not fade;

- Dries quickly;

- Cracks and “wrinkles” do not appear on the surface;

- To clean the brushes, you only need water;

- Low price (compared to oil ones);

- Can be used in rooms with high humidity

Flaws:

High difficulty in removing acrylic paint from the surface.

Alkyd paints. The coating is very resistant to high temperatures. There is a fairly large selection of this paint in different colors on the market and in specialized stores. But when dried and at high temperatures, this paint emits an unpleasant odor.

Advantages:

- Durable;

- Elastic;

- Dries quickly;

- Do not lose brightness;

- Do not crack or shrink when dry.

Flaws:

- Fire hazardous;

- They are afraid of alkalis.

Water-dispersion paints. It is considered the best choice, since this type of paint does not have the standard unpleasant odor and also dries much faster.

But pay attention to the packaging; the packaging must be marked “for painting heating radiators and pipes.” Advantages:

Advantages:

Cheaper than acrylic paint.

Flaws:

Less resistant to moisture and mechanical damage.

Today, the best paint for radiators can be considered acrylic; it has a lot of advantages, at a fairly low price.

Preparing the radiator for painting

Sequencing:

- We clean the surface from dust and dirt.

- We wash off the old paint.

- Then the surface is sanded with sandpaper and degreased.

- An anti-corrosion primer is applied to the cleaned surface.

There are paints in stores that already contain a primer; they are usually applied to the surface without preliminary work (but they need to be cleaned and degreased).

Painting process:

- Turn off the heating (if possible, if not, then at least turn off the hot water).

- Choose paint;

- Cover the floor (put paper, wallpaper or fabric);

- Apply paint from top to bottom;

- First the internal floors, then the external ones;

- Wait for the first layer to dry;

- Apply a second coat.

With careful priming and high-quality painting, you can forget about rust stains on the batteries for a long time and again admire your bright batteries.

But if you are not satisfied with the simple design of the batteries, you can improve it by reading THIS ARTICLE on how to decorate the battery with your own hands.

What does the battery consist of?

If we are talking about old-type radiators, then in appearance they resemble accordions, while modern models are flat, due to which they heat up more evenly. Cast iron is a very strong material, but even it is not eternal, it has a limit of stability.

So the service life varies from 20 to 30 years, depending on operating conditions. If maintenance is carried out in a timely manner, the service life increases several times and the battery will last almost a hundred years.

Unfortunately, problems often arise in the places where the sections are fastened to each other; they wobble due to water or crack due to age. This is where the leak begins, which is best localized as soon as possible.

Placing a basin or saucepan under a dripping radiator is not a solution, as the crack tends to grow, so that one day a flood may occur! If we are talking about the winter period, then there is generally boiling water in the pipes, which poses a serious danger to the life and health of people.

Construction of cast iron radiators

This type of heating device consists of sections. Models of the old type, even today, are produced in the form of “accordions”, while the new generation has a flat outer panel, which provides better heating of its entire area.

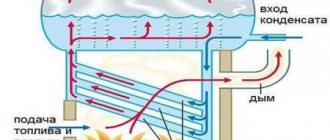

When operating, these devices use two types of heat transfer:

- Radiation, or as professionals call it, radiation accounts for up to 25-30% of heat. It not only heats the air, but is transferred to nearby objects, providing better heating of the room.

- Convection produced by the heating battery ensures constant movement of air masses around the room and accounts for about 75% of the heat transfer.

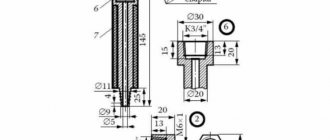

The structure of the cast iron battery, despite all the external changes, remained the same. It consists of sections equipped with:

- plugs;

- locking devices;

- traffic jams;

- shank and thermostat;

- locknuts;

- nipples and gaskets.

No matter how strong cast iron is, even it has its limits. As a rule, the service life of cast iron radiators is 25-30 years, and with proper care and optimal operating conditions they can operate without interruption for 50 to 100 years.

The same cannot be said for the parts that hold the sections together, such as spacers. With frequent water hammer, they can “sway” or crack over time. In this case, a leak appears between the sections of the cast iron battery, which, if not eliminated in time, can cause a serious accident and a threat to human health and life.

To avoid this, you need to check the condition of cast iron radiators after the end of the heating season. In this case, you can detect completely different problems in the heating system.

What breaks most often

Although cast iron is a great conductor of heat, batteries have wide channels which minimize the risk of the battery clogging. In this case, it will heat the room worse. So why might the battery burst?

The radiator is too heavy , if the brackets are installed weakly or not deep enough (and it also happens that they are completely forgotten about and the battery hangs on the pipe), over time it sags under its own weight and tilts.

It would seem that this is not the case, but the slightest deviation is fraught with a decrease in the efficiency of the device. If no one paid attention to this and did not correct it, corrosion appears and leaks begin. Initially, corrosion damage appears as a small brown spot that gets larger.

Many people mistakenly believe that older radiators last much longer and work better, but there are also those who prefer newer models. Both will work properly if they are located no higher than the 6th floor.

Provided the water flow is stable and there are no water hammers, in this case the battery will heat and operate at least on the 10th or 20th floor. Otherwise, a leak may form at the joints . Any hardware store has a lot of sealants that will help correct the situation or prevent it altogether.

Rust on the heating battery what to do

The service life of cast iron heating radiators is so long that residents take their work for granted, so if a leak or fistula appears in the wall of the device, they do not know what to do. It is especially unpleasant if the breakdown occurred in the midst of cold weather, but even in the off-season you cannot leave heating elements unattended. As a rule, preventive maintenance carried out by heating network workers can reveal the presence of contamination or leaks in the device.

In this case, there are simple ways to eliminate a leak in a cast iron heating battery.

Construction of cast iron radiators

This type of heating device consists of sections. Models of the old type, even today, are produced in the form of “accordions”, while the new generation has a flat outer panel, which provides better heating of its entire area.

When operating, these devices use two types of heat transfer:

- Radiation, or as professionals call it, radiation accounts for up to 25-30% of heat. It not only heats the air, but is transferred to nearby objects, providing better heating of the room.

- Convection produced by the heating battery ensures constant movement of air masses around the room and accounts for about 75% of the heat transfer.

The structure of the cast iron battery, despite all the external changes, remained the same. It consists of sections equipped with:

- plugs;

- locking devices;

- traffic jams;

- shank and thermostat;

- locknuts;

- nipples and gaskets.

No matter how strong cast iron is, even it has its limits. As a rule, the service life of cast iron radiators is 25-30 years, and with proper care and optimal operating conditions they can operate without interruption for 50 to 100 years.

The same cannot be said for the parts that hold the sections together, such as spacers. With frequent water hammer, they can “sway” or crack over time. In this case, a leak appears between the sections of the cast iron battery, which, if not eliminated in time, can cause a serious accident and a threat to human health and life.

To avoid this, you need to check the condition of cast iron radiators after the end of the heating season. In this case, you can detect completely different problems in the heating system.

The most common problems and their symptoms

Although cast iron perfectly tolerates the imperfections of the central heating coolant, and the radiators made from it have wide enough channels so that debris does not accumulate in them, problems can arise even with them. And this despite the fact that there is no wear to this metal. The following factors may be to blame for a cast iron battery bursting or a fistula appearing in its walls:

- Everyone knows the heavy weight of radiators made of this metal. If during installation of the structure, insufficiently strong brackets were used, or there were not enough of them, over time it may sag under its own weight and tilt. Even a slight deviation of just a couple of millimeters will reduce the efficiency of the device, and if the distortion is not corrected, then after a few years corrosion will appear in the place where the coolant is missing. At first it will look like a small brown spot, which will grow with each heating season until a fistula forms in its place.

- The reputation of “long-living” is characteristic of both old and new models of cast iron radiators, but provided that they are installed in the contour of an apartment building no higher than six floors. If the heating network is reliable and does not suffer from strong water hammer, then they can be installed in nine-story buildings. Otherwise, under strong water pressure, the cast iron battery may leak at the joints of the sections. In the event that a cast iron battery leaks during the heating season, you need to know in advance how to repair it. Today there are a lot of sealants that will help the device “hold out” until warm days.

- The internal structure of domestic batteries is such that the cast iron from which they are made has roughness that is completely absent in imported analogues. That is why a lot of debris is deposited on the walls over time, which fills the water in the heating network. Suspensions, particles of rust and metals, all settle and make the wide channel so narrow that it is no longer able to easily pass coolant under high pressure. In this case, the structure may burst anywhere, and then you will have to urgently decide how to eliminate the leak in the cast iron battery.

- Nipple gaskets and threads are the weak “link” of heating devices . If cast iron does not have a statute of limitations, then the same cannot be said about the parts that make up the battery. In order not to lead the situation to the point where repair of the cast iron battery is required, the connections must be checked after each heating season and the gaskets on them must be periodically changed.

As practice shows, most often it becomes known that something is wrong with the heating system when repair of cast iron radiators is already required. To find out about a problem in advance, you need to listen for “help signals” that indicate the presence of defects.

The first signs of trouble

There are a number of factors that indicate that something is wrong with the heating circuit or batteries. These include:

- Feeling of coolness in the room. In this case, it is worth asking your neighbors how warm it is in their apartment. If everything is in order, then you can start looking for problems in yourself. The reason may be simple contamination of the channels, misalignment of the device, or the presence of fistulas. In the first case, it is enough to wash the batteries, in the second, fasten or change the brackets and check the correct installation with a building level, and in the third, provide assistance to the “sick” radiator.

- If an incomprehensible coating appears on the battery, visible to the naked eye, then the reason for this is worn out gaskets. You will have to turn off the system, remove the batteries and install new ones, for example, from paronite.

- The leak is immediately noticeable. If it is small, then you can get by with a clamp or cold welding, otherwise you will have to completely change the device.

Source: https://bryanskinfo.ru/2019/11/16/rzhavchina-na-bataree-otoplenija-chto-delat/

DIY repair

The inside of the cast iron is rough; if the radiator is foreign-made, then there are no roughnesses. Due to roughness, debris clings to the walls and settles inside.

If the battery is not cleaned, it will clog and simply burst from the high pressure of water.

If there is a leak at the joint, then a simple bandage and epoxy glue will help to cope with this, coat the joint with glue and soak the bandage with it, then wrap the joint tightly, wait until the glue sets and once again, sparing no glue, coat everything, then you can touch up the place no repairs were visible.

This is a temporary measure; after the heating season ends, it is worth replacing the section.

If a crack has formed , then a bandage and glue will not save the situation; you will need a clamp. It is better to use cold welding, a sealant that is very similar to window putty. Knead it thoroughly and cover the crack with it, after a few minutes everything will set and you can sleep peacefully for another heating season.

All other methods, unfortunately, are useless. Even after such independent repairs, after the end of the heating season, it is worth turning to a specialist for help.

Even the best cold welding is not a guarantee that the leak will not return after some time. Carry out technical inspections and minor repairs in a timely manner and let the radiator serve you faithfully.

Central heating allows you not to worry about the need to light the stove on time, as well as the fact that it is impossible to leave your home for a long time. But it also has its drawbacks. The main one is the invoice that comes every month. Another disadvantage is breakdowns that occur from time to time. This applies to both central highways and points within the house. When a problem occurs in the house, it is important to know what to do if the heating battery is leaking. The causes of the leak and how to eliminate it will be discussed in the article.

Do-it-yourself cleaning of the heating system in a private house

Heat exchangers can be made of cast iron, aluminum and bimetal. The cleaning method largely depends on the type of material.

Cast iron batteries continue to be actively used in the interior as a decorative item. They have become even more massive, have a rough inner surface, which is why they need cleaning more often. During their disassembly, welding equipment may be needed.

Thanks to the alloy of aluminum and steel, the inner surface of bimetallic radiators is least susceptible to corrosion. The relatively light weight allows even one person to cope with their dismantling and cleaning.

When washing bimetallic and aluminum surfaces, do not use caustic acidic or alkaline compounds; their use can lead to severe corrosion.

Otherwise, the process of removing dirt from heat exchangers of different types is the same.

Where is the leak

The entire system consists of heat-transfer devices and wiring, which is represented by pipes. There is also a central riser through which hot water is supplied to the home. Any of the modules can leak. The cause of the leak may be poor-quality assembly, as well as defective material from which the pipes or radiators are made. Knowing this, you can predict where a leak might appear. Among such places are:

- the junction of the outlet pipe with the riser;

- pipe seam;

- leakage between battery sections;

- leak at the pipe inlet to the radiator;

- the appearance of a fistula in the radiator section.

Each type of leak requires its own approach to elimination. In some cases, the same materials may be used.

Features of the use of inhibitors

Specially developed reagents for heating systems have the following features:

- Protect all types of metals from corrosion;

- Reduce the adhesion of water-soluble components;

- Prevents the formation of sediments of insoluble substances in the heating system;

- Designed for use at temperatures above 100 °C;

- The period of effective protection is 5 years;

- The regent should occupy 2 - 2.5% of the total volume of coolant in the heating system. This significantly reduces the cost of protecting heating systems;

- Additives contain volatile substances that, when evaporated from water, create a protective layer on surfaces that do not come into direct contact with the coolant;

- Additives do not contain harmful substances;

- Slows down the development of bacteria and algae.

First actions

Since the reasons why leaks occur, as well as the locations of leaks, are different, there is no one universal rule that would quickly solve the difficulties that have arisen and eliminate the leak. But there is a certain procedure that can be followed when a leak is detected:

- leak localization;

- blocking the water flow;

- maintenance or replacement of the problem area.

Knot near the riser

A leak at the branch point from the riser may occur due to a leaky connection. If it is welded, then the cause of the leak may be a corrosive effect, which intensifies when using the heating system, like zero when unwinding the meter. Another reason for such a leak is the negligence of the craftsman who performed the joint. Also, the problem of leakage may be due to low-quality material that was purchased to save money. Often, a leak appears when the pipes are under high stress, which occurs due to welding work or loads on them with heavy objects.

The simplest way to eliminate a leak in such a place is a metal clamp and a piece of rubber. If such a leak is not uncommon, then you can stock up on a sufficient number of rubber seals in advance to eliminate the leak. They can be cut from an old bicycle inner tube. The sizes can be very different, because you never know where you will have to use this method. The first step is to try to temporarily eliminate the leakage using improvised means. Next, two clamps are loosened and put on the pipe. The cut piece of rubber is placed at the leak site and clamps are placed on it. It is worth clamping them with a screwdriver until the leak stops.

If it becomes clear that in a certain place the pipe wall has become thinner than necessary due to corrosion, then you can use a plaster or cement clamp rather than a rubber clamp to eliminate the leak. This method is also suitable when the leak is due to a crack in the pipe. A small amount of cement and gypsum must be added to warm water. The substances are mixed until a homogeneous mass is formed, but it must have good fluidity. You will need a thick bandage. It must be well soaked in the prepared solution. It is advisable to cut it into pieces of 20 cm. The soaked bandage is wrapped around the damage where there is a leak; this must be done in several layers so that the leak completely disappears.

In some cases, the problem occurs due to a leak directly on the thread. There is no point in delaying the decision to eliminate the leak. It is advisable to take a radical method and cut off the burst part, weld the pipe and cut a new thread. But while waiting for the repair team, you can apply a tourniquet to the leak site. It is done according to the principle of the previous one, but before soaking it in the cement mixture, you need to moisten the bandage with water and sprinkle it with salt.

How to flush a heating radiator at home

It must be emphasized that cleaning the batteries should be done at the end of the heating season.

Scheme of chemical flushing of the heating system.

To wash the heating battery yourself, you need to drain the water from the heating system and dismantle the radiator. Washing is carried out with mixtures of caustic soda, acetic acid, whey, and also using household chemicals.

Radiator cleaning is done at home in the bathroom. In order not to destroy the enamel of the bathtub, thick rags are lined on its bottom, and a mesh is placed in the drain hole so that large contaminants do not seep into the drain.

Flushing the cooling system.

Flushing the cooling system on a Priora car. The dude mixed 2 antifreezes and ended up with an “explosive mixture”...

Cleaning the cooling system from RUST.

This video shows how to clean the cooling system from rust.

after long-term operation of the motor on water.

All plugs must be removed from metal batteries, and hot water . After the first fill, the radiator must be shaken and the water and debris must be drained. Pour water a second time, but with the addition of a cleaning agent: soda ash or caustic soda, whey, vinegar. Vinegar essence with a concentration of 70% is used in the entire bottle for one radiator.

After pouring this solution, the plugs should be closed and the device should be left for at least 1 hour. After the time has passed, the battery must be shaken well and tapped with a wooden hammer so that the remaining rust and plaque are separated from its inner surface. The solution is drained and clean water is added again. Flushing with water is carried out so many times until clean water flows out of the battery. It is also important to thoroughly rinse the radiator cavity because residual lactic or acetic acid can cause the formation of rust.

Radiator cleaning diagram.

As a cleaning agent for a heating device, you can use a car radiator cleaner. To do this, pour hot water with the addition of this liquid. Only a few grams of radiator cleaner should be added, strictly following the instructions on the package.

After closing the holes, the battery should be turned over and shaken every 10 minutes. After two to three hours, the water with the chemical composition is drained and the radiator is washed with plenty of water.

As a cleaning agent, you can use cleaning compounds for sewer pipes, for example, “Mole”.

Radiator sections

Although old cast iron radiators are the best option for central heating, they are often the cause of leaks. One of them may be water leakage in the place where the fins connect to each other. It is not always clear where the hole appeared due to pressure. Often water completely covers the battery. To identify the area where there is a leak, you need to completely turn off the water with the taps and wait until the pressure drops through the hole or release it with the Mayevsky tap. When the water stops flowing, you need to wipe the batteries dry and try to determine where the leak occurred. If the cast iron battery has leaked at the junction of the sections, then using cold welding would be an excellent solution.

Usually this substance is two-component and is sold in small tubes. At its core, cold welding is an epoxy resin with metal powder additives. Before using it, it is necessary to clean and degrease the area where the leak is noticed. It is important to remove not only rust, but also paint from the leak site; it is better to make small indentations on each side so that the interaction area is large. The leak area can be cleaned using a knife sharpening stone. Cold welding usually indicates the method of its use, but some types are not suitable for use with water, because when exposed to it, polymerization is impossible.

Methods for repairing cast iron radiators

There are several methods that allow batteries to last not only until the end of the heating season, but also for a couple of years. These include:

- If there is a leak at the junction of sections, it can be quickly eliminated using a bandage and epoxy glue. The material is impregnated with glue and wound around the leak. After it sets, you can paint this place to match the battery, but the main thing to remember is that such an “operation” is considered temporary, and it is better to buy and install a new section after the cold weather ends.

- If a fistula or crack is detected, a clamp will be required. You can buy it at a building materials store, or you can make it yourself from rubber or tin.

- Cold welding for cast iron batteries is the best way to quickly eliminate a defect. This is a special sealant that looks like children's plasticine. It must be thoroughly kneaded and applied to the damaged area. The product sets quickly, is resistant to temperature changes and is quite suitable for quick and temporary repair of a cast iron battery.

Knowing how to weld a cast iron battery using a welding machine with an inverter circuit, you can save the device from leaks for quite a long time.

Battery input

One of the problem areas where leaks often occur is the junction of the battery with the pipe from the riser. Typically, the appearance of such a leak is not caused by damage to the area, but by a leaky seal on the thread. To eliminate such a leak in the heating battery, it is necessary to close the riser as quickly as possible. After this, the pressure in the battery is reduced using a Mayevsky tap or another method. Using an adjustable wrench, unscrew the nut or coupling that makes the connection. Next, the rust at the leak site is cleaned, and the old sealant in the form of flax fiber is removed.

In case of such leak repair work, it is advisable to acquire a new nut or coupling. If they have been used for a long time and have not been changed, then they can easily burst while eliminating the leak. When the threads on a pipe are damaged, you can use a die to fix them. Several turns of tow are wound around the joint and it is covered with Unipak paste. After these steps, the assembly is reassembled and the supply tap is gradually opened. This will allow you to timely determine whether the leak has been completely eliminated.

Sequence of actions

There is no single rule here, and therefore each person has his own point of view on how to properly wash a radiator.

But as practice shows, you can first clean it from accumulated dust, and if the radiator is located in the kitchen, then from greasy film. After removing the battery and carrying out the necessary work inside it, you should simply correct the places where stains remain, and then pour water on top. After this, it is left for the necessary time to dry.

How to remove dust from the outside of a radiator using the dry method

There are two ways to clean the outside of the battery from dust without water:

- using a vacuum cleaner;

- using a hair dryer.

The first method is to use a vacuum cleaner. If the radiator fins are located close to each other, or, even worse, there are plates between them, then you should work with this technique with nozzles. Among them there are small ones, they are specially adapted for small crevices and hard-to-reach places.

The second way to clean the battery is to place a large damp cloth between it and the wall, leveled over the area of the wall. Then blow out all the dust between the ribs. It flies towards the wet material and sticks to it. At the end of the procedure, carefully remove this rag and rinse.

These options for removing dust from batteries are suitable for weekly cleaning, but for general cleaning, the radiator should be washed more thoroughly.

How to properly wash the battery?

Many housewives want to know how to quickly and efficiently wash the battery. To answer, you need to know the degree of its contamination.

It may be lightly soiled with dust. In this case, in addition to dry cleaning, you can wash with plain water. The best option would be boiling water, because at high temperatures the liquid has increased activity and you can get better results.

To carry out the washing procedure, you need to prepare. To do this, stock up on containers into which water, rags and boiling water should eventually flow. You should place a rectangular dish under the radiator so that it sits organically near the wall, under the radiator. They begin to carefully pour boiling water over the top of the radiator; it will flow into the prepared dishes and take the dust with it.

A good answer to the question of how to wash the battery inside between the ribs is to use a steam mop. Before starting the process, spread cotton rags so that moisture is well absorbed. Hot steam does the job easily.

In case of severe contamination of radiators, “heavy artillery” is prepared. These are detergents with sprayers and various brush configurations (with fancy bends). Housewives begin their work by moistening the battery, and then they spray household chemicals over its area. After this, leave the radiator for a while so that the product does its job. Then wash with warm water and brushes.

Fistula in the rib of the battery

This type of leak can be considered one of the most unpleasant, since it requires significant effort to eliminate. But temporarily, you can use a simple method to eliminate such a leak. If the hole where the leak came from is small, then you will need to enlarge it a little. For these purposes, the water is completely shut off and the pressure in the batteries is reduced. After this, using a small drill, the hole is slightly drilled out. This is done in order to insert a peg into the hole from which water is leaking. It can be cut from a small wooden block. It will swell with water and plug the leak well.

Consequences of clogging

Regardless of the source of the blockage in the heating pipe, the outcome is almost always the same:

- after a certain point the pipes become clogged;

- the movement of water in the pipes decreases and later even the water pump will not be able to pump water through this system.

The situation is much worse with thermosyphon heating, where there is no such pump. As a rule, once clogged, heat is not allowed to pass through and the pipes remain cold. And this is only part of the problem. In addition, the boiler itself begins to heat up very much, which can lead to its breakdown.

Some owners carry out annual cleaning of blockages in such a system by changing the water. In other words, the old unclean, rusty water is drained and filled with new water. And this is reasonable, because when the old water is drained, a small amount of chips and rust leaves it. But there is also the opposite side. For rust to occur, iron and oxygen are required. If the pipe is metal, then there is always iron in it, but oxygen is contained in the water. As a rule, when you do not change the fluid in the heating system for a long time, the oxygen content in it decreases significantly, which means that the rusting process stops. With a constant change of water, on the contrary, it is activated. To summarize, we can say one thing - this method helps to get rid of a small amount of rust, but, on the other hand, we only accelerate the new process of its formation.

Scheduled Maintenance

All of the above methods are mostly used in winter, when something urgently needs to be done. During the warm period of the year, you can carry out scheduled maintenance of risers and batteries so that leaks do not occur in winter. The battery is completely removed from its place and unrolled into sections. All threaded connections are cleaned of old sealant. If necessary, nipples are replaced with new ones. Intersectional gaskets are also completely replaceable. The detected fistulas are welded or sealed, and the battery is installed in its place. In the video below you can see other ways to eliminate leaks.

Selection and recommendations for using an inhibitor for a heating system

This or that inhibitor must be selected based on several indicators:

- An open or closed type expansion tank is used;

- Type of construction materials used: ferrous metals, alloys based on copper or aluminum;

- Water pH indicator;

- Indicators of water “hardness” (the amount of dissolved salts in the coolant).

Depending on the hardness and acidity of the coolant, as well as the characteristics of the heating system, it is necessary to select an inhibitor of a certain composition. The following additive compositions are distinguished:

- Orthophosphate. The reagent forms a protective film and causes the precipitation of salts in large quantities. It is necessary to add to the coolant based on the proportion of 10 - 20 mg/l. Used in heating systems where the elements are made of ferrous metals and the pH level of the water is less than 7.5 units. A chlorine concentration in water of 300 mg/l or more neutralizes the effectiveness of orthophosphate and leads to metal corrosion. Can be used in combination with a zinc polyphosphate or phosphate additive;

- Polyphosphates. Used to protect pipelines made of ferrous metals with water Ph in the range of up to 7.5 units. When using polyphosphate, water softening is not required. The amount of chlorine also does not affect the properties of this inhibitor. The effectiveness of polyphosphates is increased with the help of zinc. The optimal amount is 10 - 20 mg/l;

- Phosphonates. Use only in combination with zinc, orthophosphates or polyphosphates. The composition will be effective at a concentration of 10 - 20 mg/l and at Ph 7 - 9. Protection of ferrous metals is ensured by the addition of calcium;

- Molybdate The reagent protects ferrous and aluminum alloys. It is necessary to add to the coolant at the rate of 75 - 150 mg/l; in order to reduce the amount of the composition without reducing efficiency, the addition of phosphorus components is required. Recommended pH of water is 5.5 - 8.5. Hard water causes molybdate to precipitate. Chlorine and sulfur impurities neutralize the use of molybdate, but without the occurrence of pitting corrosion;

- Silicate. Used for soft water at a concentration of 10 – 20 mg/l. Provides protection for systems made of ferrous metals and copper alloys with water having a Ph 7 or higher. A protective coating forms on surfaces over several weeks;

- Zinc. It is used as an additive to other additives: orthophosphates, polyphosphates, phosphonates, molybdates. And also with combinations of inhibitors that do not contain zinc: orthophosphate/polyphosphate, orthophosphate/molybdate, a mixture of phosphonates in an amount of 0.5 - 2 mg/l. Zinc strengthens the protective film and allows you to reduce the amount of the main inhibitor. If the pH of the water exceeds 7.5, it is necessary to use zinc stabilizers;

- Benzotriazole. The required concentration is 1 - 2 mg/l in water with Ph 6 - 9 to protect copper alloys;

- Tolytriazole. Benzotriazole analogue;

- Calcium orthophosphate. Used to eliminate the adhesion of calcium phosphate deposits. The content of calcium orthophosphate in water should be 10-15 mg/l;

- Polyacrylates, polymaleates, hydrolyzed polyacrylamides and acrylate substances. Used for biological contamination. The optimal concentration is 2-3 mg/l;

- Chlorine and bromine are used to destroy microorganisms. A concentration of 0.1 - 0.5 mg/l is sufficient. Chlorine is effective only in water with a pH below 8. If the pH exceeds this value, bromine is used;

- Zeolites. Used to soften water;

- Nitrite. Used in closed systems, it causes the formation of a stable film of iron oxide on the surface. Effective in concentrations of 250-1000 mg/l and increasing Ph to 9 - 9.5 by adding borax. The amount of nitrite can be reduced to 300 mg/l if molybdate is used in the same amount. Nitrites can be decomposed by bacteria, so in combination it is also necessary to use a non-oxidizing bactericide, copper corrosion inhibitors and a polymer dispersant;

- Alkalis (caustic soda, ash). Used to increase the pH of water to 9 - 10.5 units.