Today, increasingly, plumbing and heating systems are made not from steel pipes, but from polypropylene. But this is plastic, and the question arises - what is the maximum temperature that a polypropylene pipe can withstand?

Let's look at this issue in more detail. Let's consider the properties of polypropylene material. Let's get acquainted with the types of polypropylene pipes and their characteristics. We’ll also talk about the temperatures that this pipeline can withstand, and the features of its use in hot water supply lines.

Properties of polypropylene

Polypropylene is a synthetic polymer product in the form of a white powder; a profile is made from it by melting or pressing. This is the hardest and most resistant type of plastic, not subject to corrosion.

The main physical properties of polypropylene are durability, reliability, wear resistance, and resistance to high temperatures. It is not susceptible to the action of chemicals, salts and alkaline solutions, so these substances in water are not dangerous for this pipeline.

Polypropylene products:

- weigh less than steel;

- do not emit substances harmful to health - suitable for installation in domestic premises;

- the inner surface is smooth, which does not allow scale deposits;

- the level of thermal conductivity is low;

- good sound insulation;

- high electrical insulation;

- heat capacity index 2.0 kJ/(kg.°C);

- permissible temperature level -15 - +120;

- density value – 0.92 kg/cm³.

Polypropylene softens at +140 degrees, and the melting point is +175 - this is the temperature of steam.

This factor makes a polypropylene pipeline suitable for cold or hot water supply (especially reinforced ones) , where the temperature of the coolant is kept at +95, but it cannot be used as a steam pipe.

When heated, polypropylene becomes soft, and after cooling, all its physical properties return to it, and it becomes hard again, so assembling a water main from these products is appropriate, and the process of connecting pipeline elements is quite simple. It is enough to heat its ends and join them; it is also possible to connect them with couplings.

The main disadvantage of polypropylene is its plasticity. When heated, the product softens and can be easily bent. But when such a profile is bent, the internal diameter decreases significantly and the throughput level decreases.

In addition, this material is afraid of light; the product may lose its shine, crack, or fade. To avoid this, various components are added to polypropylene.

It is worth noting that polypropylene does not tolerate frost well; it becomes brittle at temperatures ranging from minus 5 to 15 degrees. This material deficiency can also be eliminated by adding ethylene or ethylpropylene rubber.

The standard pressure indicator for polypropylene products is 30 kg per 1 cm2. But according to manufacturers’ recommendations, it should not exceed 10 kg.

Types of polypropylene pipes

Polypropylene pipes are divided into two main types: reinforced or unreinforced . They are also divided according to their layout and material of manufacture. If the product has a blue stripe, then it is recommended for cold water supply, and a red one for hot water supply.

Products made of polypropylene of any type are marked with the letters PN. The number next to the abbreviation PN affects the cost, and accordingly, the larger it is, the higher the price.

Polypropylene and Heating? It makes sense?

unreinforced

The purpose of non-reinforced types is cold water lines. They are not suitable for hot water supply, since when heated, the pipeline can lengthen - every 10 meters by 150 mm, which will cause it to rupture. Although, in low-temperature structures, installation of unreinforced models is possible, but only if the pressure is not high.

Such types have increased flexibility, ductility and low cost. Conventional profiles are easy to install, since the connection areas with the fitting are free of obstacles.

The following markings are placed on polypropylene products, which indicate the permissible maximum temperature:

- PN 10 - permissible temperature + 45 (for floor heating) and + 20 (for water supply), pressure 1 MPa. Wall thickness - 10 mm, diameter - from 20 to 110 mm.

- PN 16 - permitted pressure 1.6 MPa, temperature value + 60. Wall thickness from 3.4 mm.

- PN 20 - permissible pressure of 2 MPa, at a temperature of + 80 degrees. Wall thickness 16 - 18.4 mm.

The service life of unreinforced mains when used in cold water supply reaches 50 years, 30 years if heated coolant moves through them.

Reinforced

Reinforcement - the presence of an additional aluminum or fiberglass layer. This material makes the product stronger, increases its service life, even in the presence of hot coolant, the profile will last up to 50 years.

In addition, reinforcement allows the use of this pipeline with water heated to + 120 degrees, without the risk that linear expansion will occur, with further rupture of the line.

The purpose of models with reinforcement is hot water supply with high pressure. This type:

- more resistant to chemicals;

- its expansion coefficient is 5 times lower than the usual profile;

- ability to withstand high temperatures and maximum loads.

According to the reinforcement material, profiles are:

- With an aluminum layer - these models have a high operating pressure level, so they are suitable for central heating and hot water. The aluminum layer reduces the degree of thermal deformation and oxygen diffusion.

Installation of an aluminum-reinforced profile is difficult, since contact of the aluminum layer with water is not allowed. Therefore, the joints must be cleared of a few centimeters of the reinforcing coating.

- Fiberglass reinforced - have a low level of expansion. Fiberglass fiber reduces deformation when heated. Compared to aluminum models, such products have a lower heating pressure, so they are less in demand.

The installation process of this type is simpler, because no stripping is required. Fiber fibers are connected to each other with molten polyethylene, and there is no delamination of the material.

- Pipes reinforced with basalt fiber. This type has a lot of advantages, compared not only with any reinforced models, but also with profiles made of plastic and metal. It is easier to install compared to aluminum coating, since there is no need to strip it. Basalt products are easily connected to any types of polypropylene fittings.

Reinforced pipes are marked PN 20 and PN 25. They are able to withstand temperatures of + 95 and pressures of up to 2.5 MPa.

But not all reinforced products are able to withstand higher degrees of heating. For example, aluminum ones cannot withstand the temperature that a fiberglass-reinforced polypropylene pipe can withstand - + 120 (although also not for a long time).

What temperature can a polypropylene pipe withstand according to the table?

The thermoplasticity of polypropylene is a factor limiting the scope of its operation. When heated to a certain temperature, it begins to gradually transition into a softened state. In this regard, the question becomes relevant: what temperature can polypropylene pipes withstand, and whether they can even be used to supply hot water.

A good example

As an example, consider a simple case. In regions located in Siberia, the Far East and the European north of the Russian Federation, in winter frosts can reach 35-40 or more degrees below zero.

Heat losses from buildings at such times are very significant, and to compensate for them, boiler houses and thermal power plants increase the supply temperature to 110-130°C. And to prevent water from boiling in the system, the pressure increases to several tens of atmospheres.

Under such conditions, water does not go into a vapor state.

Upon entering the house, due to losses of thermal energy along the way, the water temperature already drops to +70...75 degrees established by GOST, but the pressure in the system continues to remain elevated.

As a result, there is an increased likelihood of rupture of a polypropylene pipe, since its plasticity increases when heated. Therefore, it is not advisable to use polypropylene for heating systems for this reason.

However, modern industry produces polypropylene pipes intended for hot water supply, but they also have their operational limitations.

Temperature table for PP pipe markings

On the domestic building materials market you can find several types of polypropylene pipes. They differ in markings and colors.

The color scheme usually includes four primary colors - white (the most common), green, gray and black. Black PP have increased resistance to ultraviolet solar radiation.

The remaining types of colors do not have any technological function, being purely decorative.

Another thing is the marking of PP pipes. It carries a direct information load, indicating by what technology and using what types of polypropylene this product was produced. The technical and operational characteristics of the pipe directly depend on this.

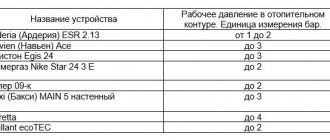

The table below shows the markings found on our market, operating pressure and maximum temperature:

| Marking | Purpose | Max. working to | Operating pressure in the system (atm.) |

| PN-10 | Cold water supply | +40 оС | 10,2 |

| PN-16 | Universal | +60 оС | 16,3 |

| PN-20 | Universal | +95 оС | 20,4 |

| PN-25 | Hot water supply | +95 оС | 25,5 |

When choosing a material for pipeline installation, it should also be taken into account that exceeding the operating parameters established by the manufacturer leads to a reduction in the service life of the pipe.

Conclusion

Polypropylene (general designation - PP) is today the most common material for the manufacture of water pipes. This “popularity” is due to a number of factors:

- Low cost, which allows significant savings when installing a water supply system.

- Easy soldering, making it possible to do the installation yourself.

- Long service life, reaching over 50 years.

But the main property of polypropylene, which distinguishes it from many other polymers, is excellent thermoplasticity.

That is, when heated, this material can easily transform into a soft state, and when cooled, it can harden again.

Thanks to this, the simplicity of assembling water supply systems from PP pipes is achieved: the ends of the parts are simply heated and connected to each other using special couplings, or by direct joining.

As you can see, PPR pipes are best suited for cold water supply. But if necessary, they can also be used for hot water. In this case, attention should be paid to the marking, since the maximum operating temperature of polypropylene pipes directly depends on their production technology.

Source: https://vodatyt.ru/plastikovye-truby/maksimalnaya-temperatura.html

Marking

In addition to the PN marking, which indicates temperature and pressure, all plastic pipes have:

- the word "pipe";

- abbreviated name of the material;

- SDR - the value of the ratio of the external size to the thickness of the walls;

- external profile size;

- operational class;

- working pressure limit;

- Standart room.

For example:

Pipe PP-R SDR 11-20´ 1.9 class 1/1.0 MPa GOST R 52134-2003, where:

- random polypropylene profile – copolymer SDR 11;

- outer diameter 20 mm;

- wall thickness 1.9;

- class 1;

- permissible pressure 1 MPa.

According to their structure, profiles are divided into:

- S - single-layer;

- M - multilayer;

- TI - with a thermal insulation layer;

- PP - standard;

- PP-RP - high pressure resistant.

By type of material there are:

- PPB - they have high strength, their purpose is floor heating with hot coolant;

- PPH - have an increased internal diameter, mounted on ventilation systems and cold water;

- PPR is a universal type that can withstand elevated temperatures.

By class they are divided into:

- class 1 - up to +60 C, intended for water supply;

- 2 - up to +70 (pipelines);

- 3 - + 60 (warm floors);

- 4 - +70 C, used for heating;

- 5 - + 90 (heating);

- class XB - for cold water supply.

Some manufacturers put a trademark on their products.

Temperature table

For clarity, we have presented a table of temperatures that polypropylene pipes can withstand.

| View | Purpose | Maximum temperature level | Working pressure (atm) |

| PN 10 | Cold water supply | +40 C | 10,2 |

| PN 16 | Universal model | +60 | 16,3 |

| PN 20 | Universal | +80 – 95 | 20,4 |

| PN 25 | Hot water | +95 – 120 | 25,5 |

Features of use in a heating system

Destruction temperature of polypropylene pipes.

Today, polypropylene profiles are increasingly installed both in central heating systems and are used to heat private buildings. They do not deform, do not allow oxygen to pass through, are able to withstand sub-zero temperatures and, as a result, freezing of water in the main does not cause damage to the system as a whole.

To the question of which polypropylene pipe for heating is best to purchase, you can give a clear answer - you need to take a pipe that can withstand a maximum temperature of +60 - +95 C. The most suitable models are PN 20 with a heating degree of +60 or PN 25 - +95.

When choosing polypropylene profiles for heating, in addition to temperature, you should consider that:

- Plastic products are rigid and difficult to bend. To turn the highway, you need to install an angle, which is not very convenient.

- The cross-section of the pipes must correspond to the size of the risers to which they will be connected. In a private house, the central wiring is made from a profile with a cross-section of 32 mm, the connection to the batteries is made with pipes measuring 20 - 25 mm.

- PP pipe fittings have a large cross-section, which worsens the appearance of the system.

- Polypropylene stretches when heated, this leads to thinning of the walls and sagging of the pipeline, which looks unsightly when installed openly.

When installing a plastic pipeline, it is important not to overheat it, as this will lead to a decrease in the passage when inserting it into the fitting. This error significantly reduces the efficiency of the system.

In addition, polypropylene products are not recommended for piping boilers. In the boiler room there is a frequent change in temperature, which is contraindicated for this profile.

If you take into account all the above points, then polypropylene types with a maximum temperature of +95 are quite suitable for heating.

What temperature limit can a polypropylene pipeline withstand?

The popularity of polypropylene pipes for use in the laying and installation of water supply and heating networks has grown significantly in recent years. The reliability and durability of the system is perhaps the main criterion when choosing pipes from this material. However, the question of what temperature this material can withstand in heating systems deserves a separate discussion.

Physical properties of polypropylene

Polypropylene is polymerized propylene gas. Appearance: White uncolored powder. Of all plastics, it is the least dense and the hardest, which means it is wear-resistant. All types of polypropylene are practically not subject to corrosion cracking.

Due to the properties of physical reliability: durability and temperature stability, polypropylene is actively used in the mass industrial production of pipes.

Pressure and temperature

The manufacturer determines the service life of a polypropylene pipe to be 50 years. The pressure level and temperature of the working environment are important indicators on which the durability and reliability of polypropylene pipes depends.

The higher t, the lower the pressure level should be. The permissible pressure for operating a PP pipe is 30 kg/cm2, but such indicators at high pressure can be critical. In polypropylene pipes, the operating pressure level should still not exceed 10 kg/cm2.

Important! Ideal conditions for PP pipes to serve as long as possible are that the temperature of the liquid should not be higher than 70° at a pressure of 4-6 atmospheres.

Why do you need pipe reinforcement?

To ensure a sufficient level of heat in apartments, it is necessary to turn on the return pipeline and increase the water temperature to 10 ° C. At close operating temperatures, simple polypropylene pipes begin to lose their properties and, in addition, a linear expansion of their dimensions is possible.

This is especially important when laying pipelines with high temperatures in a concrete screed. There is a possibility of concrete cracking and breakdown of the entire heating system. To reduce this effect and completely eliminate it, polypropylene pipes are reinforced.

Reinforcement is the strengthening of the load-bearing capacity of the base material of a product with another material that has a higher level of strength. This increases the ability to withstand temperature changes. Reinforced pipes fully comply with the standards of the heating system, and do not deform when it increases significantly.

The following materials are used to reinforce polypropylene pipes:

- aluminum foil applied to the surface;

- fiberglass inner layer;

- inner layer combining fiber and glass fibers.

the inner layer of aluminum located along the entire diameter of the pipe, closer to the outer surface;

Aluminum and fiberglass cost about the same. The price mainly depends on the parameters of the pipe itself and the manufacturer. Nevertheless, fiberglass reinforcement has a number of advantages over aluminum:

- no cleaning of the pipe edge is required during installation;

- short time for soldering joints (as with unreinforced pipes);

- there is no internal delamination due to the fusion of glass fiber into polypropylene;

- the strength of the product increases.

There is only one drawback of fiberglass - the linear thermal expansion of pipes reinforced with glass fiber is 6% higher than that of pipes reinforced with aluminum.

The use of polypropylene pipes in the heating system

In municipal and private heating systems, the most popular are reinforced polypropylene pipes PN20 (working temperature - 60°) and PN25 (working temperature - 95°).

Their increase in price due to reinforcement compared to solid polypropylene pipes is not so great in comparison with their service life and quality. When replacing an old and probably rusty water supply system, the question of choosing between metal and plastic is practically no longer an issue.

The main thing is to choose the right type of polypropylene pipe in accordance with its purpose: hot or cold water supply; heating and temperature variation in winter and summer at the installation site; requirements of building codes and regulations.

And don’t forget about checking the quality of the pipe. It should not have visible inclusions, bubbles or delaminations.

Source: https://InfoTruby.ru/polipropilenovye/maksimalnaya-temperatura

Application of polypropylene pipes in hot water supply

When installing a hot water line, you must remember that polypropylene pipes have a high expansion coefficient when heated. If the heating level of the coolant increases by 10 degrees, then the polypropylene pipeline increases by 1.25 mm per meter. When using reinforced - 0.32 mm/m.

The heating temperature of the coolant supplied to individual consumers ranges from + 45 to 75 degrees. Based on this, in order to ensure uninterrupted supply of such systems, it is recommended to install reinforced polypropylene pipes of grade PN 20 or 25, with a pressure of 2 to 2.5 MPa.

Polypropylene, a common material in the production of water pipes. With the right model, and if you follow all the recommendations for using polyethylene pipes, they will serve you for decades.

Testing polypropylene ch1

What temperature can polypropylene pipes withstand? Let’s look at them

The maximum coolant temperature for polypropylene pipes is 950C Celsius. At 1400C this material is easily deformed due to its softness. There is a risk of rupture. If the heating reaches 2000C, the material begins to melt.

Since the heating of hot water in the heating system of most apartments and houses does not exceed 900C, these products are quite suitable for use. However, they are made from different components, so not every model can withstand even 600C. Also, special requirements are imposed on products used in the “warm floor” system.

Is it possible to use polypropylene at temperatures above normal? Experts give a negative answer. Yes, the material can withstand a short-term jump, but this temperature should not be constant. Otherwise, the service life of the data is reduced significantly. A model designed for 50 years of use will barely last a year at twice the normal rate.

Dependence of pressure and temperature

An important parameter is not only temperature, but also pressure. The limit parameter is 30 kilograms per square centimeter. However, the manufacturer recommends not exceeding pressure over 10 kilograms.

What temperature can polypropylene pipes for hot water with average characteristics withstand? For the longest possible service life, it is recommended that the heating of the liquid does not exceed 700C and the pressure does not exceed 6 atmospheres.

When choosing pipes for cold or hot water supply, it is important to check the quality of the material. The product must not have:

- Bundles.

- Interspersed.

- Bubbles.

Otherwise, the service life will not correspond to that declared by the manufacturer.

Temperature and marking

You can find out what temperature the products can withstand by looking at the markings:

- PN 10. This model is perfect for cold liquids. Polypropylene pipes and RTP fittings for internal sewerage and water supply are designed for temperatures up to 450C.

- PN 16. Can be used both for cold coolant and for supplying liquid to the heating system. Water heating can reach 600C.

- PN 20. Water temperature can range from 0 to 800C. This characteristic allows them to be used for heating systems.

- PN 25. A distinctive feature is reinforcement, due to which the model is able to withstand high pressure and temperature. The product marked PN25 can withstand heating up to 950C. Reinforcement can be done with several materials (more on this a little later).

Important! It is worth knowing that there is a direct relationship between price and labeling. The higher the number after PN, the more expensive the product will be. Therefore, it is not necessary to purchase pipes marked higher than PN10 for cold water supply and sewerage. But for heating systems you should choose PN16, 20 or 25 products.

What does reinforcement affect?

In order to obtain good heating of the room, a return pipeline is installed in the apartment and the water heating is increased by 100C. As heating increases, the material loses its properties and expands in diameter. If the temperature rises significantly, the product may burst. This is especially dangerous when installing communications in a concrete screed. It leads to:

- Cracking of concrete.

- Heating system leaks.

In order to reduce the expansion coefficient, manufacturers reinforce pipes - they enhance the load-bearing capacity of polypropylene with another material:

- Aluminum foil, which is applied to the outer surface.

- Aluminum, which is located inside the product, closer to the outside (in particular, Valtec PP-ALUX pipes).

- Fiberglass (for example, Valtec PP-Fiber pipes).

- A composition of fiber and glass fiber.

In addition to reducing thermal expansion, reinforcement helps maintain the strength of the material during significant heating. Even if the liquid heats up to 1200C, the product will not burst, as will happen with non-reinforced analogues.

Experts recommend choosing products reinforced with fiberglass. At the same cost, such models have a number of advantages:

- No edge cleaning required before installation.

- They have a short soldering time (same as non-reinforced analogues).

- There is no internal delamination of the material.

Polypropylene pipes with fiberglass comply with the PN25 marking, and therefore can withstand temperatures up to 950C while maintaining their thickness. The critical temperature for such products is 1200C. The material can withstand short-term heating, but with constant exposure, the product’s lifespan is significantly reduced.

Let's sum it up

We found out that products for cold water supply are designed for temperatures up to +450C, for hot water – from 60 to 950C. When choosing communications for your home, it is important to consider several characteristics:

- Type of water supply (cold/hot).

- Temperature difference in the apartment in winter and summer at the place where communications are installed.

- Heating type and building code requirements.

Knowing these parameters, you can choose the most suitable type for a particular case without overpaying for a more expensive option.

Source: https://santl.ru/kakuyu-temperaturu-vyderzhivayut-pp-truby/