Here you will learn:

- Design and operating principle

- How the design works

- Advantages and disadvantages of coaxial chimneys

- Kinds

- Which gas boilers do they use a coaxial pipe on?

- Regulatory requirements for installing a coaxial chimney

- Mounting options

- We carry out the installation

- Popular manufacturers of coaxial chimneys

Understanding the question of what a coaxial chimney is is simple at first glance, but in fact it is a rather complex design in terms of technology. However, having certain knowledge and rules of installation and installation, you can install it yourself, the main condition is to adhere to accepted norms and rules.

In simple terms, a coaxial chimney for a gas boiler is a “pipe within a pipe.” Often, such devices are used in closed chambers, heaters, and the like. The main feature of this design is its technical ease of assembly, because each element is a separate puzzle, which is assembled from several component blocks. The parts are inserted into each other and held there by jumpers pre-provided by the manufacturer, so-called “blind” locks. They do not allow the parts to interact directly, there are no shocks, movements, or sliding of parts.

Design and operating principle

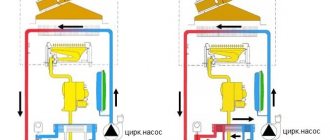

The name itself means “double channel”. This refers to two pipes of different diameters, with one being inserted inside the second. At its core, the device of a coaxial chimney for a gas boiler is a set of a pair of pipes nested one inside the other - a narrow one inside a wide one. In order for their central axes to coincide with each other, their surfaces are connected by jumpers that hold them in the desired position.

The internal circuit with a diameter of 60 mm is designed to remove combustion products. Through the outer one, with a diameter of 100 mm, an air supply is provided, called the “inlet”. The supply of oxygen is necessary for maximum fuel combustion, which significantly increases the efficiency of the boiler and reduces harmful emissions into the atmosphere.

How the design works

Air masses from the street enter inside through a larger diameter pipe. Passing through the external channel, they absorb heat from the internal channel, which serves to remove exhaust gases. The movement of air of different quality and temperature occurs in different directions. It enters the combustion chamber already hot, no additional energy is wasted on heating it, which significantly increases efficiency. At the same time, gas consumption per unit time decreases, making heating equipment much more economical.

Heating from the inside, the air from the outer channel simultaneously cools it, preventing overheating. This feature, firstly, ensures a long service life, and secondly, makes it possible to install it even in a wooden house without any additional protection: in good condition it is not at all fire hazardous. But nevertheless, it is often additionally thermally insulated with basalt insulation, as this significantly improves traction and efficiency.

Advantages and disadvantages of coaxial chimneys

Such systems for supplying air and removing combustion products have now gained wide popularity. This is easily explained by the many advantages of such a scheme:

- First of all, the advantage is that the air necessary for the combustion of “blue fuel” is taken not from the room, but from the street. This circumstance greatly simplifies the organization of general ventilation - no calculations are required for additional inflow, there is no need to resort to frequent ventilation or organize other ways of bringing in air from the street. This is especially important for those cases when the boiler is installed in the “living area” of a house or apartment, for example, in the kitchen. In frosty weather there will be no unnecessary influx of cold into the premises.

- In principle, combustion products cannot enter the room - they are immediately discharged from the closed chamber to the street.

- The air taken from the street receives very noticeable heating from the internal pipe, through which waste products flow in a counter flow. And this is important for uniform and complete combustion of gas, for maximum boiler efficiency. In addition, complete combustion of gas ensures minimal emissions of substances that can cause air pollution. On the contrary, combustion products are effectively cooled, which significantly increases the fire safety of the system. The likelihood of ignition of soot particles, which can accumulate in the pipe over time, is sharply reduced. And at the outlet the gases no longer have a dangerous temperature.

- The outer surface of the coaxial pipe does not heat up to too high temperatures. And this is a big “plus” in the sense that the requirements for organizing safe passage through walls (floors, roofs) are significantly reduced. No other type of chimney, including sandwich pipes, allows such “liberty”.

Even through a wooden wall, you can lay a coaxial chimney without cutting out a huge window for a fireproof penetration.

- Installation of a coaxial combustion product exhaust system will not involve large-scale construction and installation work, as usually happens when installing “classic” vertical chimneys.

- The installation itself is quite simple and intuitive. Any kit is always accompanied by detailed instructions. So in many cases it is quite possible to carry out the installation work yourself.

- There is a wide range of coaxial chimney kits on sale, and therefore it is possible to select the desired system for a boiler of a certain model. As a rule, it is purchased immediately along with the heating equipment. And for any system, the assortment includes the necessary additional parts - tees, 90 or 45 degree bends, condensate collectors, inspection chambers, cuffs, clamps, fasteners, etc. That is, there are no problems with acquisition.

The main disadvantage of coaxial chimneys is the abundant formation of condensation, which is inevitable at the border of distinctly hot and cold gas flows. And as a result, ice freezes at the tip in severe frosts. And this, in turn, is fraught with failure not only of the combustion product removal system itself, but even of the heating unit.

In severe frosts, despite the very hot exhaust, ice build-up may form on the pipe of the coaxial chimney. This phenomenon must be combated so as not to “ruin” the entire system.

This drawback is often attributed to the fact that coaxial chimneys were originally developed for European countries with much more benign climatic conditions than in Russia. In an effort to increase the efficiency of boilers, designers tried to reduce to a minimum the possible diameter of the internal pipe for gas removal, which led to a shift in the dew point inside the air duct and heavy freezing of the condensate that fell.

In modern boilers and coaxial chimneys leading to them, this negative feature has been generally leveled out. However, in regions with very cold winters this phenomenon can still occur. And you have to fight it with one method or another. One of the most common and effective approaches is additional insulation of the outer section of the external pipe. Craftsmen also come up with other interesting and very effective solutions.

Additional insulation of the outer section of the outer pipe of a coaxial chimney is a simple and effective means of combating icing.

The second, but very conditional, disadvantage is the high cost of high-quality coaxial chimneys. But there is something to argue with here. Firstly, the price still doesn’t look scary compared to the overall costs of the heating system. And secondly, if you add considerable savings on construction and installation work, then it becomes ridiculous to talk about cost in general. And this is without taking into account the other advantages of the coaxial system.

What is a coaxial chimney for a gas boiler

The method consists of a two-row arrangement of pipes through which combustion products exit and fresh air enters when operating two-chamber boilers. The classic chimney system forcibly draws air from the room into the combustion chamber. The coaxial model takes air from the street and forces it into the firebox.

Combustion products exit through the inner pipe to the street, and a flow of fresh air moves towards the boiler. A heat exchange effect occurs.

The principle of operation of the chimney is based on the attraction of the flow of outside air and the removal of combustion products

Fresh air enters the firebox in a heated state, this increases the efficiency of the gas boiler. Due to heat exchange, the hot air at the outlet cools and comes out not hot, but warm, which significantly reduces the temperature of the pipe and allows the chimney design to be classified as safe.

Constructions are distinguished by types:

- External and internal location of the chimney. External devices are attached to the outer part of the wall of the building; for internal devices, a channel is built indoors

- Insulated and non-insulated structures. In regions with cold, harsh winters, experts recommend insulating the canal. However, this leads to a decrease in operating efficiency due to the fact that the supply of oxygen to the firebox is reduced. Insulated chimney systems ensure continuous operation of heating equipment at low air temperatures. Chimney insulation is a must for northern regions

- Collective and individual chimney systems. Collective ones are placed in cases where several heating devices are located along the riser

- Horizontal and vertical placement. Installation methods are selected individually for each home

An important advantage of the coaxial method is that the air intake for the furnace comes from the street. As a result, installation requirements for the necessary ventilation in the boiler room are reduced.

System advantages:

- quick installation;

- suitable for any type of heating device;

- good traction performance if all installation rules are followed;

- possibility of use in multi-storey buildings;

Flaws:

- during installation, additional approval from the Sanitary and Epidemiological Supervision Authority is required; Attention! When operating a two-channel system, toxic condensate is released, which requires proper disposal. Insulating the pipe will prevent its formation.

- Improper installation can lead to icing of the tip and reduced traction. Icing of the tip is a consequence of improper organization of the chimney

Kinds

Depending on the installation method, chimneys can be vertical, through the roof, or horizontal, through a wall or window. Durability and performance parameters are determined by the properties of the material from which they are made.

Aluminum

It is lightweight and can withstand temperature fluctuations and all kinds of corrosive effects without damage. But due to the low operating temperature, it is extremely rarely used for the production of coaxial chimneys. Typically used in combination with plastic.

Stainless steel

For the manufacture of chimneys, acid-resistant stainless steel is used, which can safely withstand sudden temperature changes and can operate at temperatures up to 550 ⁰C. Guaranteed service life - at least 30 years. Manufacturers produce two varieties:

- Pipes without insulation are used in heating systems in industrial and domestic facilities. The disadvantage is the formation of a large volume of condensate during operation. To reduce it, it is necessary to install a layer of thermal insulation.

- Insulated - most often used as vertical collective chimneys in multi-storey buildings. They have improved aerodynamic properties. The rules do not prohibit the connection of heating systems with both forced and natural draft. Installation is carried out during the construction of the house according to a project developed by a specialized organization.

Double-channel plastic chimneys

They are made of heat-resistant material with operating temperatures up to 205 ⁰C. Plastic is inexpensive, weighs little, and is easy to install. Coaxial structures of this type are designed to work with gas condensing boilers with low-temperature flue exhaust. Disadvantages include a short service life and restrictions imposed on use in conventional gas boilers.

When choosing coaxial pipes, it should be taken into account that some manufacturers produce boilers with non-standard pipes. Therefore, for installation it is necessary to use components from the same manufacturer.

Types of pipes for coaxial chimneys

Modern types of two-channel chimneys are made of metal and plastic. Each of the materials has its own advantages and disadvantages.

- Plastic chimneys are suitable for low temperature condensing boilers. Made from special heat-resistant plastic, they can withstand temperatures up to 200-205 degrees Celsius. They are the most affordable and easy to install due to their low weight. The main disadvantage of plastic chimneys is their short service life, temperature restrictions for the boiler, and vulnerability to aggressive components in the exhaust gases.

- Chimneys made of metal - stainless steel or aluminum - are characterized by a long service life (from 30 years) and resistance to chemical attack. They can withstand temperatures up to 550 degrees Celsius. The disadvantage of a metal structure is its tendency to form condensation, which is why it has to be insulated with basalt wool or other heat-insulating materials.

Which gas boilers do they use a coaxial pipe on?

A coaxial chimney is purchased if forced draft equipment is to be installed. The heating boiler must include a fan designed to eject combustion products. Those. the equipment must be turbocharged. This device allows you to stabilize the combustion process in a closed chamber. When installing a chimney for a condensing boiler, high tightness of the butt joints should be achieved.

The boiler must be turbocharged

Regulatory requirements for installing a coaxial chimney

State standards and rules for installing a coaxial chimney for a gas heating boiler with a closed combustion chamber are set out in SNiP 42-01-2002 (SP 62.13330). Design, calculation and installation work is carried out in accordance with regulatory documents. Failure to comply with the recommendations leads to a refusal by the Gas Service to commission the heating system.

Standards regulate the distance from the coaxial chimney to windows, doorways, and nearby buildings. Minimum requirements related to the manufacture of fire resistant cutouts and other safety standards are indicated. In particular, SNiP stipulates:

- The location of the coaxial chimney on the facade - the head is placed no lower than two meters from the ground level. The size of the hole in the wall should exceed the diameter of the coaxial pipe by 1 cm, in the case of a brick wall, by 5 cm for a wooden wall.

- The use of coaxial chimneys in multi-storey residential buildings - standards allow the installation of pipes of this type, subject to the following conditions. The minimum distance to window and door openings located on the same level is at least 0.5 m. To a window located above the chimney pipe is at least 1 m. There is no danger of poisoning from combustion products discharged through a coaxial pipe when using a condensing boiler . Provided the system is installed correctly, the impact of exhaust flue gases on residents of the upper floors is negligible. Violations during the installation process lead to condensation on neighbors' windows.

- Fire regulations and safety requirements. The gap between the wooden wall and the coaxial chimney is 5 cm. The minimum gap is determined by the fact that during operation the surface of the outer contour of the pipe practically does not heat up. It is necessary to install non-combustible materials between the coaxial pipe and the wooden wall. It is optimal to use basalt insulation. The regulated distance from the coaxial chimney, relative to the windows and doors of neighboring houses and other buildings, is at least 1.5 m. The area should not be blocked by walls, tree poles, etc. Discharge of combustion products from a condensing boiler into a conventional chimney, instead of a coaxial one, is prohibited.

- A coaxial chimney can be either horizontal or vertical. Installation of a collective smoke exhaust system is carried out only after obtaining permission from the gas service. It is not allowed to connect boilers with forced and natural removal of combustion products to the same network.

- Horizontal section - laying a two-channel chimney through an adjacent non-residential premises is allowed only if the length of the pipe does not exceed 3 meters. In turbocharged models, with the presence of a function for forced removal of combustion products, it is allowed to increase the horizontal section to 5 m.

- Restrictions on output through the facade. The prohibition against draining condensate onto the ground must be carefully observed. The pipe is installed at an angle to the boiler. If there is a condensate drain, it is possible to slope the outlet pipe towards the ground to drain rainwater. When connecting collectively, you will need to coordinate the disposal of accumulated condensate with the sanitary and epidemiological authorities.

- Installation standards - the coaxial chimney must protrude from the wall at a distance of at least 30 cm. For turbocharged boilers, with a chimney section of about 1 m, a narrowing diaphragm must be installed - a unit that compensates for the insufficient length of the chimney. A diaphragm in a coaxial chimney is needed to limit the flow of air into a closed combustion chamber. Turbocharged boilers are designed to use a chimney 5 m long. The diaphragm eliminates the difference.

- Coaxial pipe maintenance - the system is serviced annually, at the beginning and end of the heating season. The accumulated condensate is removed, the tightness of the joints and the absence of burnout in the structure are checked.

Requirements regarding the safe operation of coaxial chimney systems may change, therefore, before purchasing and installing, you should consult a specialist.

Condensate in a coaxial chimney - FuranFlex

A coaxial chimney consists of pipes of different diameters nested inside each other.

The inner pipe ensures the removal of combustion products, and through the space between the outer and inner pipes, oxygen is supplied to the boiler. The coaxial chimney got its name because one pipe is nested inside another.

The advantages of this solution:

- no air is consumed from the room;

- ease of installation;

- increasing the efficiency of heating equipment;

- reduction of fuel consumption;

- high degree of fire safety.

Coaxial chimneys are recommended for use with the following types of boilers:

- gas single-circuit boilers;

- gas double-circuit boilers;

- liquid fuel boilers.

Reasons for the formation of condensation on the inner pipe of a coaxial chimney

With the arrival of cold weather, condensation appears in the coaxial chimney of a gas boiler . The main reason for the appearance of condensation is the large temperature difference between the walls of the pipe and the combustion products that are discharged outside. The following factors may contribute to the occurrence of this phenomenon:

- incorrect installation (insufficient tilt, low outlet location, etc.);

- lack of insulation;

- inconsistency of the chimney parameters with the heating equipment (large or small pipe diameter, insufficient chimney length, etc.);

- Incorrect setting of the gas boiler (the settings are set to minimum values for a large area of the house).

The problem requires an immediate solution, since when the temperature drops below zero, ice may appear in the pipe. The flame in the boiler may die out due to lack of draft. In addition, the electronic control unit may generate an error. You can find out why the chimney freezes here

If a Buderus boiler is installed in the house, the manufacturer provides recommendations for installing the chimney in the instructions for use.

- Correctly calculate the diameter and length of the pipe, following the recommendations from the manufacturer.

- Take into account the power of the equipment, cyclical operation and other factors. If you have insufficient experience, you should use the help of qualified specialists.

- Select quality systems.

Typically, coaxial chimneys are routed through the wall for convenience. On the one hand, if SNiP standards are met, such installation is permitted. The pipe should exit outdoors at a height of more than 2 m. The distance from windows, doors, ventilation openings is at least 50 cm. There should be no trees or other obstacles at a distance of 1.5 m from the coaxial chimney. On the other hand, if condensate collectors are not installed or other errors are made during the design and installation of the chimney system, condensate will destroy the boiler pipes and elements. When condensate mixes with soot and soot, aggressive acidic compounds are formed.

Ways to eliminate condensation in a coaxial chimney of a gas boiler

To eliminate the appearance of condensation in the chimney, people resort to the following methods:

- Changing the system configuration. This method is only effective if errors were initially made during the design. The main disadvantage is the need for destruction and the duration of the work. In winter this can be inconvenient.

- Insulation of the outer part of the pipe. In general, such measures help reduce the amount of condensate, but it is unlikely that you will be able to get rid of it, so you need to install condensate collectors. In other words, solving the problem should be approached comprehensively.

- Boiler power increase. Some people turn their heating equipment up to maximum. When more fuel is burned, the boiler shuts down less often, so temperature changes are less significant. And although this method is effective, it is definitely not worth resorting to. Firstly, this reduces the service life of the gas boiler. Secondly, energy is consumed irrationally. Thirdly, this does not completely solve the problem.

Application of FuranFlex

If condensate flows from the pipe , the chimney should be lined with a FuranFlex polymer liner. Those interested can familiarize themselves with the technical characteristics of the material, as well as its advantages. The peculiarity of the technology is that the pipe starts in a soft state, but after polymerization it becomes durable, resistant to moisture and aggressive substances. FuranFlex is able to reduce the amount of condensate and provide reliable protection for the main structure of the chimney system. Its installation takes only 3-4 hours, and the work can be carried out at any time of the year.

Our specialists can advise you on the creation of chimneys from FuranFlex for boilers Buderus or other manufacturers. On the site you can find out how to extend a coaxial chimney, as well as other useful information.

By submitting information via an electronic form, you consent to the processing, collection, storage and transfer to third parties of the information you provide under the terms of the Personal Data Processing Policy.

Source: https://furanflex.ru/kondensat-v-koaksialnom-dymohode/

Mounting options

Complete with a factory-assembled coaxial chimney, detailed installation instructions are required. Following and carefully implementing these recommendations is reflected in the operation of the boiler and the efficiency of the smoke exhaust system. According to experts, the main reason for the boiler to blow out, the appearance of frost or ice, is associated with errors in calculations and when connecting the chimney.

Horizontal installation of coaxial pipes

Horizontal installation is carried out taking into account the technical characteristics of the building. Initially, the location where the pipe exits the wall is selected. There are restrictions related to the distance to the nearest neighbor's window when removing a horizontal coaxial chimney from the wall, which must be carefully observed.

Additionally, the following parameters are calculated:

- The height of the pipe is from the boiler outlet to the passage hole in the wall; for floor-standing gas boilers, the height must be at least 1 m. Direct pipe outlet from the outlet to the street is not allowed. For wall-mounted gas boilers, the height can be reduced to 0.5 m.

- The number of rotary couplings on the site should not exceed 2 pieces.

- The maximum length of the horizontal section is 3-5 m, depending on the boiler model. To extend the pipe, a coupling with heat-resistant sealing rubber bands is used. The use of silicones and sealants is prohibited.

A peculiarity of using a two-channel chimney in winter is the increased production of condensate. The reason for moisture loss is that the system was originally designed for more favorable operating conditions. If the formation of condensate increases, the pipe will need to be insulated.

Vertical installation of a two-channel pipe

Vertical installation of the chimney provides two connection methods:

- Cascade diagram for connecting collective chimneys of condensing boilers. Several heating units are connected to one pipe at once. The cascade scheme is used in apartment buildings. The chimney is installed outside or inside the building. Vertical installation of the pipe is carried out only after careful calculations and preparation of design documentation, taking into account the rules set out in SP 60.13330 (SNiP 41-01-2003).

- Individual connection - the maximum length of the vertical coaxial combustion product removal system is 7 m, which allows installation in a two-story building. In a house made of aerated concrete blocks, the pipe is installed exclusively inside the building. The walls of the building cannot withstand the heavy load on the walls. In brick houses, a smoke removal system is installed inside and outside the building. In any case, mandatory thermal insulation of the coaxial type chimney is carried out.

How to install a coaxial chimney with your own hands

Installation of a coaxial chimney can be horizontal or vertical. When installing horizontally, it is important to strictly observe the requirements regarding the distance between the chimney and the window, as well as neighboring buildings and structures.

Attention! A prerequisite for horizontal connection of a floor-standing boiler through a coaxial chimney is that the outlet hole in the wall must be at least 1 m higher than the boiler pipe. For a wall-mounted boiler, this distance can be reduced to 0.5 m. Direct outlet of the chimney is strictly prohibited.

Instructions for venting a chimney through the façade of a building

Vertical installation is an easier way to install a structure, while for horizontal installation it is not always possible to meet all the requirements.

When installing the chimney vertically, its maximum height should not exceed 7 meters.

When venting a coaxial chimney through a roofing pie, you have to make holes in the ceiling and the outer layer of the roof.

It is mandatory to use insulating pipes to prevent heating of the roof upon contact with the pipe.

Algorithm of actions:

- A round hole is made in the wall and an insulating gasket or asbestos-cement pipe is inserted into it.

- The outlet part of the chimney pipe is placed in the prepared hole.

- The pipe is connected to the combustion chamber pipe and secured with a clamp

- All pipe elements are connected to each other (usually the structure consists of several sections of pipes, elbows and crimp clamps).

- A protective structure (vane, deflector) is placed on the outer part of the chimney.

Attention! The outlet section of the chimney should be installed at a slight slope (about three degrees) so that the condensate has the opportunity to drain. According to SNiP standards, the condensate drainage pipe must be connected to the rainwater drainage.

We carry out the installation

If you need to independently install an internal chimney, then all actions are performed in the following sequence:

- Check that the dimensions of the boiler pipe and the chimney pipe match.

- Prepare a hole through which the pipeline will be led out. Its diameter must be made slightly larger than that of the pipeline.

- Connect the corresponding element of the smoke exhaust system to the gas boiler pipe.

- Secure the connection with bolts and clamps.

- Consistently assemble the entire chimney system. Each element is installed in its “own” place, after which it is secured with clamps (they increase the level of reliability of the connection).

- Install overlays that perform decorative functions over the fastenings. They will help maintain the aesthetic appearance of the structure.

- Bring the chimney pipe outside.

- Ensure the joint is tight.

- Place a protective casing on the pipe. This will help improve the safety level of uncontrolled fires.

After completing the described installation process, you need to check the tightness of the joints and cover them with a special apron.

If we are talking about an external type of chimney exhaust system, then the installation procedure has its own characteristics. When it is necessary to install such a chimney, you must adhere to the following algorithm:

- Determine the exit location and mark its location on the wall of the building.

- Make a hole where the mark is. The diameter must correspond to the cross-section of the pipe.

- Connect the chimney to the heating device. To do this, you need to use a double-circuit elbow and a special tee. It is needed to ensure the stability of the finished structure in a vertical position.

- Secure the “structure” to the wall using brackets.

- Seal the area where the chimney exits the wall and continue to assemble it to the desired height.

- Secure the structure to the external wall using clamps.

To ensure a reliable connection of double-circuit pipes, it is necessary to use adapter units.

Transition units connecting double-circuit pipes are important elements of the device design

Installation of coaxial chimneys

One cannot but agree with the advantages of coaxial chimneys, but only if the installation is correct and of high quality. If the installation work is carried out unprofessionally, without following technology, its environmental friendliness and safety may be in big question.

This is important to know! Before starting installation, you need to check the availability of chimney parts in the kit, as well as the necessary tools and materials.

For assembly you will need:

- coaxial pipe or several pipes;

- smoke exhaust pipe;

- adapter for connection;

- flange for linings;

- two wall covers;

- connecting clamp;

- tip on the pipe.

The chimney is connected to the boiler and taken outside the room. If there are foreign interfering objects, they are removed before the pipe is removed. In addition, it is recommended to clear the space around it from flammable objects and substances.

The layout of the coaxial chimney must be carefully thought out and comply with installation rules

Installation of a coaxial chimney begins with choosing a location, including for the boiler itself. It is recommended to install a gas boiler with a coaxial chimney at the same time. The best option is to place it 1–1.5 meters above the boiler. If necessary, the chimney is extended, but so that there are no more than two bends, with a total height of up to 3 meters. Next, as already noted, everything unnecessary is removed. Then a hole of the required diameter is drilled, which can be from 11 to 12.5 cm.

This is what a coaxial pipe and boiler look like indoors

Next, the pipe is connected to the neck of the boiler using a clamp, which is clamped with bolts on both sides. Then the structure of the desired configuration is assembled. All parts are connected with clamps. The chimney exiting the room must have a slight slope to allow spontaneous removal of moisture (condensation).

After installation, decorative overlays are put on in the right places to perform an aesthetic function. Overlays can be of different shapes, as well as from different materials. Fastened with liquid nails or using regular construction adhesive. It is recommended to seal the holes with foam so that there are no gaps that allow cool air to pass through and accumulate moisture.

Upon completion of the work, it is necessary to check the quality of fastening of the entire structure and connecting elements, pay attention to the slope of the smoke exhaust pipe and other details. For maintenance - preventive inspection, cleaning and other actions, the boiler must be turned off, wait until the pipe has cooled, and then carry out work.

Popular manufacturers of coaxial chimneys

A technically advanced chimney has become such a popular product that many boiler manufacturers not only began to include it in the kit of supplied equipment, but also to produce it for separate sale. Universal devices can be connected to almost any gas boiler. Let's look at the most popular brands.

Chimneys Buderus

The German quality of these chimneys is beyond praise. They are made from steel with an enamel coating and are sold as a set. These kits can only be used for boilers of the same name.

Kit from Buderus

The well-known Ariston

Household appliances from this company are known to Russian consumers. Italian quality has earned the trust and respect of millions of customers around the world. The chimneys of this manufacturer, as they say, keep the brand.

The outer pipe of the structure is made of enameled steel, the inner one is made of aluminum

Popular Vaillant kits

The products of this manufacturer are in great demand on the European market. The kits are suitable for Vaillant boilers and require placement away from areas of possible fire.

Vaillant boilers are very popular due to their quality and efficiency

Coaxial chimney for gas boiler Proterm

A simple and inexpensive Proterm device is suitable for boilers of the same name. Slovaks offer various extension cords, adapters and adapters for ease of installation. Every year new developments from this company appear on sale.

Proterm pipe

Coaxial chimney for Baxi gas boiler

The Italian company offers models made of steel coated with enamel. The warranty period for such a pipe is short - only a year, but users note the quality of the product and a fairly long service life. For severe Russian frosts, Baxi offers insulated models with an air intake made of composite material. You can buy a coaxial chimney for a gas boiler from Baksi at a price of 3,000 rubles.

The cost will depend on the components of the Baxi kit

Coaxial chimney: 4 advantages

The coaxial chimney has a compact size and low price.

In a wooden house, autonomous heating systems consisting of many elements are most often used. Their composition can vary depending on which coolant is chosen or how it will be heated. It is worth noting that regardless of the material used for the firebox, the boiler must have a smoke exhaust system or, in other words, a chimney. The design can have different configurations, features and even technical characteristics, but among many, the coaxial chimney is recognized as the most popular.

Advantages of coaxial pipe

A coaxial pipe for a gas boiler is not just a product, but a design that has many advantages, which is why it has become so popular. High efficiency is ensured by perfectly heated incoming air.

They are characterized by compact dimensions, since the installation of 2 large pipes is not required, but one is sufficient.

The pipe does not require installation of additional ventilation. Environmental friendliness is extremely important for humans, since one can often find heavy and cheap materials that can release toxic substances when heated.

Advantages:

- Optimal cost of the product.

- It is possible to solve the problem with the formation of condensation in the chimney, since it simply will not exist.

- Fuel consumption is reduced when it comes to a bathhouse.

- Cold air enters the chimney, which prevents overheating of the chimney when the boiler is operating.

A device such as a vertical coaxial smoke exhaust is used for a heating system in which a gas boiler is installed with a closed combustion chamber. A device for direct heating can be in the form of a gas boiler, convector or radiator. The installation of a double-circuit coaxial chimney must be carried out as correctly as possible so that the principle of operation is not violated. Each circuit is responsible for its specific task. The first is required to remove combustion products from the combustion chamber in the boiler. The second is intended for the flow of air into the combustion chamber, which ensures efficient combustion.

In order to have excellent draft and uniform combustion of gas, it is worth installing a coaxial chimney in a boiler with a closed combustion chamber, the length of which, according to the rules, does not exceed 2 m. Otherwise, turbulence may form on the pipe, preventing combustion products from leaving the firebox.

Coaxial type chimney: installation requirements

In order to install a heating boiler in which the combustion chamber is closed, an independent heating system must be installed, which can be used for individual construction, as well as in an apartment building or industrial premises. If you decide to install a coaxial chimney, you will need to follow certain rules and requirements so that the installation is carried out as correctly as possible and without mistakes.

Requirements:

- The maximum length of a coaxial chimney should be 2 m, however, it is often necessary to extend the distance if a floor-type Ferolli is used during installation. In this case, coaxial chimneys are used, the length of which is 4-5 m.

- The pipe should only be routed horizontally through the wall near which the gas boiler is installed. The length of this output section is 90-100 cm.

- If there is a need to install forced draft, then you should choose a fan; in this case, you will not need to install the vertical part of the system.

- The hood or outlet is located at a height of 2 m from ground level, but it must be at least 1.5 m from the boiler.

- The place where the chimney outlet will be laid should be next to the wall, at a distance of 50 cm from the window.

It is categorically not advisable to install a coaxial chimney pipe under a window opening, but if there is no other option, then there should be a distance of 1 m. To eliminate condensation, installation of a coaxial chimney and a slight slope of the pipe is required.

Functions of a coaxial boiler

A coaxial boiler works, like all others, to heat a room, but why is it called that? Coaxial boilers got their name due to the installation of coaxial chimneys.

This chimney performs the following functions:

- Combustion products are removed;

- The design of the chimney is very simple;

- The peculiarity is the installation of a pipe in a pipe.

The internal cavity is responsible for the removal of smoke. Air is also supplied to the combustion device or, in other words, the air mass is taken in. Due to the air, the boiler operates through the cavity of the outer pipe.

Stages of installation of a coaxial chimney

The chimney for a coaxial boiler must be installed in accordance with provisions such as SNIP standards, carefully thought out, of high quality and working properly. A coaxial chimney differs from a vertical and traditional device in that it is not difficult to install, and also does not require a number of special skills or training; be sure to follow the instructions so that the installation technology is not violated. Only in this way can you be sure that the product is working properly and the penetration of smoke into the room is strictly excluded.

Stages:

- The first stage of connection is to prepare the site for the future location of the boiler. Floor-standing boilers should be installed on footrests, and wall-mounted ones on the surface of the outer wall.

- The outlet openings on the chimney should be marked on the surface of the same wall near which the boiler will be installed, but only at a height of 1.5 m. The diameter of the place where the chimney is planned to be located should be slightly larger than the size of the pipe itself.

- The installation of a special connecting element is required, through which the installation of the heating boiler and chimney will be carried out. Each turn and joint of the pipe is secured with a special fastening clamp.

Installation of a coaxial chimney is strictly prohibited using adhesive tape or sealant. The hole in the wall space must be lined with a special non-combustible insulation.

If forced ventilation is installed in the boiler, then only the section of the chimney that is horizontal needs to be installed.

If there is a need to make a turn in the pipe, you can use a special rotary elbow, and a maximum of 2 elbows can be installed per chimney. Installation of the pipeline on the wall surface is carried out using brackets so that they are necessarily present at each joint. At the end of a coaxial chimney, it is not advisable to install additional elements such as an umbrella, deflector and others.

Maximum length of a coaxial chimney for a gas boiler and advantages of the chimney pipe

Depending on the model of the coaxial boiler, the length of the chimney is selected, however, extension is possible if this is permissible according to the technical characteristics. On average, the length can be 3 m. A coaxial chimney has certain advantages, due to which its popularity is increasing almost every day.

The advantages are:

- Ease and speed of installation;

- Possibility to use the product for any heating equipment;

- Excellent traction, provided that the installation is carried out correctly and strictly according to technology;

- Possibility of using the device for an apartment building.

Unfortunately, there are also disadvantages of such products, but against the backdrop of many advantages, they sometimes fade into the background. To carry out installation, you need to coordinate the actions with the sanitary and epidemiological inspection. When the chimney is operating, toxic condensate is released, which is prohibited from being poured into the ground, and is a direct pollution of the environment. Disposal of such condensate should be carried out in a separate area. If you install a structure of this two-channel type in a house with many apartments, then there may be outrage from the residents. If there is no appropriate permission from the organization, you will not only need to remove the installation, but also pay a fine. No matter how the condensate is isolated, it will be too large, and a minimal violation of the installation technology will lead to many problems.

What is a coaxial chimney (video)

A coaxial chimney is an excellent option for installation on combustion product exhaust pipes for a gas boiler, since compared to other structures, it has a lot of positive aspects and a long service life. The most important thing is to purchase high-quality equipment and carry out installation correctly.

homeli.ru