To carry out bath procedures according to all the rules, you must solve the issue of heating water for washing. Owners who remain true to traditions do not think much about this and, even at the design stage of the bathhouse, include a heater in it. However, you can avoid the labor-intensive work of heating it if you choose a modern solution - an electric boiler. True, there are difficulties here too.

You will have to choose a suitable heater model with a heat exchanger. But you can save money if you decide to make it yourself. But in order for this device to perform its functions well, it would not hurt you to first learn about the purpose of the heat exchanger and the rules for its installation.

Sauna stoves with water tanks - selection rules

In general, if there are any specific criteria for choosing a sauna stove, then the main one is this: the stove must have sufficient thermal power

and – preferably – a wide dynamic range of regulation of this power.

Since stoves for bathhouses with a tank burn quite hotly and heat up well, it is prohibited to make any extensions from combustible materials directly near them, since this is very dangerous

and often leads to fires.

For safety reasons, you should follow some rules for installing a sauna stove with a water tank:

- The minimum distance between the walls of the furnace and structures made of flammable materials should be 50–70 cm. If there are protective partitions (for example, made of metal), the distance can be reduced.

- The gap between the roof and the pipe must be sealed with galvanized iron.

- A metal sheet is placed on the wooden floor in front of the stove to prevent fire from falling coals.

There are now many ready-made options

sauna stoves running on electricity, gas and wood. Which one should you choose for a bath?

If the bathhouse is located next to the house or adjacent to it and needs additional communications, then the stove should undoubtedly be made of stone.

There are options in which the stove, in addition to the main functions (heating the steam room), performs additional functions, i.e., serves as a water heater for baths

. This is the so-called country option.

Types of sauna stoves with water tanks

Of course, it is easier and more convenient to use ready-made stoves, which are now offered in huge quantities - from a simple, lightweight stove for a summer residence to an elite, massive stove with panoramic glass

, which can simultaneously serve as a heater for a steam room and a chic fireplace for a relaxation room.

Factory stoves have both general characteristics and features specific to each model.

Models also differ in shape: round, oval, triangular

etc. There are stoves with a built-in tank and an external boiler connected to a built-in heat exchanger, as well as with a tank that is placed directly on the heating part of the stove (samovar type).

Advantages of metal furnaces:

- Fast heating. Within 30–40 minutes. after the start of the fire, the temperature in the steam room reaches 8–100° C.

- They are compact and take up little space.

- They are easy to install.

- They are light in weight, so there is no need to create a solid foundation.

- Already during the heating process you can take bath procedures.

- They come in a variety of shapes, allowing you to choose the best option for yourself.

Stove made from an iron barrel for a bath

This is the most economical design in terms of cost.

After a hole for the chimney is cut in the top cover, it is installed on top of the barrel. This type of design has a very serious drawback.

. It consists in the fact that to supply steam you must first lift the lid, since water is poured onto the stones from above.

This type of stove is more suitable for a small bathhouse in a summer cottage.

Brick stove design

But if you prefer a traditional Russian bath with a real park and the aroma of wood, you can make a heater that is not very complex in design. Moreover, it has been proven that only such a stove can provide the ideal combination of humidity and temperature

.

Before you start building a sauna stove with a water tank, you need to correctly determine the location. In a small bathhouse, the stove is installed in the middle of the room.

Now you need to select a brick

. It must be fireproof. The mortar for masonry is being prepared. You can use clay: mix water and clay 2:1.

The design is a closed heater for direct heating of stones, that is, the stones are heated directly from the heat of the stove gases. The stones are located inside the combustion chamber and lie on a grate made of fireclay bricks.

First we lay out the base

, then the stove will warm up well and the heat will flow into the bathhouse, and not go to the floor. Before laying the base, it is necessary to place a bitumen pad on the foundation for waterproofing. The bricks of the first layer should be moistened with water.

Now we're making a blower

. It is used to clean smoke ducts and ventilation. Without it, there will be no reverse draft and the firewood will not ignite. The blower can be secured with galvanized wire or steel strips (the second option is preferable).

we cover one half of the structure

so that air enters the firebox and the firewood does not fall down. Taking into account the fact that iron expands under the influence of temperature, for a more reliable placement of the grate, recesses are made in the bricks (1-2 cm is enough). We lay the rest of the structure with bricks butt joint. The oven base is ready.

At the next stage we lay out the firebox

. To avoid having to frequently add firewood to the stove, the firebox should be twice the size of the vent.

The combustion part of the furnace, along its entire height, is also made of fireclay bricks. Thus, the furnace has a fireclay combustion core. There is a gap between this core and the walls of the furnace, which is technologically necessary, since the core gets very hot and expands when heated.

This gap can also be used to generate convection heat for additional heating of the steam room. For this purpose, a special door is made

.

The convention proceeds as follows:

Cold air from the lower part of the bathhouse enters the stove and, passing between its outer and inner contours through the gap, heats up and when the upper door is opened, the already heated air comes out.

After the firebox is finished, the door is closed and the steam room is subsequently heated by radiating heat from the outer walls of the stove, as well as by supplying steam through the heater.

A hole is made in the front wall of the stove for a water tank if you plan to install a built-in boiler.

Heat exchanger for a chimney: how this design works + analysis of 3 device options

Russian people do not like to lose in anything: neither in money, nor in comfort, nor in warmth. And therefore, at dachas, and in private houses, and in greenhouses, and in bathhouses, you can often see quite interesting devices from neighbors “for the sake of saving money.” And in the same way, folk craftsmen did not ignore the completely unnecessary heat that sometimes mediocrely escapes from the steam room, installing a heat exchanger on the chimney, and not on the stove or wall. And indeed, this turns out to be very profitable: why take away valuable heat from the stove if we sometimes don’t know how to cool a hot chimney pipe at least a little? But a water or air heat exchanger for the chimney is an excellent solution!

What metal is best to make a heat exchanger from?

It is better to install the exchanger itself on the pipe from food grade stainless steel. It is also called austenitic. Even at high temperatures, its characteristics do not change - after all, its welds are strong and not susceptible to cracking, and nickel reacts with oxygen on the surface to form a special protective film that is resistant to salts and acids. This is the most durable option.

As for zinc, already at a temperature of 200°C it will begin to evaporate, and at 500°C its concentration in the air will reach a dangerous value. Therefore, if you have hung a galvanized profile on the heat exchanger, but it does not heat up more than 200°C, you don’t have to worry. But you can install it - this profile serves well to enhance the convection of air that flows around the heat exchanger. Of course, such a heat exchanger is not suitable for constant heating of a house, but for quickly warming up an attic, for example, this is what you need! Those. you arrived with friends at the bathhouse, started to light the stove, and in just half an hour it was already warm in the attic or recreation room. And you don’t need to think about either the boiler or the second oven.

Installing a heat exchanger on a chimney with your own hands is quite simple. It can be attached to an ordinary iron stove, and even then covered with brick, just like a stove. It is also possible to lay the brick itself on its edge - the structure will still be stable.

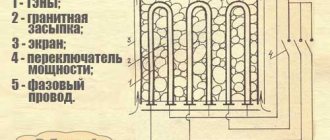

For example, here's how to make a heat exchanger for a potbelly stove:

Options for connecting structures

The heat exchanger on the chimney can operate in two main modes. And each of them has its own process of heat transfer from smoke to the inner pipe of the heat exchanger.

So, in the first mode, we connect a remote tank with cold water to the heat exchanger. Then water condenses on the inner pipe, causing the heat exchanger itself to heat up solely due to the heat of condensation of water vapor from the flue gases. In this case, the temperature on the pipe wall will not exceed 100°C. And the water in the tank will take a long time to heat up.

In the second mode, condensation of water vapor on the inner wall of the heat exchanger does not occur. Here the heat flow through the pipe is more significant, and the water heats up quickly. To more fully understand this process, conduct this experiment: place a pan of cold water on a gas burner. It will be clearly visible how condensation will appear on the walls of the pan and it will begin to drip onto the stove. And despite the flame being 100°C, this state will continue for a long time until the water in the pan itself warms up. Therefore, if you use a heat exchanger on a pipe as a register for heating water, then give preference to small designs with thick walls of the inner pipe - this way there will be much less condensation.

Pipe on tin - simple and durable!

This option is simple, practical and convenient. In fact, here the chimney is simply wrapped around a metal or copper pipe, it is constantly heated, and the air distilled through it quickly becomes warm.

You can weld the spiral to your chimney using an argon torch or semi-automatic welding. You can also solder with tin - if only you degrease it with phosphoric acid in advance. The heat exchanger will hold on to it especially tightly - after all, samovars are soldered with tin and last a really long time.

Corrugation - cheap and cheerful

This is the simplest and lowest-budget option. We take three aluminum corrugations and wrap them around the chimney in the attic or second floor. The air will be heated in the pipes from the chimney walls, and it can be redirected to any other room. Even a fairly large room will be heated to hot temperatures while you heat the steam room stove. To make heat removal more efficient, wrap the corrugated spirals with regular food foil.

Heat exchanger-hood - for warming up the attic

Also, in the chimney section in the attic room, you can install a heat exchanger that would work on the principle of a bell-type stove - this is when hot air rises up, and cools down slowly. This design has its own huge advantage - an ordinary metal chimney on the second floor usually becomes so hot that it cannot be touched, and such a heat exchanger will significantly reduce the risk of fire or accidental burns.

Some craftsmen also cover such heat exchangers with a mesh with stones to accumulate heat and decorate the heat exchanger stand. In this case, the attic becomes even more comfortable and can be used as a living space. After all, based on practice, the temperature of the sauna stove pipe does not exceed 160-170 °C if there is a heat exchanger on it. And the highest temperature will already be located only in the gate area. Warm and safe!

stroy-banya.com>

Types of furnace tanks

Built-in tank

. It is installed on channels located in the chimney and fixed vertically by the side walls of the masonry. This is a very efficient use of heat, as the temperature in the chimney can reach 500 degrees.

The boiler is mounted so that the chimney pipe passes inside it. The heat coming from the pipe will heat the water. The shape of such tanks can be different: round, square, rectangular

- whoever likes it better. Water is poured into the container from above, and taps are used to drain it.

The disadvantage of these water boilers is that the water boils there all the time, forming “heavy” wet steam in the bathhouse, which is not entirely suitable for a steam room. Therefore, you constantly have to add cold water and drain hot water. Samovar-type tanks have the same drawback.

Mounted tank

This is a sealed container equipped with a tap and a hinged or removable lid. Mounts on the back or side wall of the oven. Iron hooks are usually used as fastenings.

The boiler can also be installed on a beam or cable. The base of the tank is attached to the wall or ceiling of the bathhouse

. But this design poses some danger in use: there is a risk of cable breakage.

Attached tank

A very interesting, but little used option

water boiler. The principle of its operation is as follows: a pipe, sealed at one end, is welded into the furnace, its other end (open) is placed in the lower part of the water boiler, which is installed above the furnace itself.

From the bottom of the tank, water enters the pipe, where it is heated to a boiling state. When heated, hot air bubbles rise into the boiler, where, under the influence of cold temperature, they burst. This is how some of the heat is transferred.

Before buying or making your own boiler for a bath, you must first decide on the material

. In practice, a 5mm stainless steel tank performed better than others. Occasionally there are enamel water containers, but they are short-lived.

It is also necessary to pay attention to the quality of the weld. Ideally, it should be located inside, which significantly improves the aesthetic appearance of the product. The seam should not be burnt. In addition, vermiculite insulation can be used.

A view is made at the top of the chimney

, so that smoke can freely exit the firebox.

The sauna stove for the Russian bath “Samovar NEW” creates both a hot, up to 120 degrees Celsius, and a soft, humid microclimate in the steam room. When designing the Samovar NEW devices, the designers of the First Perm Furnace Company paid special attention to the temperature of the exhaust flue gases. The lower it is, the more comfortable bathhouse visitors feel - there is no hard infrared radiation from a hot chimney. The relatively low temperature of the pipe also indicates that the stove has a high efficiency - more heat goes to the stones and the body of the heating device. To ensure the longest service life of the product, the stove is made of high-quality sheet metal with a thickness of 6 six, 8 eight and 10 millimeters.

Metal sauna stoves “Samovar NEW” are used to heat rooms with a volume of up to 36 m3. Operation of the “Samovar NEW” model requires the presence of a well-assembled chimney to remove combustion products of solid fuel - firewood.

The wood-burning stove “Samovar NEW” has the following advantages:

- Favorable price-quality ratio;

- Quickly and gently heats the room to the required temperature. This model is especially popular among customers, as it generates light steam and an acceptable temperature for the body. The presence of a heater helps generate steam and maintain a pleasant temperature. The water tank can be secured using powerful hooks on any side of the stove body: back, front, left or right;

- Compact and mobile. The “Samovar NEW” sauna stove model is made of three types of metal: 6, 8 and 10 mm thick. The weight of the stove varies in different modifications around 150 kilograms. This product can be transported, moved and installed by two people. The stove is installed directly on the floor of a steam room and does not always require preparation of the foundation.

- Modern appearance. “Samovar NEW” has an elegant design. The body of the product is covered with heat-resistant Certa enamel in different colors. An additional advantage is that “Samovar NEW” has modifications with transparent doors equipped with heat-resistant glass DT-3S and “Onego”, which allows bathhouse visitors to peacefully watch the flames.

- Central location of the chimney pipe. The chimney of this model runs directly along the center line of the product. This greatly simplifies the installation of the chimney system.

- Removing the firebox. The sauna stove for the Russian bath "Samovar NEW" has a firebox extension of 200 millimeters and can be mounted in the room adjacent to the steam room - in the relaxation room or locker room. At the request of the buyer, the extension of the firebox can be extended in multiples of 100 millimeters by the required amount. The deep firebox can accommodate firewood of almost any size.

Types of water tanks

Tanks for heating water are divided into three main types:

- Samovar type

- Remote

- Built-in

In a samovar-type tank

The water is heated by the hot gases from the chimney. Such a container is installed in place of the first chimney elbow, and hot air with a temperature of about 500 degrees passes directly through it, quickly heating the water. This is a cost-effective solution: heated air is used for heating, which previously was simply discharged through a pipe to the street.

In a remote tank

The water is heated by hot water from the register (heat exchanger). It happens like this: a stainless steel heat exchanger is mounted on the stove chimney, and a tank located in another room is connected to it using two pipes. When burned, the wood heats the chimney and the walls of the heat exchanger connected to it. The temperature of the water in the heat exchanger rises, and it is displaced by colder water from the tank. Hot water enters the container. This ensures constant circulation of water between the tank and the heat exchanger of the furnace.

Built-in water tank

– a traditional way of heating water in a bathhouse. This method appeared first and is still used today. The built-in water tank is an integral part of the sauna stove. Water is heated directly from the flame formed as a result of fuel combustion. In the built-in tank, the water heats up quickly and its high temperature is maintained for a long time.

Features of sauna stoves with a tank

All models of sauna stoves can be equipped with a water tank. A number of models are already equipped with tanks.

A samovar-type tank can be installed on any model of the Teplodar sauna stove, even a small one. Installation of such water tanks is possible even on sauna stoves with the chimney axis shifted to the front wall - for this purpose, our assortment includes a corresponding tank with a volume of 70 liters. A samovar-type container located above the open heater of the stove (for example, in the “Novaya Rus”, “Cascade”, “Taman” models) heats up even faster due to the double influence of heat sources - from the chimney and from the heater.

Sauna stoves with a built-in tank are convenient, since no additional installation work is required. The built-in tank can be combined with the top or side of the firebox, depending on the configuration of the sauna stove. A tank of this type, located on the side wall, is equipped with some modifications of the Sahara sauna stoves - Sahara 10 LB and Sahara 10LBU and Taman 10TB.

If you have chosen a remote water tank, please note that these parameters correspond to a number of models of Teplodar bathhouse stoves, equipped with a register or having the ability to install one. Registers for remote types of tank are of two types:

- built-in (the abbreviation of the furnace name contains the index “P”)

- universal (installed separately)

Sauna stove models are already equipped with a heat exchanger register

Any universal register will work for the following models

You can view all the specifications

You can view all the specifications

Selecting a tank for heating water

Each type of water tank has its own characteristics, among which there are specific advantages and disadvantages that can become significant when choosing a specific sauna stove if you plan to install a tank for heating water on it.

| Samovar type tank | Remote tank | Built-in tank | |

| Advantages |

|

|

|

| Flaws |

|

|

|

The choice of tank type for a sauna stove is also influenced by several factors:

- 1. Type of steam room

- for a Finnish sauna, a remote tank is recommended, for a Russian sauna - a samovar type. - 2. Size of the steam room

- in small rooms, a remote tank saves space. You can also consider installing a stove with a small built-in tank. - 3. Average duration of use of the bath

- for short sessions of steaming and washing (2-4 hours) a samovar-type tank is suitable, and for long sessions (more than 4 hours) a remote tank is more convenient. - 4. Location of the washing compartment

- if the sink is located directly in the steam room, then a samovar-type tank will be the best solution; for separate washing and shower rooms, a remote-type tank is more convenient. - 5. Features of the room

- in some cases, installing a samovar-type tank turns out to be difficult due to the characteristics of the steam room and difficult access to the tank lid. - 6. Material

– on sale you can find tanks made of enameled steel and cast iron, but stainless steel tanks are considered more practical and popular (the range of Teplodar water tanks is represented only by stainless steel models).

When choosing a water tank, it is also important to accurately calculate what volume of water on average will be required for use in the bathhouse. A tank that is too small will force you to constantly heat additional volumes of water, and heating a large one requires a large amount of heat, preventing the room from warming up quickly.

To correctly select the tank volume, use a simple tip: one person needs 8-10 liters of water, plus 8-10 liters are required for steaming a broom. Thus, the optimal tank capacity is 55-80 liters.

If you choose the right tank and install it on our stoves, the water will heat up to 70-75 degrees by the time the temperature in the steam room is 90 degrees. Heating time 30 - 50 minutes.

And, of course, the technical parameters of water heating tanks are of great importance.

The table shows the technical characteristics of tanks for furnaces from

You can get acquainted with all the characteristics of tanks and registers

Modern sauna stoves with a water tank from Teplodar offer versatility, thoughtful, elegant design and maximum operating efficiency.

Hot water is a prerequisite for any bath; without it, it is quite difficult to imagine staying in a steam room. A metal tank serves as a container for heating and also storing hot water, in which it is heated to the required temperature. Regardless of the design, be it a remote tank for a sauna or a built-in analogue - in most cases, heating occurs from the main stove.

Despite the presence of a direct connection between, there are several modifications of water heating systems that differ significantly from each other, both in appearance and in technical characteristics. Also, the performance characteristics depend on the material from which the bath tanks will be made.

The instructions below on how to choose tanks for a bath will help you understand the variety of modifications and make the right choice. This information will be especially useful for those who are planning to do the installation themselves - with its help you can choose the most suitable product for your circumstances and wishes.

Bathhouse and samovar. So different, so similar...

At first glance, there is very little in common between a bathhouse and a samovar. A samovar is a dish, and a bathhouse is a place for washing and relaxing. But in fact, the operating principles of both have many similarities, not only with each other, but also with the oven. It is therefore possible that it was the bathhouse and the stove that prompted the first inventors of the samovar to come up with this kind of design. Judge for yourself...

Inside the body (or body) of the samovar there is a pipe, at the lower end of which there is a grate, a tray and a blower, which provides the necessary draft for high-quality combustion.

The chimney can be heated with wood or coal. The body of the samovar is mounted on legs, and the upper part of the pipe is covered with a special lid. Sometimes a teapot is “put on” it, which allows you to brew tea in true Russian traditions.

Built-in

Built-in analogues are located inside the stove - installation of containers of this type involves heating water directly from an open fire in the firebox. This is the most traditional type of hot water tank - this analogue is most often found in village steam rooms.

Products of this type do not require special devices or heating systems, which makes them simple and economical to use on a daily basis.

Advantages

- High efficiency. Since the container is heated directly from the fire in the oven, the efficiency of this system is very high. As soon as the required temperature is created in the firebox, the water will heat up quickly enough with virtually no loss of time and heat from fuel combustion;

- Material. As a built-in container, you can use an ordinary cast iron tank, the price of which is quite affordable compared to stainless counterparts, which allows you to significantly save on the construction of the furnace. In this case, appearance plays practically no role, since most of the structure is located inside the furnace;

You can get more detailed information by watching the video in this article.

Tin pipe

Tin as a material for smelting a heat exchanger is very practical and reliable. Essentially, a chimney with a heat exchanger for a bath will look like a pipe wrapped around a smaller metal or copper tube. During the heating process from the tube, the air passing by will also warm up.

It will be enough to weld the spiral tube. Soldering can also be done with tin, previously degreased with orthophosphate acid. In this case, the heat exchanger will be secured especially securely, because it is not without reason that tin samovars are considered the standard of reliability among analog products.