Solid fuel heating appliances do not lose their relevance in the conditions of widespread gasification. Manufacturers annually update their range, offering more and more advanced models.

Foreign devices are rightfully considered more technologically advanced. However, they are very sensitive to operating conditions and can fail with small deviations from the norm. Domestic products are more reliable. Solid fuel boilers Zota Mix from the Krasnoyarsk plant have proven themselves well when working in harsh conditions.

Features of Zota boilers

Zota heating devices are designed specifically for use in temperate and cold climate zones. Despite the variety of models, boilers have some common features.

Features of the units:

- Strength. Made from high quality boiler steel.

- Versatility. Suitable for heating residential and industrial premises, open and closed heating systems.

- Energy independence. Basic options do not require power supply.

- Uniformity. Installing a heating element unit operating from the electrical network makes it possible to maintain the set temperature in the absence of combustion.

- Economical. The design of the firebox and heat exchanger promotes rational fuel consumption and maximum heat transfer: a water jacket around the entire perimeter, fireclay bricks.

- Easy to clean. Movable grates and removable panels make the process easier.

- Efficiency. The efficiency of the units is from 70 to 90%.

- Aesthetic appearance.

Popular models

The Dymok model has a hob

The most common models are the following. They have gained popularity due to their technical characteristics and properties.

Zota Dymok

Zota electric boilers of the Dymok series are direct-burning solid fuel appliances. The air supply can be adjusted manually using a damper. The boilers are non-volatile.

The combustion chamber is made of steel and is also equipped with a cast iron hob.

The company offers two modifications - KOTV and AOTV. The difference is that the AOTV series has a hob. The power of KOTV boilers is offered in two versions - 14 and 20 kW. The power of the AOTV series is divided into 3 levels - 12, 18, 25 kW.

The boiler system makes it possible to configure many parameters, which will ensure autonomous and safe heating operation.

Zota Lux

Zota Lux boiler for an apartment or private house, wall-mounted

Electric boilers Zota Lux series are intended for autonomous heating of industrial premises and residential buildings. The area of the heated building is from 30 to 1000 m2.

The user can adjust the temperature from +30 to +90 degrees, which allows the devices to be used in a “warm floor” system without auxiliary control equipment. The boiler will automatically maintain the set temperature.

The tunic has small dimensions and weight. The manufacturer has made it possible to easily connect to external circuits, such as sensors or pumps.

Other

List of other popular models:

- Zota MK – medium power devices;

- Zota Smart – high-tech models with a wide range of functions;

- Zota Topol-M – products with a gas-tight insulated body;

- Zota Master - models whose body is lined with basalt wool;

- Zota Econom are economical devices that perform optimally.

https://youtube.com/watch?v=dWD2vxzWkZk

How to choose the right boiler

When choosing a heating unit, the buyer should focus on his individual needs and capabilities.

Significant criteria:

- Available type of fuel resource. Depending on what you plan to heat the boiler with, choose a solid fuel or mixed option.

- Convenience. Operation should not cause difficulties for the user.

- Price. Usually they choose the most inexpensive of the models with similar suitable parameters.

- Power. It is believed that to heat an area of 10 square meters. m. requires an average of 1.5 kW of thermal power. For example, for a house measuring 100 square meters, a 15 kW boiler is suitable.

Types of boilers operating on solid fuel

All equipment of this class can be divided into 2 groups:

- Automatic fuel supply

- Manual loading

The first are pellet boilers. In them, granules play the role of fuel; they are loaded into special bunkers and from there they enter the furnace. Such devices have high efficiency and can operate automatically for weeks, without human intervention.

The latter, depending on the design features, are divided into 3 types:

- Classic

- Pyrolysis

- Long burning

They can use firewood and wood waste as fuel.

A traditional or solid fuel boiler using wood has been produced for a very long time, and its design has remained virtually unchanged. In it, the combustion chamber is located at the bottom and is considered the hottest part. Most often it is made of cast iron or steel. However, such heating of a wooden house with a solid fuel boiler is used quite rarely, as it requires frequent maintenance.

Pyrolysis devices are a new step in the field of solid fuel equipment. Their work is based on the principle of decomposing wood into solid residues and gases and burning the latter. The advantages of this device include high efficiency, minimal formation of ash and soot. Among the disadvantages is the need to burn dry wood with a humidity of no more than 20%.

Long-lasting combustion - their operating principle was developed in Russia and has no analogues in the world yet. It is a new generation boiler not only in terms of design, but also in its operating principle. Its main advantage is the simplicity of its design and the ability to service it once a day when operating on fuel with natural humidity. A solid fuel wood boiler has the most precise power control and can produce a given amount of heat.

Review of model range and prices

You can buy a solid fuel boiler “Zota” in a specialized store; the extensive model range and price range allow you to choose the appropriate option.

Carbon

The Zota Carbon steel coal boiler is heated with lump coal of a fraction of 1-5 cm. Provides up to 14 hours of operation on one full load with an efficiency of 80%. The series consists of 7 products with power from 15 to 60 kW.

Design features:

- The large size of the door with a locking mechanism and the inclined location of the hatch make loading bulk material convenient.

- Two operating modes: ignition and combustion. With the help of the ignition damper, the route of smoke exit changes: the draft increases and rapid ignition occurs. The combustion mode switches the heat exchange channel to the standard position.

- Fire bricks promote efficient use of fuel. As it heats up, it burns out the particles of fuel material contained in the flue gases.

- The three-circuit heat exchanger increases the heat removal area.

- Built-in thermomanometer shows pressure and temperature.

- Large area of water frame of the firebox, including under the ash compartment. This allows you to increase heat removal. The water jacket cools the ash pan and prevents it from burning out.

- Convenient cleaning of ash due to the fact that the grate is located at an angle.

- A mechanical draft regulator is included in the delivery package.

Technical characteristics and cost of Zota Carbon models.

Prices for solid fuel boilers Zota Carbon

Zota Carbon

Mix

Zota Mix is a combined device that works up to 10 hours on one tab. They provide an efficiency of 80%. The line includes 4 variations with a power range of 20-50 kW. They use wood and coal as fuel. Can be transformed to burn gas, pellets, diesel fuel.

Zota Mix boilers are characterized by the presence of:

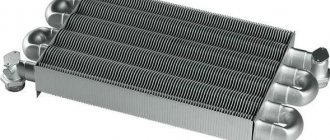

- X-shaped heat exchanger. A successful solution that allows you to increase the heat transfer surface.

- Thermal manometer on the front panel (included).

- Possibility of transforming the design for a liquid fuel, gas or pellet burner.

- Large ash box.

- Mechanical draft regulator.

- Washable ash chamber.

- A mechanism for supplying air directly to the fireplace area. Provides even combustion with low draft.

- Removable end panel. Helps to comfortably clean the heat exchanger.

The main parameters and price offers of Zota Mix are presented in the table.

Prices for solid fuel boilers Zota Mix

Zota Mix

Box

The Zota Box unit has a small power of 8 kW. Its modest dimensions of 630 x 380 x 460 mm are ideal for small spaces. Works on coal and wood for up to 7 hours without interruption, has an efficiency factor of 70%. Unit weight - 71 kg. The volume of the loading chamber is 26 l.

Advantages of the Box model:

- Cast iron burner with removable covers. Can be used for laying coal or for household needs.

- A layer of thermal insulation between the body and the casing.

- Additional heating due to convection through slots in the cladding.

- Built-in thermometer for temperature control.

- Convenient ash drawer-scoop.

Cost: 18,290 rubles.

"Master"

The Master series has a standard range of 6 devices with a power of 12-32 kW. One load of fuel provides up to 12 hours of operation. The efficiency is 73-75%. The boiler is fired with wood and coal. On models 20 and 14 kilowatts, it is possible to connect pellet and gas burners.

Series features:

- Cast iron stove with a collapsible burner (except for Master-14 and 20 models).

- Thermal insulation with basalt cardboard.

- Combined heat exchanger: water jacket plus pipe compartment.

- Ventilation holes on the front panel for cooling the case.

- It is possible to install a draft regulator.

- Air supply directly to the fireplace.

- Thermometer.

Comparative characteristics of the Zota Master versions.

Prices for solid fuel boilers Zota Master

Zota Master

"Topol M"

A line of solid fuel boilers operating on wood, briquettes and coal in the basic version. They have the ability to switch to gas and pellets. The working time on one bookmark is 10-12 hours. The efficiency of the device is 75%.

Model features:

- Basalt insulation reduces heat loss.

- It has two loading hatches: horizontal and inclined. The first is convenient for storing firewood, the second - coal mass.

- Adjustable blower on the ash compartment door.

- Built-in thermomanometer.

- Two-pass heat exchanger. It has a compact design and a large heat removal area.

- Installing a boost fan will increase the efficiency of the boiler.

- Washable ash drawer.

Parameters and price range of Zota Topol-M models.

"Dymok-M"

A series of traditional solid fuel boilers using wood and coal with a deep firebox. One bookmark provides 7 hours of continuous operation. Device efficiency is 70%. The units have a simple design and are distinguished by the most affordable price among Zota heating devices.

Design features:

- Availability of a cast iron panel with a removable burner in standard sizes of 12/18/25 kW.

- The water circuit is reinforced with a U-shaped steel profile.

- The water-cooled ash pan does not deform from high temperatures.

- Tightly fitting doors of the loading and ash chambers.

- Tubular heat exchanger that is easy to clean.

Brief characteristics and cost of devices.

Pellet Series

Automatic pellet boilers with an efficiency of 90%. The manufacturer offers units with capacities from 15 to 130 kilowatts. Wooden logs and briquettes can be used as fuel in the absence of electricity. The automatic system allows the boiler to operate for up to 5 days on one load (pellets). The equipment takes up a lot of space.

Advantages and differences from other models:

- In addition to the boiler, the device includes a fuel bunker.

- Pellets are dosed by a screw feeding system. The boilers are equipped with automatic reverse when jammed and give a signal during an emergency stop.

- Parameters and automation are controlled using a remote control, a mobile application and a special unit equipped with an LCD display with indication and buttons.

- The design features automatic ignition (with hot air).

- A tubular heat exchanger has been added for greater heat transfer.

- There is a function to block the fuel supply to the fireplace.

- The chronothermostat allows you to set the temperature over time.

- Installation of an external temperature sensor allows for weather-compensated control.

The main characteristics and price range of Zota Pellet are shown in the table.

Pellet Pro Series

Automatic pellet industrial boilers of high power. The efficiency of the installations is 90%. Long burning - up to 5 days per serving.

Properties of Pellet Pro products:

- Possibility of connecting additional sections to the bunker.

- Non-contact automatic ignition function.

- Vertical tubular heat exchanger.

- Large water jacket area.

- Fireproof twin-screw pellet feeding mechanism.

- An ash remover is optionally connected.

- A chronothermostat will help keep the house warm in the absence of the owner.

- Fuel supply blocking system.

- Weather-dependent control is possible when connecting an external temperature sensor.

- Fireclay bricks are used for complete combustion of the fuel resource.

- The adjustment is made using a block on the boiler body, via a GSM module or an Internet application.

Parameters and cost of Pellet Pro.

Series "Stakhanov"

Automatic coal unit for heating buildings up to 1000 sq. m. The most technologically advanced among the Zota solid fuel boilers. Allows you to heat the room continuously for 7 days. Power range 15–100 kW. Efficiency 90%. Automation completely controls the heating process. Fuel - coal fraction up to 50 mm.

Design Features:

- Spacious bunker.

- Fireproof mechanism for feeding coal into the firebox.

- Chronothermostat included.

- Jam protection.

- Control from the unit on the body - color LCD touch screen. There is a control panel and a plug-in GSM module.

- “Stop-coal” function that shuts off the flow.

- In a situation where there is a power outage, it is possible to switch to wood heating.

- It is possible to connect weather-dependent regulation if necessary.

- Reduced energy consumption and low heating costs.

The main characteristics and prices of the Stakhanov models are presented in the table.

Magna series

The Zota Magna semi-automatic solid fuel machine uses: coal, firewood, briquettes. Without recharging it operates for up to 32 hours. The efficiency rate is 83%. The power range is wide - from 15 to 100 kilowatts.

Peculiarities:

- Fuel material is loaded manually. The control device controls the combustion process based on data received from sensors.

- Spacious firebox.

- Three-circuit combined heat exchanger with a washed ash pan.

- Equipped with a boost fan.

- The control unit with display and buttons is located on the boiler body. You can use the remote control or install a GSM module.

- It is possible to connect a pellet gas burner device.

- Refractory bricks in heat exchange passages help to effectively burn out the fuel resource.

Technical parameters and cost options of Zota "Magna".

Review of features of Zota brand heating appliances

The Zota solid fuel boiler is manufactured within the walls of the Krasnoyarsk plant. It is of good quality and has proven itself to be an economical and efficient device. The first of the latest developments were solid fuel boilers "Topol", they are used for heating production areas and houses. The products have a steel body. The main distinguishing feature of such equipment is the fuel loading. The devices are equipped with two combustion doors, one of them is horizontal, the other is vertical. The user can load fuel through any of them.

The combustion chamber has a special design, which makes it possible to achieve an efficiency that reaches 70%. The Zota solid fuel boiler has an electrical kit that is controlled by a remote control. Among the advantages of the described equipment are:

- ability to operate on any type of solid fuel;

- maintaining the required temperature in different operating modes;

- excellent economic indicators;

- automatic transition to operation using the long-burning mode;

- high quality;

- affordable price.

Recommendations for installation and operation

Installation of the Zota boiler and its use are carried out strictly according to the instructions for the specific model. For installation, select a closed room with functioning supply and exhaust ventilation.

The unit is placed on a non-combustible base or concrete foundation. If the floor surface is combustible, the place under the device and in front of it (0.5 m) is covered with a steel sheet on top of an asbestos or basalt gasket.

1 m of free space is left in front for easy maintenance of the boiler. From the side to the walls - at least 0.5 m, the interval at the back - 0.4 m. The joints with the chimney and heating pipes are carefully sealed to avoid leaks and smoke in the room.

Diagram of the heating system with the Zota “Topol” boiler.

- Security group.

- Ball valve with drive.

- Circulation pump.

- Coarse filter.

- Expansion tank (expansion tank).

Basic operating rules:

- Store fuel and flammable materials at a distance of more than 0.4 m from the boiler surfaces;

- do not allow the coolant to overheat (over 95 °C), otherwise the housing will be deformed;

- do not let the water in the system freeze during the cold season;

- as waste accumulates, clean out the ash compartment;

- once every 2-3 months, scrape off resin deposits from the internal cavities, which reduce thermal conductivity;

- If there is overheating and knocking in the heating system, stop burning and allow the coolant to cool. Find out which heating radiators are best using this link.

The boiler cleaning process using the Zota Magna model as an example is shown in this video.

Reviews of boilers from the “Zota Master” series

Solid fuel boilers "Zota Master", according to buyers, have a high degree of thermal insulation. The heat exchanger, which is built into the unit, is of a combined type. The body is insulated with basalt cardboard, and there are ventilation holes on the door trim, which are necessary to cool the surface of the device. Consumers like that the ash pan door has an air damper; it is equipped with a screw with a handle that can be used to regulate the flow of primary air.

It is worth noting that the efficiency of boiler equipment depends on the degree of gas density, as well as on the design of the heat exchanger. If we are talking about Master series boilers, they use a combined heat exchanger. It contains a pipe compartment, which, according to users, has reliable qualities and is easy to clean. The manufacturer has provided the possibility of installing a mechanical regulator. The boiler is capable of operating in semi-automatic mode. The assembly ensures the tightness of the door, as well as the accuracy of adjustment.

The described solid fuel boiler "Zota", reviews of which are often only the most positive, has a combustion chamber, it is designed for the most efficient combustion of coal. The device can also use firewood. If you choose a unit whose power is higher than the others, you can put 70 cm of firewood into it.

Reviews of boilers of the “Zota Mix” series

One of the most popular from the described manufacturer is the Zota Mix solid fuel boiler. It has an x-shaped heat exchanger design, with which it was possible to achieve maximum heat transfer area. This indicates better heat transfer and increased efficiency. Users note that heat loss is reduced due to the quality of the thermal insulation used. The boiler becomes less fire hazardous. The outer casing that covers the insulation is coated with powder paint; as the owners of such equipment emphasize, it is characterized by increased wear resistance. The manufacturer has taken care of the convenience of cleaning the equipment; for this purpose, there is a removable door on the front panel that provides access to the entrance. In order to get rid of combustion products, an ash drawer is provided; it is located behind the ash pan door.

Technical characteristics, Prices for solid fuel heating boilers ZOTA "Topol-M"

| Name | "Topol M" - 14 | "Topol M" - 20 | "Topol M" - 30 |

| vendor code | TP 493112 1014 | TP 493112 1020 | TP 493112 1030 |

| Price | 28 500 | 31 500 | 35 500 |

| Rated thermal power, kW | 14 | 20 | 30 |

| Loading chamber volume, l | 38 | 46 | 53 |

| Working pressure, atm, no more | 3 | ||

| Efficiency, % | 75 | ||

| Fuel | coal, firewood, electricity, gas | ||

| Overall dimensions (width x depth x height), mm | 440*875*845 | 440*975*845 | 440*1075*845 |

| Chimney height, m | 6 | 7 | 9 |

| Chimney diameter (section), mm | 150 | 150 | 150 |

| Weight included, kg, no more | 113 | 135 | 157 |

Draft regulator FR-124 (additional option for “MASTER”, “TOPOL-M”) - 2100 rub.

Gas burner “Garant-M” UG-17 and UG 24 for “Master” and “Topol-M” - 7990 rub.

Solid fuel boilers are an excellent solution for cottages and dachas where there is no possibility of gas supply. Fortunately, we have plenty of coal and firewood in our country and they are inexpensive. Therefore, we will consider one of the most popular models of medium-power solid fuel boilers - Topol M20 from Zota. Production - Krasnoyarsk, Russia.

The Topol M20 model is a modernized version of the regular Topol with a lot of improvements and modifications aimed at increasing combustion time and increasing efficiency and heat transfer.

The average price at the end of 2021 is 35,000 rubles, so this model falls into the category of popular budget boilers. The boiler power is clear from the model name - 20 kW. Zota is a Russian company that has long established itself in the heating equipment market.

We can see the main characteristics in the photo below:

As you can see, the area of the heated room is stated to be as much as 140 square meters; most people use Topol 20 for cottages of 90-150 square meters.

You can heat it with both wood and coal. Users more often, of course, use coal, and firewood only for kindling. After all, coal burns longer and heat transfer is higher. According to reviews, it is enough to load a 12-liter bucket of coal 2 times a day (in severe frosts -30) to maintain a comfortable temperature of 23-25 degrees in a room of 120 square meters.

IMPORTANT - the Topol model is intended primarily for the southern regions of Russia, where the temperature does not drop below -15. If you are choosing a boiler for the Central and Northern parts, for Siberia - then pay attention to specialized long-burning boilers - here, of course, Buderus is ahead of the curve.

Boiler features

The first way it differs from other models is its top loading. It is very convenient to add coal.

An extended firebox is another convenient design solution that allows you to load longer logs inside.

The only thing that disappoints is the rather thin walls. The wall thickness is 3 mm (if you take, for example, some models of Buderus boilers, the thickness is 5 mm), so when burning coal, it is not known how long the boiler will last, whether it will burn out quickly, and so on. Fortunately, I personally have a friend who heats his private house of 120 square meters with this particular model - Topol M20, the boiler has been in service for the second year and so far everything is fine. It heats with medium-fraction coal, sometimes with wood (when the coal runs out).

Operating time without loading, coal or pellets?

It is stated that the boiler can operate for up to 10 hours at full load. In reality, this figure is slightly lower, and only if the firebox is fully loaded with coal. But 6-7 hours is not bad at all.

Is it possible to burn with pellets? You can often see this question on forms from new Topol owners. The answer here is obvious - of course you can, it’s how much money you will waste - a lot. It is many times more efficient and cheaper to burn with coal, even with low-quality coal.

You can throw in huge pieces of coal (the main thing is that they fit into the firebox) and the boiler will heat and heat. Compare for yourself - a ton of high-quality coal costs 3,500 rubles, low-quality coal costs 2-2.5 thousand per ton. A ton of pellets costs as much as 6,500 rubles. The difference is already 2 times!

Boiler advantages

Disadvantages of the boiler

Topol boilers have a lot of disadvantages, but they all stem precisely from the cost - the boiler is a budget boiler and there is nothing to expect from it super-results, as from boilers that cost 2-3 times more. Steel is 3 mm, for such a price this thickness is exactly what it should be.

It smokes - there are a lot of comments precisely because the boiler smokes when you open the door to load the next portion of fuel. This can occur either due to poor draft (a problem with all boilers in general), or due to the diameter and height of the pipe, or due to the fact that the pipe is not insulated.

Well, and most importantly, it smokes due to the fact that the design of the chimney is such that the chimney pipes inside the boiler become coked (they are small in diameter - 50 mm and there are 8 of them) and they need to be cleaned often. So an indispensable attribute that you will need to use the Poplar boiler is a metal brush for cleaning pipes.

The scorching grate will sooner or later all burn out, because there is direct contact with burning coal, as a result, it becomes red-hot and burns slowly but surely. Although it is 1 cm thick, it is unknown how long it will last when fired with coal.

Settlements remote from civilization are not always supplied with natural gas, so property owners in such areas are looking for alternative heating options. There are quite a lot of them today, but diesel fuel and electricity are expensive, so modern consumers are increasingly turning their choice towards solid fuel. Many modern heating devices work on it, but foreign models do not correspond to domestic climatic conditions. Domestic products are in greatest demand among buyers. It is offered for sale by different enterprises, each of which produces boilers with certain features and characteristics.

For reference

If you purchase a Master-20 brand boiler, it can be supplemented with a gas burner, which will make the equipment more versatile. Each device can be equipped with a heating element, the capacity of which is 9 kW.

- The boiler body has become thermally insulated and more gas-tight. The water jacket of the boiler under the decorative casing is now covered with basalt cardboard, which has significantly reduced heat loss. The fire door opens in a horizontal rather than vertical plane and is locked with a lock. The ash pan door is equipped with a blower damper, which is adjusted manually using a screw or controlled by a mechanical draft regulator, which is installed as an option. Thus, the increased gas density of the boiler makes it possible to more accurately regulate the oxygen supply and extend the fuel combustion cycle on one load to 10-12 hours.

- the combustion chamber has undergone changes: an additional horizontally located heat exchanger in combination with a removable damper makes the gas duct a three-pass one. This increases the heat transfer area and improves heat transfer efficiency. The damper is made removable specifically for cleaning the heat exchanger. In addition, there is a cleaning hatch on the flue, which makes it easy to remove soot.

- A thermometer is installed on the top panel of the boiler to measure the temperature of the water supply.

- Topol M uses coal and wood as fuel. As an alternative, electric heating is possible, which is provided by a built-in heating element with an external control panel (installed upon request and is an option). It is also possible to install a gas burner in place of the screw door. In addition, the presence of a screw door creates additional convenience for loading firewood into the firebox. The depth of the firebox ranges from 38 to 58 cm. A separate ash door allows you to remove ash at any time while the boiler is firing. For user convenience, new ergonomic handles are installed on all three doors.

- Due to the design features of the fuel combustion chamber, increased gas density and quality of workmanship, the Topol M series of boilers has the highest efficiency among budget models of solid fuel and combined boilers.

- possibility of additional installation of the “TENB 2” kit.

Steel solid fuel boiler of the Zota “Topol-M” series with convenient vertical loading. Options - mechanical draft regulator, heating element, gas burner. Power 20 kW. The area of the heated room is 150 sq.m. with ceilings up to 3 m. Working water pressure - 3 atm, volume 54 l. Dimensions (H*W*D), mm: 845*440*975. Weight 135 kg. Firebox volume 46 l. The depth of the firebox is 48 cm. Instead of a plug, it is possible to install a 3...9 kW heating element block on a 2″ thread. Connecting size for water 1 1/2″ no.

About Zota “Topol-M” boilers

The new line consists of power boilers. 14, 20, 30 and 42 kW. The boiler body has become thermally insulated and more gas-tight. The water jacket of the boiler under the decorative casing is now covered with basalt cardboard, which has significantly reduced heat loss. The fire door opens in a horizontal rather than vertical plane and is locked with a lock. The ash pan door is equipped with a blower damper, which can be adjusted manually using a screw or controlled by a mechanical draft regulator, which is installed as an option. Thus, the increased gas density of the boiler makes it possible to more accurately regulate the oxygen supply and extend the fuel combustion cycle on one load to 10-12 hours.

The combustion chamber has undergone changes: an additional horizontally located heat exchanger in combination with a removable damper makes the gas duct three-pass. This increases the heat transfer area and improves heat transfer efficiency. The damper is made removable specifically for cleaning the heat exchanger.