When preparing to build a stove, each owner will have to solve many problems. For example, if he does not plaster it, or even does not cover the heating structure with tiles, then he should think carefully about which brick is best to use for the stove. If it is of poor quality, then jointing will not help. Therefore, the issue of choosing a brick is a very important matter.

Types of bricks for the stove

Important! When choosing a stone for the construction of a stove structure, you need to remember that the functioning of the heating unit, as well as the safety of the entire building, depends on it.

In this regard, you should familiarize yourself with the different types and shapes of bricks and their main qualities in order to decide which brick is best for the stove. It is clear that most of the stone for the future structure must be fireproof. Depending on the material of manufacture, there are the following types of heat-resistant bricks:

- fireclay;

- quartz;

- carbon.

Fireclay brick

It is most often used in domestic buildings, although it is often used in the construction of industrial facilities.

This heat-resistant brick owes its name to a special material - fireclay, which is produced from white kaolin clay in rotary or shaft kilns by firing at very high temperatures (about 1400-1500⁰C). Therefore, such products can be used at high temperatures and remain neutral to chemical, acid and other influences. This type of alumina brick can have different shades.

Features of the production of fireclay bricks for furnaces greatly influence its price. And therefore, in order to reduce the cost of the stove, such products are usually used when laying the combustion chamber and some elements of the chimney system.

Main characteristics

Fireclay bricks are different:

- high fire resistance;

- the ability to accumulate and release thermal energy;

- high porosity, which is ensured by the presence of aluminum oxide in it.

By the way, the latter quality determines the long heating and the same cooling of the stone.

Important! The percentage of thermal conductivity of a brick is inversely proportional to its mass. That is, the greater the mass of the stone, the lower the thermal conductivity.

*

Therefore, when purchasing, you should pay special attention to this quality.

Regular fireclay bricks are produced in sizes 250x120x65 mm. Due to the increasing pace of construction and demand for products, the production of shortened and elongated blocks, as well as bricks of various volumes and configurations, has now been launched.

Thanks to the wide range of colors of products, more and more consumers are buying fireclay bricks for laying stoves and do not use facing or clinker tiles at all.

Quartz

If the clay mass used to produce refractory bricks for the furnace needs to be reinforced with large grains of quartz, graphite or coke powders, then after burning, the result will be a brick with different properties, respectively, of different types: quartz and carbon.

Quartz, like its carbon counterpart, belongs to the red refractory brick. It is used to construct vaults in reverberatory furnaces. In addition, it is used to construct the walls of furnaces, which in the future will only come into contact with metals or fire.

Clay is used to cement such products, which gives the fired product incredible strength.

Carbon

*

If you press clay together with coke or graphite, you get a high-quality carbon-type refractory brick. But such stones are not used for domestic purposes, but only in industrial production. For example, without them it is impossible to build an open-hearth furnace or a blast furnace.

Criteria and requirements

In order for the heating structure to last for a long time, it is necessary to make masonry from high-quality raw materials suitable for specific conditions. The material is selected individually for each home or room, taking into account the wishes of the owner, based on the main characteristics of brick products. The criteria for which brick is best to build a stove from may be different, but the requirements for this building material are the same.

Marking

Blocks for assembling furnaces are separately marked with the letter M, after which they put a digital designation of the weight load to withstand. The numerical parameter is calculated for each square centimeter of the product and can vary from 150 to 250 kg.

It is better to ignore other letter designations - the letters U (thickened) or P (hollow, hollow) are completely unsuitable for the construction of stoves.

Fireclay blocks are designated by the letter Ш, after which the presence of the signs A or B is a direct indicator of their purpose for laying furnaces. When a number is written instead of the second letter, it means that the manufacturer deviated from the standard procedure during the manufacture of bricks. But this release method must be carried out in accordance with approved technical specifications.

Marking

Heat-resistant bricks for stoves, which are best suited for heating structures, are most often not marked in any way.

What kind of brick is needed for laying a stove? When choosing raw materials, you should pay attention to the presence of a label on the frost resistance of the product, which is also important when building a structure. Optimal indicators are any in the range from 75 to 100

Size

There are many options for bricks, among which there are standard sizes of red brick for laying a stove - 25*12*6.5 cm. This option is optimal for stove equipment and is very convenient to use.

There are wedge-shaped blocks, one half of which is 2-3 cm narrower than the other. This option is used in rotating places, when laying out the outer part of the crucible, if cooking or heating food using an oven is intended.

Dimensions

It is possible to use European products of a thickened or modular type, which have slightly different dimensions: 25 * 8.8 * 6.5 cm.

Form

Brick blocks may vary slightly in shape. The best option is a standardized rectangular look, but for a more complex look, you can use one of three options: wedge-shaped, rib or end blocks. The wedge shape involves smoothing one corner, which helps to make corner areas as beautiful as possible or lay out interesting decor. For the end and ribs, the blocks differ mainly in thickness.

Form options

Most often, when forming an arched vault, wedge-shaped bricks are used, in which one side is narrowed, which helps to make a neat turn.

Color

The color of a brick is a direct indicator of the quality of production. Uneven color or stains indicate a defective product.

Also, the color scheme helps to determine the intended purpose of the manufactured products: which ones are used for the construction of buildings, and which bricks are most often used for stoves. Red refractory blocks are used for laying stoves, as they are characterized by resistance to temperature changes and thermal pressure without compromising the integrity of the structure.

Color spectrum

In the places where the firebox and ash pit are formed, yellow bricks are used, since in these places there is no direct exposure to fire and heat. Otherwise, such blocks are called fireclay.

A white fireclay block meets all the characteristics perfectly as the main material for stove masonry, but is noticeably more expensive than its red counterpart. If you have general parameters, it doesn’t always make sense to overpay for a shade.

A more detailed analysis of brick products for building stoves is shown in the following video review:

Features of clinker bricks

This type of ceramic brick first appeared in Holland. Due to the elevated temperature during firing, the product has virtually no inclusions or pores, which contributes to a significant improvement in its performance characteristics.

Important! It is characterized by increased strength, frost resistance, durability, and low water absorption.

These qualities explain its extraordinary popularity in the construction world.

But in terms of its properties, it is significantly superior to its “brothers”. And the whole point is that: Firstly, it is made from a special type of clay - refractory for different periods of time.

Secondly, clay is fired at temperatures of 1250-1300⁰С, while the usual construction option is at 800-900⁰С.

Clinker brick for kiln

Clinker is also made from clay, but the technology differs from the production of ceramic bricks. The raw materials used are special - the clay must be refractory, the recipe includes mineral additives. Firing is carried out at temperatures much higher than for ceramics. Sintering the mass to the characteristics of glass produces blocks that have record strength for brick (more than M300), frost resistance and durability. Clinker is highly resistant to chemical aggression of flue gases and thermal shocks. For the base that carries the entire mass of the stove and chimneys, the use of high-strength clinker bricks is also optimal.

The arguments against clinker - heavy weight, high price and lack of porosity - are a clear example of how disadvantages are a consequence of advantages. Stove makers claim that the stove must “breathe”, and for this there is nothing better than high-quality clay bricks. Clinker types of bricks will not be able to provide proper breathing for the stove.

Requirements for bricks for laying stoves

*

Brick for the construction of furnaces must meet certain requirements and differ:

- resistance to high temperature changes;

- sufficient mechanical strength;

- the ability to accumulate and conserve thermal energy.

All bricks for ceramic-type ovens, in terms of compliance of products with certain shapes and sizes, must meet the requirements of GOST 390-96. This document also indicates the temperature limits for the use of each type.

The fireclay type of brick must comply with GOST 390-96, which specifies the requirements and standards for these products.

The operation of furnaces is accompanied by regular heating and cooling. Therefore, stones are exposed to temperature changes, causing them to expand and contract. In this regard, the brick must have a sufficient margin of strength, otherwise it will not be able to withstand deformation and destruction.

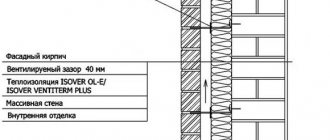

Different bricks for different parts of the furnace

Furnace units for solid fuel are distinguished by a variety of designs. The functioning of composite heating systems occurs under different conditions. Let's find out together what kind of brick is needed to build a stove, as well as its individual parts.

Typically, two types of bricks are used for laying stoves: simple ceramic and refractory. The first of them is an excellent option for the construction of external stove parts, including chimneys, the second is indispensable when laying fireboxes. In details.

General structure of the furnace

The photo clearly shows the structure of the furnace, the components of which are almost identical to all structures of this kind.

Firebox with ashlar

The combustion chamber is characterized by the presence of two-layer walls. To create the outer part of the heating device, they use a facing type of ceramic brick, and the inner part - fireclay brick.

This is due to the fact that the temperature loads of the outer wall are much lower in comparison with its outer part, therefore more attention is paid to decorative characteristics.

Smoke channels

They are nothing more than heat exchangers of significant volumes, the temperature in which decreases with height, but is still relatively high. Therefore, this element of the heating structure is most often constructed from fireclay bricks. Although for beauty, the outside of the chimney is lined with facing tiles or bricks.

*

Chimney

This part of the fuel system is exposed not only to precipitation, but also to temperature changes. Therefore, it is advisable to use frost-resistant and heat-resistant stones for the construction of chimneys. Most often, these elements are characterized by a two-layer structure, with the presence of decorative finishing in the form of metal boxes or decorative types of brick.

Therefore, we can conclude that if bricks with appropriate properties are used for the construction of stove elements, then the entire structure will be endowed with excellent thermophysical properties and will last for decades. For experienced stove makers, the selection of material for laying a stove is a very important issue. Upon careful inspection, they reject bricks with large cracks, deep damage, chips and give preference to good material.

Using old bricks

Layout of brickwork. There are two main methods of bricklaying: with single-row (chain) and multi-row ligation of seams.

The question often arises: is it possible to lay used bricks? It is quite possible to lay bricks in the future furnace that were located in chimneys, ceiling cutting, and in the first rows. They must be thoroughly cleaned of soot and solution. The smoky side should be laid inside the masonry, as traces of soot can appear in the form of rusty spots through the plaster and whitewash. And your new stove will look unpresentable.

But bricks that previously experienced high temperatures in the firebox cannot be reused!

A high-quality stove is not only the right stove brick, but also the choice of good clay. It is divided into fatty, medium and skinny. If the clay is oily, the sand ratio is 1:10 or 1:8, in medium clay the ratio is 1:8 or 1:3, in lean clay there is more sand than 1:3.

Determining the quality of clay is quite simple. Roll it into a sausage as thick as your finger. If the sausage bends and does not break, and does not crack when drying, you have fatty clay. If the sausage breaks and cracks when it dries, you have medium clay. It is difficult to form a sausage out of thin clay, but if you succeed, it crumbles when it dries.

The oven requires the use of oily and medium clay. It is very good if you add fireclay powder to the clay solution. you will purchase it in the same place where fireclay (alumina) material is sold.

We advise you to study - Ecowool - disadvantages and advantages of insulation

I would like to emphasize once again that a stove in the house is not only warmth and comfort, but also an increased fire hazard

Therefore, when constructing it, it is important not only to accurately follow the laying technology, but also to use high-quality materials

A brick oven heats the entire house evenly and slowly. It keeps warm throughout the day. It will be enough for you to heat it once every 24 hours.

What types of bricks are there?

Any refractory brick, including red, belongs to a specific grade, which is determined by its quality.

There are the following types of bricks for laying a furnace:

- First grade: characterized by good annealing and density, optimal number of pores and their size. The surfaces of the edges are smooth, do not crumble, the color is rich red. After tapping, a ringing sound is heard. The high quality of stones is indicated by the presence of iridescent spots or a continuous film.

- The second grade is characterized by slight underburning. It is characterized by low frost resistance, lower heat capacity, and increased porosity. When tapping, a dull short sound is heard. The cut has shallow nicks, the edges are slightly crumbled. A rainbow film will never appear on such specimens. Such bricks must be discarded.

- The third grade is burnt. It is characterized by high density, high thermal conductivity, low frost resistance, and very low porosity. It is not able to withstand high loads, the color is dark cherry, even brown, the cut can be torn, and the ribs can be crumbled. After tapping it makes a ringing sound.

Choosing bricks by appearance

Classification of bricks by appearance includes 5 varieties:

- Masonry. These are ordinary blocks used for interior masonry. They are not shown on display.

- Smooth. These blocks have at least one of the sides very smooth, and they are used for cladding.

- Rusticated. The edges of such blocks are specially made uneven, with bulges of various shapes. They are also intended for decoration and cladding.

- Fluted. A finishing material, its difference is that a depressed relief is created on the surface of the blocks.

- Broken. Decorative form, also used for cladding. Broken blocks are obtained by chipping or breaking. This method is used in the production of hyperpressed bricks. Finishing with this material makes the buildings look like beautiful old stone houses.

We advise you to study - Boho style in the interior - an original style for extraordinary people

Which facing brick to choose? It depends on the preferences of the home owner

However, it is very important to take into account the geometric dimensions of the blocks when choosing. Small errors (up to 1 mm) are acceptable even for high quality materials

Still, you need to understand that if the length and width of the blocks for cladding the facade can vary within 3 mm, then such an error for their height is already critical - you can decorate a house beautifully only with perfectly smooth bricks.

It is, of course, easier to lay out the façade of a building with bricks of the correct shape (rectangular), but this is not the only solution. There are many varieties of facing materials - they produce corner, two-corner, semicircular and other brick blocks that allow you to create architectural elements on the walls, highlight window and door openings and implement other design ideas.

Which brick should you not use to build a stove?

If the brick has low heat resistance and an unsuitable composition, then it should not be used when laying a stove.

In this regard, it is prohibited to use when creating a furnace:

- ordinary building bricks, which can only be used in the manufacture of low-heating units. Under no circumstances should this type of stone be used when laying a firebox or even a chimney;

- a hyper-pressed analogue, since highly molded products are suitable for stoves. During firing, water completely evaporates from such a product, and the pores formed inside make the pressed product weakly strong, and therefore of poor quality;

- silicate material, since it is filled with lime and other additives. Therefore, at high temperatures, the firebox will begin to crumble and crack. Plus, when exposed to heat, it begins to release substances harmful to health;

- decorative items. It is only allowed to use them to veneer fireclay surfaces, and then only in cases where the laying was done correctly (then the heating of these surfaces is small - within 55-60⁰C).

Possible options for placing bricks in the kiln

If you were asked which brick is best to use for a stove, the answer is clearly visible in the photo. That is, from the point of view of the “bricks”, the stove should look like this: 1 – foundation, 2 – firebox, 3 – smoke circulation part, 4 – chimney, 5 – chimney.

Foundation

It is the basis of the entire stove structure, so it must be very durable. In addition, it must be vapor- and moisture-proof, since even a minimal amount of water should not penetrate through it. Otherwise, the entire unit will become damp, and it will be impossible to talk about the quality of heating. In winter, a significant part of the base may have a temperature below zero degrees. Therefore, the foundation must be built with frost-resistant brick, which can be first-class material or 3rd grade brick. You can also use clinker stone.

* So, what material is better to choose for the stove? In order:

- in terms of price - red brick of the 3rd grade;

- in the case of creating a heavy structure (for example, Dutch), give preference to the 1st grade, as the most durable and high-quality;

- in areas where there are predominantly long winters and severe frosts, clinker bricks are best suited, since they are highly durable and frost-resistant.

Firebox

In this part of the furnace, temperatures can be within 1100⁰C and higher. Therefore, ceramic material is not suitable here at all, since it can melt (the limit for it is 1150-1180⁰ C).

The firebox is subject to low mechanical loads. The main function of this stove element is to quickly receive a large amount of thermal energy and transfer it faster to the heat storage device (accumulator) - the smoke circulation and facing parts. It is clear that fireclay, with which the firebox is laid out, has such properties.

Smoke circulation part

It does not have direct contact with fire, but still the heating from the flue gases is decent: 450-800⁰С. One of its functions is to allow them to burn out completely, which means that the gases here are still chemically active. In addition, a lot of thermal energy accumulates in the smoke circulation, which must be released so that it is enough until the next combustion process. Therefore, there are no options here: 1st grade.

Facing

It also plays a big role in the process of heat transfer, but, so to speak, it largely ensures the “breathing” of the heating structure. In addition, the cladding must hold the finish well, which is not easy in such conditions: temperature changes are too large. Considering this circumstance, it is best to cover the structure with second-grade brick.

The fact is that such stones are characterized by sufficient heat capacity for a given location and increased porosity, which together will provide the stove with deep, even breathing. Plus, some unevenness and roughness of the edges of the 2nd grade brick will ensure ideal adhesion to the mortar of any ingredients during further cladding with ceramic tiles.

Chimney

If you look at the chimney, then the part above the view is the chimney, indicated in the photo by the number 5. It is here that there are maximum fluctuations in relative humidity (from 10-15% to 100%) and temperature indicators (from 400⁰C to -45⁰C). In addition, rain or snow or other precipitation may directly enter it. Plus, there are large wind loads that can change in direction over a short period of time. Despite this, the material for the pipe must be such that it can quickly warm up, otherwise there will be no normal draft, which will lead to slow heating of both the stove and the room as a whole. Therefore, it is recommended to construct the chimney from 1st grade brick (under normal conditions). A good option is to use used bricks impregnated with soot (the so-called mezhigorka). Although such material is used only inside the building, since stains may appear on it, which can break through the best finish.

If you live in places with harsh weather conditions, then you need to lay out a double-layer pipe. To do this, you should lay hollow, first-class material on the outside, and use the clinker option on the inside. This is the only case of using hollow material in the furnace business.

Choosing stove bricks: suitable types, application, rejection

05/01/2016 11575 Pechnik (Moscow)

Content:

1. Worker or stove?

2. What kind of bricks are used in the kiln? 3. Bricks in the kiln 4. Rejection and selection 5. Finishing the kiln 6. To summarize: what to choose from? A brick oven is expensive due to its positive impact on the human condition. During the winter cold or cool off-season, you don’t have to worry about optimal temperature and humidity levels, and the microclimate of your home is characterized as favorable. A high-quality stove can only be built from good material, the main one of which is brick. If you are not careful when choosing a brick, the effect may subsequently be the opposite. A competently selected assortment of bricks for fireplaces directly influences its subsequent cost-effectiveness of use. Most of the heat from a stove built randomly from materials, without placing them in a specific place, will simply evaporate into the atmosphere, and this will happen when the heating device is lit. Thus, when laying stoves and fireplaces, it is impossible to use the same type of material; the bricks must first be disassembled and a thorough inspection must be carried out.

Attention! The cost-effectiveness of brick fireplaces is especially important for the owner, since the performance of the structure depends on the type of material used and the type of construction.

A fireplace is another popular type of heating device, and today it is considered a guarantee of comfort and a symbol of the security of its owner. But this hearth should not be taken only as a stylish piece of furniture; it must be built with all responsibility, because later it will be used as a heating object. First you need to decide on the type of brick for laying out the fuel part; if you do this correctly, the fireplace will be an economical and highly productive device.

Among other things, using a special figured brick, you can get an elegant and impressive object without the use of any expensive finishing. Note that by overpaying for decorative material, you save on expensive finishing. By installing such a fireplace in your home, you can style the room much more effectively than, for example, a bio-fireplace equipped with fire-resistant glass.

Thus, let's take a closer look at such an important material as brick, consider the types and varieties, how the material can be sorted and rejected, as well as which brick is suitable for decorating stoves and fireplaces.

Worker or furnace

Of course, it is easier to purchase stove bricks sold in specialized stores, made from selected raw materials.

However, there may be a problem here. In order to improve the grade of the material, manufacturers use additives (additives), which subsequently do not allow the furnace to “breathe”. In addition, there is the cost of the material. Bricks purchased in stores will cost you much more than kiln bricks. That is why ceramic brick is most often used to lay out hearths. Rejection options can be very different; the main thing is to determine them from photos of samples and by examining the entire batch.

Regarding the discrepancy between the standard size, which is also called a “module”, of heat-resistant and ceramic bricks. Modern refractories are produced in different sizes, and determining their quality is much easier than can be done with ordinary bricks.

What bricks are used in the kiln?

The hearth mass is made, as a rule, from traditional ceramic bricks - working and facing.

The material should have even, smooth spoons and pokes. Based on this, this or that masonry is given a name, that is, depending on which side faces outward. If the spoon is facing outwards, it is a spoon laying; if it is a poke, it is a poked laying. To lay out the stove, bedding is not used, which is considered fragile and is used (but only in rare cases) for lining round stoves. For laying the stove, solid single bricks are used, in which there are no internal voids. All material must correspond to the module, but the modules can be different, so it is not recommended to use one module for the same fireplace; the masonry may turn out to be short-lived and the stove will simply fall apart. It is possible to lay out a firebox from one module, because it still has to be made as a block built into the body of the hearth with thermal expansion joints.

Which brick is better to refuse?

Unfired raw brick, as well as silicate and slip-cast materials cast by a special method, are absolutely not suitable for the construction of stoves and fireplaces. Raw brick has increased hygroscopicity, and a fireplace made from it will become limp even in a dry room. Silicate is considered low heat resistant, which entails rapid thermal conductivity. The cast one does not fit well, since the solution in it does not sinter, but dries out, which can turn the oven into a pile of rubble with frequent mechanical shocks. Hollow bricks are also subject to mechanical destruction.

Red clay brick must be made in a special way, only then can it be used to build a stove. There are two ways to perform the material. The first is plastic molding, and the second is semi-dry pressing.

First way:

Before firing begins, the molding mass should be passed through a profiled die, resulting in a layer of the required shape. After this, the layer is cut into pieces of the required size, adhering to the module.

Second way:

a pre-prepared molding mass, to which a small amount of water is added, is placed in a mold, then pressed, the water is squeezed out, and the material is fired. Firing is carried out for eight to fifteen hours at a temperature of nine hundred to one thousand one hundred and fifty degrees. The second option is considered the most perfect, since the material is of the required size and its surface is smooth.

According to experts, only the highest quality ceramic bricks and only plastic molding are used to lay the hearth mass. Follow this rule, because we are building a stove to last for years, and it can serve not only you, but also your children. And yet, why plastic molding? The answer is simple, water imparts plasticity to the molding mass and participates in the chemical reactions that occur during the initial combustion of the hearth. Pressed bricks have many shapes, so they do not withstand thermal loads well and do not “breathe” well.

Today, some domestic and foreign manufacturers offer an interesting version of brick with pimples (it is shown in the picture). It seems like a good option - the pimples increase the adhesion of the bricks to the mortar and, as a result, the durability of the entire heating device. But! Such a brick can only be obtained by pressing, so later, when using such a stove, a problem may arise with periodic heating of the hearth - the material may simply burst in the center. So, be careful! Choose the material wisely, but if you don’t have enough such knowledge, turn to professionals.

Solutions.

It's no secret that the main stove mortar is clay mortar. A cement-based solution can be used to line the fireplace. It can also be used for laying out the fuel part, but as the basis of heat-resistant concrete. It is also used if aluminous cement of the GC-40 or GC-50 grade is not suitable for external work. As a filler for the firebox, fireclay fillers ZShA, ZShB are used, as well as the fireclay itself.

Fire bricks

Refractory (heat-resistant) bricks are produced by firing under high temperatures or by pressing. When laying out furnaces, fireclay or quartz bricks are most often used. More often, of course, fireclay, since quartz has a small coefficient of thermal expansion. Quartz brick is made on the basis of quartz sand, which allows it to be used in places of contact with metal elements, such as beams and pallets.

Quartz brick is afraid of pairing with substances that have an alkaline reaction, so it is dangerous to use it in fireplaces.

There is only one single case in which the material can be used, but we will talk about it further. Fireclay brick is considered the best furnace refractory. The method of connecting it to ceramic material represents a fairly popular unit and is five to six millimeters. If the material is properly prepared and laid with high quality, it will serve you faithfully for many years. Fireclay bricks can be of different colors, depending on the type of clay used. The best option is straw-yellow bricks.

Fireclay and quartz bricks are very similar to each other; they can be distinguished by small dark inclusions that are present in the quartz material.

Brick size and shape

The parameters of a traditional working solid red brick are twenty-five by twelve by six and a half centimeters; this is a building module. Provided that you will build a fireplace from this material, the fireclay brick used for the fuel chamber must also be appropriate. Regarding the building module, fireclay bricks are produced under the brand Ш-8.

Before building a hearth, a project is carried out. In this case, the project begins to be done from the firebox. Today's variety of materials, and a huge variety of special shaped bricks are produced by industry, allows this to be done without much difficulty. The parameters correspond to the furnace module, which has been used since ancient times and is twenty-three by twelve and a half by six and a half centimeters. Therefore, these will be the default material sizes for most heating appliances.

Sh-8 brand brick is also produced in a furnace module, so when purchasing, you should check the dimensions of the material. In addition to everything else, they produce narrowed and narrowed bricks of reduced thickness, the dimensions of which are two hundred thirty by one hundred fourteen by sixty-five millimeters and two hundred thirty by one hundred fourteen by forty millimeters. Using tapered bricks, you can design a firebox made from working bricks. This is not easy to do, but the firebox will give off heat as efficiently as possible later.

Shaped bricks

. Wedge-shaped bricks and wedge bricks require special attention. They can be rib or end. The rib elements are presented in the form of an isosceles trapezoid. The dimensions of the bases of the trapezoid in the brick type mark are written using a fraction: 230x114x65/55 mm. The most popular sizes of rib wedge bricks are the following numbers: 230x125x65/55, 230x125x65/45 and 230x114x65/55 mm.

End-type wedges are usually used for laying the locks and heels of semicircular arches, as can be seen in the figure. When constructing fireplaces, such bricks are produced as shaped decorative bricks (in the picture they are shown on the left at the very beginning). Since stove arches are most often shallow, they can be built from ordinary bricks with varying seam widths. But at the same time, the thrust bearings on the horizontal masonry should be cut off.

Box, three-center and semi-elliptical arches are built somewhat differently. To make the heels, ribbed wedge-shaped bricks are used here. If you do not comply with this requirement, the arch may not withstand it and fall apart, which will render the stove unusable. In this case, rib wedges are used (size - 230x125x65/45 millimeters) with undercuts, they are also solid, and 230x125x65/55 millimeters.

Bricks for lining furnaces

. The requirements for it are not as strict as for the material from which the fuel chamber and the hearth array are laid out. Often second grade brick can be used for cladding. Of course, you need to sort bricks not according to external features, but according to technical characteristics.

Just like working bricks, the facing material used for laying hearths must be produced by plastic molding. They can be seen in the picture on the left - the material is smooth and beautiful. On the right, the bricks are pressed or slip; they do not adhere well to the mortar and do not tolerate temperature changes well.

Clinker brick

made from clinker - a mass based on special clay. Clinker is fired at elevated temperatures (from one thousand three hundred to one thousand five hundred degrees Celsius). By and large, it's just a badly burned brick. According to its external characteristics, it represents a dark-colored element, and frozen smudges are noticeable on the spoons.

Clinker bricks can withstand heating up to one thousand two hundred degrees Celsius and are distinguished by their high strength and thermal conductivity. Since solid brick has almost no pores, it has good frost resistance, does not react to aggressive substances and fits well with red ceramic bricks. Due to its high cost, it is rarely used in the construction of hearths.

Brand of brick, what should it be?

The brick marking represents a letter with a number. The numbers indicate the compression force (in kilograms per square centimeter). Typically, a standard kiln uses M150 brick. if the stove is two-story, then the brand is M200 - M250. The highest grade of brick made from natural raw materials is M300, then the question arises, where does the material of grade M350 - M500 come from? It's simple, it's a matter of synthetic additives. However, if such additives are possible during the construction of buildings, then for the construction of fireplaces they must be excluded.

It is worth noting that grades M75 and M100 are not recommended even for the construction of small country stoves. Why? To produce the material, poor raw materials are used, so the brick does not tolerate temperature shocks well.

The marking of bricks is also related to their size. For the construction of a fuel chamber, the cheapest option is most often used, such as Ш5, Ш8, ША5 and ША8. ША8 and ША5 – lightweight lightweight material. When constructing a firebox, this difference does not matter. Typically, Ш22 – Ш45 are used for combustion vaults. in this case, the first numbers indicate the type of wedge: either rib or end.

Brick in the oven

We will look further at how to cull bricks unsuitable for construction and select those suitable for laying.

Well, now we have looked at what constitutes first, second and third grade material. It is worth noting that the division into varieties is absolutely arbitrary; it would be more correct to call them categories. A quality brick is considered to be one that is laid with skill in a place suitable in terms of parameters and characteristics. Let's turn our attention to the stove from a material point of view. In the figure we can observe the foundation (1), firebox (2), smoke circulation (3), cladding (4), chimney (5).

The foundation distributes the total mechanical load of the entire heating device, and therefore must be strong and durable. however, this is not all - the base must be laid out in such a way that no hearth becomes damp over time. Thus, the foundation must have high moisture and vapor resistance. Since our winters are cold, the foundation below can be cooled to sub-zero temperatures, so it must also be frost-resistant. It follows from this that for laying the foundation you need to take only the most selected material. It must be clinker or third grade brick. How? let's list:

- The cheapest brick is considered to be the third grade.

- when building a tall Dutch oven, it is more rational to use first-grade brick, because all grades come out when sorting the same pallets.

- in areas with harsh climates, it is recommended to use clinker bricks, which are able to support any weight.

The temperature mark in the fuel chamber area can reach one hundred thousand degrees Celsius, this is the limit for ceramic bricks, and at one and a half thousand the material begins to melt. Note that in a mechanical load panel, the firebox does not experience great impacts, but must actively receive heat and fully accumulate it, transferring it further to the hearth array. Thus, the fuel chamber is lined with fireclay material, the thermal conductivity of which is better than that of the working one.

Let us separately make a reservation that fireplaces with intense thermal conditions should be made of refractory ceramic bricks.

Smoke tooth

An interesting name for an important element of a stove or fireplace, which is used to eliminate smoke in a heated room. The requirements for a smoke tooth are quite high: it must be durable, tightly connected to the body of the stove, and most importantly, the smoke tooth must reflect heat rays well. This is especially important for a fireplace; the fireplace releases heat into the room by convection, so the inclined surface of the tooth represents a kind of thermal mirror.

Thus, the chimney tooth represents the only place that can be laid with quartz bricks. If earlier it was difficult to do this, since there was nothing to cut the material with, today the brick can simply be cut with a grinder and a diamond wheel.

Smoke circulation does not have close contact with the flame, but this does not mean that the temperature there is low; sometimes the temperature reaches four hundred to eight hundred degrees Celsius. Flue gases usually burn out in smoke ducts, and therefore are characterized as chemically active. Among other things, heat is also accumulated here so that it is enough until the next heating, so this part is made of first-grade brick.

Attention!

Indicators such as thermal conductivity and heat capacity of brick directly depend on the density of the material. The first grade is considered the highest quality brick, therefore it is recommended for the most critical areas of the stove or fireplace.

The significance of such a part of the hearths as cladding is of great importance, although at first glance it seems that the finishing plays a purely decorative role.

Do not mistakenly think that the cladding is used only to ensure that the finish adheres to it. To cite some numbers as an example, the temperature underneath can reach one hundred and twenty to one hundred and forty degrees, and outside – from eighteen to twenty-five degrees. Thus, it would be more expedient to line the stove with second-grade brick; the material has the necessary porosity, which will allow the stove to breathe and fill the scrap with heat. And if you take into account the roughness of the brick, you can guarantee excellent adhesion to any mortar. According to experts, a pipe is considered to be some part of the chimney located above the view. In this place, the temperature can vary from minus forty to plus four hundred degrees, and humidity - from ten to one hundred percent. This area may be subject to precipitation and gusts of wind. But, be that as it may, the pipe must be heated in a variety of climatic conditions; if this requirement is not met, a slow increase in thrust will occur and excessive fuel consumption will occur, as well as sedimentation of solid combustion products. Thus,

- if normal conditions for using the fireplace are expected, first grade brick should be used.

- You can also use old stove bricks, called “mezhigorka” or small bricks, this is considered the best option. Let's make a reservation that old brick should only be laid from the inside of the fireplace, since dark spots can show through the finish.

- in areas with harsh winters, the masonry should consist of two layers. The inner layer is clinker brick and the outer layer is made of first grade hollow brick. Note that this is the only case where hollow brick can be used.

Bricks for sauna stoves

The specifics of the functioning of a sauna stove are known and described in many literary sources. In literary terms, the breathing of the hearth must be precise and sharp, so you need to start digging bricks, guided by the following characteristics:

- Fireclay and quartz bricks cannot be used for laying sauna stoves, since according to the technical specifications their use and storage is unacceptable at a relative air humidity of more than sixty percent.

- The fuel chamber is usually lined with ceramic refractory material.

- the other part of the sauna hearth is made entirely of first-class brick.

- It is recommended to build a small stove from clinker bricks; as a result, the stove will be almost equivalent to a cast iron structure, which means high temperature and rapid heat transfer.

Choosing bricks for a Russian stove

When choosing a material for building a Russian stove, the following features should be taken into account:

- absolutely all orders of Russian stoves are adjusted to the main stove module: twenty-three by twelve and a half by six and a half centimeters.

- the entire hearth is built from first-class ceramic bricks.

- the lower part of the furnace (under) is built from refractory ceramic bricks, this can be a hearth brick or its close analogues.

What does the name "hearth brick" mean?

the hearths of some variants of the hearth are laid out of it, in this case, the Dutch oven and the Russian oven. Among other things, pallets with bricks of this type are installed under the kiln or on a special lower shelf of the rack. Thus, the brick does not overheat during firing, which allows it to be of high quality. In specialized stores, bricks are supplied exclusively separately. Analogs of this material include Gzhel refractory brick, as well as Borovichi material.

Rejection and selection

Bricks rejected for the following characteristics are considered unsuitable for heating structures:

- With dimensions that do not correspond to the module.

- With visible cracks, burrs and burrs from cutting, as well as with foreign inclusions.

- Bricks that are heavily burned are dark in color, bloated, warped, with spots appearing on the edges.

- This group also includes bricks that have traces of gases in their solids. If the solid of the element contains traces of gas emissions, which usually appear during firing, they have the appearance of rounded shells (also called “cavities”) with a single-colored inner surface.

Separately! For fireclay bricks, you can have up to four shells per element, but there should not be more than one per face.

Brick varieties

Ceramic bricks are sorted as follows (see image):

First grade

bricks (on the left in the figure) - a uniformly annealed element with optimal density, number and pore size. The surface of such bricks is smooth, and the color is beautiful and bright, saturated, from pure red to slightly yellowish. When you tap the material, you get a beautiful, even, metallic sound. A fifty-gram hammer is used for tapping. The cuts are without visible burrs, the edges of the brick do not crumble, they are smooth and straight. Often, the presence of iridescent spots can be noted on the edges, or a continuous film is noted.

Second grade

brick (shown in the center) represents slightly unburnt material. Such a characteristic as frost resistance is weak, but the porosity is slightly increased, the heat capacity of the second grade brick is slightly less than that of the first grade elements. The characteristic features of bricks are their large number per ton, almost up to four hundred and twenty pieces versus three hundred twenty to three hundred and forty pieces of second-grade bricks. If you knock on the bricks with a hammer, the sound is clear, but a little dull. When cutting, small nicks and chipping of the ribs are formed. There is no rainbow film; if there is one, it is due to the plasticizers used.

Third grade

brick (image in the figure on the right) - the material is moderately burned. It has a high density, about two hundred and ninety pieces per ton. It is not recommended for foundation construction, as it has low frost resistance and good thermal conductivity. Externally, the color is deep dark to brown. The brick begins to ring when tapped and often has crumbled ribs. On sale it is called “iron ore”.

Rules for rejecting fireclay:

A reliable way to reject fireclay bricks is simple; just drop them from a height of about one meter onto the stone floor. With such a fall, high-quality material splits into large elements, and bad ones into small parts. The method is quite reliable, so it is often used in production, testing several pieces from different batches of material. But not all companies will allow you to hit bricks, so you can use another method:

- We run our fingers across the ribs, there are no crumbs or dust left on the hand, we check further.

- tapping: the sound is even, long-lasting, this is the first grade, which is suitable for laying out fuel chambers, as well as furnaces operating under intense conditions (bell-type furnaces, Kuznetsov furnaces).

- if the sound is clear, short, abrupt, you have a second-grade brick, also suitable for other fireboxes.

- but the dangerous dull sound of a brick - this is a marriage.

Furnace finishing

Provided that the stove plays an independent role and is used in everyday life not only for heating, but also as part of the interior design of the room, then it is more advisable to use plastic-molded facing bricks for its decoration. Almost always this is a second-grade material, which is more suitable than any other for lining a heating device. The finishing of the stove with bricks is carried out during the laying of the unit, thus, it is possible to achieve two goals at once: the stove will subsequently breathe and release the required amount of heat into the room, the fireplace will acquire a beautiful aesthetic appearance, and the necessary neat bandaging of the seams will also be carried out.

When covering an old fireplace, it is necessary to evaluate the condition of the old seams. If they dry out, the problem should be corrected to prevent the material from peeling off later. Professionals first line the stove with unglazed tiles, and only after that bricks are laid on the mortar. Nowadays it’s much simpler - the mortar for laying the cladding is mixed with aluminous cement.

To summarize: what to choose from?

As a rule, there are practically no offers from manufacturers of bricks of the second or third grade, and they do not sort it, since it is believed that the third grade is suitable for construction.

This results in the presence of different materials in one pallet. When you decide to build a stove, at the initial planning stage, immediately calculate how many bricks will be needed for your hearth. Since more than one pallet will be required for the fireplace, decide with the manufacturer, first selecting the material visually based on pictures and prices, and after that, in the warehouse, inviting a knowledgeable craftsman, buy bricks using the selection and tapping method.

Stock up on material for future use, as situations are different, and a small amount of additional bricks will not hurt.

Video to watch

Just a little about solutions

Usually, when laying a stove, clay mortar is used. Although, for example, the cement composition is also used in the furnace business - when lining an already finished structure. It is also sometimes used as fire-resistant concrete when arranging a firebox.

When performing work in the combustion chamber, fireclay sand or special fireclay fillers ZShA or ZShB are used as a filler. Although the labeling of these mixtures is different, there is practically no difference between them.

The quality of the stove’s functioning depends on the choice of brick. Due to the variety of brick products, it is important to choose the right building material for each stove element, which will ensure optimal operation of the entire heating unit. Home comfort, warmth in your homes, a quiet life and the well-being of the whole family depend on this.