Home / Heating

Back

Published: 12/18/2020

Reading time: 3 min

0

793

The question of what is the difference between a hydraulic accumulator and an expansion tank remains unclear to some consumers, although such equipment has been used in boiler houses for quite a long time.

Water supply and heating systems cannot be imagined without such successful additions; most people are accustomed to distinguishing these devices by their shade.

One of the units is available in blue, and the other in red, but their structure has its own nuances. I want to analyze in detail the differences between the devices and describe the purpose of installing each type of device.

- 1 Design and purpose of the expansion tank

- 2 Design and purpose of the hydraulic accumulator

- 3 What are the differences 3.1 How does the expansion tank work

- 3.2 How a hydraulic accumulator works

What is an expansion tank?

An expansion tank is a container that compensates for the thermal expansion of the liquid inside the heating system.

There are two types:

Open expansion tank

- Open type - designed to work in heating systems with a working pressure of 1 atmosphere. It is a steel container with threaded connections. Most often, this type of expansion tank is used in gravity heating systems. They are still popular among villagers because of their independence from electricity.

- Expansion chambers or membrane tanks - this type is designed to work in closed heating systems, the pressure in which does not exceed 3 bar. The maximum temperature of the coolant in them should not be more than 100 degrees Celsius, and the pressure should be kept within 8 atmospheres. In addition, they are used for “piping” indirect heating boilers, where they compensate for the increase in the volume of sanitary hot water. It is worth remembering that in this case they do not replace the boiler safety group.

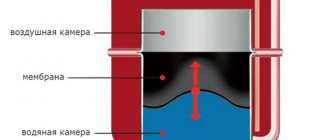

At its core, it is a steel casing divided into two parts by a rubber membrane.

In one part of the tank there is coolant under pressure, and in the other part air is pumped.

For clarity, look at the figure below:

Design of a membrane tank and principle of operation

Among buyers, models with a balloon-type membrane (in slang it is called a pear or a heating pad) are more popular.

This is explained by their maintainability - in case of damage, the membrane is easy to replace.

The thread on the pipe can have two standard diameters - 3/4 or 1 inch.

This depends solely on the manufacturer and is not a fundamental point.

The standard air pressure value, in turn, is 1.5 bar and can be changed by the consumer.

I will give advice on my own behalf - it is better to install a tap with a drain valve on the connection pipe.

This is necessary to periodically check the air pressure.

Tap with drain valve

It is done in the following order:

- The tank is cut off from the heating system by turning off the tap.

- The drain valve removes the water remaining inside the container.

- Using a car pressure gauge, air pressure is checked.

If the check is not done, the air pressure will sooner or later drop.

This will cause the membrane to begin to rub its walls against the steel body, which will lead to accelerated wear.

Continuing the topic of checking the condition of the expansion tank, I suggest you watch the following video:

Expansion tanks with a membrane in the form of a diaphragm can most often be seen when opening the lid of a wall-mounted gas boiler or electric mini boiler room.

It can look different, but most often you will see this:

Expansion tank in the boiler

If the rubber band inside such a model breaks, then it can only be replaced entirely.

Since it is hermetically sealed at the manufacturer’s factory. Now let’s talk about these “rubber bands” in more detail.

How is the membrane for the expansion tank constructed?

As mentioned above, the membrane is needed in order to divide the tank capacity into two parts.

It is a rubber product with thick walls (this is necessary to maintain tensile strength), which has a neck on top for a flange.

If you don’t understand what it looks like, look below:

Replacement membrane for expansion tank

Membranes are currently made from an elastomer called EPDM. It is approved for use with drinking water and does not release any harmful impurities into it.

Expansion tanks with such a rubber band can be used not only with boilers, but also with indirect heating boilers.

And if necessary, they can also be used as hydraulic accumulators for pumping stations.

We'll talk about them a little later, but now we'll learn how to choose an expansion tank for your heating system.

Design and purpose of devices

Expansion tank

Both types of devices used in autonomous systems have a similar design and operate on the same principle. Let's look at the main elements of the products using the example of an expansion tank for a heating system:

- The main purpose of the tank is to compensate for the expansion of the coolant. When heated, water increases in volume, and quite strongly (+0.3% for every 10 degrees Celsius). In this case, the liquid practically does not compress, so the heated coolant will exert significant pressure on the walls of the pipes, joints and shut-off valves.

- To compensate for this pressure, as well as to minimize the consequences of water hammer, an additional reservoir is built into the system - an expansion tank. The first tanks were of a leaky design, but today pneumatic-hydraulic models are almost universally used.

- Inside such a tank there is a membrane made of elastic material. Since the membrane is in contact with a heated coolant, it is made from polymers that are resistant to high temperatures - EPDM, SBR, butyl rubber and nitrile rubber.

- The membrane divides the tank into two cavities - the working cavity (the coolant enters it) and the air cavity. As the pressure in the system increases, the air chamber decreases in volume (due to air compression), and this compensates for the load on the pipes and shut-off valves. Approximately the same thing happens with water hammer - but here the process occurs at a faster speed.

- As the temperature of the coolant decreases, the volume of water decreases, and the air, exerting pressure on the membrane, displaces an additional volume of hot water into the pipes of the heating system.

Hydraulic accumulator

The hydraulic accumulator, at first glance, is practically no different in design from the expansion tank:

- The base is the same container made of corrosion-resistant steel, only painted blue.

- There is also a membrane inside the container - although it is slightly different in shape from the membrane of the expansion tank.

- The internal volume is also divided into two chambers, only in hydraulic accumulators the water chamber is located inside the membrane, i.e. Contact of the liquid with the metal walls of the tank is completely eliminated.

And the design functions on a similar principle, although it is used for a different purpose:

- When the pump is turned on or water is supplied through a centralized water supply, the chamber is filled with liquid under a certain pressure.

- If the pressure drops for some reason, the air chamber increases in volume and water from the working chamber enters the system. Thanks to this, the pressure in the pipes is stabilized, and the equipment (washing machines, dishwashers, etc.) works without failures.

- The second aspect of the operation of the hydraulic accumulator is protecting the pump from frequent starts. While it is possible to compensate for the withdrawal of water from the system due to the reserve in the tank, the pressure switch will not operate and the pump will not start pumping water. Thus, the equipment will turn on less often, which means it will work longer.

- A large hydraulic accumulator (50, 100 or more liters) is also a water supply. Yes, you won’t last long on such a supply, but if you use it sparingly, you can easily survive a water supply accident or a power outage that will make the pump impossible to operate.

- In addition, the hydraulic accumulator, like the expansion tank, compensates for water hammer.

Calculation of the volume of the expansion tank for heating

As we said earlier, the main function of the expansion tank is to compensate for the thermal expansion of the liquid.

Therefore, the volume of the tank will depend on the total volume of liquid in the system, as well as on its expansion coefficient.

Let's calculate the volume of the membrane tank you need using the following formula:

Vtank = Vcoolant*kexpansion/P, where P = (Psystem - Pair)/(1+Psystem).

Let's decipher the formula:

- Vtank is the required volume of the expansion tank.

- Vcoolant is the total volume of coolant in the heating system.

- kexpansion is the coefficient of thermal expansion of the coolant. This value depends not only on the chemical composition of the liquid in the system, but also on the operating temperature range of the boiler.

- Psystems - the maximum possible pressure in the boiler.

- Pair - air pressure in the expansion tank. Typically it is 1.5 bar.

To calculate the volume of an open expansion tank, it is enough to take the pressure in the system equal to 1 atmosphere, and the air pressure will be equal to zero. Since the open tank does not have a membrane.

Let's sum it up

Hydraulic accumulators and expansion tanks have different purposes, but belong to a common group - expansion tanks. What to choose specifically in your case? First you need to evaluate the entire system and decide what function this device should perform. If you need a pressure tank for drinking water, you should use a hydraulic accumulator with a pear-shaped membrane.

If it is necessary to compensate for the expansion of the coolant in the heating system, then use a membrane expansion tank (expanzomat), in which the diaphragm is designed to operate at high temperatures.

☛ Select expansion tank

Installation of a heating expansion tank

Now let's talk about how to properly install an expansion tank in a heating system.

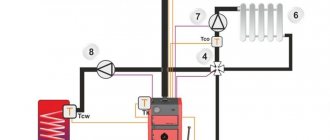

Let's start by looking at the following picture:

Installation of an open heating expansion tank

The picture above shows a heating system with an open expansion tank.

With the help of this figure, the issue of its installation is clearly and clearly resolved - an open-type expansion tank should be installed at the highest point of the system.

Usually, it is installed in the attic or, in extreme cases, under the ceiling.

If this is not done, then water or antifreeze will simply begin to pour over its edge.

In the case of a closed heating system in which a membrane expansion tank is installed, there are no such restrictions.

Usually, they are located directly in the boiler room next to the boiler. It looks like this:

Installation of a membrane expansion tank for heating

To secure the container to the wall, brackets of different designs are used.

Some manufacturers combine them with security groups. For clarity, look at the figure:

Bracket with safety group for expansion tank

This is not the only possible fastening option, but we will not consider the others.

Let's move on to the next part of the article, dedicated to hydraulic accumulators.

What is a hydraulic accumulator?

For a better understanding, I will immediately show you a picture showing a pumping station:

Pump with hydraulic accumulator and pressure switch

From the picture you can see that a hydraulic accumulator (abbreviated as HA) is a container to which a pump with a pressure switch is attached.

Inside, this container is designed in the same way as a membrane expansion tank.

Moreover, they often have exactly the same EPDM membranes.

The air pressure in the HA is also 1.5 bar and, if desired, it can be increased or decreased.

Many installers use hydraulic accumulators instead of expansion tanks in closed systems.

It’s not uncommon to see photos like these on the Internet:

Hydraulic accumulator in the heating system

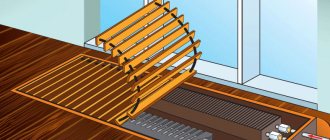

In addition to horizontal GA models, stores have their vertical counterparts.

They are most often used to assemble a pumping station based on a deep-well pump.

Hydraulic accumulator operating principle

A separate article has been written about the need for this.

What does a hydraulic accumulator do?

Why do you need a hydraulic accumulator?

This “device” has two main functions:

- It is necessary for the correct operation of the pumping station automation. This applies not only to the pressure switch, but also to some pump control units. For this function, the tank volume is not particularly important. For example, miniature pumping stations with a vortex pump have a tank volume of 1 liter.

- Reducing the number of pump starts - this helps reduce the negative impact of starting currents and save energy. For this function, volume is most important. If you need a full-fledged buffer container with water, then you need to choose a capacity of 80, 100 or more liters.

How to choose a hydraulic accumulator?

Based on what was written above, we can say that the choice of a hydraulic accumulator is not strictly tied to the parameters of the water supply system.

But this does not mean that you need to buy the first one you come across.

For example, if your pumping station will operate in conditions of high humidity, then it is better to purchase a hydraulic pump made of stainless steel. This will significantly increase its service life.

That's probably all. I look forward to your questions in the comments and likes on social networks. See you again on the pages of this blog!

Hydraulic accumulator

The main functions that a hydraulic accumulator performs in a water supply system are similar to the functions of an expansion tank in a heating system. First of all, this concerns maintaining sufficient pressure. The most common water supply scheme for a private home includes not only a pump that lifts water from a well or a well, but also a hydraulic accumulator that provides a small supply of water in case of a power outage or pump breakdown.

However, the main task that the hydraulic accumulator solves is to ensure stable pressure regardless of changes in pressure in the system caused by opening the tap or turning the pump on/off. It is selected taking into account the characteristics of the pump, the number of taps, plumbing fixtures and the number of residents. The optimal choice allows you to significantly extend the service life of the pump, because reduces the number of on/off switches. Without a hydraulic accumulator, the pump would turn on every time someone opened the tap for a minute.

The required volume of the hydraulic accumulator can be calculated using the formula

Vt = K * Amax * ((Pmax+1) * (Pmin +1)) / (Pmax - Pmin) * (Pair + 1)

where Amax is the minimum water flow, liter/min; Pmax - pressure at which the pump turns off, bar; Pmin – pressure at which the pump turns on, bar; Pair – pressure in the air chamber, bar;

K – coefficient taken depending on the power of the pump motor

- — for a pump with a power of 0.55–1.5 kW – coefficient 0.25; - 2.2-3.0 kW - 0.375; - 4.0-5.5 kW - 0.625; - 7.5-9.0 kW - 0.875.

The resulting value will be optimal in most cases, however, if there are frequent power outages, it makes sense to choose a larger volume. At the same time, it is worth remembering that if the water is idle for a long time, its quality will deteriorate.