The heating unit, developed in Canada specifically for mobile teams of lumberjacks, has won recognition all over the world due to its high efficiency and safety in operation. The wood-burning stove Buleryan (bullerjan) is used today as a heat generator for air and water heating of private and country houses and outbuildings.

Stove Buleryan (Breneran)

How does the Buleryan stove work?

The Buleryan stove is often compared to a potbelly stove and a regular long-burning wood stove. We can say that the device took elements from both.

The operation of the oven is based on the principle of convection. Pipes for heat exchange are connected to the volumetric secondary chamber, in which the process of burning wood occurs. The principle of their operation is very simple. Cold air enters the pipe at the base of the Buleryan stove, and then comes out already heated at the top of the structure.

The furnace body can be of two shapes. For small rooms, cylindrical Buleryan stoves are most often made. For a large heating area, the stove takes on a teardrop shape. Pipes are placed on the outside of the structure. To ensure maximum heat transfer, they are soldered into the structure and protrude by only one third.

Operating principle of the Buleryan stove

The furnace firebox consists of three parts. A grate or fire-resistant mesh is placed at the bottom of the firebox. They can be made of cast iron or steel with a thickness of at least 4 millimeters. There is a special compartment at the top of the firebox. It is obtained thanks to a partition, for the manufacture of which a steel sheet is used. This compartment is also called the secondary chamber. In it, the combustion of gases occurs, which are released during the burning of wood. Combustion of fuel in the furnace itself is not complete. The released combustion products pass into the chimney. The length of the chimney is about 1 meter. Due to this part of the furnace, the combustion process becomes slower, and the combustion products cool down. The chimney is made curved and contains an economizer. Thanks to this device, secondary combustion of gases occurs. This stove structure increases heat transfer by 20% compared to other stoves.

The combustion process of wood is regulated using a damper. The damper is a damper near the exit from the firebox that regulates the intensity of the draft. It is attached to the pipe using a special metal rod. On the door, by changing the position of the gate, you can regulate the intensity of the oven.

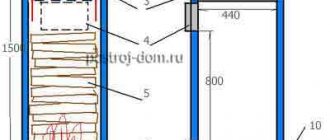

Scheme of the Buleryan furnace

The Buleryan stove is enough to heat a room of 100 m3. This will take no more than 3 hours. Large designs of the Buleryan stove are suitable even for heating large rooms, up to 400 m3. Not every oven can cope with such a task.

Keeping warm is also easy. Buleryan is an economical stove that requires adding firewood only twice a day.

Furnace structure and its elements

The design of Buleryan stoves is designed for the use of solid fuel - firewood, less often coal or compressed wood waste is used.

The design of such stoves is extremely simple, which allows you to assemble them yourself using a minimal set of tools. Collapse Contents:

- Principle of operation

- Dimensions

- About water bullers

- Bullers without pipes

- What is the efficiency and can it be increased?

- Conclusion

The Buleryan-type potbelly stove is externally a steel barrel with pipes that can be located on top and/or bottom of the structure. It combines the pyrolysis type of combustion and the functions of a convection heater. The heat generated during fuel combustion immediately goes into the pipes (air ducts), which increases its productivity by up to 80-85%.

Construction of the Buleryan stove in the photo (sectional view)

Structural design of the Buleryan furnace:

- The largest part of the structure is the combustion compartment of the placed solid propellant element (occupies 85% of the volume) - the processes of primary ignition and generation of pyrolysis products occur.

- Compartment for afterburning fuel (25% of the internal volume of the unit) - pyrolysis products enter, after which the residual fuel burns to form a flame, the process is accompanied by the release of high temperature.

- Injectors - tubes for supplying air to the afterburning chamber (necessary for carrying out the combustion reaction of pyrolysis products).

- Pipes for the convection process - this element of the Buleryan pyrolysis furnace is made from thick pipes made of metal. They receive heat released during the combustion process, which exits into the room through an opening in the pipes in the form of streams of warm air.

- Regulators - this part of the stove consists of two mandatory elements necessary to regulate the operation of the unit - the damper and the throttle on the door. A function is implemented that allows you to regulate the air supply to the afterburner chamber. The temperature of the released air is controlled.

- The chimney (with or without a container for collecting condensate) is a function of removing combustion products.

- Ash pan (located at the bottom of the structure).

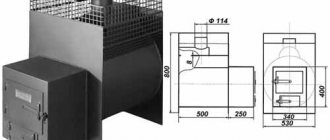

Buleryan device with a water circuit

The Buleryan wood-burning boiler with a water circuit has a simple and effective design. The equipment is equipped with levers to control the combustion process, a power regulator, a gasifier, and a large combustion chamber. Afterburner injectors are located in the front pipes.

Setting up the stove is easy, it is done using levers, the combustion chamber is sufficient for a large volume of fuel, but it is recommended not to fill it completely. To increase efficiency, ash is also left in the firebox during operation.

An example of a buleryan with a water circuit

Buleryan device with a water circuit

The Buleryan wood-burning boiler with a water circuit has a simple and effective design. The equipment is equipped with levers to control the combustion process, a power regulator, a gasifier, and a large combustion chamber. Afterburner injectors are located in the front pipes.

Setting up the stove is easy, it is done using levers, the combustion chamber is sufficient for a large volume of fuel, but it is recommended not to fill it completely. To increase efficiency, ash is also left in the firebox during operation.

An example of a buleryan with a water circuit

Operating principle

General operating principle of the furnace:

- a manifold is placed on the convection pipes to connect the return and supply;

- during heating, pressure is created, the liquid can rise to a height of up to eight meters without using a pump;

- when pressure is created, the coolant flows to the radiators of individual rooms (a slight slope of the pipes is used for natural circulation);

- From the radiators, cooled water flows to the boiler for heating.

The principle of operation of a buleryan with a water circuit

Advantages and disadvantages

Buleryan has the following advantages:

- standard radiators are used for heating;

- the stove can be used for buildings without basements;

- connection to any heating system is available;

- the structure is assembled from heat-resistant steel that can withstand negative operating factors;

- installation of the structure is quick and does not require special knowledge.

Among the disadvantages, it is necessary to note the strict requirements for the arrangement of the chimney and the impossibility of operating the structure without a water jacket

Characteristics and selection criteria

The characteristics are, first of all, determined by the parameters of the room where they are going to install it.

For production, steel and cast iron are mainly used. Buleryans made of cast iron have great reliability and durability. At the same time, they are more massive and difficult to use in small rooms. Steel heaters are well suited for small spaces, but at the same time, they have less efficiency compared to cast iron ones.

The second important parameter is the number of water circuits of the heating system. A single-circuit system is designed for space heating only. In addition to heating, the dual-circuit system heats water for domestic needs.

The third parameter is the manufacturer of the solid fuel boiler. In this choice, you can rely on the reviews of people who have already become happy owners of a boiler from this manufacturer.

The remaining selection criteria do not depend on the parameters of the room and the boiler itself. This is the volume of the room, the material of the walls and ceilings, and the height of the chimney.

Pros and cons of the boiler

Buleryan’s device allows it to be used to quickly warm up and maintain temperature in various types of rooms.

The stove has become widespread due to a number of advantages:

- High rate of room heating. The presence of a convector made of metal pipes allows you to quickly warm up the air masses. Heat is transferred to the surface of the collector directly in the firebox.

- Long burning time. The Buleryan boiler can operate for up to 12 hours without additional fuel. This allows you to save wood and does not require the constant presence of a person near the stove during operation.

- Easy to install. No specialized education is required to install the product. If necessary, you can quickly dismantle the stove and transport it to another location.

- Safety. With the constant movement of air mass through the pipes, their surface is partially cooled. This eliminates the risk of burns when touching Buleryan surfaces.

- Easy to use. To understand how to drown Buleryan, no special knowledge or skills are required.

- Possibility of modernization. If necessary, you can make Buleryan with a water circuit.

The list of advantages does not end there. The high efficiency of Buleryan allows it to be used effectively for heating both residential and non-residential premises.

In addition to the above advantages, the oven also has a number of disadvantages:

- Requirements for the quality and type of fuel. The device allows for the use of wood or shavings as fuel. It is strictly forbidden to lay coal. The high temperature of its combustion will lead to rapid failure of the furnace surfaces.

- Formation of condensation. Firewood contains a large amount of moisture. When the stove operates, it evaporates and settles on the internal surfaces of the chimney in the form of condensation.

- Large product sizes. The Buleryan long-burning stove has a three-dimensional design. This requires free space in the room.

Installation of the Buleryan stove

The oven is mobile. Installation and dismantling of the product is not difficult. Installation does not require specialized education.

A person with minimal technical knowledge can perform the work.

Fire safety standards for installation

Buleryan is a furnace, some surfaces of which can heat up to high temperatures. This should be taken into account and fire safety standards must be observed during installation.

The stove is installed:

- on a non-combustible base. If the floor in a room is susceptible to fire when exposed to high temperatures, it is necessary to arrange a specialized area on which the product will be installed;

- distance to walls. Before installing Buleryan, you need to choose the right installation location. The stove heats the room by heating air masses. When choosing a location, you need to take into account the distance from the stove surfaces to the walls.

This parameter depends on the material from which the vertical surfaces are made. For wooden, unplastered walls, a minimum distance of 1 m is required. for concrete surfaces this figure is reduced.

Is a foundation needed for Buleryan

The location and method of installing the boiler differs depending on the preferences of the owner of the room and the materials from which the surfaces are made.

At the installation site, it is necessary to equip a specialized platform made of non-combustible material. Typically, a sheet of metal is used or a foundation is fabricated.

Some experts mount the stove on a stand made of a profile pipe.

The foundation is made with a height of 10–30 cm. The material for arranging the site can be brick, cinder block, concrete, etc.

The overall dimensions of the foundation must exceed the dimensions of the boiler. The protrusion located under the fuel loading hatch should protect the floor covering from sparks and heat.

Possible mistakes

When installing the Buleryan stove with your own hands, it is important to maintain all the necessary distances to vertical surfaces. This will ensure fire safety and free access to the boiler for maintenance.

What to look for when choosing

Before purchasing a stove, it is necessary to determine the volume of the room for heating which it will be used. It is better to purchase a product whose power exceeds the minimum required.

When choosing, there are a number of factors to consider:

- type of hatch for loading fuel. The oven door can be made in 3 options - all-metal, cast iron, with built-in glass. From an aesthetic point of view, it is better to choose a product whose hatch is equipped with an observation window. Manufacturers use heat-resistant glass. Thanks to this, the window does not collapse even with strong heat;

- type of draft control damper lever. Some manufacturers equip the damper control handle with an extension. In such models, adjustments do not require going to the back wall of the oven;

- presence of a hob. The stove can be manufactured in 2 versions - classic or with a built-in cooking surface. The Buleryan cooker does not differ in its characteristics from the classic model. If the stove will be used not only for heating the room, but also for cooking, you can choose a model with a built-in surface;

- a method of adjusting the amount of air supplied to the firebox. The blower hatch can be made of a damper or a latch located on the door body in the form of a butterfly. The choice is made based on the person’s personal preferences;

- protective screen. Some models have a casing on the side surfaces. It is used to protect against burns when touching Buleryan. If the stove will be used in a residential area, it is better to choose a model with a protective screen.

DIY installation of a heating stove "Buleryan" with a water circuit

Many people wonder whether it is realistic to do such an installation themselves and whether it will save money.

It is not difficult to build such a stove, because no special skills are required. To do this, you need to stock up on certain materials and tools. If you do not have any equipment, you can rent it at any repair shop.

Materials required to make the stove:

- pipes with a diameter of 5-6 mm;

- sheet metal with a thickness of 2.5 mm and more;

- gas cylinder;

- welding machine;

- angle grinder;

- Bulgarian;

- pipe bender;

- metal scissors, electrodes.

The furnace is built according to previously prepared drawing. As a basis, you can take the plan of a small stove for a utility unit and adjust it to the required dimensions.

Before work, it is important to practice welding seams: they must be strong. The safety of the entire system depends on their tightness.

Next, you need to prepare the parts of the furnace. To do this, you will need eight pieces of pipes (air ducts) of different lengths - from 1 to 1.5 m. Wide strips with semicircular ends must be cut from sheets of metal. All these parts bend at an angle of approximately 80 degrees.

The front and rear walls of the structure are made similarly to each other. First, a template is drawn, then a part is cut out of sheet metal using it. A loading window is cut out on the front wall, shifted slightly lower in the center. After this, strips of metal are welded along the entire diameter of the window, and from the outside. As for the rear wall, a hole is cut in the upper part in accordance with the dimensions of the pipe. A T-shaped pipe with a valve is mounted into the resulting opening, which is then welded to the body.

The air ducts are installed in a staggered pattern, starting from the rear wall. The outlet part of the rolled metal product must go outside. This design must be accurately calibrated and installed. Additionally, wooden blocks are used. Next, the seams are sealed at the joints.

The bottom wall is welded on the inside of the structure. To prevent the sheet from moving, it is first fixed pointwise, then along the entire perimeter. Ready-made metal strips are welded between the pipes.

The door for the Breneran stove with a water circuit is like a short cylinder. It must be designed to fit perfectly into the collar of the loading window. To increase the reliability of sealing, asbestos rope is used.

The next step is to cut out a hole for blowing, where you need to weld a pipe with a throttle valve. This element is quite simple to make. To do this, the pipe is cut along the axes and a flat disk with a pin is inserted. In addition, it is necessary to install a heat-reflecting screen on the inside. The fire door is hung on hinges and equipped with a lock. Similar parts can be made from leftover sheet metal or purchased ready-made.

Buleryan long-burning stove from a gas cylinder

Buleryan from a gas cylinder

A simple configuration of a Buleryan stove for self-production, the basis will be a used old gas cylinder. This will be a combustion chamber and will help avoid the additional work of welding the base. This configuration of the Buleryan stove is the most accessible for making at home, without special equipment.

Scheme drawings dimensions

Buleryan’s DIY diagram below provides complete information on the size and complexity of this design.

Material

- The metal is no thinner than 3 mm for the ash pan.

- Cast iron door purchased or prepared in advance.

- Reinforcement or pieces for legs and grate.

- Used gas cylinder.

- For a chimney (pipe blank).

Tools

- Welding + electrodes.

- Grinder or grinder.

- Metal brush.

- For markings, chalk, marker.

- Roulette or ruler.

- Electric drill with drills of the required diameter.

- Pliers, hammer, chisel, metal file.

Step-by-step instruction

Step-by-step diagram for assembling a Buleryan stove

Before starting work, we first prepare the cylinder. To avoid the cylinder exploding, you need to make sure that there is no gas (residues) in it. A simple method is to fill the container with water to the brim, then drain the water and drain the container.

Drawing for buleryan from a gas cylinder

We mark the holes we need on the cylinder: square for the door, round for the chimney. To make a round hole you need either a cutter, or holes are drilled in a circle and then knocked out with a chisel and hammer. Clean it thoroughly with a file.

The simplest method for making a grate, if you don’t have one ready-made in size. We drill holes of the required diameter in the bottom of the oven, i.e. the cylinder.

Holes for ash pan

We weld a box for ash from the bottom of a sheet of metal, weld a door to this box and this box will act as a blower.

Blower for Buleryans

The doors are purchased, or we make them ourselves.

Doors for the Buleryan oven

We attach a pipe from a piece of pipe of the required diameter to the top of the cylinder. And finally, the last step is to secure the boiler to the legs or stand. The DIY Buleryan stove is ready for use.

Disadvantages of Traditional Ovens

If you take a closer look at the Buleryan stove, it will become clear that this is the most ordinary pyrolysis potbelly stove, equipped with a productive convector. Traditional wood stoves have many disadvantages:

- Fast combustion of fuel;

- Low efficiency rate;

- Low heat generation.

Potbelly stoves have become extremely popular stoves where there is no gas main. They have a simple design, and craftsmen have learned to make them themselves, using old barrels, aluminum cans, gas cylinders and scraps of sheet metal. As a result, quite powerful heating units are born, delighting consumers with a large amount of heat.

The efficiency of a conventional potbelly stove rarely exceeds 80%. The thing is that most of the heat flies up the chimney. The surface area of the stoves is not the largest, so thermal energy is poorly dissipated. To increase efficiency, potbelly stoves are lined with stone, fireclay bricks, and equipped with simple metal convectors. Thanks to this, they retain heat longer and transfer it better to heated rooms.

An ordinary potbelly stove, even with many improvements, will never be able to compare in efficiency and quality of heating the room with even the simplest Buleryan stove.

However, in cold climates, a classic potbelly stove does not look like the most suitable option for heating houses that are not connected to gas mains - slow heating and rapid combustion of wood take their toll. The problem is partially solved with the help of pyrolysis combustion of fuel, which makes combustion longer and more efficient. But in order to quickly fill any building with heat, an alternative device was needed.

How to install Buleryan

The main stages of installing a Buleryan heater

- When choosing a place to install the stove, the main thing is to ensure free air convection for better heating of the room.

- The boiler gets very hot during operation, you need to provide a fireproof place for it.

- Under the boiler and in front of the firebox, it is necessary to place a metal sheet on the floor to prevent fire.

- It is recommended to install the stove no closer than 30 cm to the wall and with a distance of at least 60 cm from furniture and other objects.

- if the boiler is located in the corner of the room, then it is advisable to protect the walls with fireproof materials (metal, stone, brick).

- We put the Buleryan stove 20 cm from the floor for natural air convection, for this we mount a stand.

Boiler stand Buleryan

Chimney device

Types of chimney installation: one of them is classic (or traditional). This installation method is used at the initial stage of building a room. The chimney pipe is located vertically and passes through all ceilings.

Types of chimney devices

This method excludes the horizontal arrangement of any nodes. The second method is used at any time, at any stage of the construction of the premises, even after the construction is completely completed. This method is called coaxial; it works more efficiently than the traditional one, as it ensures high-quality removal of combustion products and is less fire hazardous.

Distributing heat throughout the rooms of the house

For the most effective use of the Buleryan stove, in order to heat not one room, but several or the entire house, corrugated pipes can be connected to the heat exchange pipes coming from the stove.

Corrugated pipes are distributed in rooms

The pipes are routed accordingly through the walls of the premises, if necessary through the ceiling. Decorative grilles are installed in the rooms to receive warm air.

Heat distribution between rooms in a large house

However, it should be taken into account that the air leaving the furnace has a fairly high temperature; when passing pipes through partitions and ceilings, the conditions that are provided for the installation of chimneys must be observed. The photo below shows several wiring options.

Heat distribution from a common box

Galvanized or corrugated pipes are used for wiring.

Efficient heat distribution between rooms

Improving the stove design

Buleryan stone finishing

Very often, buleryan is a design element, especially when it comes to a country house or a chalet-style house.

Brick screen for Buleryan stove

But if we are talking about a homemade device, its aesthetic parameters are of course inferior to products made in production.

Buleryan in the interior of a country house

The most successful way of decoration is to use brick or decorative stone.

Buleryan in the interior

To do this, it is not at all necessary to completely cover the stove with bricks; it will be enough to decorate the walls around the boiler or make a background wall-screen behind which the stove itself will be.

Decoration of the Buleryan stove

The photographs show interesting design options for our heater.

Buleryan boiler in a country house

About water bullers

Buleryan can also carry out heating and water heating at the same time. Boilers equipped with a water circuit are used in homes and factories. Buleryan - a stove with combined functions in design and design is similar to the conventional modification, which uses air convection for full heating.

Example of water buleryan

Device Features:

- There are pipes around the combustion chamber.

- The basic principle of operation is chemical processes: pyrolysis or gas generation.

- The pipes are filled not with hot air, but with heated coolant liquid.

The Buleryan system furnace with a water circuit operates as follows:

- Pipes (convection) in the lower part have a collector (lower and upper).

- An outlet is specially mounted on the lower of the collectors, which is necessary to return the liquid to the system.

- The upper element has a pipe that is required to supply coolant liquid to the system.

- The water or other liquid heat carrier used in the system gradually heats up. This happens during the process of firing the furnace.

- The desired pressure is created (selected by setting).

- Liquid circulation occurs under the influence of physicochemical factors and its rise to a height of 7-8 meters.

- The coolant fluid moves through pipes and is supplied to heating devices (batteries, convectors), which are located in rooms (living rooms, production workshops or greenhouses).

The cooled liquid heat source is returned back to the system using an outlet on the lower collector.

In this case, the gas formed during the combustion of solid fuel takes part in the heating process. For this purpose, the design of the furnace provides two, rather than one, combustion chambers - in one, the main fuel is burned (firewood, pressed sawdust or coal briquettes), in the second, the process of afterburning of gases occurs.

Water buller connection diagram

After heating the firewood combustion compartment, it is recommended to switch the boiler to gas generation mode. In this phase of operation, the fuel does not burn, but smolders. This allows you to increase the heat transfer time, but the system will function autonomously. Feature - the efficiency remains the same as when burning wood or other solid fuel. A Buleryan home stove with a water heating system allows you to obtain hot water for domestic needs if the pipes are connected to a special container. Water heats up to 100 degrees in 30-40 minutes, depending on the model chosen for use, which requires about 2.5 kW of energy.

What is the efficiency and can it be increased?

The efficiency of Buleryan, depending on the size and power, as well as the correctness of the settings, is 70-90%. These figures can be increased by 3-5% by installing no more than 6 pipes per unit. Important: Efficiency may decrease if the furnace power is less than the maximum permissible area of the house or other building for the selected model. The Buleryan stove has the following disadvantages that can negatively affect this indicator:

- The use of coal reduces the heat output.

- The efficiency is as promised only when using dry firewood.

- 60% of gases go into the chimney.

- It is necessary to correctly regulate the process of adding and limiting air access.

If all the disadvantages of buleryan are taken into account, the efficiency will increase. Installing glass for the Buleryan stove (in the door of the combustion chamber) will create the effect of a fireplace in the house

Principle of operation

The modern Buleryan potbelly stove is used in different areas - for heating a home, industrial or gardening buildings. Buleryan's thoughtful device makes it possible to obtain maximum thermal output from solid fuel. The Buleryan wood stove works according to the following principle:

- The required volume of firewood is loaded into the firebox (you can add a little paper or ignition mixture to facilitate the process of engulfing in flames).

- After the fire burns confidently, it is necessary to limit the air flow.

- The process of pyrolysis occurs - ignition under the influence of a secondary air flow.

Schematic representation of the operating principle

The heat generated during the active process of smoldering and residual combustion of wood fuel and pyrolysis products then enters the air heat exchanger. To ensure complete tightness of the combustion chamber, the pipes at the base of the heat exchanger, if the stove is assembled with your own hands, must be welded together with sheet iron.

Important! The amount of heat generated by the unit is sufficient to create a fully functioning distribution of pipes that heat other rooms or spaces.

Gases heated by fire release thermal energy (up to 90%) into the curved pipes of the structure. If you correctly calculate the power of the stove and the area of the room it heats, then you will need to add fuel 2-3 times a day.

The lineup

It is worth noting that such stoves do not have a large range of models, but this will not prevent you from choosing the most suitable option.

For example, the Breneran-Aqua model.

It allows heating of significant volumes of water, so it is most often used for water heating. Its efficiency is 70%, but with just one tab it can work for almost 12 hours straight.

Another model is a gas generator. It is designed to quickly heat indoor air and can heat 4.5 cubic meters of air in one minute.

Good to know: Breneran stoves, unlike conventional potbelly stoves, can operate without even getting hot. In general, any Breneran model can quickly increase the temperature in the desired room. This allows you to start bathing procedures after just half an hour. But the most important thing is the enormous savings in firewood, with an excellent rate of injection of thermal air.

Bullers without pipes

What is a Buleryan stove without pipes? This is a modification of a conventional stove with a heat shield, to which an afterburner has been added. Inventor – Professor Butakov I.N. The design system and operating principle of Butakov furnaces are similar to conventional Buleryan, but the design is devoid of complex components and elements, which makes it possible to reduce the size and dimensions.

Brick lining

To increase heat distribution in the steam room, as well as to increase the service life of the stove, a specialist is recommended to create a “protective casing”.

It is not difficult to understand how Brenaren is covered with bricks.

Laying must be done in a checkerboard pattern. To do this, the brick must be soaked in advance. After this, it is shaken, freeing it from excess water, and placed on the cement solution, leveling it with a wooden hammer.

When the installation is completed, the brick walls will need to be dried, leaving the mortar to set for several days. After this, the surface can be finished. At the same time, the first fire must be carried out extremely carefully so as not to overheat the furnace and thereby allow the solution to finally thicken.

Watch the video in which a specialist reveals the secrets of installing a stove and a chimney for it:

Where can I use the Buleryan stove?

Buleryan heating stoves can be successfully operated in absolutely any conditions. If we take the history of their creation, then initially these devices were planned as compact and highly efficient heating systems to ensure rapid heating of fairly large rooms with various types of fuel, including those with low heat transfer.

The photo shows an option for installing the stove

Based on this, these stoves can be used in dachas, garages, utility rooms and even in private homes, as an additional backup source of cheap heat. And if you are deciding which fireplace to choose for a country house or apartment, and the main criterion for you is heat transfer and efficiency, be sure to pay attention to this design .

Tags

Buleryan fireplace stove

Conclusion

Canadian technology, which is used to manufacture heating boilers and their analogues in other countries, is an effective source of heat with low consumption of solid fuel. Correctly configured system will allow you to maintain optimal temperature in rooms of any size. It is important to adhere to the rule: the ratio of the power of the unit and the size of the premises so that the efficiency is optimal. To heat several rooms and/or water for domestic needs at once, it is recommended to choose special systems that use a liquid heat exchanger and gas generation process for their operation. Additionally, the Buleryan stove for a greenhouse or house with a water heating circuit uses the principle of pyrolysis in its operation.

Sources

- https://pechiexpert.ru/osobennosti-ustrojstva-pechi-buleryan-02/

- https://otopleniehouse.ru/pech-buleryan/

- https://pechnoy.guru/pechi/otopitelnye/buleryan/buleryan-s-vodyanym-konturom-otopleniya.html

- https://lucheeotoplenie.ru/teplovoe-oborudovanie/pechi/buleryan-s-vodyanym-konturom.html

- https://househill.ru/kommunikacii/otoplenie/kotel/tverdotoplivnye/osobennosti-pechej-buleryan-s-vodyanym-konturom.html

- https://kotle.ru/otoplenie/pech-buleryan

- https://PechnoeDelo.com/otopitelnie-pechi/buleryan-s-vodyanym-konturom.html

- https://SdelaiKamin.ru/pechi/kak-sdelat-pech-buleryan-svoimi-rukami-opisanie-i-chertezhi

- https://pechnoy.guru/pechi/otopitelnye/buleryan/ustrojstvo-buleryana.html

- https://teplo.guru/pechi/piroliznye/ustanovka-breneran.html

[collapse]

Dimensions

Canadian Buleryan stoves have the following size range:

- Height – 71-96 cm.

- Width – 49-75 cm.

- Depth – 69-150 cm.

By groups:

- Group 00 – height 71 cm, width – 49 cm, depth – 69 cm.

- Group 01 – height 75 cm, width – 56 cm, depth – 82 cm.

- Group 02 – 85 cm, width – 85 cm, depth – 99 cm.

- Group 03 – height 90 cm, width – 62 cm, depth – 112 cm.

Buleryan type 01 (Vancouver)

The choice of group depends on the individual characteristics of the structure where the device is supposed to operate. There are also two groups that are recommended to be installed in production areas:

- Group 04 – height 96 cm, width – 71 cm, depth – 134 cm.

- Group 05 – height – 96 cm, width 75 cm, depth – 150 cm.

Example of Buleryan from group 04 (Toronto)

Power also needs to be taken into account. Depending on the model, they produce 6-45 kW. The volume of the room that can be heated using the unit (m3) is 100-1300. Number of pipes – 7-16. The smallest Buleryan is capable of heating a small cottage (up to 100 m3) or a greenhouse.

Positive and negative aspects of Buleryan’s work

The Buleryan stove is formed on the principle of smoldering wood in a combustion chamber, releasing gas. They are called gas generators because they can release additional gases.

This device cannot be called a large unit, which releases all the energy from the gases of the generator. In this case, air is supplied under pressure by a special catalyst. The temperature should be much higher than in conventional ovens.

With the help of kindling, while supplying air to the hot wood allows it to reach a high temperature and thereby quickly warm up the building. This process takes about half an hour.

Gasification process. This is when the stove is completely filled with wood, the door is closed tightly, and the damper is set to minimize air entry.

It is important to know! This type of stove produces this amount of heat only using dry wood.

To accurately assess Buleryan, you need to understand the aspects of his work.

Use of furnaces of these designs

Heating a greenhouse with a stove

Most often, Buleryan stoves are used for heating greenhouses, as they are safe and very economical. The Buleryan stove heats the air perfectly, although it is not suitable for heating water vapor. If you want to buy a heating device of this design for a bath, check with the seller in advance for the address of the steam room where it has already been used.

For greenhouses, these stoves are indispensable. They work perfectly on any wood.