- Features of gasification of non-residential premises

- Procedure for obtaining technical specifications

- How to install gas into a country house

- Is it possible to carry gas into SNT

- Gasification methods

- Gasification of the bathhouse

- Garage gasification

- How to supply gas to a summer kitchen

- Conducting gas into an unformed extension

- How to arrange gas heating

Is it possible to pipe gas into a non-residential building? There is no clear answer to this seemingly simple question. When writing a review article, it turned out that even experienced lawyers express opposing opinions on some aspects of the problem. The article does not pretend to be the judge of last resort. If readers have personal experience, for example, gasification of SNT, non-residential premises, or know how to legally install gas in a summer kitchen, please share the information in the comments.

What documents are needed to connect gas to a sauna?

It is adjacent directly to the house, equipped with an entrance from the residential part of the building, therefore, unlike a detached one, it does not require access to the street in winter, nor does it require laying a heating main.

The location of the gas boiler room depends on the living space and the homeowner’s own preferences. From a safety perspective, attached and freestanding are the best choices.

The requirements are absolutely identical for any type of gas boiler house:

- You cannot install more than two boilers or other heating devices, or store flammable materials in the room.

- It is prohibited to install floors with any other material other than concrete or tiles.

- It is unacceptable to decorate walls with flammable materials. You can use brick, concrete, tile or metal.

- It is recommended to place the boiler in the center of the room.

There are two ways: either turn to Gorgaz, then you will save money, but lose 6-8 months of your time and effort, or turn to a private company, which, naturally, will be much more expensive, but faster. To draw up a project, you need a list of appliances that consume gas and the rules for their operation, as well as the location of the appliances in the house in accordance with your room and the chimney.

- When all the paperwork has been completed, installation and construction work begins.

- The final stage is connecting gas to the house. Gorgaz employees should come to you and check that all conditions are met.

This will take 2-3 weeks. Afterwards, a technical supervision receipt is issued, after which, along with all the documents, it is submitted again to Gorgaz.

Hiring a contractor Project documentation is drawn up based on the list of connected devices, as well as the actual connection of this equipment, carried out in full compliance with all safety rules and the location of chimneys. When the necessary data is provided, a specific person is determined who is responsible for connecting the gas pipeline to the house. After drawing up the project, installation and construction of the pipeline is carried out.

Taking this into account, when choosing a private contractor, they give preference to those companies that not only draw up the project, but also carry out the connection. In addition, comprehensive services involve quite significant savings.

Supplying gas to a private home The final stage of gasification is a gas test. This procedure takes from fourteen to twenty-one days. Private specialists cannot provide this service. This is illegal.

Necessary calculations Involve calculation of thermal load. This parameter consists of several factors:

- total area of housing construction;

- lack or presence of high-quality insulation;

- number of window and door openings;

- ceiling heights.

It is much easier to carry out the necessary calculations if you contact a specialist.

Attention

Heating using gas for a room of 20 square meters. m. with ceilings of 2.5 m requires the presence of appropriate equipment with a power of 2 kW. A correctly calculated heat load is necessary not only for paperwork, but also for the purchase of boiler equipment. Therefore, if you are not sure, it is better to hire a specialist.

How to obtain technical specifications? Documents are either prepared independently or with the help of specialists. The cost of such services depends on the complexity of the project and varies.

The more complex the work, the higher the price.

Even if you live near a gas pipeline, you will have to pay more than 200,000 rubles for the opportunity to enjoy the benefits of civilization. At the same time, the temperature regime in Siberia and the Far East is so diverse that the tariffs proposed for the central part of Russia are clearly not suitable.

- Having analyzed prices in Russia, we can conclude that gas supply to a private home on average costs from 70,000 to 400,000 rubles.

- Benefits At the same time, in our country there are many citizens who are supported by the state, and they are provided with a large number of benefits, but they do not apply to gas supply. There are concessions only for gas payments. The federal government left the right of choice to local authorities to provide benefits to various categories of citizens.

403 forbidden

The service company pays a connection fee and monthly payments. The exact amount is determined by the owner of the gas pipeline.

The main condition for gasification involves the inclusion of the site on which the house is located in the general gasification scheme and an uninterrupted supply of energy. If this condition is met, then you can begin collecting the required documentation.

This process takes approximately 20-30 days (working days). In addition, it is necessary to take into account the distance from the house to the gas main. Here the maximum permissible length and gas consumption are taken into account.

The first parameter is 210 meters, and the second is 5 cubic meters per hour.

Dependence of price on region

- In the Moscow region, the price range is large; it depends on the distance from Moscow and ranges from 400,000 to 700,000 rubles.

- In the Leningrad region it is easy to see that the situation is a little simpler, and it is quite possible to keep within 300,000 rubles.

- In the Nizhny Novgorod region, the cost of this service ranges from 150,000 to 200,000 rubles.

- In the European part of Russia, the price drops sharply to 70,000 - 120,000 rubles.

- In the Asian part of the Russian Federation, the situation is worse, due to the remoteness from industrial centers and gas pipelines, equipment has to be transported from Asia-Pacific countries and the West (for example, in the Novosibirsk region prices increase to 200,000 rubles).

- The situation is much worse in the Far East, since this is due to the low availability of main gas pipelines and, at the same time, the low price of equipment.

Application

After studying this article, it will be much easier for you to carry out gasification of a private house in practice, since you already thoroughly know the procedure for carrying out the work and can easily reproduce it step by step. To make paperwork easier, you can use the tips below, which, without any doubt, will only speed up the process of achieving your desired goal.

Advice: to obtain a chimney inspection report, you need to invite a specialist from the VDPO or the Ministry of Emergency Situations, but for this you must first prepare the room - equip it with a hood of the appropriate diameter and design. If the room is isolated, then it is necessary to ensure the presence of a tightly closing door, the design of which does not include glass.

If the chimney is made in the form of brickwork, then its internal diameter must be larger than the diameter of the outlet of the gas boiler. The riser must be equipped with a blower with a tightly closing door; it is through this hole that the inspector, using a mirror, checks the size of the chimney and its condition.

Advice: in the case when the road from the main gas pipeline to your home passes through someone else’s land plot, this issue needs to be discussed with the owner of the land before submitting an application to GorGaz, since its decision may delay the gasification process for a long time. If the neighbor does not give his consent, then GorGaz does not have the right to begin work. If permission is received, then do not forget to confirm it in writing by writing an application to GorGaz in any form addressed to the manager of GorGaz, and attaching a copy to it. Typically, the issue of laying a gas pipeline through a neighboring area is resolved privately, and an agreement between the parties is reached through a one-time payment for the use of the land. If it is impossible to supply gas to your site, it is worth considering autonomous gasification of a private house (gas tanks).

Advice: when purchasing a gas meter, you need to pay attention to the most important aspect - the brand must match the one indicated in the project documentation. The device must be accompanied by a technical passport

It is necessary to check that the number indicated in it and on the meter itself are identical, otherwise it will be impossible to register it with GorGaz, and this will entail a stop in the commissioning work, which will be postponed until the inaccuracies are eliminated in the documentation.

General provisions for gasification

Let's start with the basics, that is, with an understanding of where and for what purpose gas equipment can, in principle, be installed.

If we talk about residential buildings, it is allowed to gasify any individual buildings if a central or distribution pipeline with natural gas is located nearby. They make a branch in accordance with the specifications and a project specially created for specific conditions, and then, using the gas service, they lay a pipe to the house and ensure the supply of fuel.

Gasifying a dacha or cottage in which a family permanently lives has recently become easier thanks to new rules. The main problem remains the accessibility of the nearest gas pipeline

To develop a project for connecting a gas pipeline to non-residential facilities, technical conditions for connection are required, which can only be issued by a gas distribution organization.

The project should reflect the following points:

- the use of energy-efficient equipment approved for use by federal authorities and having certificates;

- accounting and control of fuel consumption, installation of gas meters;

- use of automatic control systems;

- necessary thermal insulation of equipment and gas pipelines according to design standards;

- control of the composition of combustion products and combustion temperature.

We suggest you read: What to smear your face in a bath

Simply put, all processes responsible for the production and accumulation of heat must be efficient in terms of heat transfer, safe for the environment and for operating personnel.

Specifications for the efficient use of fuel are issued by Rostechnadzor, but first you need to collect a package of documents, which includes copies of specifications for connection to the gas distribution network and technological calculations, characteristics of all equipment, information about metering and control devices.

If gas equipment cannot be installed in the room, there are conditions when a boiler room equipped with special units is allowed to be located outside the building

You can find out more detailed information about the legal framework by looking at the “Safety Rules for Gas Distribution and Gas Consumption Networks” or by contacting Rostechnadzor.

There are often contradictions in laws, and in reality you may encounter problems if you want, for example, to install a gas stove in a bathhouse or equip a city office with a gas stove. And not just with problems, but with a ban on connection - so let’s look at controversial cases encountered in practice.

There is one summer kitchen on the site, is it possible to supply gas?

If you do not agree, then in accordance with the Law on the procedure for considering appeals from citizens of the Russian Federation (as amended on November 3, 2020), which obliges officials of all state and municipal bodies to respond to any appeals, comments and complaints from citizens. If you do not agree with the decision, you can appeal it to a higher official; in the absence of a positive decision, contact a higher authority, apply to the court to appeal the refusal.

Hello. According to the requirements of clause 9.3.4, “The possibility of installing gas stoves, heating and other devices in buildings located outside a residential building is decided by the design and gas supply organization, taking into account local conditions. At the same time, the premises in which the installation of gas appliances is planned must comply with the requirements for premises where the placement of such appliances is allowed.”

Yes, you can without any problems. Contact gas workers to issue you technical specifications and technological connection. Attach documents for land and summer kitchen to your application.

| b) the direction of gas use, as well as the characteristics of its use - the proposed heated area, the composition of gas-using equipment, other characteristics of gas use (determined by the applicant if necessary). |

the planned date of commissioning of the capital construction project (if relevant information is available);

implementation of connection measures (technological connection) provided for by the technical specifications and the connection agreement;

Read other lawyers' answers:

- Legal and Technical Work of a Notary What is it

- What is the Time Limit for Unearthing a Treasure of Drugs?

- Who Pays for the Replacement of the Electricity Meter in a Municipal Apartment

- How to Get a Money Back for a Technically Complex Product

- When Can a Lawyer Refuse to Defend a Defendant?

How to pipe gas into a bathhouse from home – Construction and repairs

It is unrealistic to imagine a suburban area without a bathhouse. There are no limits to the imagination of customers or builders when building baths.

Russian steam rooms, Arab hammams, Roman baths, Finnish saunas, Japanese ofuro or sento - you just can’t find anything in the Russian expanses.

Each of these baths has its own advantages. However, there are problems that are the same for baths of any type and size, which owners have to solve individually each time when building them.

Let's say coal, oil or gas heating in a bathhouse is still a rarity.

Moreover, gas is currently the cheapest type of fuel of all existing ones. In general, it is used quite widely in everyday life, mainly for cooking. That is, gas equipment is quite familiar to us.

In many ways, the spread of such heating systems is hampered by the prevailing ideas in society about the dangers of gas as a fuel. Gas heating in a bathhouse has its own disadvantages.

To talk about the pros and cons of a heating system, you must first determine what requirements it must satisfy.

And this:

- Safety.

- Economical.

- Ease of use.

- Warm-up speed.

Knowing the requirements listed above, you can see how gas sauna stoves meet these points.

- The main advantage of gas heating is its low cost. Energy prices are steadily moving upward, so cost-effectiveness considerations, even for wealthy owners, play a significant role.

- In second place, perhaps, it is worth putting the environmental safety and hygiene of gas as a fuel - there is practically no soot, no soot that would have to be removed regularly and, importantly, the gas burns odorless.

- The operation of most types of gas heating equipment is fully automated and does not require constant monitoring and intervention by the owner. In general, the need for any effort when using gas is minimal - there is no need to deliver and unload firewood, load the stove with it, etc. Therefore, gas heating is especially convenient for baths intended for a large number of users. Any experienced bathing enthusiast has a good idea of how much effort it will take to heat a steam room designed for, say, 10 people, to the required temperature.

- The heating time for a bath when using gas is minimal and even for large rooms usually does not exceed 3, maximum 4 hours.

Selection of pipes for a gas pipeline

Knowing the types of gas pipelines, you need to familiarize yourself with the types of pipes that are used during installation. Just two decades ago, exclusively steel pipes were used for laying gas pipelines, but today polyethylene pipes, which have some advantages due to their physical and mechanical properties, are in much greater demand:

- have increased resistance to the negative effects of environmental factors and chemical compounds;

- along with high strength, they also combine sufficient plasticity, which allows them to be used for laying gas pipelines in harsh climatic conditions (even at a temperature of -45 degrees, polyethylene retains impact strength);

- plastic does not conduct electric current at all, which means that pipes made of this material are not exposed to stray currents and are reliably protected from electrical damage. In addition, when polyethylene pipes are laid in the ground, there is no need for additional protection;

- installation of polyethylene pipes is convenient and quite simple;

- the weight of a plastic pipe is 7 times less than that of its steel counterpart, which greatly facilitates their transportation;

- The warranty period for plastic pipes is more than 50 years, which is 2.5-3 times higher than steel pipes.

Note: the gas pipeline is introduced into the house exclusively using steel pipes, the same applies to wiring carried out inside the house.

In addition to a number of advantages of constructing a gas pipeline from polyethylene pipes, there are some limitations to their use:

- It is prohibited to install a gas pipeline from polyethylene pipes in those areas where the outside air temperature drops below - 45 degrees;

- it is prohibited to use polyethylene pipes for installing gas pipelines in areas where there is seismic activity of more than 6 points;

- The use of polyethylene pipes for the installation of above-ground and underground gas pipelines in canals, tunnels, collectors, as well as inside buildings, on land plots where there is a need to make transitions through natural and artificial barriers is prohibited.

Non-residential premises of MKD

In urban or rural apartment buildings, gas is often used as fuel for heating and hot water equipment. Five-story buildings with hot water heaters and gas stoves still occupy a large percentage of the country's total housing stock, especially in the provinces.

At the end of the last century, gasification took over almost all regions of Russia. Multi-storey buildings were connected to the central highways; according to the old edition of SNiP 2.08.01-89 - 9-storey buildings inclusive

The new document SNiP 01/31/2003 (current edition SNiP 2.08.01-89) says that even now it is prohibited to install gas stoves on floors above the 11th, but there are no clear wordings on the prohibitions. Hence, there are many disputes about whether it is possible to supply natural gas to non-residential premises, and, as a result, a series of court cases.

We are interested in non-residential premises - and these are areas that usually occupy 1-2 lower floors. When a residential building is put into operation, usually all apartments belong to the housing stock, therefore they are equipped with gas equipment and, accordingly, are gasified. But the first floors are being bought up and used for offices and various service businesses.

Let's say you want to convert a 1st floor apartment into a hair salon and leave the gas stove. Is it possible? Most likely not, for two reasons.

Firstly, you will have difficulties with the procedure for transferring residential premises to non-residential premises. According to the new rules, in order to organize an area in an apartment building for a pharmacy, warehouse, office, store, workshop, etc., it is necessary to collect a huge package of permits and involve organizations such as the BTI, the Federal Migration Service, the housing office, and the management company.

Payments for the owner of non-residential premises are made in the same way as for the owner of an apartment - according to metering devices: how much water, electricity, heat was spent - that's what he paid

But the most important obstacle that novice entrepreneurs may face is the impossibility of obtaining the consent of apartment building residents. Not everyone wants their entrance to be turned into a “passage yard”, and the benches on the playground to be occupied by some suspicious characters waiting their turn.

Secondly, leaving gas equipment will most likely be prohibited. Moreover, at the expense of the owner of the non-residential premises, it will be necessary to cut off the gas supply pipe, and, if necessary, install a new one to the floors located above. Simply put, you must provide gas supply to all residents of the house, bypassing your non-residential area.

With 2 floors it is even more difficult: gas equipment still cannot be used in non-residential premises; the main line will have to be cut off and moved. But there is one more point from which to start - you can transfer an apartment on the 2nd floor to non-residential premises only if there is also a non-residential premises underneath it on the 1st floor.

In order not to complicate the process of converting space from residential to non-residential, many simply comply with the requirements: get rid of gas and install electrical equipment, which is allowed in all types of apartment buildings

The requirements for basements are clearer. According to SNiP 21-01-97, which talks about fire safety, flammable gases and other flammable substances cannot be stored in basements and basements, and therefore gas lines cannot be installed.

We suggest you familiarize yourself with: Barrel bathhouse disadvantages of operation

Non-volatile and volatile gas boilers

Volatile boilers provide natural circulation, but have the following disadvantages: a large pipeline diameter, an open expansion tank through which water intensively evaporates, difficulties in installing the system (the need to withstand slopes), and most importantly, the inability to regulate the air temperature inside the room. In this case, the room where the boiler with an open combustion chamber will be installed must be provided not only with a chimney, but also with exhaust ventilation.

Volatile boilers are equipped with circulation pumps, have a closed expansion tank and electronic automation that ensures autonomous operation of the boiler. Without exaggeration, this type of roof can be called a mini-boiler room. When purchasing a volatile boiler, you need to take into account that for its reliable and stable operation you will need an uninterrupted supply of voltage of 210-230 Volts.

Only a true specialist can choose the right gas boiler, determine its power and piping circuit, and also determine the need to equip it with additional automation. To calculate the approximate power of the boiler, you need to make simple calculations, based on the fact that per 10 sq.m of room you need 1 kW of boiler power and another 20-25% of the reserve required to pay off unforeseen heat losses.

Another important aspect of the operation of gas boilers is the removal of combustion products, which occurs naturally or forcedly. Forced draft involves a fan being built into the boiler, while natural draft is provided by the draft existing in the chimney.

Most often, gas boilers equipped with a “turbo” system are installed in those facilities where a traditional chimney is not provided. In this case, specialists install a coaxial chimney, which is a “pipe within a pipe” leading through the wall to the street. The inner pipe ensures the removal of combustion products, and the outer pipe supplies air. In a private house, a gas boiler with forced draft is installed only if it is impossible to ensure excess air intake from the room

When installing a coaxial chimney, you should pay attention to the following features:

- The distance from the ground surface to the chimney pipe must be at least two meters;

- At the gas pipeline design stage, it is necessary to ensure that combustion products cannot enter the house through open windows;

- The coaxial chimney must be placed at an angle of 2-3 degrees with a slope to the surface of the earth to drain the resulting condensate;

- The distance from nearby buildings to the outer end of the coaxial chimney must be at least 1.5 m to ensure unhindered discharge of combustion products to the street.

Garage Heating Options

When planning a heating option, be sure to take into account the distance of the heated room from the main (residential) house. If the distance is 20 m or more, no special changes are necessary when removing gas from the general system, since fire safety is observed under such circumstances. Otherwise, an autonomous heating system can be installed.

Gas heating for a garage using propane and a gas burner is possible with the correct selection of the device’s power. The burner is convenient because it differs:

- mobility (can be moved to another place that needs heating);

- practicality (do not require additional equipment or connection to the electrical network);

- ease of use (the burner is lit with matches and turning it on does not take much time).

To heat a garage using a gas gun, it is necessary to correctly install and operate all structural parts of this heating device, strictly observing all safety rules. The fact is that when heating with a gun, a stream of warm air that goes out into the garage is mixed with waste products formed after fuel combustion. In such a situation, good and regular ventilation should not be neglected.

The design of a gas gun has the following elements:

- heat exchanger housing;

- gas-burner;

- extension cord for the burner (use a pipe having about 8 cm in diameter); fan;

- pipe for the exit of air heating the room.

Heating a garage can be done using an infrared ceramic gas heater if the area to be heated is small. The operating principle of such a device is based on heating a ceramic plate with gas. During operation of the described type of heater, infrared rays are generated, which in turn heat the air and surrounding objects. After this, heat is released and distributed to the rest of the garage.

The design of a gas-ceramic heater is simple. The metal case contains a reflector, a heating element and a gearbox. The design also assumes the presence of some auxiliary components and heat-reflecting elements.

Gas heating in the garage can also be achieved by installing a gas convector. This is a device that runs on natural gas and heats the garage using hot jets and streams. It is located in the lower part of the room to heat the lower cold air layers. The heating convector device includes:

- temperature sensor;

- heating element associated with gas equipment;

- control block.

Due to the action of the fan, controlled by the user of the heating device, the air is heated by the gas convector.

Another option for arranging a warm room for storing a car is heating the garage with gas from cylinders and a water circuit. It is easy to supplement a gas boiler with a water circuit welded from metal pipes in which heated water will circulate. It is convenient to place such a system of water pipes around the perimeter of the entire garage.

Heating a garage will be safer and more environmentally friendly if it is possible to install a boiler that runs on solid fuel. This may include, for example, firewood or coal. It is important to install a “potbelly stove” that, after just adding the selected fuel, will be able to heat the garage room enough for a comfortable stay in it even in the cold Russian winter.

Structurally, the solid fuel heating device consists of:

- horizontal tank for firewood or other solid fuel;

- air heat exchanger. It is needed to change the movement of smoke gases in order to ensure even greater heat transfer;

- Ash pan made of sheet metal.

For constant and precise control of the air temperature in the garage, you should choose an electric heating option. It is worth remembering that electricity consumption will be quite large compared to the money spent on other types of fuel. If there is a constant supply of electricity to the garage, you can begin to select an electric heater of the required power.

An undeniable advantage for this heating option is the lack of expenditure of money and physical effort on the purchase of fuel, lubricants, other materials and maintenance of a “capricious” solid fuel or gas boiler. Typically, electric convectors or heated floors are used. Read more about heating with underfloor heating right here.

Liquid fuel devices for heating a garage are a godsend if the owner has free access to used engine oil, because it can be used as fuel for a garage heating furnace. The consumption of this substance will be approximately 1 liter per hour.

Electric heating is the most expensive, since the cost of money for modern electricity supply is high. It turns out that any of the listed types of gas heating will be economically profitable. When using a gas cylinder and other gas supply devices, safety precautions must be observed.

Having your own bathhouse on a country plot is a real dream for many owners of dachas and cottages. This tradition dates back many centuries, and therefore has moved from the category of simple hygienic procedures to the rank of a real way of life.

The main problem in the arrangement is not only the construction of a beautiful and comfortable structure, but also the organization of heating.

Practice shows that gas heating in a bathhouse is the best option, characterized by cost-effectiveness, efficiency, and reliability.

The technology has many positive features and is superior to other equipment, regardless of the type of fuel used:

- Economical. Gas in Russia is considered one of the cheapest energy sources; if it is possible to connect to the main network, the benefits will be especially noticeable. The operation of such equipment will be several times cheaper than in the situation with electrical analogues, which is especially noticeable if the bathhouse has a large area.

- Crash resistance. A sudden power outage, typical of the countryside, can become a real disaster. The water will begin to freeze in the pipes and boiler; if it is not drained urgently, the resulting ice will simply destroy the metal structures. In the case of gas, this problem disappears; even if there are interruptions in the main line, you can switch to power from the cylinder.

- Environmental Safety. This property is especially important for owners who actively use the site for growing crops. Gas combustion occurs without smoke, soot or unpleasant odor; combustion products do not settle and do not pollute the soil and water bodies. This property also ensures that there is no need to regularly clean the chimney and pipes from combustion products. This is a huge advantage of the equipment over diesel and solid fuel units.

- There is no need to organize a place to store fuel. This problem is most relevant for liquid fuel boilers, for which you need to constantly have a supply of tens of liters of diesel, and for solid fuel (wood or coal).

- Operational simplicity and safety. The operation of modern gas boilers is automated; numerous sensors monitor the pressure in the system, make sure that the burner does not go out due to an accidental blow of wind, and that there are no leaks. Thus, the owners can concentrate on enjoying the bath procedures, rather than constantly being at the boiler, fearing any problems.

We invite you to familiarize yourself with: Scandinavian style bathhouse

Are there any disadvantages?

Yes, the gas unit has a couple of disadvantages.

The first disadvantage is the initially high cost of the equipment, the second disadvantage is the need to attract professionals for installation to ensure the tightness and correct connection of all pipes and power sources, checking the operation of sensors, mechanisms and electronics. But should these negative qualities be considered significant? Probably not.

The reason is simple - all initial investments will be fully justified within a few seasons of operation; after just a couple of years, gas equipment will turn out to be much more profitable than electric and other models.

Variety of choices

A heating boiler may have a different number of circuits:

- One circuit is exclusively for space heating;

- Two circuits - space heating and water heating for hygienic and domestic needs. The most common option for a bath;

- Three circuits - heating the room, heating water for hygienic needs, heating water in the pool or ensuring the functioning of underfloor heating systems.

If we talk about the types of burners used in furnaces, they look like this:

- An atmospheric burner is the cheapest option; air enters through the chamber with ash, a slightly open hole in the main compartment. The main advantage of this device is its low cost, due to the simplicity of the design, the absence of control sensors and other electronics. Unfortunately, this method of air supply is not always effective; a lack of oxygen leads to a drop in flame intensity, that is, the efficiency is significantly reduced.

- Pressurized burners use fans that force air, meaning the fire is always supported by a large amount of oxygen and burns brightly. Improving the design leads to its rise in price, in addition, there is a dependence on the stability of the power supply necessary for the operation of the fans.

A bathhouse with efficient gas heating can operate using a stove made of any material; here everything depends solely on the wishes of the owners. The brick version is considered traditional, as it looks attractive and also helps retain heat for a long time.

Features of the chimney device

One of the most important conditions that guarantee uninterrupted operation of the boiler is the presence of chimneys with natural ventilation, which can be either internal (passing through the roof of the house) or external (installed along one of the external walls)

When choosing a chimney, it is important to know that the internal diameter of the chimney must exceed the diameter of the boiler neck. In addition, when installing a chimney, you should try to avoid elbows and bends, and, if possible, minimize their number, as well as take measures to prevent the formation of condensation

The chimney should be located 0.5 m above the top of the building, and if the roof contains flammable materials, then it is better to place the chimney 1.2-1.8 m above the ridge of the roof. When installing a chimney outlet, you also need to take into account the height and proximity of nearby buildings.

The use of heat-resistant sealant as a seal at the joints of chimney modules will help prevent smoke leakage. Only high-quality chimneys can guarantee the smooth operation of modern boilers and prevent such common problems as carbon monoxide entering the heated room, grease stains on the ceiling and walls, and destruction of brickwork.

The best option when assessing price-quality parameters are chimneys made from stainless steel materials. They can be either single or double layer. The former are most often used in the case of installing a chimney indoors. The main disadvantage of a single-layer chimney is the presence of a large amount of condensate that appears during the removal of gases from modern high-power gas boilers. It is quite obvious that double-layer stainless steel chimneys cope with this kind of problem quite simply due to the fact that insulation is placed between the layers.

When choosing a chimney, you need to be guided by such basic parameters as the temperature of the exhaust gases, boiler power, shaft material and the degree of its insulation, as well as other features that can affect the draft force, reliability, durability, and most importantly - the safety of the chimney.

Note: if the boiler power does not exceed 60 kW, then the chimney can be made from sheet iron without any problems, but if the power is higher, then it is better to use brickwork.

The cost of gasification of a private home is of most concern to every home owner. Design work carried out by design institutes can cost from 4 to 6 thousand rubles. The average price for 1 meter of pipeline is 800-1400 rubles, which corresponds to approximately $23 and $39, respectively, for an above-ground and underground gas pipeline. A more accurate figure can only be determined when drawing up an individual project, since its cost may largely depend on the length of the route being laid, the number of holes in the walls of the house, the number of bends, the diameter of the gas pipeline, etc.

In general, it turns out that to carry out gasification of a private house, an amount of 110 to 150 thousand rubles will be required. This amount includes the development of design documentation and all types of approvals, commissioning and installation work, including wiring around the house, as well as the installation of a chimney and the purchase of a boiler.

How to connect country houses to gas?

It seems that what is easier - to gasify a non-residential premises on your own summer cottage, for example, a bathhouse or a garage? However, many owners of garden plots and country houses are faced with the reluctance of gas distribution authorities to connect cheap fuel to buildings other than a residential building.

Installing a gas stove in a bathhouse easily solves problems with heating and water heating, in a summer kitchen - with cooking, and in a garage - with heating a large room in winter

There are many reasons for refusal to issue technical specifications and supply gas:

- lack of a highway passing nearby;

- gas workers do not have the required amount of fuel to meet their needs;

- the premises are not properly equipped;

- the equipment does not meet fire safety and energy efficiency requirements, etc.

But if you fully comply with all the requirements, it will be possible to install a gas boiler or stove in a non-residential premises.

Simply put, if the design organization, and with it the gas service authority, allow it, then gas can be supplied to any outbuilding.

Commissioning works

After the gas has been started, you should contact the organization with which the agreement regarding the service of gas equipment was signed, so that all gas equipment is put into operation. This is one of the most important conditions for warranty service of equipment installed in your home. The service period depends on the area of residence and current laws and can range from 1 to 3 years.

At this stage, you will need the documents necessary to carry out the thermal calculations necessary to determine the choice of gas boiler power and supply of hot water to a private home. Specialists from housing and communal services will help solve this issue, who can provide plans of all heated premises indicating their heights and areas, indicate the number of hot water intake points, and also describe the possibility of using the boiler for technical needs.

It is necessary to take into account that the owner of the house can do all the approvals not only independently, but also resort to the help of an organization that will help save time and take on all the hassle of gasifying the house and installing the gas pipeline.

Bath gasification options

It’s rare that anyone refuses to build a bathhouse on their own property - it’s not just a washing room, but a place of relaxation associated with a lot of rituals and traditions of the Russian people. But it’s too expensive to heat a bathhouse with wood, and even more so with electricity, which is why there is a logical desire to install a gas fireplace or stove.

Maintenance of all equipment, home and bath, is carried out by the gas technical service using devices installed in one place - for example, on the wall of the house

But in reality, everything is complicated - the bathhouse does not meet legal standards and is not considered a suitable room for installing gas equipment.

However, no one prohibits the supply of gas to residential buildings, so resourceful owners have found two legal options to circumvent legal obstacles:

- include the construction of a bathhouse in the house construction project, that is, place them under one roof;

- register the bathhouse as a residential guest house with separate gas heating equipment.

Both options are actively used, and very successfully. But some owners of country houses were even luckier - they were simply given permission to gasify their bathhouses. This also happens, so in order not to waste extra effort and money, contact gas workers first - what if you get lucky?

It turns out that no laws prevent the installation of a bathhouse right in the house, and many people use it successfully. It turns out that the use of gas in non-residential premises of a residential building is possible.

However, there are several special conditions:

- it is necessary to equip a separate emergency entrance;

- for the manufacture of doors, use only heat-resistant materials;

- you can open the emergency entrance from both sides;

- install a fire alarm and fire extinguishing system;

- Only certified factory-produced gas equipment may be used.

An interesting addition to the law is that the sauna premises cannot be used for commercial purposes.

The entrance to the steam room can be arranged directly from the corridor or hallway, and the emergency exit is to the terrace, which can easily replace the dressing room

If gas or fire inspectors take their responsibilities responsibly, they will not allow the operation of a bathhouse without an automatic fire extinguishing system and well-functioning ventilation.

But not everyone can allocate a piece of living space for a bathhouse or sauna, so let’s consider another option.

First, you will have to come up with a project for a guest house or summer kitchen, which could later be converted into a bathhouse, that is, the building must have a solid foundation and walls with mineral insulation, lined with non-combustible materials.

The main point in the design will be a gas boiler installed for heating and water heating. Usually, questions about why a separate unit is needed do not arise.

You will also need sewerage and shower equipment - but this is not surprising if it is designed for a guest house in which seasonal accommodation is planned

The approved project is implemented and a house is erected, then it is registered with the BTI, changes are made to the general house-building plan and an application for gasification is written. If the inspector, after inspecting the premises, does not identify any violations, he will issue a permit and draw up a sketch of the location of the equipment and gas outlet.

After issuing technical specifications, you may have to adjust some things, for example, make forced ventilation or additionally insulate the boiler installation site.

All that remains is to lay the pipes and connect the boiler to the system. If a residential building is gasified, then making a branch is not difficult and will not take much time.

After testing and commissioning, the gas service representative gives the go-ahead for operation, and after he leaves, you can finally turn the house into a bathhouse - for example, install a heater

Using the same principle, you can pipe gas into the garage. According to reviews, sometimes gas workers allow gas to be supplied to any buildings, including garages - but subject to a number of requirements for fire safety and ventilation.

Types of gas pipelines

Now that you are familiar with the conditions for gasification of a private home, it would not be amiss to familiarize yourself with how gas pipelines exist and how they are selected. First of all, gas pipelines are classified according to their location relative to the ground - aboveground and underground. They differ from each other in the method of introducing risers and internal gas supply networks into the house, as well as in the features of connecting gas-consuming devices.

It is known that the installation of an underground gas pipeline is 50-60% more expensive than an above-ground one, but this does not make it less in demand and popular. The main advantages of an underground gas pipeline are that the pipe running underground is more reliably protected than the one running through the air, which means that its service life is an order of magnitude longer.

Safe installation of an underground gas pipeline may require partial or complete blocking of vehicle traffic on certain sections of the road. The organization carrying out the installation work has the right to do this, which must, based on the design documentation, draw up diagrams of the organization of the movement of pedestrians and vehicles, the placement of equipment with reference to a specific area, and also indicate the geometric parameters of the road section under work, determine the installation locations of road signs and indicate access points to houses. The drawn up diagrams must be agreed upon with the traffic police, who, in turn, are required to issue a warrant to carry out work on laying an underground gas pipeline.

An overhead gas pipeline has not only disadvantages compared to an underground one, but also some advantages. Although exposed areas are more susceptible to corrosion, they are much easier to connect to and carry out repairs and maintenance. Underground gas pipelines operate more reliably, but their repair requires additional costs.

In order to get the most complete picture and make it easier to choose the type of gas pipeline, it is best to make a comparison:

- if in the area where you live, groundwater comes close to the surface and increases the corrosion of soils, then the best option would be to install an overhead gas pipeline;

- if there is a high-voltage power line in the immediate vicinity of the gas pipeline installation site, then it is better to give preference to laying an underground gas pipeline;

- in the event that it is necessary to run a gas pipeline through a neighboring area, it is better to give preference to the installation of an overhead gas pipeline. This will protect the fertile layer of soil from damage and make it easier to obtain consent from neighbors;

- If, during the process of laying a gas pipeline, an obstacle in the form of a road is encountered along its path, then you can choose a combined option - lay an overhead gas pipeline along the site, and an underground one across the road.

Conclusion

We can summarize that providing blue fuel to a bathhouse, a garage, or supplying gas to a non-residential premises in an apartment building is expensive, and most often impossible. However, before choosing heating or hot water equipment, we recommend contacting the gas distribution service and asking about the conditions under which the premises can be gasified.

If the answer is no, then you will have to choose an electric boiler or stove. We don’t recommend engaging in amateur activities - fines for moving pipes alone start from 2 thousand rubles!

Have you ever encountered the issue of gasification of non-residential premises? What difficulties arose and how were you able to solve them? Please share your opinion in the comments section.

Using gas stoves in a sauna allows you not to worry about the fuel burning in the firebox and enjoy the sauna procedures. All that remains is to choose the appropriate model and install it correctly in the steam room. In addition, we must not forget about fire safety rules and carbon monoxide. In the video presented in this article you will find additional information on this topic.

Tags: bath, carry out

« Previous entry

Features of installation of floor and wall models

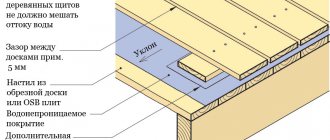

To heat the garage, floor-mounted or wall-mounted gas boilers are used. To place floor models on a pre-leveled surface, it is necessary to build a support platform made of heat-resistant brick or concrete. To make the installation of the boiler even more stable, you can make a small pocket in the floor. There is no need for this if the boiler comes with a special stand for floor mounting.

To install wall-mounted units, the nearest sections of the walls must be finished with fire-resistant material. The stove should be fixed so that its position corresponds to the vertical and horizontal levels. The nearest wall or element of furniture should be at a distance of 30-50 cm from it for fire safety purposes and ease of access.

Connection to water and gas pipelines

Upon completion of all installation work, the boilers are connected to the circulation pipelines. Before doing this, turn off the water supply and prepare the mounting flanges or threaded couplings. To additionally seal the joints, tow is used.

Pipes are connected to floor-standing and wall-mounted boilers in different ways:

- to the first - from above and from the side;

- to the second - from the transverse side.

If necessary, ball valves are installed in areas where coolant is supplied to radiators. If the garage heating is not equipped with an electric pump, then the pipes must be at a slope of up to 5 mm per linear meter, otherwise there will be difficulties with the natural circulation of water in the main.

Piping diagram for a double-circuit gas boiler. Click on photo to enlarge.

After connecting the pipelines, a test run of the system is carried out to check the furnace for operability and make sure that the tightness of the joints is not broken in any area. If necessary, additional sealing is performed.

Connection to the gas pipeline

This type of work is carried out only by gas service employees who have special tools and sealing materials to completely eliminate gas leakage during equipment operation. At the same time, installation of KTP, gas meter, taps and other fittings is carried out.

A plan for laying gas pipes into the garage boiler room must be developed in advance and approved by the competent authority. The project must describe in detail all aspects of gasification and technical nuances of this premises. If boilers are connected unauthorized or in non-compliance with the gasification plan and current standards, this may result in gas being turned off and a fine being imposed.

Safety Recommendations

Converting the boiler and reconfiguring it to consume liquefied gas dictates the need to “reconfigure” your attitude towards the device for supplying and storing blue fuel.

You must remember that:

- Cylinders or gas tanks, which are gas storage tanks that supply fuel to household appliances as needed, need to be refilled periodically.

- To fill a group of cylinders or a gas holder with gas, you need to contact certified organizations that have equipment to record the weight of the gas in the cylinder and its actual volume in the gas holder.

- Filling closed gas tanks is carried out to 85% of the useful volume of the vessel. This reserve is necessary in case of thermal expansion of the fuel to avoid an explosion.

A non-hazardous situation that requires special attention when replenishing liquefied blue fuel reserves is the filling of liquid with a density different from the density of the previous liquid. Because of this difference, the remaining liquefied gas may not mix with the newly filled portion.

In the tank, due to the difference in density, a kind of two non-connecting sectors are formed, in each of which liquefied gas circulates. However, convective heat exchange will occur at the sector boundary after a short period. After the temperatures are equalized, the densities will be equal and the liquids will be able to mix.

Liquefied gas, like main gas, is a highly flammable, combustible liquid with a high flame propagation speed. To avoid catastrophic situations, you should strictly follow the operating rules and fill the cylinders no more than 85%

Usually this process, meaning direct mixing, is accompanied by intense evaporation of liquefied gas. To avoid associated losses, mixing devices should be used during the filling process. But it is better to choose a method that eliminates the above-described phenomenon.

Replenishing cylinders and gas tanks with blue fuel in general is a process that requires increased attention, otherwise problems can be very serious and even catastrophic. The rapid spread and evaporation of the liquefied gas mixture is recognized as a significant problem.

If the rules for the safe operation of gas-consuming equipment are not violated, main methane rarely explodes. This only happens with significant leaks, if the technical state of the gas in the surrounding space changes dramatically. For example, in a kitchen with obvious signs of a leak, instead of mandatory ventilation, they turn on the light.

When liquefied gas expands in a closed container due to external heating, it will necessarily explode if there is not enough space left in the container for its expansion. Blue fuel burns extremely intensely. Since the gas is quickly absorbed by the atmosphere, the combustion zone expands at high speed.