close ×

In country buildings or cottages, metal wood-burning stoves are often installed for heating rooms and cooking. This is economical, practical and functional, since by heating such a structure, you can simultaneously cook food, heat water and supply warm air to the rooms. Traditional brick stoves do not have such high productivity, so owners of country houses choose steel/metal stoves for heating.

Before installing such a structure in your own home, there are several factors to consider. First, the expected frequency of use of the oven. Secondly, will people live indoors permanently, or only periodically, and over what period of time this will happen. Thirdly, the area of the house and the location of the rooms are taken into account. If you are not in a hurry, you can choose the best option for a country stove that runs on wood.

Advantages of metal stoves

Iron stoves have a number of advantages. These include:

- Heat dissipation. Wood-burning stoves made of metal warm up and begin to give off heat much faster than brick products.

- Small dimensions. Installation of metal stoves is possible if there is a minimum

- a lot of free space in the room.

- Mobility. Iron products can be easily moved from one place to another if necessary.

- Simplicity. Anyone can use a metal wood-burning stove.

- Functionality. Many modern models are equipped with a hob and oven. This allows you to cook food on them.

- Saving. An iron stove can be used to heat a house without the cost of additional equipment (radiators, pipes, etc.).

The advantages of these products also include the fact that, in addition to their main functions, they give the room a respectable appearance and comfort.

Furnace materials

An iron stove for a home should be selected taking into account a number of factors and parameters of the design itself. The technical characteristics and design features of the stove directly affect its efficiency and reliability. One of the most important parameters is the material used to make the stove.

Different materials can be used for the production of metal furnaces:

- Steel;

- Heat-resistant steel;

- Cast iron.

As a result, structures assembled from these materials have a number of differences, so it is worth considering each type in more detail.

Operating principle

Using a metal stove in a home or non-residential premises requires regular monitoring of the operation of the device. The loaded fuel is enough for a certain period of time. Therefore, it is necessary to constantly reload firewood into the firebox. Home ovens may differ in design, but the principle of operation is the same for all models.

The principle of operation of a metal stove for the home

Firewood is loaded into the combustion chamber. During the combustion process, air enters the combustion chamber through a specialized hatch (blower). The blower is equipped with a door, with the help of which the amount of supplied air is regulated. The more oxygen supplied to the combustion chamber, the faster the fuel burns. Products resulting from combustion are released into the atmosphere through a smoke duct.

Depending on the model, ovens can be additionally equipped with hobs and ovens. The flame in the combustion chamber quickly warms up the cooking surfaces. For aesthetic purposes, many manufacturers make the combustion chamber door from heat-resistant glass. So, you can see the process of burning wood while working.

Application and fire safety measures

A metal stove can be installed in any room. It can be wooden, brick, concrete or a room made of any other material. The main condition for installing the device in a house (or other room) is the presence of a chimney. It must be performed separately from the centralized ventilation system.

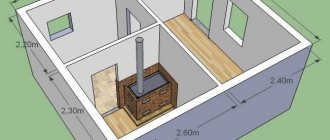

Installing a metal stove in the house

If you use a product of large size and weight in your home, you will need to take care of the installation base. A heavy iron stove can damage a wooden or even concrete floor. A foundation must be made. It can be made of various materials. The best option would be to make a concrete foundation. To increase the strength of the base, before pouring concrete, it is necessary to install a frame of metal reinforcement.

Factory stove models meet fire safety requirements. You can easily obtain permission from the fire inspectorate to install such a product. There are models of metal stoves, the installation of which does not require obtaining permits from the fire inspectorate.

Attention: in order to avoid a fire, it is necessary to equip the wall near which the stove is installed with a screen made of heat-resistant material!

Advantages and disadvantages

Among the advantages of steel furnaces are the following:

- high heat transfer rates, capable of heating rooms that are quite large in size;

- heat up quickly and supply heat to your home or cottage in a short time;

- safety: modern models are equipped with protective screens, so the possibility of getting a burn from an accidental touch is eliminated;

- they are compact and portable, so they can be moved from one room to another at any time;

- installation of steel furnaces is simple;

- reliable, modern samples are created from high-strength steel and cast iron;

- There is a wide variety of models on the market, made in interesting design solutions.

Metal stoves for summer cottages and wood-burning houses also have a number of disadvantages. First of all, the fuel burns out in a short time, which means that the room also cools down quickly. But the advent of long-burning stoves solved this problem. So, on one stack of firewood the unit can work for 8-10 hours.

A metal furnace is characterized by a low efficiency. But, more modern models are equipped with special heat accumulators, thanks to which the optimal temperature regime in the house is maintained.

Types of stoves for home

Metal devices, depending on the duration of combustion, the type of fuel loaded and technical characteristics, are divided into several types. These include chamber products, channel products and long-burning devices.

Chamber furnace

This type of construction is made of steel or cast iron. There is a combustion chamber inside. Fuel is loaded into the chamber through a special hatch. The bottom of the firebox is made in the form of grates, through which burnt fuel spills into the ashpit. The ash is removed through a door located in the ash pan. This door also regulates the air supply to the combustion chamber.

Channel product

Channel devices are cast iron or steel stoves. The combustion chamber of such devices is equipped with special partitions. They are located horizontally and prevent the rapid escape of formed gases into the smoke channel. Thus, gases, mixing with oxygen, burn out, and the efficiency of the metal furnace increases.

Long burning stove

This type of device differs from others in that fuel loading must be carried out much less frequently. The air into the combustion chamber of such a stove is supplied not from below, but from above. Thus, gradual combustion of the upper part of the fuel occurs.

Possible designs and their features

Metal furnaces are made in closed, open and combined designs.

Closed design

Such a furnace usually includes three compartments:

- the lower one, in which there is a combustion chamber with a blower;

- medium, which includes a heater and a steam outlet;

- the top one, which is a tank for heating water.

Ovens of this type are lined inside and outside with refractory bricks. This helps to increase the heat capacity of the unit. To speed up the heating process, the tank and the steam outlet are closed with a special damper. To warm up a room with a volume of 10–12 m³, it takes from 60 to 100 minutes.

Open design

Unlike the previous type, the stones are placed on a metal grate located above the combustion chamber. There is no overlap between the firebox and the stones. As in the first case, these stoves are intended for use in small baths and steam rooms. To increase the heat capacity, a galvanized sheet cover is used to cover the stones.

Combined type of furnaces

A distinctive feature of the design of this type of furnace is the presence of an enlarged combustion chamber equipped with double valves and grates. The presence of two pairs of such elements in the design contributes to the efficient operation of the blower and heater. Stones are placed in the upper part of the unit, in its neck. These elements are placed around the chimney pipe.

Famous manufacturers

The Russian market offers a large selection of metal, cast iron and stainless steel stoves. Products from the following foreign manufacturers are in great demand:

- Trend.

- Magnum.

- Thorma.

- Alma Mons.

- Konig Feuer.

- Efel.

- Ferlux.

- Olimp.

The Harmony model from the Belgian manufacturer Efel has proven itself well. It is equipped with a hob and has enough power to heat a large house. The time interval between fuel loadings is about ten hours.

There are many models and domestic manufacturers:

Cinderella stove Termofor

- Termofor;

- Ligov;

- Teplodar;

- Eco fireplace;

- Ermak.

Domestic models come in various types, sizes and shapes. Some can be transported independently and moved from one place to another. Others are permanently installed and have a high mass. Many of the models are equipped with hobs, ovens and transparent doors made of heat-resistant glass.

Choice

When choosing metal wood-burning stoves, it is worth considering the material of manufacture.

Devices made of ordinary steel. The most commonly used is ordinary steel. This material is characterized by high strength, the limit values for long-term exposure are 400°C, and for 2 hours - 600°C. The thickness of the steel is 4 mm, but the stove will quickly burn out due to intense heating, so such a unit is not suitable for areas where there are severe frosts in winter.

But not all steel units have this defect. Long-burning furnaces are produced that do not maintain long-term heating of the body above 600°C, and those structural elements that are subject to the greatest heating are made massive and replaceable. Such devices are quite suitable for use in large rooms and at low outdoor temperatures.

Fireplace stove made of heat-resistant steel ETNA with stove and heat exchanger

Devices made of heat-resistant steel. Material such as heat-resistant steel is commonly used in industrial production. For the manufacture of furnaces, 3 mm steel is used. Such units are characterized by a long service life (20 years or more), their efficiency is high - from 80% and they weigh little, so if necessary, the stove can be easily moved to another room.

Wood-burning stoves made of heat-resistant steel need to be installed on the floor, and they also need to be connected to the chimney. All manufactured units are certified, are highly safe and are well suited for weather conditions characterized by severe frosts. Many models are equipped with a hob.

Cast iron models. Wood-burning metal stoves made of cast iron can also be found quite often on the heating equipment market. Cast iron incorporates the characteristics of steel (it is just as durable) and ceramics (fragility and heat capacity). In order for the stove to heat up, you will need to wait 30-40 minutes.

To make the stove, cast iron with a thickness of 6-25 mm is taken. You cannot take a greater thickness, because... The heating coefficient may be too large and will negatively affect the quality of heating, but they also do not take a lower one, since then the device will be too fragile.

High performance of cast iron stoves is achieved in rooms with an area of no more than 60 m³. Such a device will not be able to heat large houses.

You can read more about cast iron fireplace stoves on this page.

In order to improve the performance characteristics of a metal stove, you need to know how to properly line a metal stove with bricks. This procedure will reduce fuel consumption, increase heating time and the stove will not cool down so quickly.

To line a metal stove, you must use high-quality bricks that are fireproof and heat-resistant.

The process is quite labor-intensive; it requires care and precision in following the installation technology.

How to choose a stove for a wooden or country house

The walls of a house made of wood have lower thermal conductivity than those made of stone or concrete. A low-power metal stove is perfect for a wooden house. For a wooden house, you can purchase a steel or cast iron product. Power calculations should be made based on the heated area.

Stove for a wooden or country house

To install on a wooden floor, you must choose a product with special legs. Installation can be carried out either in the middle of the room or against the wall. Before installation, it is necessary to equip the wall with a heat-resistant screen. The stove is connected to the chimney. The best option for a wooden house would be to use a corrugated chimney.

For country houses, you should choose products with enough power to heat the room. A compact metal stove will provide uniform heating of a small house. A good option for a country house would be to purchase a long-burning device. This will eliminate the need for frequent fuel loading. You can purchase a stove with a built-in hob and oven.

Photos of do-it-yourself metal stoves

Read here - How to make a balcony with your own hands - tips on how to make a balcony in an apartment beautiful. Step-by-step guide to the use of modern building materials + 70 photos of the best design options

Cons of metal devices

Despite all the advantages, metal stoves for the home also have some disadvantages. These include:

- Frequent loading required. Fuel must be loaded after a certain period of time;

- High heating temperature. The walls, ceiling, and floor at the installation site must be equipped with heat-resistant screens.

One of the disadvantages of metal stoves for the home is that they consume a lot of wood for heating.

From the above it follows that metal stoves for the home are an excellent solution when it is necessary to heat residential or non-residential premises. In addition to their main function, they can be used for cooking.

Chimney design, its manufacture and installation

The chimney arrangement has its own characteristics. At the junction of the chimney pipe and the roof there is an expansion of the masonry. On the outside, this protrusion protects the structure from precipitation, and on the inside, it reduces the temperature of the outlet flow. The diagram shows the order of the chimney pipe for a metal stove.

The fluff makes it possible not to use insulation

Heater with water tank for gas bath

The design is almost no different from a standard unit that runs on wood. Gas sauna stoves are easy to use. They can be connected either to the main gas pipeline or run from cylinders.

When installing a stove with a water tank, you need to take into account the following elements that distinguish it from other models operating on other types of fuel:

- fuse (the ability to control proper operation);

- gas chamber (sealed);

- thermostat (allowing you to regulate the temperature);

- gas cylinders.

An approximate calculation of fuel consumption shows that to ensure high-quality heating of the room for 12 months, you need to have 65 gas cylinders (50 liters each).

The operating principle of the furnaces is based on the passage of gas through a special chamber in which oxygen saturation takes place. It is supplied through a special pipe connected to a central gas pipeline or cylinder.

If a sauna stove with a heat exchanger for heating is heated by gas cylinders, they should be located in a specially designated area. It is best to install them outside the premises so that residential buildings are located at a great distance.

Tools and materials

In order to make a sauna stove with your own hands, you will need the following materials:

- Sheet steel . The optimal thickness is 2 - 3 mm. Sheets of greater thickness are expensive and heavy; smaller ones can quickly burn out. And only for the firebox it is better to take a thicker sheet, for example, 5 mm.

- Cast iron for grate . If the design of the stove includes a grate between the ash pan and the ash pan, it is better to buy it ready-made or make it from cast iron beams - this material is more fire-resistant.

- Asbestos thread . Braided into a cord, it serves to seal the connections.

- Special fire-resistant paint for finishing coating.

For the firebox, it is better to take not ordinary black steel, but chromium steel containing 13% Cr.

It holds a higher temperature and does not burn out. The minimum set of necessary tools looks like this:

- Inverter welding machine with a set of electrodes, mask, leggings.

- Angle grinder (grinder) with cutting and grinding wheels for metal.

- Drill with a set of metal drills.

- A set of plumbing tools: a hammer, a pair of files, pliers.